Generic laboratory safety assessment - full version

advertisement

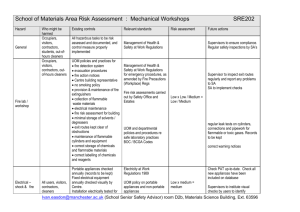

SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Fire (office) Fire lab/work Who might be harmed Occupiers, visitors, contractors, students, out-ofhours cleaners Existing controls Relevant standards Risk assessment UOM policies and practices for fire detection system evacuation procedures fire action notices Centre building representative no smoking policy provision & maintenance of fire extinguishers collection of flammable waste materials electrical maintenance fire risk assessment for building Management of Health & Safety at Work Regulations for emergency procedures Low x Low / Medium = Low / Medium Occupiers, visitors, contractors, outof-hours cleaners UOM policies and practices for fire detection system evacuation procedures fire action notices Centre building representative no smoking policy provision & maintenance of fire extinguishers collection of flammable waste materials electrical maintenance fire risk assessment for building minimal storage of solvents / degreasers exit routes kept clear of obstructions maintenance of flammable cylinders and equipment correct storage of chemicals and flammable materials Management of Health & Safety at Work Regulations for emergency procedures, as amended by Fire Precautions (Workplace) Regs Fire risk assessments carried out by Safety Office and Estates Fire risk assessments carried out by Safety Office and Estates UOM and departmental policies and procedures re safe laboratory practices BOC / BCGA Codes Future actions SA to inspect exit routes regularly and report any problems – implement checks Low x Low / Medium = Low / Medium Supervisor to inspect exit routes regularly and report any problems – implement checks regular leak tests on cylinders, connections and pipework for flammable or toxic gases. Records to be kept Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Who might be harmed Existing controls Relevant standards Risk assessment correct warning notices correct labelling of chemicals and reagents Electrical – shock & fire All users, visitors, contractors, cleaners Future actions Portable appliances checked annually (records to be kept) Fixed electrical equipment annually checked visually by Centre. Installation electrically tested for safety by Estates on 8 year basis Electricity at Work Regulations 1989 Low x medium = medium UOM policy on portable appliances and non-portable appliances Check PAT up-to-date. Check all new appliances have been included on database Supervisors to institute visual checks by users to identify damaged cables, overloaded sockets (and identify any training need) Manual handling (office) Staff lifting boxes of paper, prospectuses, and similar items Trolleys used to transport boxes from delivery point to storage cupboard / room. Manual Handling Operations Regulations 1992 Medium x low = medium Supervisor to identify all lifting tasks, and check if further use can be made of mechanical aids. Where manual lifting still required, supervisor to identify training needs (with advice from SA or Occ Health staff) and arrange for formal assessment. Manual handling (lab/workshop) All staff and students Movement of gas cylinders, work pieces, deliveries, equipment, etc Trolleys used to transport materials, including cylinders, from delivery point to lab. Manual Handling Operations Regulations 1992 Medium x low = medium Supervisor to identify all lifting tasks, and check if further use can be made of mechanical aids. Manual handling minimised by using mechanical aids Generic assessments for routine work Detailed assessments for nonroutine handling Lifting Operations and Lifting Equipment Regulations 1998 Where manual lifting still required, Supervisor to identify training needs (with advice from SA or Occ Health staff) and arrange for formal assessment. Supervisor to maintain records of all written risk assessment for manual handling tasks, including Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Who might be harmed Existing controls Relevant standards Risk assessment Future actions UOM guidance on DSE work Health & Safety (Display (formal policy in preparation) Screen Equipment) Use of HSE self-assessment Regulations 1992 form for each individual, with follow up by SSA. Provision of information on risks by distribution of advisory leaflet “Working with VDUs”. Provision of information and training on use of adjustments to workstation and need for regular breaks. Advice from SA or Occ Health on ergonomic issues. Referral of anyone complaining of symptoms associated with use of DSE to SSA or Occ Health UOM Policy on eye tests Low x low = low generic