On-farm Corn Variety Demonstration based on soil type

advertisement

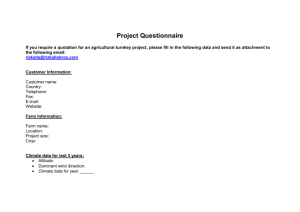

2014 Mississippi County Agriculture Demonstration Report Ray Benson Mississippi County Extension Staff Chair Jason Osborn Mississippi County Extension Agriculture The Arkansas Cooperative Extension Service offers its programs to all eligible persons regardless of race, color, national origin, religion, gender, age, disability, marital or veteran status, or any other legally protected status, and is an Affirmative Action/Equal Opportunity Employer. Table of Contents Demonstration Page Insecticide Termination in Cotton Using COTMAN Rules ………………………….. 3 Evaluation of Foliar Fertilizer Products in Cotton …………………………………… 7 Nitrogen Rate Study - N-STaR for Wheat …………………………………………….. 9 Procedures for Grid Soil Sampling …………………………………………………… 12 Timing the Initial Irrigation in Soybeans …………………………………………….. 15 Cotton Response to Three Seeding Rates ……………………………………………. 18 Multiple Inlet Rice Irrigation ………………………………………………………… 24 On-farm Corn Variety Demonstration based on soil type …………………………… 25 Phaucet Irrigation in Mississippi County ……………………………………………. 53 PHAUCET Irrigation vs. Conventional Irrigation …………………………………... 54 Rice fungicide Demonstration ……………………………………………………….. 55 2014 On-Farm Rice Variety Demonstration ………………………………………….. 56 Surge Value Irrigation Demonstration ……………………………………………….. 58 Insecticide Termination in Cotton Using COTMAN Rules Ray Benson Cooperator: Tom Veach Purpose: Knowing when a cotton crop has researched maturity is the key for producers to make informed end-of-season management decisions. Determining when the crop no longer requires protection from fruit feeding insects can help producers eliminate unnecessary and expensive pesticide applications. Methods: A northeast Arkansas cotton field, which was enrolled in the Cotton Research Verification Program, was monitored for progression of the number of Nodes-Above-White-Flower (NAWF) duing the 2014 production season. Deltapine 0912 was planted on May 10, 2014. Production inputs during the seaon were based on weekly inspections of the field and followed University of Arkansas Divisionn of Agriculture Cooperative Extension Service recommendaitons. Beginning at approximately first flower, NAWF values were collected from the field and entered into the COTMAN management system (Figure 1.). The analysis generated by the COTMAN program identified that the crop reached cutout; ie NAWF = 5 on August 5, 2014 (Table 1). Once the field had reaced cutout, daily heat units were recorded. According to University of Arkansas research, a boll which has accumunulated 250 heat units is considered safe from plant bug feeding. Therefore, once the field had reached NAWF = 5 + 250 heat units, insecticide termination plots were established. Treatmens in the study included plots which received no insecticide after NAWF = 5 + 250 heat units, plots which were treated one additional time after reaching NAWF = 5 + 250 heat units and plots which were treated twice after reaching NAWF = 5 + 250 heat units. On August 12, 2014, the field had accumulated 180 heat units beyond NAWF = 5. Insect scouting procuderes on that date identified sufficient levels of plant bugs to warrant an insectidice application. The entire field was treated with 0.75 lbs of Acephate + 4.2 oz Bifenthrin per Picture 1. Plant bugs feeding white flowers, Veach Farm 2014. acre. This treatment represented the last treatment under current University of Arkansas recommnedations for plant bug control in cotton. Any additional insecticide applications were establishe as treatmens in the study and were only triggered when plant bug populations were high and the producer/consultant believed yield losses may occur if left uncontrolled. Field observations indicated a large build-up of plant bugs on August 22, 2014 (Picture 1.). Plots were randomized, marked for application, and treated on August 25, 2014 using 5 oz Bidrin/Acre. Plots were established as 56-rows wide and ran the length of the field. This deminson matched the producers spray equipment and would allow entire plots to be collected in individual modules (Picture 2.). Picture 2. 2014 Insecticide Termination Study, Veach Farms. Insecticide treatments terminated at NAWF = 5 + 250 heat units. Treated 2 additional times after NAWF = 5 + 250 heat units. A second treatment was established and treated on September 5, 2014 using the same procedure and chemical. Plots were machine harvested using the producers 6-Row John Deere cotton picker on October 19, 2014. Harvest area, module weights and lint yield per acre (Table 2.) were analyzed to determine treatment effects. Results: Harvest resulted in no statistical difference among treatments. The results indicate that controlling fruit feeding insects after the crop has reached NAWF = 5 + 250 heat units does not increase the lint yield of cotton and supports the University of Arkansas guidelines for insect control in cotton. Spraying after the crop is safe from insect damage can reduce overall profitability as well as contribute to the development of resistance in the future. Using 2014 crop enterprise budgets, application costs for producers using personal spray equipment is $2.32 per acre per application. Additionally, the price of Bidrin (the product used in this study) is estimated to be $5.40 per acre pre application. In the case of this study, terminating insecticide applications for the control of plant bugs would result in a savings of $7.72 per acre per application ($15.44 for two applications). Projected on the approximate 80,000 acres of cotton in Mississippi County, producers could have reduced their expenses by $1.2 million dollars by using current University of Arkansas recommendations for terminating the use of insecticide in cotton. Figure 1.COTMAN growth curves for insecticide termination study at Veach Farms, 2014. Table 1. NAWF, Heat Unit Accumulation Values, and InsecticideApplication Dates for Veach Farms, 2014. Insect Population Date NAWF Heat Units Level Treatment August 5, 2014 5 0 Low August 12, 2014 3.4 180 TRT Level None 0.75 lbs Acephate + 4.2 oz Bifenthrin August 21, 2014 NA 350 Low None August 25, 2014 NA 450 High (> 1/ft) Bidrin @ 5 oz/A September 5, 2014 NA 695 High (> 1/ft) Bidrin @ 5 oz/A Table 2. 2014 Plot Harvest Data from Insecticide Termination Study, Veach Farms. Area (average) Module wt (average)2 % T.O.3 Lint Yild/A4 Control 5.14 acres 16,013 lbs 38.39 1196 a 1 additional spray 5.88 acres 17,053 lbs 38.39 1120 a 2 additional sprays 5.26 acres 17,460 lbs 38.39 1269 a Treatment 1 LSD (0.05) 5 1 2 3 4 5 Control plots received no insect control measures after NAWF = 5 + 250 HU's, 1 additional spray represents plots which were treated one time after NAWF = 5 + 250 HU's and 2 additional sprays represents plots which were treated twice after NAWF = 5 + 250 HU's. Module weights are represented as total weight for the whole plot and have not been adjusted to a per acre weight. % turnout was based on the average turnout for the entire field. Lint yield was calculated on a per acre basis. Numbers followed by the same letter are not significanly different (P=0.05) NS Evaluation of Foliar Fertilizer Products in Cotton Ray Benson, Bill Robertson and Jason Osborn Location: Manila Airport Research Location Purpose: Figure 2. Spraying foliar fertilizer plots at Manila, 2014. Producers are looking for ways to improve production and increase yield to help off-set low commodity prices. Several foliar fertilizer products are now commercially available. Evaluation of these products will help determine the potential for yield improvements. Methods: Stoneville 5288 B2R was planted at the Manila Airport Research Field on May 8, 2014. The field was managed based on University of Arkansas recommendations for cotton production. General manufacturer recommendations for the products in this test were to apply within the first week of flower. Treatments were established on July 17, 2014, approximately 10 days after first flower, and included four 38 in rows by 50 ft. long. Plots were randomized three times and foliar products