jace13480-sup-0001-DataS1

advertisement

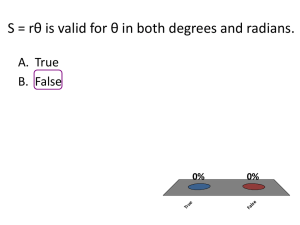

Supporting Information for the paper entitled:

“Evidence

of a fractal

percolating network during geopolymerisation”

by J. Rouyer and A. Poulesquen

I - Theoretical background

1. Oscillatory Rheology (OR)

Dynamic rheology is an approach which is widely used to measure viscoelastic

moduli. Taking a fixed pulsation 𝜔0 , a sinusoidal monochromatic strain is applied to

the sample under investigation and the resulting harmonic stress response is recorded.

The stress 𝜎 and the strain 𝛾 are expressed as follows in the linear regime:

𝛾(𝑡) = 𝛾0 sin(𝜔0 𝑡)

{

𝜎(𝑡) = 𝜎0 sin(𝜔0 𝑡 + 𝛿)

(1)

where 𝜎0 and 𝛾0 are the stress and the strain magnitude, respectively; the so-called loss

angle 𝛿 is the loss angle between the strain and stress signals. The viscoelastic moduli

𝐺′ and 𝐺′′, are classically defined by:

𝜎0

cos 𝛿

𝛾0

{

𝜎0

𝐺 ′′ (𝜔0 ) =

sin 𝛿

𝛾0

𝐺 ′ (𝜔0 ) =

(2)

Stress and strain magnitude and the loss angle can either be calculated directly from

the temporal signals or obtained by performing calculations in the angular frequency

domain. 𝜎0 and 𝛾0 are the spectral weight of the strain and stress Fourier transforms at

the given pulsation 𝜔0 . Likewise, the loss angle can be obtained by calculating the

difference between the phase angles in the strain and stress phases. Calculations in the

temporal and angular frequency domains yield strictly identical results.

When dynamic rheology methods are extended to a multi-decade angular frequency

range, it becomes a powerful mean of describing the rheological regime and the

mechanisms occurring between the components of the material under investigation. By

varying the angular frequency within the scope of the rheometer bandwidth, it is

possible to draw up the viscoelastic spectrum of the sample. Elastic versus viscous

moduli evolution can be used to describe the rheological behavior of the material using

well-known criteria such as the slope values, the parallelism or the crossover between

the curves of the moduli1; in this way, the evolution of the viscoelastic state, the state

of the gel and the relaxation times can be determined.

Successive iterations of several monochromatic angular frequencies within the useful

range can be performed during a relatively long period of time, depending on the

degree of refinement required. This duration will be at least equal to 182 minutes; for

example, in the case of four points per decade at angular frequencies ranging from 0.01

to 100 rad/s and a 10-cycle strain sine per angular frequency. In order to obtain an

accurate viscoelastic spectrum, the sample must show stable properties throughout this

time. Dedicated controlled environmental tools such as thermal devices, solvent traps

and convection ovens provide helpful means in order to maintain a consistent steady

state. However, this procedure is not at all suitable when spontaneous chemical

reactions or structural adjustment processes are liable to occur. More specifically, the

typical time taken by internal changes to occur has to be infinite in comparison with

the duration of the experiment. In the case of evolving materials, another means of

approaching this problem could consist of changing the mathematical formulation of

the harmonic strain load.

2. Time-Frequency-Resolved Rheology (TF2R)

This method, which was firstly described by Ghiringelli et al2, consists in using a

relatively short strain load, which contains an extended continuous angular frequency

range. It differs from the multi-wave technique3,4, where strain function is obtained by

summating a few monochromatic sine waves, resulting in a sparse spectrum (i.e. one

pair of parameters at each monochromatic frequency). The main advantage of the

TF2R method is that it can be used to measure a continuous spectrum in a multidecade frequency range experimentally in a relatively short time.