assessments for routine work, and any specific risk assessments. SA and Supervisor to review records of self- assessment, ensure records up-to-date and reflect any changes. UOM policy on reporting defects contact SA extension 63596. Supervisor to tour area regularly to check for defects to floor coverings, tripping hazards, obstructions, lighting defects, etc. Staff instructed to keep filing cabinet drawers closed when not in use. All staff instructed to remove obstructions, waste materials, trailing cables & clear up spillages promptly, and Low x medium = medium Technicians all trained (records to be kept) Display screen work (visual display units) Slips, trips and falls All staff use DSE regularly and are classed as “users”. All staff, students and visitors Workplace (Health, Safety & Welfare) Regs 1992 SA to follow up any problem areas with individuals, and consult SSA or Occ Health if solution is not obvious. Records to be kept. Supervisor to carry out (or delegate) regular inspections of office areas and keep a record. Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Who might be harmed Existing controls Relevant standards Risk assessment Future actions encouraged to report defects Hygiene & welfare All staff and visitors Toilets nearby provided with hot and cold water, soap and towels. Drinking water provided at dispenser. Shortages and defects reported to Unit TSM. Workplace (Health, Safety and Welfare) Regs 1992 Low x low = low Housekeeping & Storage All staff, students and visitors Workplace (Health, Safety and Welfare) Regs 1992 Low x Low = Low Supervisors to regularly check work areas. Environment All staff, students and visitors Workplace (Health, Safety and Welfare) Regs 1992, UOM practices on fitting out office accommodation Low x low = low Supervisor would take up complaints about provision of these basic environmental needs with Unit TSM. Falling objects Staff, students and visitors Always keep walkways free from obstruction Always clean work area after use Always keep the area safe and tidy Safely dispose of all unwanted material UOM Estates provide heating, lighting and ventilation in accordance with Workplace Regulations Space – all occupiers have sufficient space to carry out work without difficulty Light materials stored on higher level shelving; heavier items on shelves at waist height. No dangerous reagents / chemicals to be stored above shoulder height Step ladder or kick stool provided to reach upper shelves. No staff to stand on chairs. Workplace (Health, Safety & Welfare) Regs 1992 Low x low = low Senior manager to inspect occasionally to ensure storage and use of shelves as stated. Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Who might be harmed Existing controls Relevant standards Risk assessment Future actions Filing cabinets Staff Cabinets fitted with device to limit no of drawers open at any time to one only (or cabinet fitted with alternative anti-tilt device) General good office practice Low x low = low None Chemicals, dusts and biohazards All users and others entering lab. See separate detailed COSHH assessments for each chemical used / stored in Red Safety folder Minimum quantities to be stored. Containers properly labelled. Containers properly sealed. Selection and use of appropriate personal protective equipment, where other controls are not reasonably practicable Safety glasses mandatory Training, information and supervision given where required. (records kept in Red safety folder) Reagents correctly stored (i.e. Acids /solvents cabinets) If required monitoring inspections or health surveillance carried out - records to be kept Use of fume cupboards as local exhaust ventilation LEV performance monitored continuously by alarms, and examined in detail every year (records kept) COSHH regulations 2002 and Approved Codes of Practice on COSHH, carcinogens, biological agents (and forthcoming, on respiratory sensitisers) require assessment, control, maintenance of control measures, monitoring and health surveillance in certain cases, and information, instruction and training for persons exposed. Personal Protective Equipment Regulations 1992 Variable depending on substance – see COSHH assessment. Supervisor to ensure that all COSHH assessments are in order, up-to-date, and information given to those exposed. Those particularly at risk may include asthmatics if respiratory sensitisers are used. Generally, risk low as small quantities only used. Supervisor to identify any outstanding training needs. Supervisor to review personal protective equipment to ensure every item provides intended protection, is being worn correctly, and is properly maintained and stored. UOM procedures for biohazards and respiratory sensitisers. Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Power operated machinery Cutting, crushing, jabbing, Who might be harmed User (technician, or person authorised by Supervisor) Existing controls Use of more hazardous materials eliminated where possible at experimental design stage. Shelf storage has upturn or other restriction to prevent bottles falling off. Assessments explained to by Supervisor Training in safe lab techniques by Supervisor or Technician. Supervision levels specified in COSHH and risk assessments All chemicals / solutions / compounds must be properly labelled correct disposal procedures in place Sensitisers, Carcinogens and HF to be used in designated areas Users of carcinogens must be monitored registered users only and health monitoring for sensitisers registered users and vaccinations / health monitoring for bio-hazard users, where appropriate Detailed risk assessments for each machine, referring to : identification of risks maintenance procedures training for users Relevant standards Risk assessment Future actions Provision & Use of Work Equipment Regulations 1998 (PUWER) Will vary for each machine Ensure records of training, servicing and maintenance kept. Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard shearing, entanglement, etc from power driven machinery (workshop) Who might be harmed Existing controls Relevant standards Risk assessment Future actions assessment of competence of each user / authorisation guarding of dangerous parts in accordance with PUWER guard interlocks tested annually and records kept provision of stop, emergency stop and isolation controls local display of HSE poster (for abrasive wheels and woodworking equipment) removal of swarf / waste material / dust maintenance of any local exhaust ventilation detailed examination of LEV every 12-14 months (records to be kept) selection of the right equipment for the job via assessment and allocation of work hot surfaces protected by warning signs provided lighting levels around equipment and work piece adequate sufficient space to work in safety without colliding with others or with fixtures Signs and provision of relevant personal protective equipment including eye protection, aprons, gloves, etc Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Laboratory Cutting, crushing, jabbing, shearing, entanglement, etc from power driven machinery Who might be harmed User (technician, or person authorised by Supervisor) Existing controls Relevant standards Risk assessment Future actions Detailed risk assessments for each machine, referring to : identification of risks maintenance procedures training for users assessment of competence of each user / authorisation guarding of dangerous parts in accordance with PUWER guard interlocks tested every 6 months and records kept provision of stop, emergency stop and isolation controls maintenance of any local exhaust ventilation detailed examination of LEV every 12-14 months (records to be kept) selection of the right equipment for the job via assessment and Supervisor hot (or cold) surfaces protected by warning signs provided adequate lighting levels around equipment sufficient space to work in safety without colliding with others or with fixtures Signs and provision of relevant personal protective equipment including eye protection, aprons, gloves, etc Provision & Use of Work Equipment Regulations 1998 (PUWER) Will vary for each machine Records kept of all training, servicing and maintenance. Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Various from use of hand tools (Workshop) Various from use of hand tools (Stores and labs) Use of Sharp hand tools (eg needles, razor blades) Asbestos dust – from structural elements (eg ceiling / wall boards and tiles), and in equipment (gaskets, rope) Who might be harmed Staff, Students and visitors Existing controls Relevant standards Risk assessment Future actions Hand tools issued must be maintained a safe condition Good workshop practice Various None Good laboratory practice Various None Control of Asbestos at Work Regulations 1987 Low / low medium = medium Supervisor to remind technicians not to drill into or otherwise work on any structural element without consulting Estates. Regular monitoring by Workshop Supervisor (records to be kept) Staff, Students and visitors Hand tools issued must be maintained a safe condition Regular monitoring User and cleaner Technicians, and visitors to workshop Guideline for safe use and disposal ● Dispose of sharps in sharps box No new equipment, items containing asbestos to be brought into the Centre Prohibition on any work to structure without consulting Estates Area Managers UOM register of asbestos survey, and control