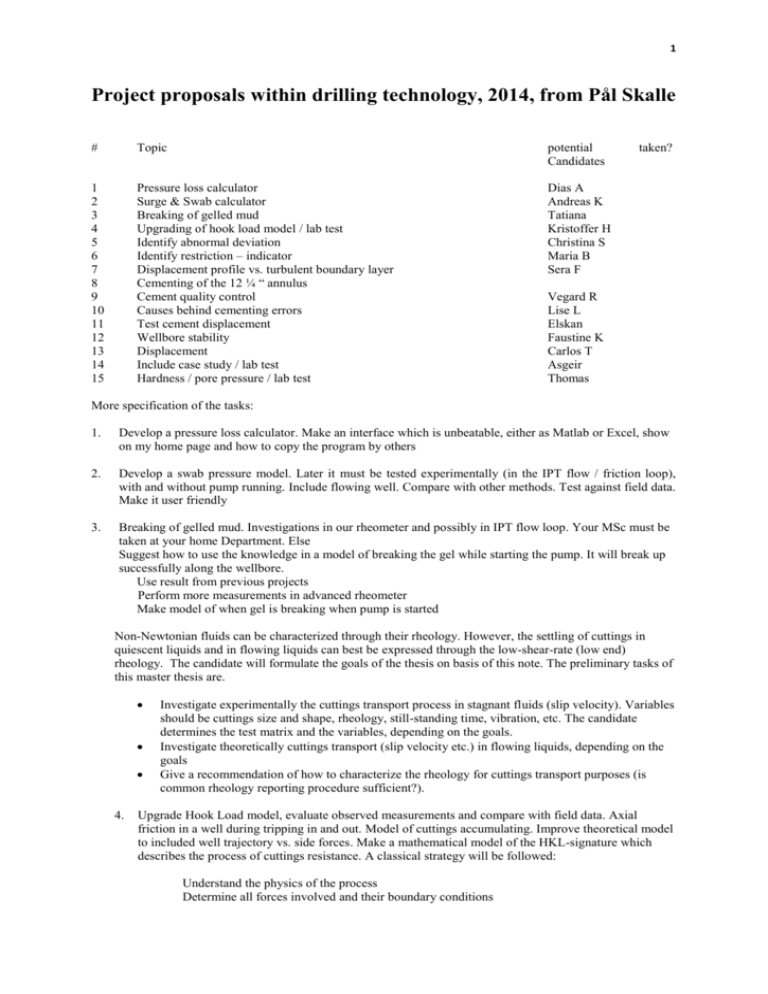

Project proposals within drilling technology, 2014, from Pål Skalle

advertisement

1 Project proposals within drilling technology, 2014, from Pål Skalle # Topic potential Candidates 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Pressure loss calculator Surge & Swab calculator Breaking of gelled mud Upgrading of hook load model / lab test Identify abnormal deviation Identify restriction – indicator Displacement profile vs. turbulent boundary layer Cementing of the 12 ¼ “ annulus Cement quality control Causes behind cementing errors Test cement displacement Wellbore stability Displacement Include case study / lab test Hardness / pore pressure / lab test Dias A Andreas K Tatiana Kristoffer H Christina S Maria B Sera F taken? Vegard R Lise L Elskan Faustine K Carlos T Asgeir Thomas More specification of the tasks: 1. Develop a pressure loss calculator. Make an interface which is unbeatable, either as Matlab or Excel, show on my home page and how to copy the program by others 2. Develop a swab pressure model. Later it must be tested experimentally (in the IPT flow / friction loop), with and without pump running. Include flowing well. Compare with other methods. Test against field data. Make it user friendly 3. Breaking of gelled mud. Investigations in our rheometer and possibly in IPT flow loop. Your MSc must be taken at your home Department. Else Suggest how to use the knowledge in a model of breaking the gel while starting the pump. It will break up successfully along the wellbore. Use result from previous projects Perform more measurements in advanced rheometer Make model of when gel is breaking when pump is started Non-Newtonian fluids can be characterized through their rheology. However, the settling of cuttings in quiescent liquids and in flowing liquids can best be expressed through the low-shear-rate (low end) rheology. The candidate will formulate the goals of the thesis on basis of this note. The preliminary tasks of this master thesis are. 4. Investigate experimentally the cuttings transport process in stagnant fluids (slip velocity). Variables should be cuttings size and shape, rheology, still-standing time, vibration, etc. The candidate determines the test matrix and the variables, depending on the goals. Investigate theoretically cuttings transport (slip velocity etc.) in flowing liquids, depending on the goals Give a recommendation of how to characterize the rheology for cuttings transport purposes (is common rheology reporting procedure sufficient?). Upgrade Hook Load model, evaluate observed measurements and compare with field data. Axial friction in a well during tripping in and out. Model of cuttings accumulating. Improve theoretical model to included well trajectory vs. side forces. Make a mathematical model of the HKL-signature which describes the process of cuttings resistance. A classical strategy will be followed: Understand the physics of the process Determine all forces involved and their boundary conditions 2 Develop the models Solve and simulate numerically and test the results Compare with field cases. Adjust models accordingly until acceptable similarity is obtained The model is initiated, as a force – string – spring system. Viscous and side forces need to be added. Start with existing and take it from there. 5. At IPT we have a package of real-time drilling data (RTDD) from two wellbore sections including the two end-of-well (EOW) reports. Drilling data are recorded every 5 th second. A major oil company has made available a link to their own data base. This base contains data from 6 wells drilled in the 17 ½“ section (the overburden). A reading / translation program is included in the data access. The data base contains also some memory-stored data. The projects listed below will take advantage of the RTDD to some degree. Most of the tasks listed below are related to restrictions, often seen during tripping operations. Study RTDD and find some of the restrictions. Then reveal some of these secrets through a theoretical estimation of the probability of its occurrence: Identify type of deviations from normal behavior of interesting parameters. Changes could indicate: Simple restrictions Narrow wellbore Shoveling of cuttings ECD-cyclic load indicator Hole cleaning indicator 6. Identify restrictions indicators in each of the responding parameters vs. manipulated parameters: Indicators: ROP HKL Torque Wellbore instability indicator Sag factor Main manipulating parameter: BPOS BPOB RPM Mechanical friction / drag indicator modelling of surface hook load signals when tripping out through incooperative cuttings bed With increasing quality of drilling parameters, our hypothesis is that wellbore restrictions can be identified through modelling of the surface response. Restrictions that seem relatively similar in the surface hook load (HKL) while tripping have completely