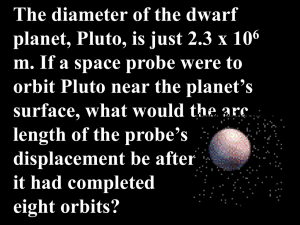

In order to illustrate how this approach is used, the frequency content of some strain

functions, which are commonly used in rheology, was studied from the signal

processing point of view. A peak holding experiment can be said to consist

theoretically of a Dirac function. By definition, the frequency content of this punctate

function is homogeneous in the Fourier domain5, as shown in Figs. 1 and 2, which

present the temporal and frequency curves, respectively. From the practical point of

view, these strains are not compatible with the experimental constraints, which involve

sampling limitations (maximum sampling frequency 𝑓𝑠 =1000 Hz) and quite-long spinup times due to the mechanical and geometrical inertia. To overcome these limitations,

a suitable square function or Gaussian function has to be chosen in order to smooth out

the beginning and the end of the rotation (as in the example presented in Fig. 1). The

theoretical advantage of applying an extremely short strain load corresponding to an

infinite frequency range amounts in practice to having a fairly narrow bandwidth. As

illustrated in Fig. 2, the square function and Gaussian function spectra give a

homogeneous bandwidth up to an angular frequency of 3 rad/s. Otherwise, higher

angular frequencies cannot be reached with these functions. In other words, the

experimental device acts like a low-pass filter when dealing with extremely short

strains.

In order to span all the frequencies covered by the rheometer bandwidth in a relatively

short time, the use of the chirp function was found to provide the best solution. Here

we focus on a four-decade bandwidth ranging from angular frequencies of 0.01 to 100

rad/s. A chirp is a pseudo-harmonic function obtained by applying a continuous

frequency sweep with time. In order to maximize the signal-to-noise ratio at the lower

frequencies, an exponential frequency sweep was used, which was expressed as

follows:

𝜔

𝛾(𝑡) = 𝛾0 sin ( 𝐾1 (𝑒 𝐾𝑡 − 1)),

with 𝐾 =

𝜔 ∈ [𝜔1 , 𝜔2 ],

𝜔

ln 2

(3)

𝜔1

𝑇1

The angular frequency sweep, which starts from 𝜔1 to 𝜔2 . 𝑇1 , corresponding to the

duration of the sweep, is classically equal to the period of the lowest angular

frequency, and hence 𝑇1 = 2𝜋 ⁄𝜔1 , where 𝐾 is the sweeping rate of the strain and 𝛾0 is

the magnitude of the strain. An example of a 𝑇1 = 628 seconds chirp is shown in Fig. 3.

The frequency distribution is continuous over the bandwidth of interest, as shown in

Fig. 2. The spectral weight of the chirp is always greater than the other loads involved.

It is worth noting that the magnitude of the strain is the same in all the temporal

functions. The energy contributed by each frequency is greater than with the other

short loads tested such as Dirac, square and Gaussian functions.

However, a typical noisy oscillation appears in the chirp spectrum at the upper limit of

the high frequencies. In order to obtain an unperturbed bandwidth, the upper boundary

is moved to 𝜔𝑢 = 400 rad/s. In the same way, the lowest angular frequency is

decreased to 𝜔𝑑 = 10-3 rad/s. The spectrum of the extended bandwidth is plotted in

Fig. 2; at the lowest frequencies involved, the spectral weights have been maximized

and the bandwidth of interest is devoid of undesirable artifacts. It can be noted that

expanding the bandwidth (keeping the same duration) firstly results in a higher

sweeping rate and secondly, in a slight overall decrease in the spectral weight.