were applied using a self-propelled plot sprayed calibrated to deliver 15 gallons per acre (Fig 1.). Plots were machine harvested on October 21, 2014. Plot weights were converted to a per acre yield (Table 1.). Results: All yields in this field were relatively high. Results of this study showed that yield was not affected by foliar treatments (Table 1 – 2.). It is possible that high yielding fields, which have adequate soil nutrient levels, may not benefit from the application of foliar products. Future plans are to evaluate these and similar products on field areas expressing historically low yield, and in areas with below adequate levels of soil nutrients. Table 1. Yields for foliar fertilizer treatments, Manila, AR, 2014. Foliar Product NOVUS K Quick Ultra with Awaken Coron 25-0-0 NOBUS B Utilize Deliverek K plus N-Pact 26-0-0 Coron Full BOR Check – No Treatment Re-Nforce Boost-it VitaBor Bloom Pro NUTRA – K Lint yield (lbs/acre) 1575 1539 1526 1502 1480 1468 1461 1458 1441 1405 1402 1386 1343 1314 P >F (0.49) NS Table 2. ANOVA for foliar demonstration, 2014. Source DF Sum of Squares Mean Square F Value Pr > F 15 243533.6071 16235.5738 0.97 0.5109 Model 26 435828.5376 16762.6361 Error 679362.1448 Corrected Total 41 2 28065.1490 14032.5745 0.84 0.4443 rep 13 215468.4581 16574.4968 0.99 0.4878 trt Nitrogen rate study - N-STaR for Wheat Ray Benson and Jason Osborn Cooperator (consultant): Scott Gifford Location: Manila, Arkansas Purpose: Figure 3. 2014 Wheat Crop - Manila, Arkansas. The purpose of this replicated field trial was to evaluate nitrogen rates effect on wheat yield. Ultimately the objective is to develop a soil test procedure for wheat which is similar to the N-STaR test used in rice. Development of a more accurate soil test and analysis program for wheat will allow producers to better manage their crops fertility. Soil test programs which account for native soil nitrogen levels may result in more economical production with potentially less environmental risks associated with over fertilization. Methods: A replicated study was conducted on a producer’s field in Manila, Arkansas during the 2014 production season. The soil type in the field was generally a sandy loam. Field preparation and planting was conducted using the producers equipment and was based on the producers standard production practices. Armor Ricochet was seeded on October 15, 2014 at a rate of 2.75 bushels/acre. After emergence, fertilizer plots were established in a randomized complete block design with four replications. Plots were arranged in a randomized complete block with 4 replications. Each plot was 10 ft widy by 50 ft long and treatments included split applications of pre-weighed urea fertilizer at rates ranging from 0 to 225 lbs per acre (Table 1). All production practices, other than fertilizer rate, were based on the producers and consultants standard practices. Plots were harvested using a plot combine with a 5 ft wide header. Results: Rains during February and March resulted in water standing on the test area for a prolonged period of time. Although all treatments were applied in a recommended time, nitrogen loss was likely due to the amount of rainfall in close proximity to application. Yellowing of the low nitrogen plots was evident during this study (Fig. 1 and 2.). Although, plots receiving the least amount of nitrogen appeared yellow, the effects on final yield were not significantly different than plots receiving high nitrogen rates. These results indicate that traditional levels of nitrogen may not be required for optimal yields. The development of a soil test procedure with accounts for residual nitrogen may help producers reduce the amount of nitrogen fertilizer applied and help improve crop profits. High numbers of army worms were present in the plots in early June. Consultation with the Extension Service’s area Entomologist resulted in the decision to not treat with insecticide. Although army worm levels were high, the stage of wheat development (beginning hard dough) likely resulted in only minor yield loss. Figure 1. Wheat plots showing nitrogen deficiency, 2014 Wheat nitrogen rate study at Manila (April 17, 2014). Figure 2. Wheat plots showing nitrogen deficiency, 2014 Wheat nitrogen rate study at Manila (April 2, 2014). Table 2. Wheat yield from nitrogen rate study, 2014. Total nitrogen applied (units N/acre) 0 45 90 135 180 225 1 Wheat Yield1 (bu/acre) 34 ab 36 ab 38 a 35 ab 30 ab 29 b Yields followed by the same letter are not significantly different at 0.05 probability level. Procedures for Grid Soil Sampling Ray Benson and Jason Osborn Purpose: Producers in Mississippi County are quickly adopting precision agriculture practices. One of the main practices consists of “grid” soil sampling for site specific soil applied nutrients. Determining how intensely a grid must be sampled is often a question. Method: A field in Mississippi County was selected to compare different grid sampling methods. The field was a 32 acre Figure 1. Soil ECa map showing differences in soil texture. precision leveled field. The predominant soil classification was a Dundee silt loam. ECa was collected in March 2014 to help determine soil textural differences in the field. After ECa collection, the field was divided into 2.5 acre grids for soil sampling (figure 2). The procedures for collecting soil samples included taking soil probe collected cores from a 4 in depth. Samples from within each grid were collected in buckets from which a sub-sample was taken and submitted for lab analysis. Within each 2.5 acre grid, samples were collected as a single core from the center of the grid (Single Core), a composite of 8 cores collected from within an approximately 10 ft diameter radius in the center of the grid (tight composite) and a composite of 25 cores collected across the entire grid (grid composite). Additionally, for comparison, a field composite sample was collected. For comparison, the grid composite was assumed to be the most accurate for accessing soil test values. Figure 2. Sample methods for grid soil sampling demonstration. Results: Variations among sampling methods were observed in this demonstration (Figures 3 – 5). All methods, except for the field composite sample, yielded generally similar soil test values for pH, K and P. The largest deviations appeared to be from areas of more coarse sand. Although this was not a replicated test, the differences among sample methods suggest that further field studies to address sample variability should be conducted in the future. Variation in pH among sampling methods pH Value 7 Single Core - pH 6.5 Tight Com. - pH Zone Com. - pH 6 Field Com. pH 5.5 1 2 3 4 5 6 7 8 9 10 11 12 Variation in soil test K values among sampling 650 Soil Test K (lbs/A) 600 550 500 Single Core - K 450 Tight Com. - K 400 Zone Com. - K 350 Field Com. K 300 250 1 2 3 4 5 6 7 8 9 10 11 12 Variation in soil test P values among sampling Soil Test P (lbs/A) 200 150 Single Core - P Tight Com. - P 100 Zone Com. - P 50 Field Com. P 0 1 2 3 4 5 6 7 8 9 10 11 12 Figures 3 – 5. Variation in soil test values among soil sampling methods. Timing the Initial Irrigation in Soybeans Justin Chlapecka and Ray Benson Cooperator: Wildy Family Farms Location: Manila, Arkansas Purpose: Expanded use of irrigation management tools are needed to improve irrigation and water use efficiency in eastern Arkansas soybean production, especially on sandy loam fields. Current University of Arkansas Division of Agriculture recommendations for irrigation timing in soybeans target the final irrigation. Irrigation timing decisions on initiation in different soil textures may be improved by using technology available to characterize soil moisture, plant requirements for water and evapotranspiration. Current recommendations on initiation timing based on ET have not been validated on sandy soils in northeast Arkansas. Many Northeast Arkansas producers are interested in recommendations for timing the initial irrigation. Development of guidelines for timing the initial irrigation could further help improve irrigation water use efficiency. Methods: The research site was a