Meltech cuts costs on inline plastics coiling machines

advertisement

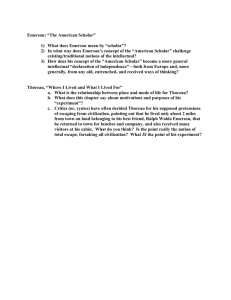

Press release Control Techniques For immediate release Contact: Katie OWEN katie.owen@emerson.com MELTECH CUTS COSTS & MAINTENANCE ON INLINE PLASTICS COILING MACHINES One of Europe’s leading manufacturers of extrusion, winding and coiling equipment for the metals, wire / cable and plastics industries has taken the design of its semiautomatic plastics inline coiling equipment one step further with the elimination of a separate PLC and reduced the need for maintenance by switching from DC to an intelligent AC drives solution from Control Techniques. Meltech Engineering Ltd of Blackburn in Lancashire has taken a fresh look at the control system for its semi-automated plastics coiling machines, versatile winders that can coil a variety of small plastic profiles such as the fine plastic tubes used in aerosols. Their chosen solution to simplify and improve reliability in one go has been to switch to Unidrive SP AC drives, four in total for each coiler, each drive featuring a powerful programmable on board plug-in SM Applications module – a PLC in its own right. This has eliminated the need for a costly separate controlling PLC and removed a considerable amount of wiring between the PLC and the drives, cutting both build time and an area of potential weakness, thus enhancing machine reliability. Control Techniques, Unit 79 Mochdre Industrial Estate, Newtown, SY16 4LE, UK T: +44 (0) 1686 612000, F: +44 (0) 1686 612999 e-mail: controltechniques@emerson.com www.controltechniques.com Press release Control Techniques The Meltech semi-automatic plastic coiler features two reels mounted on a transfer disc. When the active winder is full, the disc is rotated 180° and the extrusion is automatically transferred and attached onto the empty reel to allow continuous uninterrupted operation of the extrusion line. Depending on the product to be wound, the machine can operate at line speeds of up to 300m/min on a variety of drum and coil sizes. The winding drives are both 1.1kW Unidrive SP AC drives in speed control, the transfer disc is controlled by a 1.5kW Unidrive SP in open-loop vector mode and the traverse is controlled by a 0.37kW Unidrive SP in servo mode twinned with a Control Techniques Unimotor FM servo motor. All four drives communicate with Control Techniques’ own high-speed network, CTNet, facilitated by the SM-Applications Plus modules in each drive. The entire machine application control program is on just one of these units. “We were looking for ways to cut manufacturing costs whilst maintaining or improving reliability and decided to switch from DC to AC,” says Meltech’s Engineering Manager, Andrew Procter. “Whilst the switch to AC has brought a number of benefits, the selection of Unidrive SP drives has brought even more. Control Techniques, Unit 79 Mochdre Industrial Estate, Newtown, SY16 4LE, UK T: +44 (0) 1686 612000, F: +44 (0) 1686 612999 e-mail: controltechniques@emerson.com www.controltechniques.com Press release Control Techniques The feed for the winder drives is by slip rings. We now only need six slip-rings for the three phases on each motor – we needed eight before, which has cut build cost, improved reliability and cut some maintenance. In our development phase we considered whether we still needed encoder feedback for accurate speed control – but found that the Unidrive SP’s open-loop vector mode performance enabled us to eliminate the encoders, again saving costs and improving reliability. All users will understand that AC means less maintenance than DC, so there’s another saving here. “However, perhaps the biggest saving has been in the elimination of the PLC. The programmable SM-Apps modules have more than enough intelligence to run the machine. We found them very straightforward to programme, any one who is familiar with regular PLC programming will have no problems in adapting this approach. And all of the drives are an identical platform, so we don’t need to mix and match different drives and servo-drives.” Meltech engineers used CT-Soft, Control Techniques’ software configuration tool for setting up and to parameterise the drives and SyptPro for programming the PLC machine control program. Control Techniques, Unit 79 Mochdre Industrial Estate, Newtown, SY16 4LE, UK T: +44 (0) 1686 612000, F: +44 (0) 1686 612999 e-mail: controltechniques@emerson.com www.controltechniques.com Press release Control Techniques The Unidrive SP ‘solutions platform’ AC variable speed drive range spans 0.37kW right up to 1.9MW. It is configurable into five operating modes – open and closed loop, vector, servo and regenerating modes. With a range of plug-in module options, its on-board PLC can be supplemented with programmable and specialist feedback and communication modules. The SM Applications Plus module provides programmable automation from simple start/stop sequencing of a single drive to more complex machine and motion control applications. The module gives highspeed drive-to-drive communications via CT-Net and extremely fast I/O. “Less wiring, fewer components and identical drive platforms all adds up to a better, more reliable product requiring less maintenance. It’s a good news story!” concludes Andrew Procter. Meltech machines offer continuous winding of multiple profiles enabling significant productivity benefits compared with manual handling. Readily integrated with plastic extrusion production operations, the Meltech machines feature touch-screen control and industry-leading reliability. -ends734 words Control Techniques, Unit 79 Mochdre Industrial Estate, Newtown, SY16 4LE, UK T: +44 (0) 1686 612000, F: +44 (0) 1686 612999 e-mail: controltechniques@emerson.com www.controltechniques.com Press release Control Techniques Notes to the Editor: About Control Techniques Control Techniques, an Emerson Industrial Automation company, is a world leader in the design, production and marketing of electronic variable speed drives for the control of electric motors. Our strategy is to concentrate on delivering drives and servo products that enhance the productivity of our customer’s machines and processes. We operate through a global network of Drive Centres and Application Centres that both distribute product and add value by building our drive products into custom designed systems and by offering the highest levels of customer service. Our Control Techniques Drive Centres also provide us with invaluable feedback and market intelligence so that we can further improve our products and service. This customer focused strategy will enable us to continue to grow profitably. Our competitive edge is based on our unique focus on drives, our strength in research and development, our investment low-cost manufacturing and an effective worldwide marketing strategy. For the best in drives information visit our website: www.controltechniques.com About Emerson Industrial Automation Emerson Industrial Automation, a business of Emerson, is a global technology provider that enables productivity, efficiency and quality gains for customers across a spectrum of industries. Our products include alternators, electric motors and drives, electrical distribution devices and mechanical power transmission, fluid automation and ultrasonic joining solutions. Emerson brands include Appleton, ASCO, Branson Ultrasonics, Browning, Control Techniques, Kop-Flex, Leroy-Somer, McGill, Morse, Numatics, OZ/Gedney, Rollway, SealMaster, and System Plast. For more information, visit www.EmersonIndustrialAutomation.com. About Emerson Emerson (NYSE:EMR), based in St. Louis, Missouri (USA), is a global leader in bringing technology and engineering together to provide innovative solutions for customers in industrial, commercial, and consumer markets through its network power, process management, industrial automation, climate technologies, and appliance and tools businesses. Sales in fiscal 2009 were $20.9 billion. For more information, visit www.Emerson.com. For editorial information contact: Katie Owen, Press Officer, Control Techniques Ltd, Drive Centre Marketing, Ty Rheoli, Unit 79 Mochdre Industrial Estate, Newtown, Powys SY16 4LE Tel: 01686 612900. Fax: 01686 612999. katie.owen@emerson.com Control Techniques, Unit 79 Mochdre Industrial Estate, Newtown, SY16 4LE, UK T: +44 (0) 1686 612000, F: +44 (0) 1686 612999 e-mail: controltechniques@emerson.com www.controltechniques.com