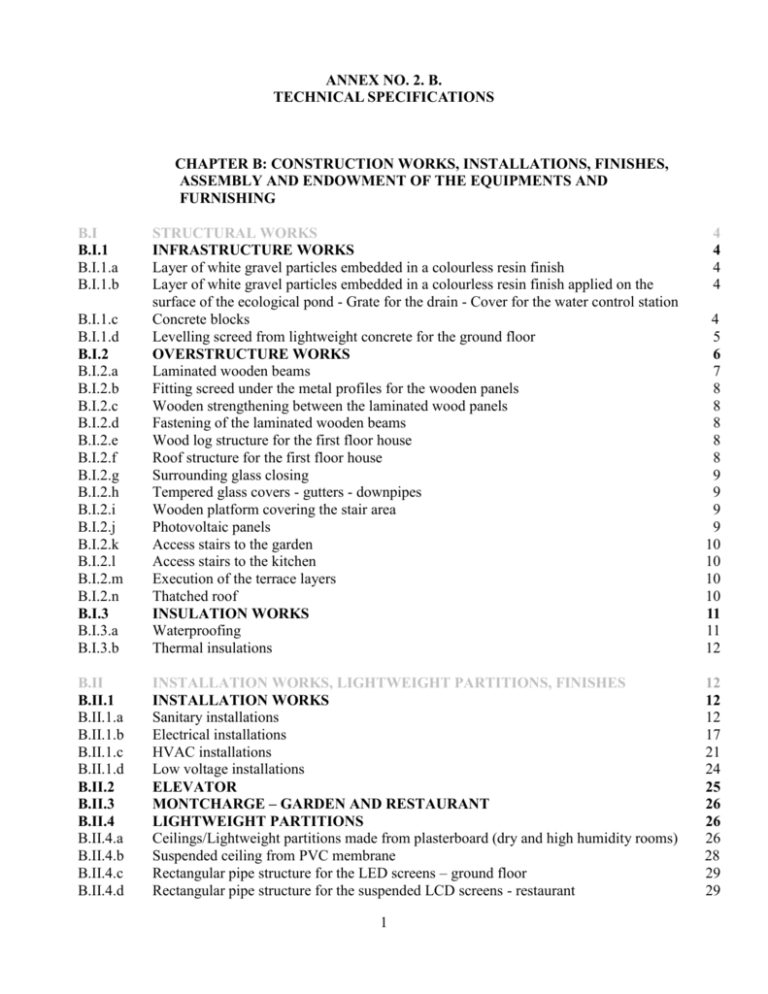

ANNEX NO. 2. B. TECHNICAL SPECIFICATIONS B.I B.I.1 B.I.1.a B.I.

advertisement