In the general case of linear viscoelastic materials, the stress response is defined by the

convolution product (⊗) of the complex shear modulus and the strain velocity:

𝜎(𝑡) = 𝐺(𝑡) ⊗ 𝛾̇ (𝑡)

(4)

𝐺(𝑡) is the so-called relaxation function of the sample. The use of the convolution

product makes it possible to shift from the temporal domain to the Fourier domain (~),

and the previous relation becomes:

𝜎̃(𝜔) = 𝑖𝜔𝐺̃ (𝜔)𝛾̃(𝜔)

(5)

The method used to model the viscoelastic moduli, which has been presented in detail

in [23], gives the following two expressions:

𝜎̃(𝜔)

]

𝛾̃(𝜔)

𝜎̃(𝜔)

𝐺 ′′ (𝜔) = ℑ [

]

𝛾̃(𝜔)

{

𝐺 ′ (𝜔) = ℜ [

(6)

A snapshot of the viscoelastic behavior of the material under investigation can

therefore be obtained by calculating the stress-to-strain ratio in the previously defined

bounded Fourier domain.

3. Mutation number in the case of TF2R

As mentioned in previous section, the possibility to obtain meaningful rheological

measurements depends on the properties consistency of the sample during the time

required by the measuring apparatus. This experimental prerequisite makes necessary

to adapt the duration 𝑇 of the chirp to the changes in the properties of the material. The

mutation number of

6,7

is therefore introduced in order to predict the changes liable to

occur during the pseudo-harmonic loading. In the present case, both moduli will result

in the following two dimensionless numbers (𝑁𝑚𝑢 ):

𝑁 ′ 𝑚𝑢 (𝑡) =

𝑇 𝜕𝐺 ′

𝑇 𝜕𝐺′′

and 𝑁 ′′ 𝑚𝑢 (𝑡) =

′

𝐺 𝜕𝑡

𝐺′′ 𝜕𝑡

(7)

The smaller the mutation number is, the more negligible the mutations will be in the

analysis of the experimental results. Negligible non-linear effects were observed with

small mutation numbers2, and the moduli were accurately determined within the

duration 𝑇 as long as 𝑁𝑚𝑢 was smaller than 15% 6; if this finding is confirmed, the

sample can be assumed to be quasi-stable during the experiment. One rad/s

monochromatic paste setting kinetics (Fig. 1 in the main text) were therefore used to

calculate the mutation number during a period of 𝑇1 = 628 seconds. It can be seen from

′

′′

Fig. 5 that the patterns of evolution of 𝑁𝑚𝑢

and 𝑁𝑚𝑢

were very similar: only the

mutation number of the elastic modulus was therefore taken into account. The highest

value recommended – 0.15 – was greatly exceeded during the process, and the chirp

initially included in equation (3) therefore turned out to be unsuitable. In order to make

the length of the chirp comply with the recommended value, the duration 𝑇1 was

decreased whenever the mutation number was greater than 0.15. Two other chirp

durations were therefore chosen: that of the shortest chirp observed, and an

intermediate duration, which were defined as follows: 𝑇2 = 368 s and 𝑇3 = 108 s. An

experimental procedure integrating the three appropriate durations was defined at

specific times during the setting process, as shown in Fig. 5, where they form a

stepwise pattern.

With a view to investigate the effects of using shorter chirp durations in the TF2R

method, preliminary tests were conducted on PDMS samples (Annex A in the main

text). These tests led us to reduce the frequency range of the viscoelastic spectrum,

depending on the chirp duration. The spectral range adopted was therefore [0.01, 100]

rad/s in the case of 𝑇1 , [0.05, 100] rad/s in that of 𝑇2 and [0.1, 100] rad/s in that of 𝑇3 .

In addition, the possibility of obtaining reliable moduli at frequencies of less than 0.1

rad/s depends not only on having sufficiently long chirp durations, but even more on

the order of magnitude of the torque measurements2. The low sensitivity of the torque

transducer can make difficult to obtain the theoretical full-bandwidth characterization

expected.

