Fulltext

advertisement

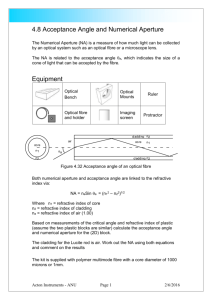

Fabrication and Characterisation of Energy Storage Fibres Ruirong Zhang1, Yanmeng Xu1, David Harrison1, John Fyson1, Fulian Qiu1, Darren Southee2 and Anan Tanwilaisiri1 1 Cleaner electronics, School of Engineering and Design, Brunel University, London, UK 2 Loughborough Design School, Loughborough University, Leicestershire, UK Abstract—Fibre supercapacitors were designed and manufactured using a dip coating method. Their electrochemical properties were characterized using a VersaSTAT 3 workstation. Chinese ink with a fine dispersion of carbon and binder was coated as the electrode material. The specific capacitance per unit length of a copper fibre supercapacitor with the length of 41 cm reached 34.5 mF/cm. When this fibre supercapacitor was bent on rods with a diameter of 10.5 cm, the specific capacitance per length was 93% of the original value (without bending). It proved that these fibre supercapacitors have a good flexibility and energy storage capacity. Keywords-supercapacitors; chinese ink; energy storage fibre; gel electrolyte; flexible I. INTRODUCTION Recently, supercapacitors (also named electrochemical capacitors) have attracted much attention as energy storage devices. Because of the high power density, long cycle life and high reversibility [1], supercapacitors have been considered as a promising high power energy source for delivering peak power demands in electrical vehicles, hybrid electric vehicles, portable electronic devices and emergency power supplies. Electrochemical energy can be stored in two ways in supercapacitors [1-4]. In electrical double-layer capacitors (EDLCs), there are no faradic reactions in the charge storage process, the capacitance arises from the charge separation at the electrode/electrolyte interface. Pseudocapacitors are another kind of supercapacitors, in which, there is a faradic reaction in the energy storage process. In recent years, there has been great interest in developing flexible, lightweight, low-cost and environmentally friendly energy storage devices. Supercapacitors can deliver higher power than batteries and conventional capacitors. However, many existing supercapacitors are still too bulky and heavy for intended applications. It is a challenge to develop highly efficient miniaturized flexible supercapacitors for future energy storage. Recently, some attempts have been made to manufacture flexible and weaveable supercapacitors [5-10]. Joonho Bae et al. developed a kind of novel fibre supercapacitor using ZnO nano-wires as electrodes, which showed a high specific capacitance of 2.4 mF/cm2 and 0.2 mF/cm using PVA/H3PO4 as the gel-electrolyte [6]. Yongping Fu et al. developed a novel flexible fibre supercapacitor which consisted of two fibre electrodes using Chinese ink as the active materials, a helical spacer wire and an electrolyte showed good capacitance [9]. Coaxial fibre supercapacitors, using Chinese ink as active materials, were designed, manufactured and characterised. The results have been discussed in this study. The particular novelty or worth reported in this paper is the significant increase in specific capacitance (from 0.5 mF/cm to 34.5 mF/cm), achieved through increasing the number of coatings for the carbon electrodes from 4 to 24. II. EXPERIMENTAL A. Materials Phosphoric acid (H3PO4, dry) and polyvinyl alcohol (PVA, MW 146,000-186,000, > 99% hydrolyzed) were used without further purification. The gel electrolyte was made by dissolving 0.8 g H3PO4 and 1 g PVA in 10 mL deionized water. Copper fibre (50 µm in diameter) was used as the core conductor material. Commercial Chinese ink was used as the active coating material. B. Design of the structure of the energy storage fibre Based on the working mechanism [1], fibre supercapacitors have been designed. As shown in Figure 1, the coaxial single fibre supercapacitors consist of five layers. The central metal fibre and the outer layer of silver coating are current collectors. Two active layers made of Chinese ink are separated by a gel electrolyte layer and served as electrodes. The energy is stored by the accumulation of electrical charges at the boundary layers between the two electrodes and electrolyte. Figure 1. 