Date - Linköping University

advertisement

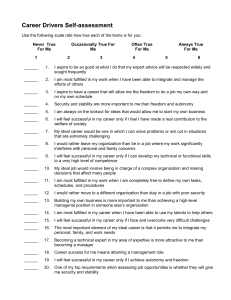

Date Ref no: June 25th 2012 IFM-2012-00305 Last day for submission of tender August 31st 2012 Validity of tender December 31st 2012 Procurement procedure Open INVITATION TO TENDER You are hereby invited to submit a tender for instrumentation for UHV Magnetron Sputtering System to the Department of Physics Chemistry and Biology (IFM) at Linköping University, Sweden according to the conditions stated in these contract documents. Ref no IFM-2012-00305 1 GENERAL INFORMATION 1.1 GENERAL INFORMATION The Nanostructured Materials research Group at the Department of Physics, Chemistry and Biology, (IFM), at Linköping University (LiU) is going to acquire a multisource UHV magnetron sputtering system equipped with an additional source port that allows for a possible fitting of a future arc evaporation source (not included in this tender). The sputtering system will be used for thin film depositions. 1.2 SCOPE IFM is a leading materials science environment in Sweden, which extensively utilizes magnetron sputter deposition and arc evaporation techniques for thin film growth and plasma characterizations. At present our laboratory features several high vacuum (HV) and ultra high Vacuum (UHV) magnetron sputter systems, a pulsed arc and a DC arc platform. To date, over 10 PhD:s with a position in our research group as well as in others are also engage in industrial DC arc evaporation technology to investigate thin films for hard and wear resistance coatings With the specified deposition system of this tender, we want to establish a deposition facility within the Nanostructures Materials group to accommodate for possibilities of combining the research made on sputtered and arc evaporated materials. Our scientific attention relates to the growth kinetics of ternary and quartenary nitrides/carbides thin films and nanolaminates sputtered from elemental and/or compound targets in fully controlled environment in terms of pressure, temperature, ion fluxes and ion energies. Also we focus on issues related to correlating the sputtering gas plasma properties to the film growth modes and properties. The system will primarily be a research tool where the possibility to control deposition fluxes, ion energy, gas flow, substrate temperature, substrate rotation, deposition geometry, and flexibility of performing in-situ film characterization e.g., plasma analysis, stress analysis etc. will be prioritized. The system will be used by PhD students, post-docs, and exam workers etc. having a professional connection to our research group and the ongoing research activities. The magnetron sputtering system specified here will enable us to grow multicomponent functional transition metal nitrides, carbides, and borides thin films as nanocomposites and nanolaminates with unique structures, phases in metastable materials, interfaces in layered structures and epitaxial systems. The possibility of adding an arc source to the system will allow for future studies on a hybrid sputter/arc evaporation growth mode of operation as well as to investigate sheer cathodic arc processes and its related plasma properties. Finally, the possibility of flux-energy tuning in angular and areal space by utilizing external ion source will provide a rout to control film morphology and generate the fundamental understandings of growth kinetics in complex materials. A detailed technical specification, stating our minimum requirements on the depostion system in order to fulfill this scope, is given in Section 3. Manufacturers are, however, encouraged to suggest additional features to better fulfill the scope of this tender. 2/27 Ref no IFM-2012-00305 CONTRACTING ENTITY Linköpings universitet Institutionen för Fysik, Kemi och Biologi (IFM) SE-581 83 Linköping Sweden 1.2.1 Contact persons Name: Maria Bruzelius E-mail: upphandling@liu.se If the tenderer wishes clarification of any aspect of the Contract documents, an enquiry must be submitted in writing to upphandling@liu.se, at such point of time that a response can be delivered six (6) days before the last day for tender submittal. Questions asked between week 27-32 will be answered w33. Enquiries will be answered and published at http://www.liu.se/upphandlingar . The tenderer is solely responsible for obtaining complete documentation. 1.2.2 Additions/amendments Complementary additions/amendments will be announced at http://www.liu.se/upphandlingar. 1.3 CONTRACT DOCUMENTS 1.3.1 List of documents The contract documents consist of the following documents and appendices: this document - administrative regulations, qualification of the tenderer and technical specifications, Appendix 1, Public contract (draft) Appendix 2, “Tender form/Declaration of truthfulness” Appendix 3, ALOS 05 E, General terms for supply of goods to the public sector The tenderer is solely responsible for obtaining complete documentation according to this list of documents. 1.4 PROCUREMENT PROCEDURE This is an open procurement procedure, in accordance with the Swedish law (SFS 2007:1091, chapter 4) of public procurements (LOU). 1.5 THE TENDER – FORMAL REQUIREMENTS 1.5.1 Validity of the tender The tender is valid provided that it is: signed by an authorized representative of the tendering company, submitted no later than August 31st 2012. The tenderer is solely responsible for the timely arrival of the tender. A tender that arrives later than stipulated, may not be considered, valid until December 31st 2012, which explicitly must be confirmed in the tender. 3/27 Ref no IFM-2012-00305 1.5.2 Formality of the tender Formal requirements for the tenders are as follows: written in the Swedish or English language, submitted in a closed envelope/package marked with Tender and reference number IFM-2012-00305. Please note that tenders submitted by delivery firms will need the outer packaging to bear the tender number also, submitted in one (1) original and two (2) complete copies, submitted electronically on a CD or USB memory stick Tenders submitted by fax or e-mail will not be accepted, since confidentiality cannot be guaranteed. 