commercial farm located in Mississippi County, Arkansas, in a field with sandy loam soil (Routon-Dundee-Crevasse Complex) that ranged from sand to sandy loam to silt loam soils. There were four irrigation treatments 1) Early Start (ET=1 in), 2) Standard UA Recommendation (Based on ET Chart, ET = 2.5 in), 3) Late Start (ET Deficit = 3 in), and 4) Rainfed (Table 1). The experiment was arranged in a randomized complete block with 4 replications. Asgrow 4633, a cultivar of Group IV soybean, was planted in twin rows on raised beds spaced at 38 in (1m). The cooperating producer performed all standard field operations. Other than irrigation timing, all production practices were consistent for all treatments in this study. Whole plots were harvested using the producer’s equipment. Harvests from each plot were collected and weighed in the producers load cell equipped grain cart. Yields were calculated on a per acre basis and yield data were analyzed using PROC GLM and ANOVA statistics with mean separation using protected LSD (SAS Institute; Cary, NC). Results: Precipitation was above normal for the 2014 (Table 2). The amount of rainfall tended to mask any differences in yield between irrigation treatments. Delaying irrigation until the R3 growth stage resulted in the highest yield in this study (Figure 1). The results would suggest that delaying the initial irrigation in soybeans grown on sandy loam soils may help producers improve their irrigation water use efficiency by reducing the number of early season irrigations. Table 1. Timing details for soybean irrigation initiation study at Wildy Family Farms in Manila, AR- 2014. Irrigation Start1 Treatment Description Early start Standard (CES recommendation) Late start Rainfed 1 ET Cue (in) 1.2 2.5 3.0 Growth stage R2.5 R3 R3.5 Date 18-Jun 24-Jun 6-Jul Days after planting 57 63 75 All irrigated treatment plots received irrigation on 6, 10, 28 July and 4, 25 August. Table 2. Monthly precipitation at Wildy Family Farms compared to long term (40 yr) average from Manila, AR Average 2014 Variation from Month Precipitation Precipitation Average ----------------------------- in ------------------------------April 4.75 6.04 1.29 May 5.37 4.51 (0.86) June 3.99 6.37 2.38 July 4.04 4.69 0.65 August 2.36 8.19 5.83 20.51 29.80 9.29 Total Season Mean yield (bu/ac) 100 Field Plot -Grain Cart 75 50 25 0 85 Early start 79 90 Standard Late start Irrigation initiation timing 75 Rainfed Figure 1. Mean yield (±SEM) determined by from field length measurements taken at harvest using our cooperating producer's grain cart with load cells – Manila, AR 2014. COTTON RESPONSE TO THREE SEEDING RATES Ray Benson Problem: Producers in Northeast Arkansas continue to look for opportunities to reduce production costs and remain profitable while producing cotton. Although the development of transgenic Bt cottons with herbicide tolerance has provided producers with tools to help improve pest management, the cost of the biotechnology represents one of the most expensive inputs associated with USA production. Reducing input costs by reducing seeding rates appears to be a promising option. As rate controllers on precision planters become more widely adopted, producers will have the capacity to apply seeding rates based on specific management objectives within a field. One option to improve the efficiency and profitability of cotton may be to reducing seeding rates in field areas with different yield potential. One of the objectives of this 2014 study was to evaluate the interactions of three cotton seeding rates across a NE Arkansas production field characterized by heterogenous soils with a history of low yield potential. Methods: A cotton seeding rate field study was conducted in NE Arkansas during the 2014 production season. The soil type in the field selected for the study was classed as a Routon Dundee – Crevasse Complex, and ranged from coarse sand to a fine sandy loam. All production practices including land preparation, fertilizer application, irrigation and weed and insect control were based on the cooperating producer’s standard practices and using his equipment (Table 1). Prior to planting, the field was partitioned into three management zones based observations of the spatial variability of yield, soil ECa, and NDVI maps (Figure 1). Management zones based on soil electrical conductivity (EC) properties classified from measurements using a dual depth Veris® 3150 Soil Surveyor. Stoneville 4747GLB2 was planted on May 4, 2014 using the producer’s 12-row John Deere 1720XP vacuum planter. Plots were 12-rows wide and ran the full length of the field. Treatments included 3 target seeding rates of 1.5, 3.0 and 4.5 seeds per foot. A 4th treatment included a variable seeding rate prescription based on 3 zones established by soil EC measurements and was provided by the cooperating producer’s local John Deere spatial technology specialist. The experiment was analyzed as a split plot design with seeding rates considered main plots and soil EC classes considered sub-plots. Other than seeding rates, all production practices were consistent across all treatments and were based on the producer’s standard production practices. Table 1. Dates of planting, irrigation and harvest for the 2014 seeing rate study, Wildy Family Farms, Manila, AR. Operation Date Days after planting Date of planting 4-May, 2014 Stand Counts 13, 20, 27 May and 4 June 9, 16, 23, 31 Insecticide 23 June 17, 28 July, 4 August 50, 74, 85, 92 Irrigation 23 June, 10 July, 12 September 50, 67, 131 Hand harvest 7 October 157 Harvest 17 October 166 Sand Sandy Loam Soil EC (mS/M) Clay Loamy Sand Figure 4. Soil management zones for the 35 acre study site were originally classified in 2012 based on four soil EC categories. After two years of extensive plant and soil monitoring, readings, management zones were re-classified for the 2014 seeding rate trial into three categories: sand blow, sandy loam and clay – Wildy Family Farms, Manila, AR. Results and Discussion The 2014 production season in Northeast Arkansas was characterized by cool temperatures during stand establishment, with high rainfall early in the season. Stand counts from prescribed, whole plot, seeding rates were consistent across all target seeding rates (Figure 2). Stand counts from the three whole plot seeding rates followed the same trend and resulted in actual stand counts ranging from 70 – 80% of the target. Stand counts from the clay soil zones tended to have the lowest percentage of the targeted rate than stands from either the sand or sandy loam zones and was most likely due to the amount of rainfall experienced during stand establishment. Stand counts from the variable rate (soil type specific) treatment resulted in much greater deviations from the target seeding rate than did any of the uniform seeding rates (Figure 2). Stand count data from the variable rate plots suggest that zone size and speed and accuracy of the rate controller could affect precision agriculture practices. 