Nanofabrication Mask Development

Nanofabrication: Mask Development

Subject Area(s) Physical Science, Science and Technology

Associated Unit Chemical/Physical changes, Nature of Science

Lesson Title Nanofabrication: Mask Development

Grade Level

Time Required

8

90 minutes

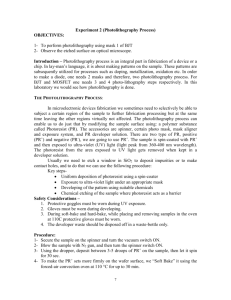

Image file: TSF27.jpg

ADA Description: The image illustrates the process of developing a pattern by use of a mask, photoresist, and a silicon wafer. The process shows both the method called positive resist and negative resist.

Source/Rights: Permission is granted to copy, distribute and/or modify this document under the terms of the GNU Free Documentation License , Version 1.2 or any later version published by the Free Software

Foundation ; with no Invariant Sections, no Front-Cover Texts, and no Back-Cover Texts. A copy of the license is included in the section entitled GNU Free Documentation License .

Caption: Photolithography (microfabrication)

Summary Nanofabrication: Mask Development is an introduction to the concept of nanotechnology and how this complicated process can be scaled down to the middle school classroom. This lesson will start as a more conceptual approach toward nanotechnology as we will research what it is, why we need it, and its potential realworld implications. Following this, students will relate these complicated concepts to a simpler application and they will create their own masks while drawing parallels between the in-class activity and the real-world engineering concepts.

Version: August 2013 1

Engineering Connection: The computer chips that we all rely on so heavily are created using the process of photolithography. As technology is progressing, there is a high demand for developing these elements on a much smaller scale—the nanoscale. With this significant decrease in size, engineers are challenged to design and utilize processes that can overcome the obstables of such microscopic materials.

Engineering Category: Engineering design process

Keywords: Photolithography, mask, photoresist, ultraviolet, nanoscale, transistors, profile, positive image, negative image

Educational Standards

State STEM Standard

Big Idea 1: The Practice of Science; Florida Science grades 4-8 (2008)

Big Idea 4: Science and Society; Florida Science grades 8-8 (2008)

Big Idea 8: Properties of Matter; Florida Science grades K-8 (2008)

Big Idea 9: Changes in Matter; Florida Science grades K-8 (2008)

ITEEA Standard

Technology and Society:

Standard 4: Students will develop an understanding of the cultural, social, economic and political effects of technology (grades K-12)

Standard 6: Students will develop an understanding of the role of society in the development and use of technology (grades K-12)

Design:

Standard 8: Students will develop an understanding of the attributes of design (K-12)

Standard 9: Students will develop an understanding of engineering design (grades K-12)

Standard 10: Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving

(grades K-12)

NGSS Standard

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions.

MS-ETS1-2. Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem.

MS-PS1-3. Gather and make sense of information to describe that synthetic materials come from natural resources and impact society.

MS-PS1-2. Analyze and interpret data on the properties of substances before and after the substances interact to determine if a chemical reaction has occurred.

Version: August 2013 2

CCSS Standard

MAFS.K12.MP.1.1 Make sense of problems and persevere in solving them.

LAFS.68.RST.1.1: Cite specific textual evidence to support analysis of science and technical texts.

LAFS.68.RST.1.2: Determine the central ideas or conclusions of a text; provide an accurate summary of the text distinct from prior knowledge or opinions.

LAFS.68.RST.1.3: Follow precisely a multistep procedure when carrying out experiments, taking measurements, or performing technical tasks.

SC.8.N.4.1: Explain that science is one of the processes that can be used to inform decision making at the community, state, national, and international levels.

SC.8.N.4.2: Explain how political, social, and economic concerns can affect science, and vice versa.

SC.8.P.9.2: Differentiate between physical changes and chemical changes.

Pre-Requisite Knowledge

Students should be familiar with the electromagnetic spectrum, specifically ultraviolet light.

Students should also understand the difference between chemical and physical changes of matter.

Students should understand the process of scientific investigations.

Learning Objectives

After this lesson, students should be able to:

Explain the process of photolithography

Describe the value of nanotechnology and its applications

Identify potential problems with both photolithography and nanotechnology as a whole and present reasonable solutions to these problems

Introduction / Motivation

--Bell Ringer: have students jot down what they think is inside their phones, computers, iPads, etc. that allows them to function. Students will then share out and come up with a class list of ideas. Eventually we will conclude that they all rely on small-scale computer chips.

--Students will watch “Sand to Silicon” video https://www.youtube.com/watch?v=Q5paWn7bFg4 and write down 2-3 interesting facts that they learned during the video

--Students will look at PowerPoint from my RET experiences to see these things happening in real life

--Students will be able to see the attire used in the cleanroom

Lesson Background & Concepts for Teachers

All of the technology that we use on a daily basis relies on the computer chip. Many of us may have actually seen these or perhaps just an image of one, but we all know that these tiny pieces

Version: August 2013 3

of technology carry immense power. There are two methods for these chips to be developed— bottom up fabrication or top-down. In bottom up fabrication, material is added layer by layer to develop the pattern and design. This requires multiple steps and a very precise plan from the beginning of the process. Top-down fabrication starts with the total amount of material and then carefully reduces the material into the desired design. Regardless of these two approaches, both processes require a common step—photolithography. Photolithography allows engineers to create and develop the patterns that they desire for the final computer chip. For the purpose of this explanation, I will walk through the steps of photolithography on a silicon wafer. The first step of the process is cleaning which usually requires a chemical treatment to remove any contaminants. The liquid used in the cleaning process then has to be removed by heating the wafer and allowing the chemicals to evaporate. Next the wafer must be coated with photoresist.