1.5.3 Submission of tender The tender can either be sent by post, by express or be delivered personally at the address stated below. Visiting and express delivery address: Linköpings Universitet Registrator, Building Origo SE-581 83 Linköping Sweden Mailing address: Linköpings Universitet Registrator SE-581 83 Linköping Sweden Office hours are Monday – Friday 09.00 – 15.00. There is a small mailbox outside the Origo building were tenders can be delivered, but it is very limited in size (27.5 cm * 3.5 cm). Keep in mind that tenders are submitted at the risk of the tenderer, and to ensure that the tender can be submitted correctly, the office hours should be taken into consideration. The contact person will send a notice of delivery upon opening of received tenders. 1.5.4 Disposition of the tender To ensure equal treatment and to facilitate assessment of tenders, the tenderer is requested to follow the order and numbering of this document. If no statement is made with respect to a requirement, the contracting entity is entitled to interpret this as the requirement is not fulfilled. 1.6 EVALUATION PROCESS Before the evaluation process starts, the formal requirements are checked in accordance with 1.5. If any of those are not fulfilled, the tender in question may not be taken into consideration. 1.6.1 Qualification of the tenderer The requirements in section 2 are to ascertain that the tenderer has the necessary technical ability and capacity to fulfil the obligations concerning this public procurement. To qualify, these requirements have to be fulfilled. 4/27 Ref no IFM-2012-00305 1.6.2 Examination The requirements indicated as “must” in section 3-7, will be checked. Only tenders that fulfill all these requirements will be evaluated further. 1.6.3 Evaluation The public contract will be awarded to the economically most advantageous tender considering the award criteria below, listed in order of priority. Criteria Criteria Weight 1. Technical performance and scientific 50 % potential of the proposed solution 2. Total price 35 % 3. Service, support and warranty 10 % 4. Delivery time 5% Criterion: 1. Technical performance The tenders will be evaluated regarding fulfillment of the “should”, “describe” and “specify”requirements, and given points in accordance with the intervals stated at each requirement in the “Technical specifications”, chapter 3. For each “should”, “describe” and “specify” request the evaluation of the tender will give a certain number of points, shown by the numbers within parentheses. Then the tenders will receive a mark between 0 and 50 for the criterion, based on the formula below: The tender´s achieved sum of points x 50 The maximum point sum Criterion: 2. Total price Tenders will be ranked with regard to the lowest total price offered. The total price criterion will be differentiated in a scale of marks where highest mark, 50, is given for the lowest total price and the remaining tenders will be given marks in relation to the lowest price as stated below: Lowest offered price The tender´s price x 50 Criterion: 3 Service, support and warranty 5/27 Ref no IFM-2012-00305 Tenders will be evaluated with regard to Service & support, as well as warranty. Points will be given in accordance with the intervals stated at each requirement in chapter 6. The tender´s achieved sum of points x 50 The maximum point sum Criterion: 4. Delivery time Tenders will be ranked with regard to the shortest delivery and installation time, conditions for installation site environment as well as warranty and service. Points will be given in accordance with the interval stated in chapter 4. The tenders will receive a mark between 0 and 50 for the criterion, based on the formula below: The tender´s achieved sum of points x 50 The maximum point sum Final result The total mark for each criterion will be weighted as stated above. The sum of the weighted marks, as in the formula below, will be the final total mark, which corresponds to the economically most advantageous tender. Ptot= Wtech x Ptech+ Wprice x Pprice+ Wservice x Pservice+ Wdelivery x Pdelivery (P=Points, W=Weight) 1.7 COMMERCIAL SECRECY In accordance with the Public Access to Information and Secrecy Act (SFS 2009:400 Offentlighets- och sekretesslag) all data pertaining to a procurement matter is subject to secrecy until an agreement has been entered into or procurement has otherwise been concluded. Any data mentioned may be subject to secrecy even after the aforementioned time. Note, however that only in exceptional cases are data and prices according to the evaluation of the tender considered to be of such nature that they may be held secret for commercial reasons. With respect to commercial secrecy for the protection of a tenderer’s data, the requirement is that the data in question refers to the tenderer’s business- or service conditions and that there is a specific reason to presume that the tenderer will suffer damages if the data is disclosed. If a tenderer considers the data submitted in connection with this procurement matter fulfils the aforementioned requirements for commercial secrecy, the tenderer must submit a request for commercial secrecy, in writing; with clarification concerning the data referred to and what damage the tenderer would suffer if the data were disclosed. The decision whether or not the data submitted by the tenderer fulfills the requirements for commercial secrecy will be made by the Contracting Entity. 6/27 Ref no IFM-2012-00305 1.8 NOTIFICATION OF DECISION Prior to signing the public contract, notification of the contracting entity´s decision in this procurement matter will be sent in writing to all tendering companies. An appeal for reconsideration of this decision may be made to Förvaltningsrätten (the Administrative Court) in Linköping. Such an appeal has to be sent within 10 days upon reception of the decision. Address: Box 406, SE-581 04 Linköping, Sweden E-mail: forvaltningsrattenilinkoping@dom.se 1.9 AGREEMENT Please note that there is no legally binding agreement until a public contract is signed by both parties. 2 QUALIFICATION OF THE TENDERER To ensure that the tenderer is suitable as a supplier for the specified procurement, the requirements below must be fulfilled. 