100 Target: 3 seeds per EC foot Target: VR based on soil 100 Target: 1.5 seeds per foot 50 25 Percent of target 75 Percent target Percent of target 125 100 75 75 50 Sand blow Clay 50 25 Sandy loam 25 0 2 9 16 23 30 0 0 2 2 Days after planting 9 916 23 16 30 23 30 Days after planting Days after planting Target: VR based on soil EC 125 Target: 4.5 seeds per foot Percent of target Percent of target 100 75 50 25 100 75 50 25 0 0 2 9 16 23 Days after planting 30 2 9 16 23 30 Days after planting Figure 2. Observed plant stand densities determined in transect sampling across each soil EC zone over four dates in the first month after planting for each of the four seeding rates (1.5, 3, 4.5 and variable rate (VR)) expressed as a % of target seeding rate in 2014 seeding rate field trial – Wildy Family Farms, Manila, AR.. 10 Sand blow 5 5 0 Daily rainfall (inches) Mean no. squaring nodes 10 0 20 40 60 80 100 120 Days after planting 5 5 10 10 0 20 40 0 60 80 Days after planting 5 5 10 Clay 120 Seeding rate 1.5 3 4.5 Standard Rainfall Irrigation 10 0 0 5 100 20406080100 120 5 Days after planting Daily rainfall (inches) Mean no. squaring nodes Mean no. squaring nodes Mean no. squaring nodes Sandy loam Daily rainfal (inches) 10 10 0 0 20 40 60 80 100 120 Days after planting Figure 3. COTMAN growth curves for plants in soil EC zones: sand blow, sandy loam and clay planted at 1.5, 3, and 4.5 seeds per foot in the 2014 seeding rate field trial – Wildy Family Farms, Manila, AR. Although seeding rate did result in slight growth differences, the greatest effect on the crops development appeared to due to soil types (Figure 3). Lower seeding rates in the sand blow zones tended to have more squaring nodes at first flower than did the highest seeding rate. Greater plant structure at first flower in the lower seeding rates may have been the result of less interplant competition, especially within sand blow area where water and nutrients may be limited. Yields from hand harvest data resulted in no differences among seeding rate treatments (Figure 5). It should be noted however, that areas with large skips between plants were avoided during hand harvest. A more non-discriminating harvest area selection procedure would likely have affected yield results. Avoiding the excessive skips in the hand harvest areas may have contributed to the consistency in yields across seeding rates. Skips, especially in the clay areas of the field, were most likely due to the frequent rain fall and appeared to be more problematic in the lowest seeding rate treatments. Hand harvest yield was significantly lower in the clay and sand blow areas than the sandy loam area of the field. Figure 5. Yield from hand harvested plots within soil EC zones in 2014 seeding rate study in 2014 seeding rate field trial – Wildy Family Farms, Manila, AR. Multiple Inlet Rice Irrigation Jason Osborn Cooperator: John Langston Purpose: Surge valves have been shown to improve irrigation efficiency and reduce total irrigation water used by as much as 25%. Current USDA-ARS and University of Arkansas estimates suggest that Arkansas irrigation must be reduced by approximately 45% to insure our ground water supply is sustainable. Methods: During the 2014 rice growing season one field was equipped with flow meters and the producer was educated on how the Multiple Inlet Rice Irrigation (MIRI) works. All planting and irrigation methods, other than the MIRI, were based on the producers normal practices. Results: Eight fields were set up using the MIRI information but only one utilized flow meters for water use. The conventional irrigated field of 32 acres used 3.5 acre inches less that the MIRI irrigated field. The reason for the increased water usage is unknown. It may be attributed to the levee spills in the MIRI being set higher. The producer noted that the MIRI fields on the rest on the farm and including the demonstration field were easier to manage and reduced labor for the season. On-farm Corn Variety Demonstration based on soil type Jason Osborn Cooperators: Jason Bennett Soil Types: Dundee Silt Loam Purpose: At the County Extension Council meeting, the council requested more on farm variety trials and to base them on soil types (Sand Silt, Clay). Having more on-farm corn variety demonstrations based on soil types will help producers and consultants choose more adapted varieties for the farms soil type. Methods: Identifying growers and working with seed industry representatives and consultants, three corn variety demonstrations were established based on different soil types throughout the county. All field work, including planting and harvest, was performed using the producer’s equipment. All cultural practices were based on the producer’s standard production practices and were consistent for all corn varieties in the demonstration (Table 1). Inputs were based on producer and consultant recommendations and were not necessary based on University of Arkansas Extension recommendations for corn production. Results: Stand counts, Growth Stage, vigor, First Tassel Disease, and Height ratings were collected for each variety in the demonstration (Table 2). Yields for each corn variety were calculated from weights collected from producer’s harvested plots using yield monitor data (Table 3). Table 1. Field Production Information for Bennett Farms, 2014. County: Lat/Lon Grower: County Agent: Location of Field: Soil Type: Previous Crop: Planting Date: Row Width: Planting Population: Irrigation Type Total number of irrigations Emergence Date Herbicides: Fertilizer: Harvest Date: Mississippi Corn 35 32' 39.49N / 90 09'42.77W Jason Bennett Jason Osborn Joiner Dundee Silt loam soybeans April 25, 2014 38 inches 34,000 furrow 0 Dryland 5/5/2014 1 pint Dual 250 Units N/ P,K variable rate September 19, 2014 Applied April 26, 2014 Table 2. Stand Count, Growth Stage, Vigor, First Tassel, Disease, and Plant Height Ratings Growth Vigor Stand Stage Rating Count Date Date Hybrid Cropland 6640 36 v-2 8 Terrell 2355 36 v-2 8 Terrell 2493 35.5 v-2 8 Terrell 2820 38.5 v-2 8 Mycogen 797 35.5 v-2 8 Mycogen 786 27.5 v-2 8 Mycogen 877 33 v-2 8 DeKalb 67-72 35 v-2 8 DeKalb 64-89 37.5 v-2 8 DeKalb 66-87 40 v-2 8 P1257YHR 38 v-2 8 P1602YHR 36 v-2 8 P2089YHR 38 v-2 8 P1739YHR 38.5 v-2 8 Delta Grow 2888 37.5 v-2 8 Delta Grow 3788 39 v-2 8 Dyna Grow 5577 43 v-2 8 Dyna Grow 5291 43 v-2 8 Dyna Grow 5646 37.5 v-2 8 Stine 9732 35.5 v-2 8 Stine 9739 35 v-2 8 121219-May May May CR_P Common Rust Present P- Present First Tassel Date 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun 23-Jun L Disease S Rust Rust Plant Rating Rating Rating Heigth 0 0 0 CR-P 0 0 0 0 0 CR-P 0 0 CR-P CR-P 0 CR-P CR-P 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 P 0 0 0 0 0 0 0 0 0 0 105 119 113 125 112 105 115 110 116 114 115 125 128 128 120 127 93 105 110 99 106 Table 3. Yield Results for Bennett Farms, 2014 Adj. Hybrid Yield1 Area Weight Cropland 6640 261.58 0.546 8,123 Terrell 2355 290.91 0.535 8,916 Terrell 2493 276.75 0.530 8,485 Terrell 2820 291.58 0.524 8,893 Mycogen 797 230.56 0.518 6,809 Mycogen 786 215.15 0.513 6,300 Mycogen 877 233.01 0.507 6,876 DeKalb 67-72 286.66 0.501 8,308 DeKalb 64-89 285.47 0.496 8,092 DeKalb 66-87 263.29 0.490 7,454 P1257YHR 264.94 0.484 7,373 P1602YHR 292.02 0.479 8,202 P2089YHR 283.74 0.473 7,860 P1739YHR 300.05 0.467 8,196 Delta Grow 2888 254.74 0.462 6,901 Delta Grow 3788 261.15 0.456 6,974 Dyna Grow 5577 250.12 0.450 6,535 Dyna Grow 5291 296.11 0.444 7,587 Dyna Grow 5646 297.36 0.439 7,570 Stine 9732 273.74 0.433 6,840 Stine 9739 265.37 0.409 6,325 1 Yield is adjusted to 15.5% moisture. 2 Plant Stand is given as plants per acre. 3 Lodging score - 1 is no lodging, 10 is completely lodged. Avg. Yld 270.2042 Yield 265.67 297.60 285.88 303.06 234.73 219.30 242.18 296.12 291.33 271.65 272.03 305.77 296.74 313.40 266.74 273.10 259.33 305.14 307.92 282.09 276.15 % Moisture 16.8 17.4 18.2 18.7 17.0 17.1 18.7 18.2 17.2 18.1 17.7 19.3 19.2 19.1 19.3 19.2 18.5 18.0 18.4 18.0 18.8 Lodging Score3 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 On-farm Corn Variety Demonstration based on soil type Jason Osborn Cooperators: Ron Holthouse Soil Types: Tiptonville and Dubbs Silt Loams Purpose: At the County Extension Council meeting, the council requested more on farm variety trials and to base them on soil types (Sand Silt, Clay). Having more on-farm corn variety demonstrations based on soil types will help producers and consultants choose more adapted varieties for the farms soil type. Methods: Identifying growers and working with seed industry representatives and consultants, three corn variety demonstrations were established based on different soil types throughout the county. All field work, including planting and harvest, was performed using the producer’s equipment. All cultural practices were based on the producer’s standard production practices and were consistent for all corn varieties in the demonstration (Table 1). Inputs were based on producer and consultant recommendations and were not necessary based on University of Arkansas Extension recommendations for corn production. Results: Stand counts, vigor, and disease ratings were collected for each variety in the demonstration (Table 2). Yields for each corn variety were calculated from weights collected from