Photoresist is a light sensitive chemical, that when exposed to light in a specific pattern will chemically alter so that the pattern is left behind. The process used here is called spin coating.

During this process, the photoresist is applied to the wafer and then spun around at a high rate to result in a uniform, very thin layer of the photoresist across the entire wafer. At this point, the engineer will be able to apply the pattern that is needed for the specific chip. A mask is created in the desired pattern in a way that will block specific areas from exposure to UV light. The mask is placed over the wafer that now has photoresist covering it and a UV light is exposed to the wafer through the mask. There are also two types of photoresist—positive or negative. Positive photoresist will leave the photoresist where the UV light contacted the chemical and the remaining areas will be lifted off. Negative resist will do the opposite and the area that was exposed to UV will separate from the wafer and the remaining photoresist will stay intact. At this point, the wafer is ready for the step called “etching” in which a chemical treatment will remove the substrate that is not being protected by the photoresist allowing the pattern to be applied to the wafer itself. Finally, the remaining photoresist must be removed. Although the activity in class will be working with easily measured materials/sizes, scientists have to be able to apply these techniques to more complex and tiny chips. Although the details behind these projects differ, the technique is the same as the photolithography that students will be modeling in class. The nanoscale technologies that will depend on this process are 100-1000 times smaller than the computer chips that we are currently using. When engineers are working at this level, we no longer use familiar units such as centimeters and millimeters. Instead, objects at this scale are measured with microns and nanometers. For context, there are one million microns in a meter, and one billion nanometers in one meter.

Version: August 2013 4

Image 2

Figure 1

Image file: Biological and technological scales compared-en.svg

ADA Description: Comparison of various biological assemblies and technological devices.

Source/Rights: This file is licensed under the Creative Commons Attribution-Share Alike 2.5

Generic license.

Caption: Figure 1

Photolithography, mask, photoresist, ultraviolet, nanoscale, transistors, profile, positive image, negative image

Mask

Nano-scale

Profile

Word

Photolithography

Photoresist

Spin Coating

Ultraviolet

Vocabulary / Definitions

Definition

Developing technique that utilizes light to imprint a pattern/design onto a solid surface

Thin “blueprint” or plan designed to block ultraviolet light in certain areas when developing a pattern

A light-sensitive chemical that will lose its ability to adhere to surfaces when exposed to UV light

Procedure that allows a viscous material applied to the center of a flat surface to evenly and thinly spread across the entire surface.

Radiation with a wavelength that is shorter than visible light but longer than the wavelength of x-rays

Sizes that are measured in microns and nanometers

The side view of an object

Version: August 2013 5

Positive Image

Negative Image

An image that is the exact copy of an original pattern

An image that is the inverse (opposite) of the original pattern

Associated Activities

Students will break into small groups of 2-4 and read brief scientific article on nanotechnology/photolithography. They will use reading strategies and note-taking techniques and then will create a small, simple diagram that illustrates the process of negative and positive photolithography.

In order to mimic the process done in a nanofabrication lab, students will create masks from transparency paper and use solar print paper to mimic the work of the photoresist. Solar print paper has a combination of potassium ferrocyanide and ferric ammonium citrate that will create a negative image when exposed to UV light. Before we begin the process, I will show them different examples of negative and positive images so that they can identify what they will be producing.

Pre-lab questions :

1. Do you think a computer chip requires one or multiple masks to be created? What are some reasons that you believe this?

2. Why is it important that masks are precise?

3. How can light cause a chemical reaction?

Procedure :

Part 1: Using a mask

1. Place the mask (transparency film) on top of a piece of solar print paper

2. Place the mask and solar print paper at the windowsill to expose it to the UV light and start your timer

3. Wait 4 minutes or until the solar print paper turns white

4. Remove the mask and rinse the paper for 30 seconds under water

5. Carefully dry the paper with a paper towel and lay flat to dry

6. Record your observations by drawing a profile sketch of the solar print paper in the box to the right

The light blue areas represent areas that were (circle one: masked / exposed to UV)

The dark blue areas represent areas that were (circle one: masked / exposed to UV)

Part 2: Designing a mask

Version: August 2013 6

1. Using a black permanent marker and a small piece of transparency paper, draw a pattern that will result in the negative image of what you developed in Part 1 of the procedure

2. Following the steps from Part 1, develop your new mask on another piece of solar print paper

3. Record your observations by drawing a box to the right profile sketch of the solar print paper in the

The light blue areas represent areas that were (circle one: masked / exposed to UV)

The dark blue areas represent areas that were (circle one: masked / exposed to UV)

When both of the solar print papers are completely dry, tape them into the boxes below:

Original Mask Your Designed Mask

Part 3: Multiple Images

If we wanted to add images to an already developed pattern, could we use this solar print paper that was already developed or do we need to start over with a new piece of solar print paper? Explain your reasoning

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Challenge:

Your goal is to take the provided image and duplicate it as many times as possible on a single sheet of solar print paper. You must follow the below requirements:

Version: August 2013 7

a. You will receive one copy of the image b. You may have one piece of solar print paper and one transparency paper c. You may shrink the pattern but it cannot lose any of its features d. You cannot re-expose any parts of the solar print paper

Write all steps that you followed in a detailed procedure list. This should be explained with enough details that I could follow the steps and produce the exact same image that you did.

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Assessment

Students will complete a CER that will answer the problem statement “How can photolithography help engineers improve the technology that we use everyday?”

Contributors

Alison Miler

Supporting Program

Research Experience for Teachers (RET), Florida International University Engineering Center

Classroom Testing Information

This activity is designed for middle school students in preparation for the Grade 8 FCAT, which encompasses curriculum from grades 6-8

Version: August 2013 8