2.1 LEGAL POSITION According to the Swedish law of public procurement (LOU) the tenderer may not: Be in bankruptcy or liquidation proceedings, under compulsory administration or subject to composition or have until further notice ceased making payments or be subject to trade prohibition. Be subject to filing for bankruptcy, compulsory liquidation, compulsory administration, composition or other similar proceedings. Have been found guilty of unprofessional conduct according to final and conclusive judgement. Have been found guilty of serious wrongdoings in professional conduct. Have failed to fulfill liabilities concerning taxes and social fees. Furthermore, checks are made that: The tenderer is registered in the companies’ register, commercial register or similar register. The tenderer is registered for reporting and payment of taxes, withheld preliminary tax and employer fees. The tenderer must confirm that there are no grounds for exclusion according to the above, through provision of the documents mentioned below. Tenderer located abroad The following national official documents must be enclosed to the tender: 1) certificate of enrolment in a professional trade register, 2) certificate that the tenderer has fulfilled obligations relating to the payment of social security contributions, 3) certificate that the tenderer has fulfilled obligations relating to the payment of taxes The information must not be older than 3 months from last day for submission of tender. 7/27 Ref no IFM-2012-00305 Swedish tenderer Registreringsbevis from Bolagsverket must be enclosed. The purchaser may check with Skatteverket and Kronofogden regarding payment of taxes and social security contributions. The information must not be older than 3 months from last day for submission of tender. All tenderer Appendix 2, “Tender form/Declaration of truthfulness” must also be signed and enclosed to the tender. 2.2 TECHNICAL ABILITY AND CAPACITY The tender must include description of at least two (2) projects, identical or similar to this one, executed during the past three (3) years, including references specified with names and telephone numbers or e-mail addresses for contact persons. 2.3 SUBCONTRACTORS If the tenderer intends to engage subcontractors to perform certain parts or services, these shall be stated, and specified in the tender. Documents, as presented in section 2.1, must be appended for each subcontractor. It is the tenderers responsibility that hired subcontractors comply with the terms and conditions in the contract. The tenderer is responsible for personnel of the subcontractor, as if it was their own staff and for any and all work performed by the subcontractor. 8/27 Ref no IFM-2012-00305 3 TECHNICAL SPECIFICATIONS INTRODUCTION The deposition system specified here will primarily be used to make novel artificially nanostructured materials in thin film form as described in the Scope (Section 1.2). In this section, a detailed technical specification, stating our minimum requirements on the depostion system in order to fulfil this scope, is given. Manufacturers are, however, encouraged to suggest additional features to better fulfil the scope. In addition to what is mentioned about the scope of the system, there are some features of the system that we consider will be of importance for realizing high quality coatings for our research. In ion-assisted magnetron sputtering the ion bombardment is used for enhancing adatom mobility on the film surface so as to offer control of film nucleation, coalescence and growth. In order to make use of the ions available in the sputtering process a substrate bias voltage will be used to attract ions from the plasma. This requires that the substrate table is electrically isolated from the rest of the chamber, and connected to an external power supply giving a negative substrate bias in the range from ground to 150 V. In order to increase the flux of ions to the substrate, the magnetic field configuration in the magnetron sources need to be unbalanced so that the magnetic field lines extends out in the chamber, guiding the plasma closer to the substrate. For ion assisted growth the ion bombardment on the film surface will be controlled either by a magnetic coil surrounding the substrate holder and/or by an external ion beam source. The idea of external ion source is to produce a low energy mono-energetic ion beam with arbitrary working nobel or reactive gas. The ion energies should be controlled from a few 10 eV up to about couple of keV. The system shall be used for sputter deposition of metals as well as reactive sputter deposition of compounds, such as nitrides, carbides, and oxides. For this purpose, a gas handling system that can control the gas flows of Ar, N2 and O2 at sputtering pressures up to 10 mTorr is needed. The dynamics of the film growth and the properties of multilayer thin films are largely influenced by the residual gas composition in the chamber. Therefore, UHV conditions (corresponding to background pressures of ~1x10-8 Torr) are required at the moment just prior to commencement of the depositions, i.e., with the sample rotating and heated to 1000 °C. In order to maintain a low deposition chamber pressure and to facilitate fast sample changes, a separately pumped loadlock system is necessary. The deposition system must feature computer-controlled deposition of thin films. This offers high degree of flexibility to custom tailor the layer/material sequence and individual layer thicknesses in multilayer thin films, and also assures reproducibility. The computer controlled parameters, for each layer in a multilayer film must be at least, deposition time, substrate bias, substrate temperature, and rotation (azimuthal spin). In addition, a computer controlled relay bank will allow for application of various external electro-magnetic stimulus (such as magnetic coils and additional biases) to the plasma/substrate, during the growth of each individual layer. Pumps, vacuum gauges and vacuum gate valves will be integrated into a computer controlled system that is used to control the vacuum system for automated, fail-safe operation. Computer 9/27 Ref no IFM-2012-00305 control will also allow for logging of growth parameters, vacuum pressures, power supply