producer’s harvested plots using yield monitor data (Table 3). Table 1. Field Production Information for Holthouse Farms, 2014 County: Mississippi 35 41’49.55N / 90 13’28.23W Grower: Ron Houlthouse County Agent: Jason Osborn Soil Type: Silt Previous Crop: Corn Planting Date: April 18, 2014 Row Width: 38 Inches Planting Population: 33,500 Harvested: September 1, 2014 Fertility: (lb/ac) N P K S --- Preplant 273 10 --- Sidedress 246 --- Pretassel Total Fertility: Herbicide: Inscecticide: Fungicide: Irrigations Irrigation Type: Crop: Zn Planted North to South P,K variable rate 100 619 N/ A N/A Power Maxx, Atrazine, Laudis lambdacyhalothrin Quilt XL 5 furrow 10 Corn N/A 100 urea 50 amminoum sulfate Table 2. Stand count, Growth Stage, Vigor, First Tassel, and Maturity Date. Hybrid NK 68B NK 72Q NK 77P DK 64-69 NK 79Z NK 78S NK 79T Pioneer 1690 NK 82V NK 83D DK 62-08 P1257YHR P1319HR P1637YHR Armor 1550 P1602YHR P1739YHR P1794YHR P2089YHR DK 66-87 Pioneer 1883 Pioneer 1319 T839 Pioneer 1319 T849 Stine 9732 Stine 9739 Dyna Grow 5646 Dyna Grow 5577 Dyna Grow 5291 Delta Grow 3788 Delta Grow 2888 Mycogen 877 Mycogen 797 Mycogen 780 DK 66-87 DK 64-89 DK 67-77 Stand Count 28 28 27 29 27.5 25.5 27.5 28 25 25.5 28.5 27 26.5 29.5 26 27.5 26 27.5 27 25 26.5 25 28.5 26 26 27 28 25 29.5 26.5 28 26 27.5 30 29 28 Growth Stage Date N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A Vigor Rating Date 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 First Tassel Date 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 Disease Rating Date N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A S Rust Rating Date N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A L Rust Rating Date N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A Maturity Date 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug 4-Aug Terrell 22BHR43 29.5 N/A Terrell 23BHR55 27 N/A Terrell 24BHR93 26.5 N/A Terrell 26BHR50 26.5 N/A Terrell 27BHR52 27 N/A Terrell 27HR83 24.5 N/A Terrell 28R10 27 N/A Terrell 28H1220 27 N/A Armor 1616 26.5 N/A Armor 1555 26.5 N/A Armor 1550 26.5 N/A AXS 4115 27.5 N/A Armor 1414 27.5 N/A Armor 1330 24.5 N/A Armor 1314 27 N/A Pioneer 1319 28 N/A Armor 1262 26.5 N/A Armor 3111 29.5 N/A Armor 4110 27.5 N/A Armor 4109 28 N/A Armor 2108 27 N/A Armor 0700 22 N/A Plant Stand is given as plants per acre. Lodging score - 1 is no lodging, 10 is completely lodged. 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 6 20-23 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug 14-Aug Table 3. Holthouse Corn Yields for 2014 Hybrid NK 68B NK 72Q NK 77P DK 64-69 NK 79Z NK 78S NK 79T Pioneer 1690 NK 82V NK 83D DK 62-08 P1257YHR P1319HR P1637YHR Armor 1550 P1602YHR P1739YHR P1794YHR P2089YHR DK 66-87 Pioneer 1883 Pioneer 1319 T839 Pioneer 1319 T849 Stine 9732 Stine 9739 Dyna Grow 5646 Dyna Grow 5577 Dyna Grow 5291 Delta Grow 3788 Delta Grow 2888 Mycogen 877 Lodging Score 3 2 2 7 8 3 2 2 2 3 8 2 2 2 3 2 2 2 2 2 2 2 2 2 2 3 4 3 2 9 2 Adj. Yield1 224.96 220.19 230.18 149.45 114.96 222.33 210.68 253.73 227.08 215.59 130.42 268.62 251.26 251.99 212.26 127.45 263.27 199.37 284.66 222.60 259.23 236.80 249.92 250.64 230.18 222.53 162.78 175.60 217.87 112.57 236.37 Area Acres 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 0.300 Weight 3,820 3,840 3,980 2,600 2,040 3,980 3,720 4,480 4,060 3,840 2,220 4,600 4,420 4,400 3,720 2,220 4,660 3,560 5,020 4,000 4,600 4,140 4,380 4,420 4,100 3,900 2,860 3,120 3,920 2,000 4,280 Yield 227.38 228.57 236.90 154.76 121.43 236.90 221.43 266.67 241.67 228.57 132.14 273.81 263.10 261.90 221.43 132.14 277.38 211.90 298.81 238.10 273.81 246.43 260.71 263.10 244.05 232.14 170.24 185.71 233.33 119.05 254.76 % Test Moisture Weight 16.4 58.7 18.6 52.9 17.9 56.5 18.4 59.3 20.0 55.6 20.7 49.6 19.6 53.6 19.6 57.2 20.6 49.2 20.3 58.4 16.6 57.1 17.1 60.9 19.3 57.1 18.7 59.6 19.0 59.5 18.5 61.5 19.8 58.1 20.5 53.6 19.5 58 21.0 51.7 20.0 60.2 18.8 57.8 19.0 60.3 19.5 56.6 20.3 55.6 19.0 55 19.2 57.8 20.1 57.3 21.1 55.3 20.1 58 21.6 55.3 Mycogen 797 5 126.77 0.300 Mycogen 780 3 193.03 0.300 DK 66-87 3 205.90 0.300 2 174.74 0.300 DK 64-89** (see foot note) DK 67-77 2 249.14 0.300 Terral 22BHR43 2 218.96 0.300 Terral 23BHR55 2 242.40 0.300 Terral 24BHR93 2 251.69 0.300 Terral 26BHR50 2 269.59 0.300 Terral 27BHR52 2 236.62 0.300 Terrall 27HR83 2 208.94 0.300 Terral 28R10 3 218.83 0.300 Terral 28HR20 3 243.91 0.300 Armor 1616 6 223.35 0.300 Armor 1555 3 158.23 0.300 Armor 1550 8 230.51 0.300 AXS 4115 2 119.62 0.300 Armor 1414 6 222.84 0.300 Armor 1330 4 164.65 0.300 Armor 1314 2 162.92 0.300 Pioneer 1319 3 252.22 0.300 Armor 1262 3 203.48 0.300 Armor 3111 2 184.09 0.300 Armor 4110 2 206.93 0.300 Armor 4109 2 211.50 0.300 Armor 2108 2 134.43 0.300 Armor 0700 2 221.30 0.300 1 Yield is adjusted to 15.5% moisture. 2 Plant Stand is given as plants per acre. 3 Lodging score - 1 is no lodging, 10 is completely lodged. ** Unload Auger on for half the plot 2,200 3,460 3,640 3,040 4,460 3,800 4,280 4,500 4,820 4,220 3,680 3,840 4,280 3,900 2,780 4,020 2,120 3,920 2,840 2,800 4,340 3,540 3,160 3,460 3,600 2,280 3,740 130.95 205.95 216.67 180.95 265.48 226.19 254.76 267.86 286.90 251.19 219.05 228.57 254.76 232.14 165.48 239.29 126.19 233.33 169.05 166.67 258.33 210.71 188.10 205.95 214.29 135.71 222.62 18.2 20.8 19.7 18.4 20.7 18.2 19.6 20.6 20.6 20.4 19.4 19.1 19.1 18.7 19.2 18.6 19.9 19.3 17.7 17.4 17.5 18.4 17.3 15.1 16.6 16.3 16.0 59.4 51.3 52.7 58.9 53.6 53.6 58.4 53 55.5 57.6 58.8 56.1 62.5 58.2 57.1 58 57 56.5 59.4 56.4 61.2 59 58.6 60.5 61 59.7 59 On-farm Corn Variety Demonstration based on soil type Jason Osborn Cooperators: David Wildy Soil Types: Silty Clay Purpose: At the County Extension Council meeting, the council requested more on farm variety trials and to base them on soil types (Sand Silt, Clay). Having more on-farm corn variety demonstrations based on soil types will help producers and consultants choose more adapted varieties for the farms soil type. Methods: Identifying growers and working with seed industry representatives and consultants, three corn variety demonstrations were established based on different soil types throughout the county. All field work, including planting and harvest, was performed using the producer’s equipment. All cultural practices were based on the producer’s standard production practices and were consistent for all corn varieties in the demonstration (Table 1). Inputs were based on producer and consultant recommendations and were not necessary based on University of Arkansas Extension recommendations for corn production. Results: Stand counts, vigor, lodging and disease ratings were collected for each variety in the demonstration (Table2). Yields for each corn variety were calculated from weights collected from producer’s harvested plots using yield monitor data (Table 3). Table 1. Field Production Information for Wildy Farms, 2014 County: Lat/Lon Grower: County Agent: Location of Field: Soil Type: Previous Crop: Planting Date: Row Width: Planting Population: Irrigation Type Emergence Date Herbicide: Harvest Date: Mississippi Corn 35 52' 30.70N / 90 15' 7.39W David Wildy Jason Osborn Leachville silty clay soybeans April 12, 2014 38 inch 34,000 furrow 5/5/2014 Gramoxone, Halex GT, Atrazine September 20, 2014 Table 2. Stand Count, Growth Stage, Vigor, First Tassel ,and Disease Ratings for Wildy Farms, 2014 Hybrid DK 62-08 P1257YHR P1319HR AR 1550 P1602YHR P1739YHR P2089YHR DK 66-87 RL 9795 RL 9858 RL 9633 RL 9583 XC 11840 RL 8898 RL 8812 RL 8430 Delta Grow 2888 Delta Grow 3788 Dyna Grow 5646 Dyna Grow 5291 Dyna Grow 5577 Terrell 2493 Terrell 2820 Terrell 2355 Mycogen 786 Mycogen 797 Mycogen 877 Stand Count 32 29.5 29 28.5 28.5 27 27 26.5 28 26 27 25.5 30.5 27 29 30.5 28.5 25 27.5 30.5 29 30 28.5 28.5 24 32 30.5 Growth Vigor Stage Rating Date 5-May N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 First Tassel Date 18-Jun 20-Jun 18-Jun 16-Jun 20-Jun 18-Jun 18-Jun 16-Jun 20-Jun 20-Jun 20-Jun 18-Jun 18-Jun 18-Jun 20-Jun 20-Jun 20-Jun 20-Jun 18-Jun 16-Jun 16-Jun 18-Jun 18-Jun 20-Jun 18-Jun 18-Jun 16-Jun Disease S Rust Rating Rating Date Date 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 L Rust Rating Date 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Table 3. Yield Information for Wildy Farms, 2014 Adj. 1 Yield Area Hybrid DK 62-08 251.37 0.500 P1257YHR 252.74 0.500 P1319HR 248.70 0.500 AR 1550 190.07 0.500 P1602YHR 254.66 0.500 P1739YHR 256.29 0.500 P2089YHR 261.26 0.500 DK 66-87 257.63 0.500 RL 9795 253.39 0.500 RL 9858 258.48 0.500 RL 9633 258.07 0.500 RL 9583 249.97 0.500 XC 11840 244.57 0.500 RL 8898 262.33 0.500 RL 8812 258.77 0.500 RL 8430 263.35 0.500 Delta Grow 2888 252.27 0.500 Delta Grow 3788 214.10 0.500 Dyna Grow 5646 265.70 0.500 Dyna Grow 5291 251.79 0.500 Dyna Grow 5577 238.50 0.500 Terrell 2493 260.57 0.500 Terrell 2820 253.23 0.500 Terrell 2355 274.08 0.500 Mycogen 786 219.74 0.500 Mycogen 797 246.85 0.500 Mycogen 877 242.04 0.500 1 Yield is adjusted to 15.5% moisture. 