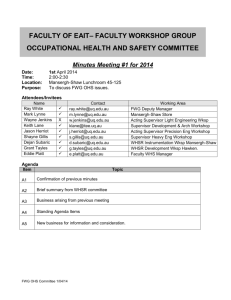

Minutes Meeting #2 for 2014

advertisement

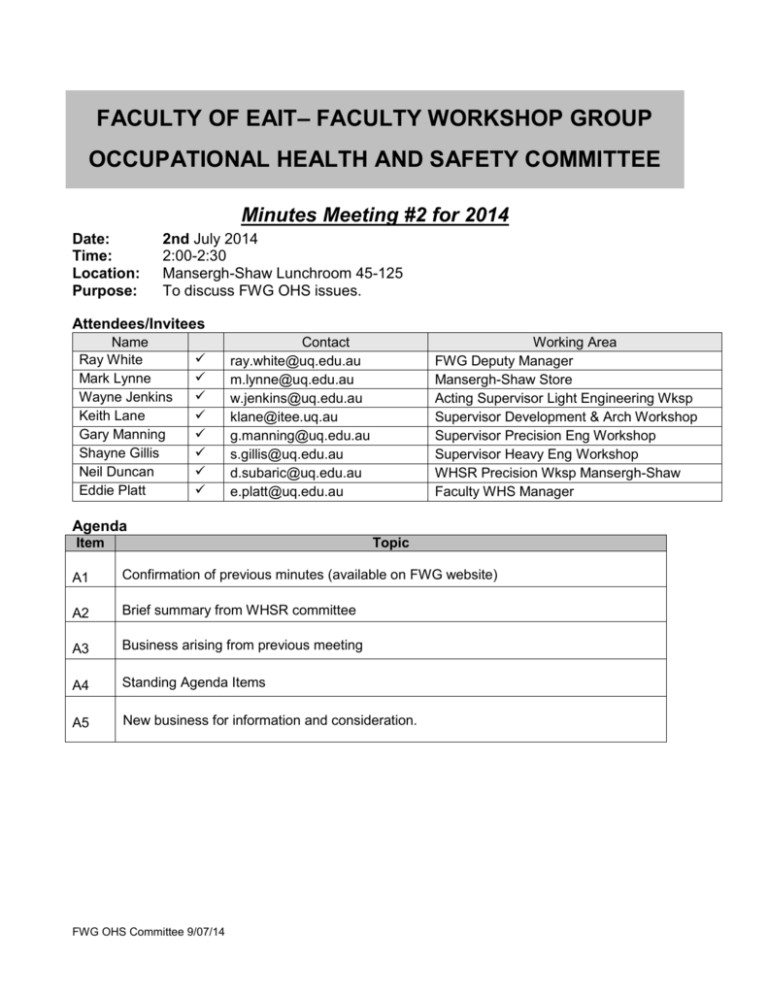

FACULTY OF EAIT– FACULTY WORKSHOP GROUP OCCUPATIONAL HEALTH AND SAFETY COMMITTEE Minutes Meeting #2 for 2014 Date: Time: Location: Purpose: 2nd July 2014 2:00-2:30 Mansergh-Shaw Lunchroom 45-125 To discuss FWG OHS issues. Attendees/Invitees Name Ray White Mark Lynne Wayne Jenkins Keith Lane Gary Manning Shayne Gillis Neil Duncan Eddie Platt Contact ray.white@uq.edu.au m.lynne@uq.edu.au w.jenkins@uq.edu.au klane@itee.uq.au g.manning@uq.edu.au s.gillis@uq.edu.au d.subaric@uq.edu.au e.platt@uq.edu.au Working Area FWG Deputy Manager Mansergh-Shaw Store Acting Supervisor Light Engineering Wksp Supervisor Development & Arch Workshop Supervisor Precision Eng Workshop Supervisor Heavy Eng Workshop WHSR Precision Wksp Mansergh-Shaw Faculty WHS Manager Agenda Item Topic A1 Confirmation of previous minutes (available on FWG website) A2 Brief summary from WHSR committee A3 Business arising from previous meeting A4 Standing Agenda Items A5 New business for information and consideration. FWG OHS Committee 9/07/14 Discussion Item A3.1 Equipment database Topic A3.2 General workshop tidiness A3.3 E-Stops fitted and updates A3.4 Competency Assessment A3.5 Equipment Lockout training A3.6 AEB access pit to Heavy Eng workshop A3.7 FWG OHS management plan. A3.8 Training for Fire wardens. A3.9 UQ OHS Forum A3.10 Two Yearly Hearing test A4.1 OH&S Minor Works Funding A4.2 OH&S Training A4.3 Review of major Incidents A4.4 Workshop Inspections A5.1 Report from EAIT Faculty OHS Committee Meeting A5.2 ENGG 1100 Workshop A5.3 Test & Tag FWG OHS Committee 9/07/14 Action Items – Active Action A3.1 Equipment Database Due Date 1/12/13 1) Equipment/plant maintenance database. 2) Equipment manuals. A3.2 General Workshop tidiness On going A3.3 E-Stops fitted and updates 1/3/14 A3.4 Competency Assessment 31/9/13 A3.5 Lockout training 4/10/13 A3.6 AEB access pit to Heavy Eng workshop. A3.7 FWG OHS management plan. FWG OHS Committee 9/07/14 1/4/14 Comment Who Equipment Database: This will be a local RW/Joy Wang asset register; this register will hold all the Workshop workshop equipment records including supervisors preventive maintenance records. The Light Eng Wksp is the last workshop to have the database system setup. The database will also be used to manage the loaning out of workshop equipment. Audit of workshop equipment manuals is taking place. All new equipment that is purchased for the FWG must be entered into the equipment database. Highlight the need to keep all emergency All workshop staff exits clear and that each workshop supervisor is responsible for assuring that their workshops are kept clean and tidy. With the exception of the Light Eng, EAll workshop staff stops have been fitted to all workshop equipment. Once the layout plan for the Light Eng workshop is complete the E stops will be fitted. Workshop supervisors are responsible for assuring that e-stops are used correctly. All workshops staff must complete RW,ML, workshop equipment competency assessments, currently 70% of staff have completed CA. Mark Lynne to meet with workshop supervisors to assist with rollout. All FWG staff must read equipment RW,ML. Lockout/Tagout Risk Assessment and SOP. Lockout stations to be setup in each workshop, in the meantime staff