settings, etc. during growth. In the present research areas of growth of nanostructured materials, there is a continuous and increasing need of in-situ analytical tools for characterization of the growth process as well as for studies of the films growth, growth surfaces and interfaces. Therefore, the deposition system of this tender must be prepared with flanges/ports allowing for accommodation of the following insitu characterization possibilities: Reflected high energy electron diffraction (RHEED), electrostatic and magnetic probe measurements, substrate temperature measurements by optical pyrometry, multiple laser beam wafer curvature measurement, spectroscopic ellipsometry, optical emission spectrometry (OES), energy resolved mass spectrometry, and differentially pumped residual gas analysis (RGA). Please note that the instrumentation for the mentioned in-situ analytical tools are not included in this tender. To enable deposition of a wide range of functional layers, e.g., adhesion layers, protective capping layers, and/or intralayer diffusion barriers in multilayers, from materials different than those constituting the main thin film or multilayer, at least four magnetron sources, well shielded from each other to avoid any cross-talk, are required. For high precision multilayer growth, fast-acting computer controlled source shutters will be used to control the material fluxes to the substrate. The shutter mechanism must have a very high reliability to enable accurate depositions of e.g., several thousands of sub-nm layers in one film. For this application, one solution we envision is a source geometry having a common focal point of the fluxes. This geometry will also be possible to use for laterally homogenous multicomponent films, in which case the substrate will spin azimuthally at a rate between 0.1 and 60 rpm. The sputtering sources need to be designed to allow for magnetic and insulating materials to be deposited either with DC or RF power. The magnetic field configurations of the magnetrons must be user modifiable in order to tailor the plasma conditions and allow for difficult materials (i.e., magnetic and reactive materials). The same arguments also apply for substrate biasing, i.e., the biasing feed-through and/or electrical connection of biasing to the substrate holder needs to be designed to allow for a proper biasing on both conducting and insulating as-grown films either with DC or RF power. NOTE: The points given for each “should”, “describe”, and “specify” request show the maximum points attainable for that item upon evaluation of the tender. The maximum number of points may only be given to a fulfilled request, accompanied with an adequate description or specification that allows the evaluators to judge the technical solution (if applicable). Please, use this document to insert answers and comments to our questions. SPECIFICATIONS OF THE SPUTTERING SYSTEM The specification concerns a sputtering system including the following main items: 1. Deposition chamber (chamber, pumping system, pressure measurement, frame and instrumentation, electronics) 2. Deposition sources and controllers (sputter magnetron sources, power supplies, shutter assembly, gas flow management system) 3. Arc source (available ports, triggers -future addition) 10/27 Ref no IFM-2012-00305 4. Substrate holder (rotation, tilt, heater, substrate bias voltage) 5. Low energy mono-energetic plasma/ion beam source(energy, density, geometry, operational gases) 6. Load lock system (chamber, pumping system, pressure measurement, sample handling) 7. Computer control system (computer control, data logging, monitoring) 8. Options 3.1 3.1.1 A FULLY FUNCTIONING SYSTEM A fully functioning system Fulfilled Yes No All components and peripherals in terms of hardware and software, with associated licenses, necessary to achieve the level of integration and technical specifications stated in the tender, must be included in the offer. 3.2 3.2.1 Deposition chamber Deposition chamber The inner diameter of the deposition chamber should be at least 500 mm. Furthermore, the overall dimension of the deposition chamber should be such to accommodate all features of this tender as well as to allow for adequate space for service work. Please, specify. Specify: (0-5p) 3.2.2 Chamber cooling The chamber walls should be water cooled for improved background pressure during deposition. Please, specify the suggested solution. Specify: (0-5p) 3.2.3 Substrate handling Fulfilled Yes No The chamber must be capable of handling substrates with a diameter up to 60 mm substrates with a thickness up to at least 6 mm. 3.3 3.3.1 Magnetrons Magnetron source ports Fulfilled Yes No The system must be equipped with at least four (4) magnetron source ports compatible with 75-mm-diameter magnetron sources. Please, Specify. Specify: (0-5p) 3.3.2 Magnetron sources Fulfilled Yes No The system must be equipped with at least three (3) 75-mm-diameter magnetron sources compatible with DC and RF sputtering at pressures up to 10 mTorr. An additional 75 mm magnetron source of the same type for future addition should be offered separately. Specify: (0-5p) 11/27 Ref no IFM-2012-00305 3.3.3 Magnetron power supplies Fulfilled Yes No Three DC magnetron power supplies, including suitable cables and connectors, capable of delivering at least 1000 V and 750 W must be supplied. The magnetron power supplies must be interlocked with cooling water flow gauges. The power supplies should be capable of delivering more than 1 kW. Please, specify. An additional DC magnetron power supplies, including suitable cables and connectors, of the same type for future addition should be offered separately. Specify: (0-5p) It should be possible to run the power supplies in constant current, constant voltage and constant power modes, and automatic arc suppression should be included. Please, specify. Specify: (0-5p) 3.3.4 Magnetron cooling Fulfilled Yes No The cooling of magnetrons must be monitored by water flow gauges. Cooling water should not be in direct contact with magnets or the sputtering targets. Please, specify the proposed solution. Specify: (0-5p) 3.3.5 Magnetron magnetic configurations Fulfilled Yes No The magnetron sources must have adjustable magnetic configurations. It should be possible to change the magnetic configuration without breaking vacuum. Please, specify how this is done. Specify: (0-5p) 3.3.6 Sputtering configuration Fulfilled Yes No It must be possible to orient the magnetron sources continuously from an allvertical (sputter-up/down) configuration to a confocal configuration. i.e. the focal point of the magnetrons must be variable. 