of contractors by Estates Dept. Estates Code of Practice E10 on “Management of Asbestos” UOM Code on Asbestos in equipment, and guidance on inadvertent exposure Departmental knowledge of presence of asbestos in equipment, and compliance with UOM Code on Asbestos in Equipment Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Noise Who might be harmed Staff, Students and visitors Existing controls Relevant standards Risk assessment Future actions Noise survey carried out by SA (details to be kept) No-one exposed to over first action level of 85 dB(A) averaged over 8 hour working day. But, noise from machine X exceeds 90dB(A) so ear protection provided for users and those present when in use. Noise at Work Regulations 1989 Low x low = low Keep under review, as legislation will tighten controls in near future. Personal Protective Equipment Regulations 1992 Specify noise levels in any new equipment. Operators trained in wearing protection. Equipment maintained regularly and kept in good order. Pressure systems (compressor / air receiver) Technicians, maintenance / examination engineers, others present Pressure system selected and suitable for load / use. Pressure Systems Safety Regulations 2000 Variable depending on equipment and use Supervisor to keep all records upto-date, and under review. UOM Code of Practice on risk assessment Variable Variable Air receiver subject to examination in accordance with written scheme (arranged through UOM insurers, records to be kept) – unless exempt under the Regulations. Technicians trained in use of pressure system (records to be kept) New hazards introduced by new work Staff, Student or visitor Each piece of work subject to risk assessment by Supervisor, or by academic designing / specifying work, unless already covered by risk assessments for routine Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Who might be harmed Asphyxiation from use of liquid N2, argon, CO2, etc in enclosed space All staff and students. Those visiting lab including maintenance, contractors, fire officers, etc Lasers (fully enclosed) Anyone in room Lasers (partially enclosed) Anyone in room Cryogenics (Liquid nitrogen and solid CO2) User Out-of Hours working User Existing controls work. See separate, detailed risk assessment for each gas species, assuming loss of containment of largest container and volume of room and ventilation. Oxygen meter to be used where required. Use of modified lift to transport asphyxiants so that cylinders travel unaccompanied. Beam path shrouded & interlocked. Restricted to authorised trained laser users only. Must comply with local rules UOM policy of lone working Beam path shrouded except during certain operations. Local rules prohibiting the wearing of jewellery and other reflective surfaces. Restricted to authorised trained laser users only. Must comply with local rules UOM policy of lone working Use in well ventilated area, trained users only, correct Personal protective equipment Out-of-hours work permit required for non staff Assessment of allowable Relevant standards Risk assessment Future actions BOC / UOM Codes and advice issued to DSAs. UOM code of practice on Lasers Local rules Low UOM code of practice on Lasers Local rules. Low / medium Handling, transportation and storage of liquid nitrogen and other cryogenic material Low / Medium School safety guidelines Low Out-of –hours and Lone Out-of –hours and Lone working risk assessment for all labs Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk SOM012 SOM Laboratory General Risk assessment: Room ……. Unit …………………………….. Hazard Who might be harmed Lone Working User Hot surfaces and furnaces User X-Ray and Ionising radiation Compressed gas usage Anyone in room Anyone in room Existing controls Relevant standards practical work Pairs rule Assessment of allowable practical work working risk assessment Warning notices on very hot surfaces PPE available Local rules wearing of film badges equipment regularly inspected Training Departmental safety policy Out-of –hours and Lone working risk assessment UOM lone working policy Radiological protection guidelines Risk assessment Future actions Low Out-of –hours and Lone working risk assessment for all labs Low PPE available and hot surfaces labelled Low SOM014 – The transport and use of compressed gas cylinders. Inspection of Gauge heads – SOM018 Risk assessment completed by ………………………………………………………………………………………………………………………………………………………... Dated …………………………………………………………… Reviewed on ……………………………………………………. Reviewed on ……………………………………………………. Reviewed on ……………………………………………………. Delete rows as appropriate, modify content is if required – contact School Safety Advisor for help or advice – 63596, ivan.easdon@manchester.ac.uk