different causes: - Accumulated material; cuttings, cavings, barite, filter cake Larger pieces of rocks or blocks; falling-in from the wellbore ceiling from weak and unstable formations Hole enlargement with shoulders and ledges; dissolution and erosion of weak formations Changes in the wellbore path; local dogleg, longer build and drop sections Key seats; evolving in build and drop sections If the type of restriction can be determined, and thus revealing the cause behind the restriction, the treatment of the problem will become more purposeful and efficient. We claim that different causes will result in completely different repair strategies. Selecting the wrong repair strategy may even worsen the situation instead of improving it. The desire to determine the cause of physical restrictions in the wellbore is therefore the driving motivation in this project. Normal HKL signals are initially determined and characterized during normal process conditions, forming a moving reference signal. Deviatoric HKL behavior must be studied in many wells and under different process conditions. 50 cases would make up a sufficient statistical case bank. Different wellbore restriction types will give different HKL-signatures. The signatures will initially be approached in a simplified manner by simply grouping the cases into two types; 3 cuttings restrictions and other restrictions. A hypothesis is formed of the physical explanation behind each signature. Collect 30 different cases which are initially assumed to resemble cuttings restrictions and 20 cases of other restriction types. Describe the cases sufficiently detailed for later mathematical simulation; wellbore and drill string geometry; drilling fluid characteristics; the drilling operation; the lithology etc. The field data are obtained from Statoil. Norwegian Universities are being granted access to Statoil-data through their Discovery Web (ref. Flemming Stene). Figure 1 presents the activity of tripping-out one stand (30 m) through a well which is properly cleaned, and therefore represents smooth, normal hook load behavior. We define the hook load behavior as normal when there are no high peaks in the hook load signature. Hook load ck Blo ion sit po Figure 1: Normal tripping operations of one stand through an 8 ½” hole in a vertical well. The operation takes typically 3 minutes. The hook load tension is more or less constant and represents normal downhole conditions. Figure 2 represents two abnormal situations. In both cases we see high peaks initially. The peaks are triggered by bringing a drill string, which have been quiescent for some minutes, out of rest. A corresponding negative HKLresponse is often seen immediately after jerking loose the drill string. In both plots it seems probable that cuttings are being accumulated, and the resistance is being increased in an axial stick-slip motion. The cuttings are alternately being shoveled; gradually more cuttings are being accumulated and jammed in narrower parts of the wellbore and finally being compressed and finally crushed. Hard stringers (narrow wellbore) combined with soft stringers (enlarged wellbore) can often be an indicative symptom of such behavior. Hook load Bloc n sitio k po Hook load Bloc n sitio k po Figure 2: Abnormal behavior during tripping in longer horizontal sections (red line – acceleration). The x-axis is the time scale in both plots, approximately 3 min across. Upper figure – Cuttings restriction in relatively smooth, horizontal wellbore Lower figure – Cuttings piling up in a more uneven, horizontal wellbore 7. The displacement profile of the cement / drilling fluid becomes very sharp, causing the cement to mix with the mud and thus reducing its quality. This is a problem only when the displacement process is taking place 4 in laminar flow, which mostly is a necessary requirement due to ECD restrictions. One factor contributing to improved displacement is the existence of local turbulence at the wall. The local turbulence is caused by the roughness of the wall; either the wall is composed of the open wellbore or the casing and its equipment. It is necessary to investigate what is determining the level of turbulence or what is causing the onset of turbulence. This cannot be determined only theoretically because the theory is complex and depending on many factors. A simple experiment must be designed to reveal some of the secrets behind the onset of turbulence in laminar flow past uneven surfaces. 8. Cement the 12 ¼ “ casing 9. Qualify 3-5 cement recipes for sustainable sealing. All necessary tests, instruments, procedures and quality checking issues should be included. Lab facilities at two laboratories are at your disposal. 10. On basis of several accidents, create a knowledge model which can contribute to reveal the main cause in real time Lab test: a. b. Determine max pulling force Determine final concentration