3.3.7 Magnetron focal points The minimum distance from the magnetron sources to the focal point should be maximum 150 mm when using 4 magnetrons and maximum 50 mm when using 2 magnetrons. Please, specify the focal points for these two cases. Specify: (0-5p) 3.3.8 Magnetron Shielding The system should include proper shielding to minimize any cross-talk between magnetrons. The shielding should be electrically isolated from ground, i.e. on a floating potential, and preferably consist of µ-metal. . Please, specify the design, and the solutions. Specify: (0-5p) 12/27 Ref no IFM-2012-00305 3.3.9 Magnetron gas supply Each magnetron should have individual gas-inlets that can be connected to the gas manifold system for reactive sputtering and low pressure operation. Please, specify the design of the gas-inlets. Specify: (0-5p) 3.3.10 Magnetron shutters Fulfilled Yes No Magnetron shutters, electrically isolated from ground, i.e., on a floating potential, must be included. The shutter actuation time must be ≤250 ms. The shutter actuation time should be ≤100 ms. It should be possible to grow sub nm thin layers with precise shutter control. Specify the proposed solution. Specify: (0-5p) The shutter actuation should be linear. Specify the proposed solution. Specify: (0-5p) The shutters should not be of a bellows sealed type. Please, specify the magnetron shutter solution. Specify: (0-5p) 3.3.11 Magnetron shutter control Fulfilled Yes No The source shutters must be possible to control by a computer. 3.3.12 Magnetron shutter insulation Fulfilled Yes No The shutters must be electrically insulated from the rest of the system. 3.3.13 Magnetron shutter design The shutter design should enable a soft action to minimize vibrations and prevent short circuits due to flakes falling upon the magnetron target surface. Please, specify the shutter design. Specify: (0-5p) 3.4 3.4.1 Arc Source Arc source port Fulfilled Yes No The system will be upgraded in futures with a cathodic arc source. For that the system must include a 6" CF port on the center of the bottom of the deposition chamber (arc source port) as well as a 3/4" CF port (trigger port), positioned 110 mm away (center-to-center) from the above arc source port. Please, specify the proposed solution. Schematics of the intended arc source port and trigger port positions. 13/27 Ref no IFM-2012-00305 Centre of chamber (bottom) 110 Arc source port 3.5 3.5.1 Trigger port Substrate Substrate azimuthal rotation Fulfilled Yes No The azimuthal rotation of the substrate must be possible to vary continuously in the range 0.1–60 rpm. It should be possible to set the sample azimuth to a specific angle. Please, specify how this is achieved. Specify: (0-5p) 3.5.2 Target to substrate distance Fulfilled Yes No The substrate height Z, and different target-to-substrate distances for both 4magnetron-configuration and 2-magnetron-configuration should be specified. Specify: (0-5p) 3.5.3 Substrate manipulator implementation The substrate manipulator azimuthal , and height Z motions should be implemented in a robust way to avoid wear and minimize the required service. Please, specify the proposed design. Specify: (0-5p) 3.5.4 DC substrate bias voltage Fulfilled Yes No It must be possible to apply a negative bias voltage of up to 1.5 kV DC during simultaneous heating and rotation of the substrate. A voltage regulated power supply delivering 0-300 V (1 A) DC must be supplied. 3.5.5 RF substrate bias voltage Fulfilled Yes No The substrate holder must be compatible with an RF bias of 100 W. 3.5.6 Substrate heater Fulfilled Yes No A substrate heater including control thermocouple, power supply, feedback control electronics, and computer control, giving 1000 °C on the surface of a Si-wafer, as measured by pyrometry, must be included. 14/27 Ref no IFM-2012-00305 3.5.7 Thermocouple type The type of thermocouple used for the substrate heater should be specified. Specify: (0-5p) 3.5.8 Substrate heater oxygen compatibility The heater should withstand oxygen to some extent. Please, specify the allowed O2 partial pressures at 600, 800 and 1000 °C. Specify: (0-5p) 3.5.9 Water cooling of substrate heater The need of water cooling of the hot parts around the substrate heater should be specified. Specify: (0-5p) 3.5.10 Substrate heating uniformity Fulfilled Yes No The temperature uniformity (at 800˚C and pressures in the range 1-10 mTorr), over the central 50 mm of a 60 mm diameter Si substrate must be better than ±25˚C, as measured by an IR pyrometer. Please, specify the temperature uniformity. Specify: (0-5p) 3.5.11 Substrate heating stability The stability of the substrate temperature at 800°C and pressures in the range 1-25 mTorr should be within ±10˚C during a 20 h period. Please, specify. Specify: (0-5p) 3.5.12 Substrate coil The chamber should be prepared with internal support for mounting a coil surrounding the substrate. Please, specify a detailed drawing of the proposed support configuration. Specify: (0-5p) 15/27 Ref no IFM-2012-00305 3.5.13 Substrate shutter Fulfilled Yes No A substrate shutter must be included. The operation should be computer controlled. Please, specify. Specify: (0-2p) 3.6 3.6.1 Low energy mono-energetic plasma/ion beam source Ion source and energy range An adequate ion source generator should be offered separately. For the stability and functionality of the ion source the co-extracted electrons should be velocity-matched to the ion component. The beam should precisely be charge compensated so that it can be readily applied to the deposition of dielectric films or dielectric substrates as well as to structures of changing conductivity. The ion source should be able to tune ion energies between 10-150 eV. Low energies will be preferred. Please, specify: (0-5p) 3.6.2 Current density The source should have