Road Testing South Africa Style

advertisement

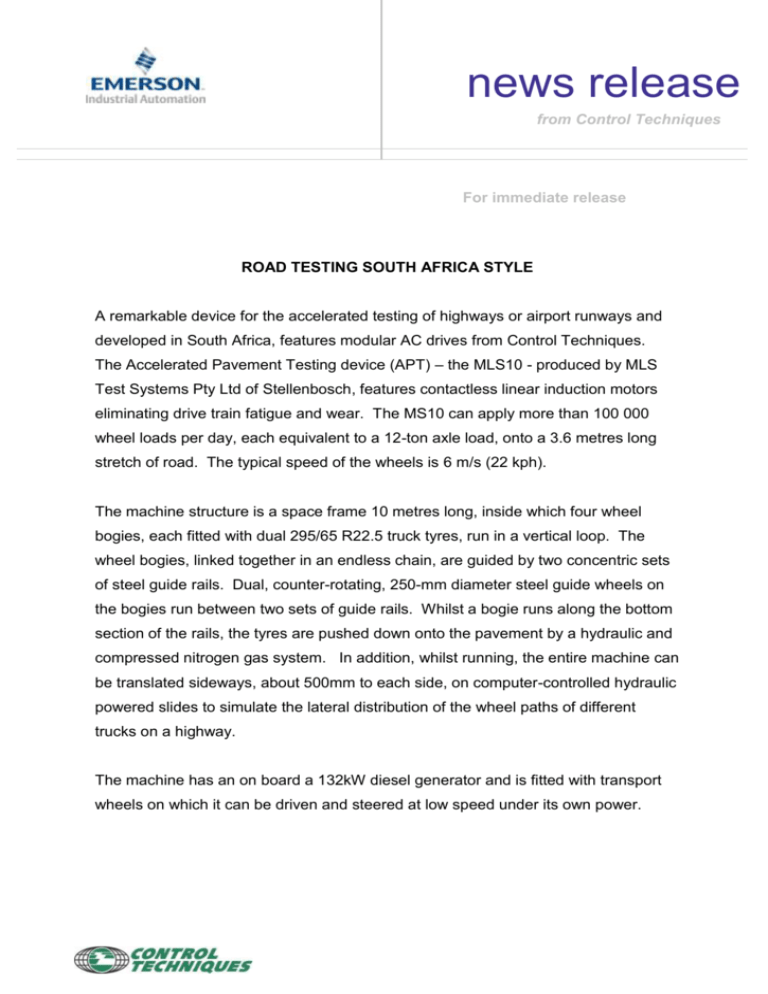

news release from Control Techniques For immediate release ROAD TESTING SOUTH AFRICA STYLE A remarkable device for the accelerated testing of highways or airport runways and developed in South Africa, features modular AC drives from Control Techniques. The Accelerated Pavement Testing device (APT) – the MLS10 - produced by MLS Test Systems Pty Ltd of Stellenbosch, features contactless linear induction motors eliminating drive train fatigue and wear. The MS10 can apply more than 100 000 wheel loads per day, each equivalent to a 12-ton axle load, onto a 3.6 metres long stretch of road. The typical speed of the wheels is 6 m/s (22 kph). The machine structure is a space frame 10 metres long, inside which four wheel bogies, each fitted with dual 295/65 R22.5 truck tyres, run in a vertical loop. The wheel bogies, linked together in an endless chain, are guided by two concentric sets of steel guide rails. Dual, counter-rotating, 250-mm diameter steel guide wheels on the bogies run between two sets of guide rails. Whilst a bogie runs along the bottom section of the rails, the tyres are pushed down onto the pavement by a hydraulic and compressed nitrogen gas system. In addition, whilst running, the entire machine can be translated sideways, about 500mm to each side, on computer-controlled hydraulic powered slides to simulate the lateral distribution of the wheel paths of different trucks on a highway. The machine has an on board a 132kW diesel generator and is fitted with transport wheels on which it can be driven and steered at low speed under its own power. The machine utilises Linear Induction Motors (LIM’s) from Force Engineering in the UK to drive the bogies inside the machine and these are controlled by specially configured modular Unidrive SPM AC drives. LIM’s, with their no-contact characteristics and their high thrust and acceleration were the perfect choice for this application, but they do require control by specially configured inverter drives. Control Techniques has worked closely with Force Engineering for many years to produce the optimum control characteristics for LIMs. The drives give a soft-start action, maximum speed being determined by winding design and supply frequency whilst torque and speed is controlled in several ways. Control Techniques’ on-board second processor technology was used to run the dedicated LIM Control Software Solution. The software was downloaded into an SM Applications Plus module which requires no panel space as it is fitted into the interior of the Unidrive SPM drive. This high-speed processor handles all motion control calculations as well the complete machine logic control. The lateral position control of the entire machine is also handled within the SM Applications Plus module. Analogue sensors provide position feedback and the actual motion is done by hydraulic actuators. The machine I/O is networked to the SM Applications Plus processor module by means of CTNet, Control Techniques’ own high-speed network, and Beckhoff remote I/O cards. In this way the designers managed reliabily to network large quantities of field I/O at very high communication speeds. An operator interface is used to setup the machine operating parameters as well as provide system diagnostics and fault reporting. The modular nature of the Unidrive SPM’s power circuits helps with fitting into nonstandard enclosures – and was a major benefit for this application. The drive still provides the full standard and optional features of the well-proven and popular Undrive SP range, and is integrated using the same software tools for commissioning and programming. The Unidrive SPM is extremely versatile, configurable into open and closed loop modes, paralleled and load sharing, with active input and regeneration, in multi-pulse