II - Testing the TF2R method on a PDMS sample

PDMS is a silicon-based organic polymer, which was used as a viscoelastic test

material since it is non-evolving and shows excellent long term stability. The

viscoelastic spectrum was measured at angular frequencies ranging from 0.01 to 100

rad/s using oscillatory rheological methods at 25°C and a strain magnitude equal to 101%. Four points per decade were determined. Measurements were performed using

plate-plate geometry with a diameter of 2.25 cm. TF2R was then carried out with the

exponential chirp strain loading at angular frequencies ranging from 𝜔𝑙 = 0.001 rad/s

to 𝜔𝑢 = 400 rad/s and 𝛾0 = 10-1 %. The superimposed viscoelastic spectra obtained

using the TF2R method and standard dynamic rheological methods are presented in

Fig. 4 in the case of the three chirp durations (𝑇1 = 628 s, 𝑇2 = 368 s and 𝑇3 = 108 s).

The relative error 𝛿𝐺 between the standard method and the TF2R method is entered in

Table 1. The discrete points in the OR were accurately matched at angular frequencies

greater than 0.3 rad/s with a relative error of less than 4 % with all the chirp durations

tested; the crossover moduli could therefore be accurately determined.

As shown in Table 1 and Fig.6, the longer the chirp duration is, the more accurately

this technique can be expected to give fine moduli values at low frequencies. The

viscous modulus was accurately assessed in general, but a limitation emerged as

regards the description of the elastic modulus at the lower frequencies tested, when the

measurements were disturbed by strong oscillations (Fig.6 for 𝑇3 ). This undesirable

effect can be attributed to the small number of sine periods present in the lower

pulsation range: the lack of redundancy reduces the accuracy of the TF2R method at

the lower frequencies.

It was therefore decided to reduce the bandwidth, depending on the chirp durations

used; [10-2; 102] rad/s in the case of 𝑇1 , [5.10-2; 102] rad/s in that of 𝑇2 and [10-1; 102]

rad/s in that of 𝑇3 . Particular attention will therefore have to be paid to how the

spectrum is interpreted in the lower angular frequency range. These preliminary

experiments provide a useful framework for applying the TF2R method to

geopolymerization processes.

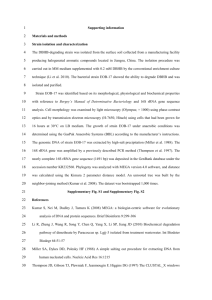

Table 1 Relative error 𝜹𝑮 between the standard method and the TF2R method with the three

chirp durations (𝑻𝟏 = 628 s, 𝑻𝟐 = 368 s and 𝑻𝟑 = 108 s) to determine the viscoelastic moduli.

Pulsation

0.01

0.03

0.13

0.32

0.80

2.00

5.02

12.62

31.70

79.62

𝛅𝑮′ for 𝑻𝟑 [%]

(-)

(-)

-13.56

2.08

1.44

0.63

3.08

3.00

2.87

2.40

𝛅𝑮′′ for 𝑻𝟑 [%]

(-)

-30.42

0.22

1.58

3.59

2.17

2.41

2.58

3.46

2.16

𝛅𝑮′ for 𝑻𝟐 [%]

(-)

30.77

2.92

0.37

3.20

1.15

2.60

2.42

2.44

1.57

𝛅𝑮′′ for 𝑻𝟐 [%]

-8.75

3.45

1.17

2.03

2.41

2.43

2.95

3.49

3.95

5.04

𝛅𝑮′ for 𝑻𝟏 [%]

-86.89

-1.33

0.16

2.44

3.23

1.36

1.93

2.18

2.47

3.09

𝛅𝑮′′ for 𝑻𝟏 [%]

-0.93

-0.69

1.18

2.05

2.57

1.89

2.90

3.16

3.82

1.42

[rad/s]

Relative errors were calculated using: 𝛿𝐺 = 1 − 𝐺𝑇𝐹2𝑅 /𝐺𝑂𝑅 – The symbol (-) denotes aberrant values in the TF2R results. Modulus

values tended to diverge at low frequencies, as shown in Fig.A.