tunable current density. As high as 1mA/cm2 current densities at the substrate position will be preferred. Please specify. Specify: (0-5p) 3.6.3 Milling rate The etching/milling rate should be calibrated for standard Si. Low energies will be preferred. Please, specify: (0-5p) 3.6.4 Beam spot size adjustment The source should be equipped with in-situ tilting feature which allows for source head angle adjustment without breaking vacuum. Please specify the spot size at different tilt angles and the tilt geometry. Please specify the port size and position in the chamber with respect to the substarte surface. Specify: (0-5p) 3.6.5 Gas source The source should be able to operate with inert and reactive gases e.g. Ar, O2 and N2.. Specify: (0-5p) 16/27 Ref no IFM-2012-00305 3.7 3.7.1 Chamber baking Chamber baking The chamber should be bakeable at least at 180 ˚C. It should be bakeable to higher temperatures. Please, specify. Specify: (0-5p) 3.7.2 Chamber baking equipment The baking equipment, including timer and high pressure stop should be included. 3.8 3.8.1 Chamber ports and feedthroughs Pyrometer port Fulfilled Yes No A pyrometer port (DN40CF), including a window suitable for pyrometer use, and manual shutter facing the substrate must be included. 3.8.2 Magnetron viewing windows Fulfilled Yes No At least one source viewing window with manual shutter must be included. It should be possible to see the source-surfaces through this (these) window(s). Please, specify how the sources can be viewed: (0-5p) 3.8.3 Substrate viewing windows Fulfilled Yes No At least one substrate viewing window (diameter ~100 mm) with manual shutter must be included. It should be possible to see the substrate at any of its positions through this (these) window(s). Please, specify the window layout. Specify: (0-5p) 3.8.4 Mass spectrometer port Fulfilled Yes No It must be possible to connect an existing mass-spectrometer (Hiden Analytical PSM003, DN67SF) at the substrate position. It should be possible to connect an existing mass-spectrometer (Hiden Analytical PSM003, DN67SF) to the chamber opposite to and directly facing at least one sputtering source. Please, specify the port layout. Specify: (0-5p) 3.8.5 RHEED ports The system should be prepared for measurements using an in situ RHEED (STAIB) equipment (DN40CF & DN67CE). Ample space outside the ports should be given to fit the equipment. Please, specify the offered solution. Specify: (0-5p) 17/27 Ref no IFM-2012-00305 3.8.6 Ellipsometry ports The system should be prepared for in-situ spectroscopic ellipsometry (J.A. Woolam) with an incidence angle of 65˚ to the substrate surface normal using stress-free view ports (DN401CF). Please, specify the offered solution. Specify: (0-5p) 3.8.7 Stress measurement ports The system should be prepared with two DN67CF ports, directed towards the substrate at as steep incidence angles as possible, for in-situ laser deflection stress measurements (kSAMOS). Ample space outside the ports should be given to fit the equipment. Please, specify the offered solution. Specify: (0-5p) 3.8.8 Optical emission spectroscopy port The system should be prepared for optical emission spectrometry through DN40CF ports facing the magnetron plasma regions. Please, specify the offered solution. Specify: (0-5p) 3.8.9 Electrical feedthroughs Fulfilled Yes No The system must allow for in situ electrical measurements, e.g. plasma characterization probes, using 4 electrical feed-throughs withstanding up to 1 kV and 1 A. 3.8.10 Thermocouple feedthroughs Fulfilled Yes No The system must have electrical feed-throughs allowing for at least one auxiliary internal thermocouple to be connected. 3.8.11 Service port Fulfilled Yes No Easy access to the deposition chamber through at least one service port with a diameter ≥150 mm must be possible. It should have more than one and/or a larger service port. Please, specify. Specify: (0-5p) 3.9 3.9.1 Gas handling Venting valve Fulfilled Yes No A venting valve for dry nitrogen gas must be implemented with the system. 3.9.2 Gas manifold Fulfilled Yes No A gas manifold for 4 sputter gases must be included (Ar, N2, O2 plus one spare). 18/27 Ref no IFM-2012-00305 3.9.3 Gas manifold isolation Fulfilled Yes No Metal sealed valves must be used to be able to isolate the gas manifold from the gas sources as well as the deposition chamber. 3.9.4 Mass flow controllers Fulfilled Yes No Mass flow controllers must be included for N2, O2, and Ar providing pressures of 10 mTorr, 10 mTorr, and 25 mTorr, respectively, with the proposed pumping system (see below). 3.9.5 Gas purifiers Gas purifiers producing >99.999998% purity of Ar, N2, and O2 should be included. Specify: (0-5p) 3.10 Pumping system and pressure measurement 3.10.1 Chamber base pressure Fulfilled Yes No The deposition chamber must be separately pumped and designed for an ultimate pressure of ≤1×10-9 Torr. The pressure achievable within 24 h following a 48 h bakeout at 180˚C should be as low as possible. Please, specify the obtainable pressure. Specify: (0-5p) 3.10.2 Pump down speeds The times needed to pump the deposition chamber to 1×10-6 Torr, 1×10-7 Torr, 1×10-8 Torr, and 1×10-9 Torr should be specified. Specify: (0-5p) 3.10.3 Chamber pressure during heating Fulfilled Yes No The pressure during substrate heating of a properly cleaned Si wafer to 800˚C must not exceed 5×10-8 Torr. 3.10.4 Pumping capacity Fulfilled Yes No The pumping system must be able to handle sputtering pressures between 0-25 mTorr. Please, specify how this is achieved. Specify: (0-5p) 3.10.5 Required gas flow Fulfilled Yes No The highest possible Ar flow needed at 25 mTorr must be specified. Specify: (0-5p) 19/27 Ref no IFM-2012-00305 3.10.6 Oxygen compatibility The pumping system should be capable of pumping pure O2. Please, specify the allowed pressure range. Specify: (0-5p) 3.10.7 Chamber backing pump The chamber backing pump should be of an oil-free type. Specify the proposed backing pump, including the pumping speed. Specify: (0-5p) 3.10.8 Pump connections The backing pump will be placed in the basement (approximately 2.5 m from the floor on which the chamber is placed), specify the requirements to connect the pumps to the deposition chamber. This connection should be delivered with the system. Specify: (0-5p) 3.10.9 Pumping line pressures Fulfilled Yes No It must be possible to measure the pressure in the pumping lines. 