3 Lodging score - 1 is no lodging, 10 is completely lodged. Row Length 1148 feet, Plot Width 19 feet Weight 7,030 7,060 6,980 5,360 7,190 7,350 7,520 7,300 7,180 7,440 7,330 7,100 7,100 7,460 7,280 7,400 7,270 6,170 7,620 7,050 6,670 7,410 7,210 7,720 6,160 6,920 7,070 % Lodging Test Yield Moisture Score3 Weight 251.07 15.4 0 58 252.14 15.3 0 56 249.29 15.7 0 58 191.43 16.1 0 59 256.79 16.2 0 59 262.50 17.5 0 57 268.57 17.8 0 55 260.71 16.5 0 57 256.43 16.5 0 59 265.71 17.8 0 57 261.79 16.7 0 57 253.57 16.7 0 59 253.57 18.5 0 56 266.43 16.8 0 57 260.00 15.9 0 58 264.29 15.8 0 57 259.64 17.9 0 56 220.36 17.9 0 58 272.14 17.5 0 58 251.79 15.5 0 59 238.21 15.4 0 59 264.64 16.8 0 57 257.50 16.9 0 58 275.71 16.0 0 56 220.00 15.6 0 57 247.14 15.6 0 57 252.50 19.0 0 55 On-farm Soybean Variety Demonstration based on soil type Jason Osborn Cooperators: Benton Felts Soil Types: (3) Alligator Clay, Sharky clay loam,& Jeaneretta Silt Loam Purpose: At the County Extension Council meeting, the council requested more on farm variety trials and to base them on soil types (Sand Silt, Clay). With the implementation of the new Farm Bill and market changes soybeans are being planted on an array of soil types. Many of those fields have a history of root Knot Nematodes (RKN) and other problems. Having more on-farm soybean variety demonstrations based on soil types will help producers and consultants choose more adapted varieties for the farms soil type. Methods: Identifying growers and working with seed industry representatives and consultants, three soybean variety demonstrations were established based on different soil types throughout the county. These variety demonstrations were IV soybeans. All field work, including planting and harvest, was performed using the producer’s equipment. All cultural practices were based on the producer’s standard production practices and were consistent for all soybean varieties in the demonstration (Table 1). Inputs were based on producer and consultant recommendations and were not necessary based on University of Arkansas Extension recommendations for soybean production. Results: Stand counts, vigor and disease ratings were collected for each variety in the demonstration (Table 2). Yields for each soybean variety were calculated from weights collected from producer’s harvested plots using yield monitor data (Table 3). Table 1. Field Production Information for Felts Farms, 2014 County: Lat/Lon Grower: County Agent: Location of Field: Mississippi Crop: Soybean 35 32'49.79N / 90 11'31.61W Benton Felts Jason Osborn Joiner Top to Bottom Alligator Clay, Sharkey Silt Clay Loam, Jeaneretta Silt Soil Type: Loam Previous Crop: rice Planting Date: April 25, 2014 Row Width: 38 inches Planting Population: 130,000 Irrigation Type Furrow Emergence Date 5/5/2014 3 oz Fierce, Prefix + Herbicides: Roundup, Quadris Top September Harvested: 22, 2014 Table 2. Stand Count, Growth Stage, Vigor and Frogeye Ratings. Growth Stand Stage Variety Count NK 47-K5 114 NK 41-J6 109.5 NK 46-L2 90.5 Armor 46R42 100.5 Asgrow 4632 118.5 Asgrow 4934 117.5 Delta Grow 4765 120 Delta Grow 4670 124 Delta Grow 4755 120.5 P47T36R 102.5 P48T53R 105.5 P49T80R 103 P45T11R 125 Terrell 4664 105 Terrell 4994 114 Terrell 4844 97.5 Mycogen 4490 106.5 Mycogen 451 112.5 Vigor Rating - 1 Poor, 10 Excellent Frogeye rating - 0 no Disease, 10 Poor Date V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 Vigor First Rating Bloom 19May Date 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A 8 N/A Frogeye Rating 24-Jul 0 1 1 0 2.5 0 0 0 0 0 0 0 0 0 0 0 0 0 Table 3. Yield results for Felts Farms 2014. Adj. Yield1 Area Weight NK 47-K5 64.58 0.469 1,739 NK 41-J6 54.76 0.469 1,473 NK 46-L2 53.49 0.469 1,442 Armor 46R42 54.70 0.469 1,473 Asgrow 4632 61.57 0.469 1,658 Asgrow 4934 69.11 0.469 1,865 Delta Grow 4765 61.57 0.469 1,658 Delta Grow 4670 69.29 0.469 1,872 Delta Grow 4755 66.81 0.469 1,803 P47T36R 65.11 0.469 1,759 P48T53R 69.11 0.469 1,861 P49T80R 63.20 0.469 1,713 P45T11R 63.54 0.469 1,709 Terrell 4664 65.11 0.469 1,757 Terrell 4994 72.28 0.469 1,942 Terrell 4844 70.17 0.469 1,900 Mycogen 4490 66.00 0.469 1,797 Mycogen 451 87.03 0.469 2,359 1 Yield is adjusted to 13% moisture. 3 Lodging score - 1 is no lodging, 10 is completely lodged. Hybrid Note: Yield 61.81 52.36 51.26 52.36 58.93 66.29 58.93 66.54 64.09 62.52 66.15 60.89 60.75 62.45 69.03 67.53 63.87 83.85 % Moisture 9.1 9.0 9.2 9.1 9.1 9.3 9.1 9.4 9.3 9.4 9.1 9.7 9.0 9.3 8.9 9.6 10.1 9.7 Lodging Score3 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 The first thirteen varieties had excess water for 2/3 of the plot lengths early due to heavy spring rainfall Plot Length 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 1075 Plot Width 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 On-farm Soybean Variety Demonstration based on soil type Jason Osborn Cooperators: Ron Holthouse Soil Types: Tunica Silt Loam Purpose: At the County Extension Council meeting, the council requested more on farm variety trials and to base them on soil types (Sand Silt, Clay). With the implementation of the new Farm Bill and market changes soybeans are being planted on an array of soil types. Many of those fields have a history of root Knot Nematodes (RKN) and other problems. Having more on-farm soybean variety demonstrations based on soil types will help producers and consultants choose more adapted varieties for the farms soil type. Methods: Identifying growers and working with seed industry representatives and consultants, three soybean variety demonstrations were established based on different soil types throughout the county. These variety demonstrations were IV soybeans. All field work, including planting and harvest, was performed using the producer’s equipment. All cultural practices were based on the producer’s standard production practices and were consistent for all soybean varieties in the demonstration (Table 1). Inputs were based on producer and consultant recommendations and were not necessary based on the University of Arkansas recommendations for soybean production Results: Stand counts, vigor and disease ratings were collected for each variety in the demonstration (Table 2). Yields for each soybean variety were calculated from weights collected from producer’s harvested plots using yield monitor data (Table 3). Table 1. Field Production Information for Holthouse Farms, 2014 County: Mississippi Crop: 35 40'8.93 N 90 11'40.72 W Lat/Lon Grower: Ron Holthouse County Agent: Jason Osborn Location of Field: Athelstan Soil Type: Tunica Silt Clay Previous Crop: rice Planting Date: May 21, 2014 Row Width: 38 inches Planting Population: 165,000 Harvested: October 27 Irrigation Type Furrow Herbicides: Fierce, Prefix + Roundup, Quadris Top + Bifenthrin, Preaxor Soybeans Table 2. vigor and disease rating for varieties on Holthouse Farms 2014. Variety Asgrow 4034 Asgrow 4232 Asgrow 4533 Asgrow 4534 Asgrow 4632 Asgrow 4633 Pioneer 47T36 Asgrow 4835 Asgrow 4135 Asgrow 4934 AG 4632 P45T11R P46T21R P47T36R Armor 47-R13 P48T89R P48T53R P49T80R P50T64R AG 4934 SO EX 46 SO EX 48 Davis 4148 Davis C47 SO EX 53 Delta Grow 4755 Delta Grow 4765 Delta Grow 4670 Mycogen 451 Mycogen 4490 NK 47-K5 NK 41-J6 NK 46-L2 Dyna Grow 4713 Stand Count 79 141 148 136 141 114 138 138 131 120 135 115 151 150 155 148 130 141 136 138 140 110 133 127 