Supporting information references

1.

Macosko CW. Linear Viscoelasticity. In: Rheology: Principles, Measurements, and

Applications. Wiley-VCH; 1994:109-126.

2.

Ghiringhelli E, Roux D, Bleses D, Galliard H, Caton F. Optimal fourier rheometry.

Rheol. Acta 2012;51(5):413-420.

3.

Ma J, Lin Y, Chen X, Zhao B, Zhang J. Flow behavior, thixotropy and dynamical

viscoelasticity of sodium alginate aqueous solutions. Food Hydrocoll. 2014;38(0):119128.

4.

Nachbaur L, Mutin JC, Nonat A, Choplin L. Dynamic mode rheology of cement and

tricalcium silicate pastes from mixing to setting. Cem. Concr. Res. 2001;31(2):183192.

5.

Smith DC. An introduction to distribution theory for signals analysis.: Part II. The

convolution. Digit. Signal Process. 2006;16(4):419-444.

6.

Winter HH, Morganelli P, Chambon F. Stoichiometry effects on rheology of model

polyurethanes at the gel point. Macromolecules 1988;21(2):532-535.

7.

Mours M, Winter HH. Time-resolved rheometry. Rheol. Acta 1994;33(5):385-397.

doi:10.1007/bf00366581.

6.

Winter HH, Morganelli P, Chambon F. Stoichiometry effects on rheology of model

polyurethanes at the gel point. Macromolecules. 1988;21(2):532-535.

7.

Mours M, Winter HH. Time-resolved rheometry. Rheol Acta. 1994;33(5):385-397.

Supporting information figures

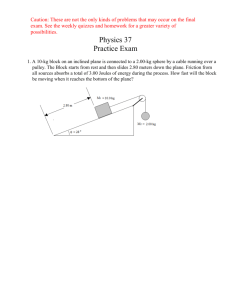

Fig. 1 Normalized graphs of the Dirac delta function (black dotted circle), the 1-second wide square

function and the 0.425-standard deviation Gaussian function.

Fig. 2 Spectral curve of the Dirac delta, the square function, the Gaussian function and the

exponential chirp functions used to illustrate the interest in the TF2R method. These curves

correspond to the module of the Fourier transform of the normalized function. This qualitative

comparison shows that the chirp gives a large spectral weight within a wide pulsation range.

Fig. 3 Representation of the exponential chirp defined with the following parameters: 𝜔1 =0.01 rad/s

and 𝜔2 =100 rad/s and 𝑇1 = 628 seconds. The corresponding spectral curve is shown in Fig. 2 (thin

continuous line).

Fig. 4 Evolution of the mutation numbers calculated with the 1-rad/s viscoelastic moduli measured

during the setting process (Fig.4) and calculated using equation (7). The values plotted correspond to

an experimental time of T = 628 second, which is the duration of the exponential chirp defined by

equation (3) and shown in Fig.3. Mutation numbers have to be less than 0.15 in order to obtain

reliable measurements within this time; this figure illustrates the situation where the experimental

duration of the chirp had to be decreased.

Fig. 5 Analysis of the mutation number as a function of the moduli led to adapting the chirp

duration to obtain a mutation number smaller than 0.15. First the shorter duration was found

to be equal to 108 seconds (a median-long duration). The chirp duration was then adapted to

the threshold meaningful mutation number, which was set at 15%. This fig. gives the chirp

durations chosen during the geopolymerization process, depending on the increase in the

moduli.

Fig. 6 Comparison between the standard OR and the TF2R methods. A 108 (a), 368 (b) and 628

seconds (c) chirp duration was employed to measure the continuous viscoelastic spectra by TF2R

(plain and dashed lines). The OR determines moduli iteratively at discrete pulsation (squares and

circles) and takes about 182 minutes to obtain 4 points per decade within a four decade pulsation

range.