3.10.10 Valves to prevent back streaming Fulfilled Yes No Necessary valves between the deposition chamber and the pumping system, to automatically prevent back streaming at power failure or backing pump failure, should be included. Please, specify. Specify: (0-5p) 3.10.11 Chamber pressure measurement Fulfilled Yes No The deposition chamber must be equipped with necessary pressure gauges for accurately measuring the pressure in the chamber at all times, including during pumpdown. 3.10.12 Capacitance manometer Fulfilled Yes No The sputter gas pressure must be measured with a capacitance gauge. 3.11 Load-lock system 3.11.1 Load-lock system Fulfilled Yes No A complete load-lock system including substrate transfer manipulator(s), viewports, sample storage, valves, and pumping system must be included. 20/27 Ref no IFM-2012-00305 3.11.2 Load-lock baking Fulfilled Yes No All parts of the load-lock system must be bakeable up to at least 150˚C. 3.11.3 Load-lock base pressure Fulfilled Yes No The ultimate pressure in the chamber must be ≤1×10-7 Torr. 3.11.4 Load-lock pumping Fulfilled Yes No The load-lock chamber must be separately pumped. 3.11.5 Load-lock pumping control Fulfilled Yes No The pump system must include necessary valves and associated control system in order to prevent back streaming at power failure or backing pump failure. 3.11.6 Load-lock venting Fulfilled Yes No It must be possible to vent the load-lock chamber with dry N2. 3.11.7 Load-lock pumping The backing pump should be of an oil-free type. Specify the proposed backing pump, including the pumping speed. Specify: (0-5p) 3.11.8 Load-lock pumping Fulfilled Yes No Pressure measurement of the load-lock chamber, from atmospheric pressure to <1×10-7 Torr, must be possible. 3.11.9 Load-lock pump down speed The time needed to pump the load-lock chamber to 1×10-7 Torr should be less than 30 minutes. Please, specify. Specify: (0-5p) 3.11.10 Load-lock sample handling Fulfilled Yes No The load lock system must allow introduction and removal of substrates by a single person. The sample handling should be as easy and safe as possible. Please, specify the offered solution. Specify: (0-5p) 21/27 Ref no IFM-2012-00305 3.11.11 Load-lock door Access to the load-lock should be by use of a fast entry door. Please, specify the solution for this. Specify: (0-5p) 3.11.12 Load-lock sample compatibility Fulfilled Yes No The system must be able to handle substrates compatible with the deposition system manipulator. 3.11.13 In-vacuum storage positions for at least 4 substrates should be included. It should contain more than 4 positions. Please, specify the offered solution. Specify: (0-5p) 3.12 System framework 3.12.1 Sputtering system framework Fulfilled Yes No The frame for the sputtering system must be of an open type, allowing for easy access to all parts of the chamber and the load-lock. 3.12.2 Electrical installations Fulfilled Yes No Electrical installations on the frame must be placed well separated from water installations. 3.12.3 Electronic equipment rack Fulfilled Yes No Racks for all instrumentation and control electronics must be provided. 3.12.4 Sputtering system access Fulfilled Yes No If special tools are needed for opening the main flange of the chamber, they must be included. If standard tools are used, these should be supplied. Please, specify the tools supplied. Specify: (0-5p) 3.13 Electronics 3.13.1 Electronics Fulfilled Yes No All necessary electronics including cables and connectors for safe operation of the system must be supplied with the system. 3.13.2 Controllers Fulfilled Yes No Controllers to pumps, magnetrons, instrumentation for pressure gauges, etc. must be housed in racks well separated from any water installation. 22/27 Ref no IFM-2012-00305 3.14 Computer control and process monitoring 3.14.1 Computer control Fulfilled Yes No Computer control of the system must be possible. 3.14.2 Computer control interface Fulfilled Yes No The electrical interface used must be based upon a standard. Please, specify. Specify: (0-5p) 3.14.3 Computer control of major parts A computer should be able to interface with all major parts on the vacuum system (pressure gauges, valves, pumps, mass flow controllers, water circuits, power supplies, source shutters, substrate shutter and substrate heater). Please, specify which parts that are computer controlled, and in what way each part can be controlled or logged. Specify: (0-5p) 3.14.4 Data logging and monitoring It should be possible to log data in a standard format, and in real time monitor the following parameters: Magnetron powers, substrate bias voltage, substrate temperature, substrate rotation, substrate tilt, process pressure, gas flow. Specify: (0-5p) It should be possible to log the cooling water flow, background pressure, states of valves and relays (see 3.2.95 below). Please, specify which parameters that are logged. Specify: (0-5p) 3.14.5 Computer controlled processes and programs Fulfilled Yes No It must be possible to define and stack process layers to create programs. The program (stack of processes) must be a simple text file which can be exported and imported into the computer program. Please, specify how deposition programs are defined. Specify: (0-5p) 3.14.6 Modification of control software It should be possible for the user to modify the control software. Please, specify what features that can be modified and available technical support for such modifications. Specify: (0-5p) 3.14.7 Software support Fulfilled Yes No Support of the software for 3 years bug-fixing must be included. Support of the software for bug-fixing of more than 3 years should be included. Please, specify how many years that are included. Specify: (0-5p) 23/27 Ref no IFM-2012-00305 3.14.8 Relays Fulfilled Yes No A bank of 16 electrical relays that can be computer controlled to supply various voltages (up to 150 V) and currents (up to 5 A), via auxiliary power supplies, to the substrates by the deposition program, must be included. The relays should be electrically isolated from the chamber (opto-coupled). Please, specify. Specify: (0-5p) 3.15 Options The following items must be quoted separately if available, for possible purchasing depending on financial resources. 