3-D schematic of four coating layers on the metal fibre. C. Manufacturing method Figure 2 schematically shows the experimental setup of the coating method for the energy storage fibre. A reel of metal fibre and two pulleys are fixed horizontally onto a plate. A weight is clamped to the bottom end of the core wire to keep the wire straight and in alignment with the coating vessel. A motor with a two-direction controller was used to connect the reel to control the coating speed. When the coating process is carried out, coating liquid is filled in the coating vessel. During the movement of the core metal wire, the wire drags the coating liquid with it, the solvent is vapourised and the coating materials deposit on the wire. D. Characterisation of the electrochemical properties The electrochemical performance of the energy storage fibre developed was studied by cyclic voltammetry (CV), galvanostatic charge/discharge and electrochemical impedance spectroscopy using a VersaSTAT 3 electrochemical workstation. The morphology of the cross-section of the supercapacitor was studied by optical microscopy. is functional, although the capacitance was not ideal. This was considered to be caused by an uneven structure of the supercapacitor, which is revealed in Figure 4, so there was not enough active material deposited. A typical cross-section of a copper fibre supercapacitor is shown in Figure 4. The five layers structure can be seen clearly. The copper fibre core is easy to see. The second Chinese ink layer was not uniform. Gel electrolyte layer as the third layer was complete but the thickness was not uniform. The fourth layer was also a Chinese ink layer and was also uneven. 0.0006 0.0005 Motor 0.0004 Reel of metal fibre Coating vessel Current, A 0.0003 Pulley 0.0002 0.0001 0.0000 -0.0001 -0.0002 0.0 0.2 0.4 0.6 0.8 Potential, V Figure 3. The Cyclic voltammogram of an initial fibre supercapacitor sample. Weight Figure 2. The schematic of coating method. A CV test is carried out by applying a positive (charging) voltage sweeping dV⁄dt (scan rate) in a specific voltage range and then reversing (discharging) the voltage sweep polarity immediately after the maximum voltage range is achieved. The electrochemical behaviour of a supercapacitor could be evaluated based on the corresponding current response against the applied voltage by the equations as: C= Qtotal ⁄2 ∆V C L = C ⁄L 3rd Gel electrolyte 2ndChinese ink layer 5thSilver paint (1) (2) C is the capacitance, and CL is the specific capacitance per unit length. Qtotal is the supercapacitor’s charge in coulombs. The charge is automatically calculated by the workstation software. L is the length of the fibre supercapacitors. III. RESULTS AND DISCUSSION Following the schematic of fibre supercapacitors (as shown in Figure 1), the first energy storage fibre was made using the commercial Chinese ink (coating 4 times) as the active material. The CV curve of an initial fibre supercapacitor sample with the length of 35 cm is illustrated in Figure 3. The capacitance and specific capacitance per unit length calculated by Equations (1) and (2) were 18 mF and 0.5 mF/cm. This shows that this kind of energy storage fibre 4thChinese ink layer 1st Copperfibre Figure 4. Optical image of the cross-section of a fibre supercapacitor. A new fibre supercapacitor with the length of 41 cm was made based on the technical manufacturing skills gained from many times of laboratory trials. The ink layer was deposited 24 times in this fibre supercapacitor, which was 6 times more than the initial trial sample. The specific capacitance of the new sample was about 34.5 mF/cm, which is 69 times that of the trial sample. Generally, when the number of coatings is increased substantially, the thickness of ink layer increases dramatically as does the amount of the active materials in each of the electrodes. This should enlarge the electrical storage capacity of the fibre supercapacitor. The flexibility of the fibre supercapacitors was also studied. The specific capacitance of the 41 cm long supercapacitor was examined when the fibre was bent on a glass rod with different curvatures. The diameters of the glass rods were 10.5, 3.0 and 1.5 cm. Figure 5 shows the CV curves of the fibre supercapacitor bent at different curvatures. It can be seen the CV curves were the same when the fibre supercapacitor