must contact the workshop supervisor or Mark Lynne to lockout equipment. Engineers are currently redesigning the pit RW,SG door to handle increased capacity and Gillian Di Corleto correct the gap problem that will stop any spillage or items falling through. Below the pit door chevron pattern to be painted on floor and adjustable barriers installed. RW, All school/unit OHS Committee’s should have an OHS Management Plan that is reviewed annually. Investigate if the EAIT OHS management plan is suitable. A3.8 Training for Fire wardens. 1/4/14 A3.9 UQ OHS Forum 1/4/14 A3.10 Two Yearly Hearing test 1/4/14 A4.1 OH&S Minor Works Funding EAIT Fire warden register will be maintained through a single source on the P&F website. A checklist will be emailed to Fire Wardens every 6 months to enable contact details to be updated. Confirm with P&F about training and update of checklist. The OHS Unit will commence a UQ OHS Forum on 3 April 2014. An OHS Governance Policy will be released to detail all the changes to OHS systems and procedures. The next OHS Forum is scheduled for 29 July. Staff will be notified one month before their hearing test is due, staff must complete a hearing test referral form and submit it to Deborah Outhwaite, Deborah will submit a RISQ form to the hearing test unit and the unit will contact the staff member to arrange an appointment. Need to include CPR. Staff to contact ML if they receive a renewal notification from an outside source. Particle dust extractor for grinding room AEB (Heavy Eng Workshop) workshop. Quote for $21,000 to upgrade extractor. EP, FWG Fire wardens RW ML, All Staff. RW, WJ TIG Brush Stainless Steel Weld Cleaning System. TIG cleaning system eliminates the need to use pickling paste which is highly toxic and hazardous. A4.2 OH&S Training Unist (minimum quantity lubrication) coolant mist spray for CNC mill in Light Eng Wksp. Request that all Fire wardens attend Fire safety Training if they have not yet done so or if the training was undertaken more than 5 years ago. Fire Wardens Nil A4.3 Review of Major Incidents A4.4 Workshop Inspection reports FWG OHS Committee 9/07/14 Although the WHSR is responsible for ensuring that the Workshop Inspections are completed it is a task that can be shared around the workshop staff to get more input and to ensure it is performed regularly. Workshop staff New Business Action Due Date Comment • A5.1 Report from EAIT Faculty OHS Committee Meeting. A5.2 ENGG 1100 workshop 2/7/14 A5.3 Test and Tag 2/7/14 The OHS Unit advised that the UQ Incident Management System had reached the threshold of its capabilities and requirements for a replacement system were being evaluated. • The review of many of the policies and procedures relating to safety within the UQ PPL is ongoing. All staff were advised to take the opportunity to review these documents and comment accordingly. • Comments are being sought by the OHS unit regarding the content and structure of the OHS training courses available through the staff development unit. Comments on any items above to be emailed to RW by 4july 20141. What level of OHS responsibility does the FWG have over the ENGG 1100 workshop. Test and tag audit report to be supplied to workshops upon completion of 6-monthly testing. Meeting closed 2:35pm Next meeting 2:00pm 30th September 2014. FWG OHS Committee 9/07/14 Who RW, ML RW/KL RW