118 145 146 139 123 136 140 140 110 155 Growth Vigor Frogeye Stage Rating Rating Date 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 6 23 7 0 Rev Exp 46 Rev 46R64 Rev 47R34 Rev Exp 47 Rev Exp 47 Rev Exp 47 Rev Exp 48 Rev 48R44 Rev Exp 48 Rev 49R94 Rev Exp 49A14 Rev Exp 49 Rev Exp 49 Rev Exp 49 Armor 43 R43 Armor AX 4430 Armor 44 R08 Armor 46 R65 Armor AX 4450 Armor 48 R40 Armor 47 R13 Armor AX 4470 Armor AX 4480 Armor 48 R66 Armor AX 4490 Armor 49 R56 Armor AX 4471 Disease Rating - 1 Resistant, 10 very susceptible Vigor Rating - 1 Poor, 10 Excellent Note: 151 139 120 138 135 129 138 158 110 131 141 136 121 145 148 157 131 149 144 137 151 146 140 147 141 152 155 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 6 23 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Heavy rains after emergence reduced stand counts on the Asgrow Varities, others showed water damage as well. Table 3. Yield results Holthouse Farms 2014. Hybrid Asgrow 4034 Asgrow 4232 Asgrow 4533 Asgrow 4534 Asgrow 4632 Asgrow 4633 Poineer 47T36 Asgrow 4835 Asgrow 4135 Asgrow 4934 AG 4632 P45T11R P46T21R Pioneer 47T36R Armor 47R13 P48T89R P48T53R P49T80R P50T64R AG 4934 SO EX 46 SO EX 48 Davis 4148 Davis C47 SO EX 53 Delta Grow 4755 Delta Grow 4765 Delta Grow 4670 Mycogen 451 Mycogen 4490 NK 47-K5 NK 41-J6 NK 46-L2 Dyna Grow 4713 Rev Exp 46 Rev 46R64 Rev 47R 34 Rev Exp 47 Adj. Yield1 57.38 51.29 52.88 63.72 59.67 60.16 67.12 62.40 61.84 63.54 57.85 59.81 60.30 62.67 64.99 60.48 60.21 59.40 57.41 54.50 56.11 55.30 52.80 52.24 57.44 Area 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 Weight 825 753 756 913 851 863 954 893 885 887 826 857 861 898 928 850 852 832 816 760 801 772 754 726 822 Yield 57.32 52.31 52.52 63.43 59.12 59.96 66.28 62.04 61.48 61.62 57.39 59.54 59.82 62.39 64.47 59.05 59.19 57.80 56.69 52.80 55.65 53.63 52.38 50.44 57.11 % Moisture 12.9 14.7 12.4 12.6 12.2 12.7 11.9 12.5 12.5 10.3 12.3 12.6 12.3 12.6 12.3 10.9 11.5 10.6 11.9 10.2 12.3 10.3 12.3 9.9 12.5 Lodging Score2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Plot Length 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 Plot Width 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 56.33 0.240 797 55.37 11.5 0 550 19 61.98 0.240 883 61.35 12.1 0 550 19 60.36 60.50 61.04 51.52 49.12 58.18 0.240 0.240 0.240 0.240 0.240 0.240 855 857 857 739 679 827 59.40 59.54 59.54 51.34 47.17 57.45 11.6 11.6 10.8 12.7 9.4 11.9 0 0 0 0 0 0 550 550 550 550 550 550 19 19 19 19 19 19 43.38 53.00 50.97 60.51 60.97 0.240 0.240 0.240 0.240 0.240 609 750 727 862 854 42.31 52.11 50.51 59.89 59.33 10.8 11.5 12.2 12.1 10.6 0 0 0 0 0 550 550 550 550 550 19 19 19 19 19 Rev Exp 47 Rev Exp 47 Rev Exp 48 Rev 48R44 Rev Exp 48 Rev 49R94 Rev Exp 49A14 Rev Exp 49 Rev Exp 49 Rev Exp 49 Armor 43R43 Armor AX 4430 Armor 44R08 Armor 46R65 Armor AX4450 Armor 48R40 Armor 47R13 Armor AX 4470 Armor AX 4480 Armor 48R66 Armor AX 4490 Armor 49R56 Armor AX 4471 1 2 59.53 56.37 53.79 60.75 57.26 52.87 0.240 0.240 0.240 0.240 0.240 0.240 849 795 762 850 813 749 58.98 55.23 52.94 59.05 56.48 52.04 12.2 11.2 11.6 10.5 11.8 11.6 0 0 0 0 0 0 550 550 550 550 550 550 19 19 19 19 19 19 57.33 57.93 53.73 54.54 59.63 51.28 56.81 44.63 62.40 62.61 53.15 58.52 50.30 61.83 58.91 58.94 58.38 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 0.240 814 817 763 758 839 712 802 633 882 888 747 829 707 868 828 834 816 56.55 56.76 53.01 52.66 58.29 49.47 55.72 43.98 61.28 61.69 51.90 57.59 49.12 60.30 57.52 57.94 56.69 11.8 11.2 11.8 9.9 11.0 9.8 11.3 11.7 11.4 11.7 10.9 11.6 10.9 10.8 10.9 11.5 10.4 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 550 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 Yield is adjusted to 13% moisture. Lodging score - 1 is no lodging, 10 is completely lodged. On-farm Soybean Variety Demonstration based on soil type Jason Osborn Cooperators: Gordon Miller Soil Types: Routon-Dundee-Conevasse Complex (sand) Purpose: At the County Extension Council meeting, the council requested more on farm variety trials and to base them on soil types (Sand Silt, Clay). With the implementation of the new Farm Bill and market changes soybeans are being planted on an array of soil types. Many of those fields have a history of root Knot Nematodes (RKN) and other problems. Having more on-farm soybean variety demonstrations based on soil types will help producers and consultants choose more adapted varieties for the farms soil type. Methods: Identifying growers and working with seed industry representatives and consultants, three soybean variety demonstrations were established based on different soil types throughout the county. These variety demonstrations were IV soybeans. All field work, including planting and harvest, was performed using the producer’s equipment. All cultural practices were based on the producer’s standard production practices and were consistent for all soybean varieties in the demonstration (Table 1). Inputs were based on producer and consultant recommendations and were not necessary based on the University of Arkansas recommendations for soybean production Results: Stand counts, vigor and disease ratings were collected for each variety in the demonstration (Table 2). Yields for each soybean variety were calculated from weights collected from producer’s harvested plots using yield monitor data (Table 3). Table 1. Field Production Information for Miller farms, 2014 County: Lat/Lon Grower: County Agent: Location of Field: Soil Type: Previous Crop: Planting Date: Row Width: Planting Population: Irrigation Type Emergence Date Herbicides: Harvest Date: Mississippi Gordon Miller Jason Osborn Leachville Routon-Dundee-Conevasse Complex Cotton April 22, 2014 38 inch 130,000 Furrow 5/5/2014 Gramoxone @ 40 oz + 3 oz Fierce / acre Dual Magnum + Roundup early post Quadris TOP 8 oz September 26, 2014 Crop: Soybeans 35 57' 0.76N / 90 17' 52.94W Applied May 6, 2014 N/A N/A Table 2. Stand count, Growth Stage, Vigor and First Bloom Ratings Variety Delta Grow 4765 Delta Grow 4770 Delta Grow 4755 Terrell 4664 Terrell 4753 Terrell 4994 Asgrow 4632 Asgrow 4934 Mycogen 451 Mycogen 452 Mycogen 449 Mycogen 479 P45T11R P47T36R P48T53R P49T80R Dyna Grow 3145 Dyna Grow 4853 NK 41-56 NK 46-L2 NK 47-K5 Armor 43R43 Armor 46R42 Armor 47R13 Stand Stand Stand Growth Vigor First Count Count Count Stage Rating Bloom Avg 90.75 93.5 112.8 111.3 103.3 107 112 101.3 117.5 89.75 98.5 96 91 107.5 89.5 105.3 95.25 88.5 108 96.5 105.3 114.5 113.8 110.3 15May V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 V-2 Date 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 Date 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 6 10 1 64.5 68.5 110.5 118.5 101 101 100 90 121 75 86 85 94 103.5 86.5 104.5 89.5 77 93 90.5 107 112 102 97.5 2 117 118.5 115 104 105.5 113 124 112.5 114 104.5 111 107 88 111.5 92.5 106 101 100 123 102.5 103.5 117 125.5 123 Vigor Rating - 1 Poor, 10 Excelent Stand Count Averages Note: On May 15 Mycogen 451 showed less sand damage than the other varities. Reasons not sure. Table 3. Yield Results Miller Farms 2014. Hybrid Adj. Yield1 Area Weight Delta Grow 4765 77.13 0.254 1,153 Delta Grow 4770 56.86 0.254 849 Delta Grow 4755 55.72 0.254 832 Terrell 4664 60.81 0.254 908 Terrell 4753 54.11 0.254 808 Terrell 4994 55.39 0.254 827 Asgrow 4632 57.06 0.254 852 Asgrow 4934 51.77 0.254 773 Mycogen 451 54.66 0.254 818 Mycogen 452 49.72 0.254 744 Mycogen 449 44.62 0.254 667 Mycogen 479 52.58 0.254 786 P45T11R 44.77 0.254 670 P47T36R 53.18 0.254 795 P48T53R 54.06 0.254 809 P49T80R 56.73 0.254 850 Dyna Grow 3145 50.53 0.254 757 Dyna Grow 4853 45.85 0.254 687 NK 41-56 55.20 0.254 827 NK 46-L2 51.73 0.254 775 NK 47-K5 52.06 0.254 780 Armor 43R43 55.93 0.254 838 Armor 46R42 50.06 0.254 750 Armor 47R13 50.26 0.254 753 1 Yield is adjusted to 13% moisture. 