was bent using the glass rods with the diameters of 1.5 and 3.0 cm. When the fibre supercapacitor was bent on the glass rod with the diameter of 10.5 cm, the specific capacitance decreased slightly to 32.2 mF/cm, which was about 93% of the original straight sample. When the diameter of rods decreased to 3.0 and 1.5 cm, the specific capacitance changed to 26.2 mF/cm for both cases, which was 76% of the straight sample. The comparison of the specific capacitance of the fibre supercapacitor at different bending conditions with the original sample is shown in Figure 6. These results show that the fibre supercapacitors are able to work at the severe bending condition, indicating the fibre supercapacitors are flexible enough to be woven into other fabrics to make smart textiles. 0.016 0.014 d 0.012 designed and setup to produce the fibre supercapacitors. The initial sample made proved the fibre supercapacitor designed to be functional. When the coating layers increased substantially, the amount of active materials deposited on the electrodes increased dramatically. This improved the electrical storage of the fibre supercapacitor tens of times. The specific capacitance of the supercapacitors at various bending conditions was examined. The results showed that the supercapacitors manufactured using the present method kept a good electrochemical performance at the severe bending conditions, which indicated that the supercapacitors designed and made in this study have a very good flexibility. This could be used as a flexible energy storage and woven into other fabrics to make smart textile materials. V. REFERENCES [1] R. Kötz, M. Carlen, “Principles and applications of electrochemical capacitors,” Electrochim. Acta. Vol. 45, pp. 2483-2498, 2000 [2] M.K Seo, S. Yang, I.J. Kim and S.J. Park, “Preparation and electrochemical characteristics of mesoporous carbon spheres for supercapacitors,” Mater. Res. Bull. Vol. 45, pp. 10-14, 2010 Current, A 0.010 Original 0.008 0.006 10.5 cm 0.004 1.5 cm 0.002 3.0 cm 0.000 -0.002 0.0 0.2 0.4 0.6 0.8 Potential, V Figure 5. CV curves of the 41 cm long fibre supercapacitor at different testing conditions (straight and bent with different curvatures). Specific capacitance per length, mF/cm 40 35 100% 93% 30 76% 76% 25 20 15 [3] H. Shen, E. Liu, X. Xiang, Z. Huang, Y. Tian, Y. Wu, Z. Wu, and H. Xie, “A novel activated carbon for supercapacitors,” Mater Res. Bull. Vol. 47, pp. 662-666, 2012 [4] H.Gómez, M.K. Ram, F. Alvi, P. Villalba, E. Stefanakos and A. Kumar, “Graphene-conducting polymer nanocomposite as novel electrode for supercapacitors,” J. Power Sources. Vol. 196, pp. 41024108, 2011 [5] V.L. Pushparaj, M.M. Shaijumon, A. Kumar, S. Murugesan, L. Ci, R. Vajtai, R.J. Linhardt, O. Nalamasu and P.M. Ajayan, “Flexible energy storage devices based on nanocomposite paper,” Proc. Natl. Acad. Sci. Vol. 104, pp. 13574-13577, 2007 [6] J. Bae, M.K. song, Y.J. Park, J.M. Kim, M. Liu and Z.L. Wang, “Fiber supercapacitors made of nanowirefiber hybrid structures for wearable/flexible energy storage,” Angew. Chem. Int. Ed. Vol. 50, pp. 1683-1687, 2011 [7] G. Milczarek, A. Ciszewski and I. Stepniak, “Oxygen-doped activated carbon fiber cloth as electrode material for electrochemical capacitor,” J. Power Sources. Vol. 196, pp. 7882-7885, 2011 10 5 0 Original 10.5 cm 3.0 cm 1.5 cm Rolling diameter Figure 6 Comparison of the specific capacitance per length of the fibre supercapacitancebeing bent with different curvatures with the original straight sample. IV. CONCLUSIONS The coaxial single fibre supercapacitors were successfully manufactured and characterised in this study. Chinese ink was used as electrode materials. A coating method was [8] D. Harrison, F. Qiu, J. Fyson, Y. Xu, P. Evans and D. Southee, “A coaxial single fibre supercapacitor for energy storage,” Phys. Chem. Chem. Phys., Vol. 15, pp. 12215-12219, 2013 [9] Y.P. Fu, X. Cai, H.W. Wu, Z.B. Lv, S.C. Hou, M. Peng, X. Yu and D.C. Zou, “Fiber Supercapacitors Utilizing Pen Ink for Flexible/Wearable Energy Storage,” Adv. Mater. Vol. 24, pp. 5713-5718, 2012 [10] X.Y. Zhang, X.Y. Wang, L.L Jiang, H. Wu, C. Wu and J.C. Su, “Effect of aqueous electrolytes on the electrochemical behaviors of supercapacitors based on hierarchically porous carbons” J. Power Sources. Vol. 216, pp. 290-296, 2012