configuration (12, 18, 24 etc.) or fitted on a common bus for circulation of energy between drives. The linear induction motors for the MLS10 Test System are supplied by Force Engineering of Leicestershire, one of the world leaders in LIM technology. The company has developed hundreds of bespoke designs – from just a few Newtons of force up to many kiloNewtons - supplying companies throughout the world for applications as diverse as rapid transit systems, amusement rides and materials handling. LIMs are used to move a steel bar a few millimetres or propel a seven tonne vehicle up to 60mph in seconds! LIMs produce a linear thrust in a reaction plate and have many advantages; no moving parts, silent operation, reduced maintenance, compact size, fast response and ease of control and installation. They develop very high acceleration and braking forces, with speed not limited by contact friction and no gears means no backlash. MLS Test Systems has extensive experience in electro-mechanical design and pavement engineering. Its core business is the design and manufacture of research and test equipment for the road and airport pavement industries. -ends780 words Notes to the Editor: About Control Techniques Control Techniques, an Emerson Industrial Automation company, is a world leader in the design, production and marketing of electronic variable speed drives for the control of electric motors. Our strategy is to concentrate on delivering drives and servo products that enhance the productivity of our customers machines and processes. We operate through a global network of Drive Centres and Application Centres that both distribute product and add value by building our drive products into custom designed systems and by offering the highest levels of customer service. Our Control Techniques Drive Centres also provide us with invaluable feedback and market intelligence so that we can further improve our products and service. This customer focused strategy will enable us to continue to grow profitably. Our competitive edge is based on our unique focus on drives, our strength in research and development, our investment low-cost manufacturing and an effective worldwide marketing strategy. For the best in drives information visit our website: www.controltechniques.com About Emerson Industrial Automation Emerson Industrial Automation, a business of Emerson, is a global technology provider that enables productivity, efficiency and quality gains for customers across a spectrum of industries. Our products include alternators, electric motors and drives, electrical distribution devices and mechanical power transmission, fluid automation and ultrasonic joining solutions. Emerson brands include Appleton, ASCO, Branson Ultrasonics, Browning, Control Techniques, Kop-Flex, Leroy-Somer, McGill, Morse, Numatics, O-Z/Gedney, Rollway, SealMaster, and System Plast. For more information, visit www.EmersonIndustrialAutomation.com. About Emerson Emerson (NYSE:EMR), based in St. Louis, Missouri (USA), is a global leader in bringing technology and engineering together to provide innovative solutions to customers through its network power, process management, industrial automation, climate technologies, and appliance and tools businesses. Emerson’s sales in fiscal 2009 were $20.9 billion. The company is ranked 94th on the Fortune 500 list of America’s largest companies. For more information, visit www.Emerson.com. For editorial information contact: Katie Williams, Press Officer, Control Techniques Ltd, Drive Centre Marketing, Ty Rheoli, Unit 79 Mochdre Industrial Estate, Newtown, Powys SY16 4LE Tel: 01686 612900. Fax: 01686 612999. katie.williams@controltechniques.com For Sales Enquiries Contact: Control Techniques UK Drive Centre, Stafford Park 4, Telford, Shropshire TF3 3BA Tel: 01952 213 700 Fax: 01952 213 701 Uksales@controltechniques.com