3 Lodging score - 1 is no lodging, 10 is completely lodged. Yield % Moisture Lodging Score3 Plot Length Plot Width 75.57 11.2 0 583 19 55.64 11.1 0 583 19 54.53 59.51 52.96 54.20 55.84 50.66 53.61 48.76 43.72 51.52 43.91 52.11 53.02 55.71 11.1 11.1 11.1 11.1 11.1 11.1 11.3 11.3 11.2 11.2 11.3 11.2 11.3 11.4 0 0 0 0 0 0 0 0 0 0 0 0 0 0 583 583 583 583 583 583 583 583 583 583 583 583 583 583 19 19 19 19 19 19 19 19 19 19 19 19 19 19 49.61 11.4 0 583 19 45.03 54.20 50.79 51.12 54.92 49.16 49.35 11.4 11.4 11.4 11.4 11.4 11.4 11.4 0 0 0 0 0 0 0 583 583 583 583 583 583 583 19 19 19 19 19 19 19 Phaucet Irrigation in Mississippi County Jason Osborn Purpose: Resource Conservation is an important part of agriculture in Mississippi County. As water table levels drop across the state and fuel prices that have doubled in the last five years, producers are searching for ways to improve efficiency and lower cost. Methods: The Mississippi County Staff answered the call by implementing and demonstrating the Phaucet Irrigation program. The program was developed by the NRCS-USDA and first used in County in 2011. The program takes well flow (GPM), poly pipe length, and row lengths of the field and calculates the correct hole size per row. Field detentions are generated by using an iPad and Google maps to plot boundaries to get the row lengths, pipe lengths and any other points needed. The program calculations give an approximate time when the field will be fully irrigated. The producer can then turn off the well at a specific time reducing irrigation cost. Results: Pumping cost average $75 an acre, and the Phaucet program reduced that cost by 18% to $61.60 an acre, which is a savings of $13.50 per acre. This equates to a fuel savings of $194,833.15 or 55,680 gallons of diesel not used in Mississippi County. The program is used on 23,682.2 acres. 33 producers use the program with 9 producers being new for 2014. Eight (8) new producers were trained in 2014 and now use the program with no further assistance from Extension Staff. This brings the county to 9 producers using the program with no further assistance from Extension Staff. PHAUCET Irrigation vs. Conventional Irrigation Jason Osborn Cooperator: Shane Adkisson Purpose: Resource Conservation is an important part of agriculture in Mississippi County. As water table levels drop across the state and fuel prices that have doubled in the last five years, producers are searching for ways to improve efficiency and lower cost. Methods: During the 2014 cotton growing season one cotton field was equipped with flow meters to show the cost savings of the PHAUCET program. The producer was trained on using the PHAUCET program and he implemented it on 1000 acres not included in the demonstration. The field was divided in roughly half. Since the acreage was not the same for each side terminating irrigation after each irrigation set was done by visual observation. One flow meter placed to show the conventional irrigation water usage using the producer selected hole size. The second flow meter was placed on the PHAUCET irrigation side to show water usage for the computer hole size section. All planting, management, and harvest methods were based on the producer’s normal practices. Results: By using the PHAUCET irrigation program and demonstrating it benefits the producer saved 19% on his irrigation cost. Pumping cost average $75 an acre, and the Phaucet program reduced that cost by 19% to $60.75 an acre, which is a savings of $14.25 per acre. This equates to a fuel savings of $14,250 or 4071 gallons of diesel not used on the producers farm. Rice fungicide Demonstration Jason Osborn Cooperators: Keith Griffin Purpose: Despite advances in rice production diseases remain as a major cause of yield loss in which profits are lowered. The use of high yielding rice cultivars with less disease resistance has increased over the past several years. Methods: To determine if there is a benefit to applying a fungicide to rice, a strip trial was conducted in the northern part of the county. The field was planted and standard cultural practices were followed. Strip treatments across the field included areas receiving an application of Quilt XL fungicide at a rate of 20 ounces per acre and areas of the field receiving no fungicide applications. The strips were harvested using the producer’s combine and yield monitors. Results: The yield differences between the treated and non-treated test showed a 7 bushel increase over the non-treated. The treated strips averaged 217 bushels (wet) per acre whereas the non-treated strips averaged 210 bushels (wet) per acre. At $6.36 per bushel the yield increase gave a return on of $44.52. Subtracting 25% for rent and the $20.00 per acre cost of fungicide and application, the return on investment was $13.39 per acre. On the 1000 acres of fungicide applied the overall benefit was $13,390.00 for the producer. 2014 On-Farm rice Variety Demonstration Jason Osborn Purpose: Mississippi County produces over 20,000 acres of rice annually. On-farm comparisons of rice varieties can help producers make a more informed decision as to which variety to pant on their farm. Methods: In response to grower’s requests in Mississippi County, effort was made to increase the number of on-farm variety tests and demonstrations. An on farm variety demonstration was established in the county. Plots were planted with the producer’s equipment and managed throughout the season based on the producer’s standard practices. All plots were harvested using the producer’s equipment and yields determined by weighs obtained from a load cell equipped grain cart. After harvest, plot was used to calculate yield per acre. Each plot’s yield was adjusted for moisture. Results: Yield differences within the two tests ranged from a low of 126 bushels to a high of 188 bushels. There was a 62 bushel difference between the lowest and highest yielding variety. Using a $4.00 price per bushel for rice, variety selection could account for as much as a $248.00 revenue difference per acre. By selecting the best varieties could increase rice revenue in Mississippi County by as much as $4,960,000. Non Clearfield Trial Planted 5-16-14 Harvested 9-20-14 Cooperator Ron Holthouse VAR/HYBRID CL 111 CL 151 CL 152 CLXP 4534 CLXL 745 CLXL 729 CLXL 756 CL 111 CL 151 CL 152 CLXP 4534 CLXL 745 CLXL 729 CLXL 756 Summary CL 111 CL 151 CL 152 CLXP 4534 CLXL 745 CLXL 729 CLXL 756 PLOT HAR. DATE 9/27/2014 9/27/2014 9/27/2014 9/27/2014 9/27/2014 9/27/2014 9/27/2014 WEIGHT 3988 3586 4142 4642 4366 4356 4210 9/27/2014 9/27/2014 9/27/2014 9/27/2014 9/27/2014 9/27/2014 9/27/2014 3667 2998 4616 4556 4620 4394 4230 Wet Yield/acre Dry Yield/acre 157.3 115.0 134 126 180.9 111.0 188.2 188.5 183.8 169.0 179.3 148.5 172.7 166.5 Dry bbl/acre 31.9 35 30.8 52.4 46.9 41.3 46.3 MOISTURE LENGTH 18.5 685 22.0 685 18.0 670 15.8 680 17.8 685 19.4 680 19.4 680 18.9 22.0 18.4 16.2 19.0 21.1 21.1 660 668 669 672 668 670 670 WIDTH 35 35 35 35 35 35 35 35 35 35 35 35 35 35 ACRES Wet Yield/acre Dry Yield/acre Wet bbl/acre 0.55 161 118 45 0.55 145 132 40 0.54 171 115 47 0.55 189 187 52 0.55 176 170 49 0.55 177 141 49 0.55 171 166 48 0.53 0.54 0.54 0.54 0.54 0.54 0.54 154 124 191 188 191 181 174 112 120 107 190 168 156 167 43 34 53 52 53 50 48 Dry bbl/acre 33 37 32 52 47 39 46 31 33 30 53 47 43 46 Surge Value Irrigation Demonstration Jason Osborn Cooperator: Ron Holthouse Purpose: Surge valves have been shown to improve irrigation efficiency and reduce total irrigation water used by as much as 25%. Current USDA-ARS and University of Arkansas estimates suggest that Arkansas irrigation must be reduced by approximately 45% to insure our ground water supply is sustainable. Demonstration: During the 2014 production season, one field was equipped with a surge valve and the producer was educated on its use. The 2014 demonstration was not designed to document water saving. The 2014 producer was shown how to set up the valve as well as how to adjust it during the season. Results: Yield was not a component in this demonstration. Water use efficiency was the focus of the surge valve demonstration. Early into the season the demonstration surge valve malfunctioned and ceased working. The producer recognizing the benefits of the valve purchased two new valves replacing the malfunctioning valve and used the second purchased valve in a different location. He noted how the field watered out sooner and with less flooding on the lower end of the fields coupled with the PHAUCET irrigation program.