3.15.1 Oxygen compatibility The system should be fully compatible with using oxygen as a sputtering gas. Please, specify maximum partial pressures of oxygen at 400, 600 and 800 °C. Specify: (0-5p) 3.15.2 Residual gas analyser A differentially pumped, computer controlled, residual gas analyzer allowing for monitoring the gas composition up to 10 mTorr should be included. Please, specify. Specify: (0-5p) 3.16 Training requirements 3.16.1 Fulfilled Yes No An on-site introduction to the system and subsequent appropriate training, conducted at the Purchaser’s premises (installation site) after approved installation test (or at a time agreed upon by the parties) must be included in the total price for a group of 2-4 persons (including all associated costs, travel, accommodation etc). The training must cover all aspects, i.e., from general usage to detailed hardware maintenance and troubleshooting as well as all software components. The content and duration of the training must be specified. Specify: (0-3p) 24/27 Ref no IFM-2012-00305 4 DELIVERY AND INSTALLATION 4.1 Delivery time 4.1.1 Fulfilled Yes No The delivery time must be specified. Time for complete delivery must be stated in weeks. Complete delivery includes installation, set up of operation, completed acceptance tests, and scheduling of training at Linköping University. The delivery of the complete system is wanted as soon as possible. If delivery time is stated in intervals, the longest delivery time will be evaluated. Specify time for delivery (0-5 p): 4.2 4.2.1 Factory acceptance test Customer witnessed acceptance test Accepted Yes No A customer witnessed factory acceptance test must be made at the factory site before the system is shipped. The technical specifications given in the tender must be proven during this acceptance test and the approval document must be sent to the customer for approval before delivery. 4.3 Site Preparation 4.3.1 Fulfilled Yes No The proposal must state any requirements of the site to make it suitable for the delivery and installation. The supplier must within the offered price take full responsibility for the installation and start-up of the delivered equipment. LiU will assist with making the necessary extension and connections of the power, water, and gas supplies to the instruments. 4.4 Installation 4.4.1 Fulfilled Yes No Installation tests must be done on site by the Contractor/manufacturer and the Purchaser in co-operation, when the delivered equipment is installed in the laboratory. See draft of public Contract 7.2. 4.4.2 Fulfilled Yes No All equipment delivered must be designed to fit the Swedish electrical system. Connections must be for 230/220 V AC or 3 × 400/380 V AC, 50 Hz. See public contract Installation 6.2. 25/27 Ref no IFM-2012-00305 4.5 Post installation 4.5.1 Accepted Yes No The tenderer must leave the site in a clean and tidy condition. This includes the disposal of all crates, packing, packaging and waste materials. 4.6 Acceptance test and sign off 4.6.1 Accepted Yes No The system must pass final acceptance test, on-site at Linköping University, for each functionality before it is accepted by the University. The system must be at IFM’s unrestricted disposal for a test period of two (2) month. The acceptance test should be performed following passed installation test. See public contract, 7.3. 5 PRICE AND PAYMENT TERMS 5.1.1 Fulfilled Yes No The price for the offered system must be fixed and given in SEK, excluding Swedish VAT and not exceed 1,9 M SEK, excluding Swedish VAT. The tender must include the total contract price, given as DAP (INCOTERMS 2010) on-site IFM incl. freight, transport and insurance costs, installation, setting the system into operation, testing, documentation, training (including travelling costs) and warranty. 5.1.2 Accepted Yes No Proposals should state the proposed payment schedule for the contract which will be subject to final agreement with the purchaser. The schedule must include at least 20 % to be paid following approved final acceptance test. 5.1.3 Fulfilled Yes No If advance payment is requested, then security in favour of the Purchaser must be presented in the form of a bank guarantee on demand, along with the public contract. The bank guarantee must correspond to the value of the advance and be valid until approved final acceptance. Please see draft contract (10.3) – Appendix 1. 6 N/A SERVICE, SUPPORT AND WARRANTY 6.1 Service Engineers 6.1.1 Fulfilled Yes No The user must have the possibility to order service without a signed service contract for a period of at least 10 years after delivery. Specify (0 – 3p): 26/27 Ref no IFM-2012-00305 6.2 Spare parts and consumables 6.2.1 Fulfilled Yes No The Purchaser must have the possibility to purchase consumables, for a period of at least 10 years after delivery. 6.2.2 Fulfilled Yes No The Purchaser must have the possibility to purchase Spare parts, for a period of at least 10 years after delivery. 6.2.3 Fulfilled Yes No Proposals must state which parts are considered consumables, i.e, typically in need of replacement within 18 months of continuous operation. Specify : 6.3 Support 6.3.1 Fulfilled Yes No 5 years availability of support by phone or mail must be guaranteed. 6.4 Warranty period 6.4.1 Fulfilled Yes No The warranty time for the delivered system must be at least one (1) year from final acceptance of the system (pos. 9.1 in the public contract (draft)) and must be a full warranty against defects in material and workmanship. All costs in connection with guarantee actions are to be borne by the Contractor including travelling expenses (excluding consumables). Specify the offered warranty periods (0-5p): 7 7.1 GENERAL Documentation 7.1.1 Accepted Yes No Detailed documentation in English of all delivered equipment, its operation, maintenance and service must be included and supplied on delivery. 7.2 Draft contract 7.2.1 Accepted Yes No The included commercial conditions, Appendix 1, are presumed to form the basis for an agreement between the parties. Comments: 27/27