Mixing_of_Solids_and_case_of_V-Blender

advertisement

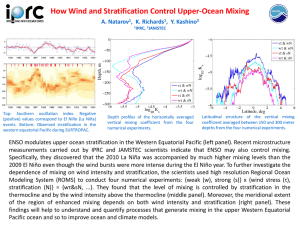

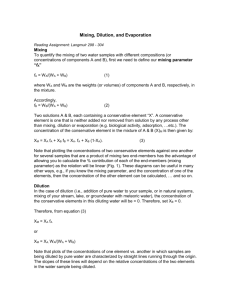

1 Mixing of Solids and case of V-Blender Kishuk Goyal1, Anshuman Kumar2, Gaurav Singh3 1 Senior undergraduate, Chemical engineering Department, IIT Delhi, goyal95.k@gmail.com 2 Senior undergraduate, Chemical engineering department, IIT Delhi, anshuman053@gmail.com 3 Senior undergraduate, Chemical engineering department, IIT Delhi, grvsingh64@gmail.com 1. Abstract The mixing of granular systems such as powders is a fundamental operation, important for a range of industries including pharmaceuticals, plastics, house-hold products (such as detergents) and food processing. The quality of products depends on the degree of mixing of their constituent materials. The desired mixing should be achieved throughout the batch if the mixing is batch operation or it should be same throughout the time if the operation is continuous. Degree of mixing is obtained from the various samples taken from different places at different times of the mixer. The locations from which the samples are to be taken depends on the mixer geometry. The samples taken are analysed for the uniformity individually and then using the methods of statistics the representation of the whole batch is created. Individual samples are taken from the mixer using mostly the thief sampling method and then methods like image analysis, FBRM can tell the distribution of particles in the sample. The next task is to find the mixing uniformity based on the samples obtained. For that task in the literature various mixing indices are developed, and there is no universal mixing index which is suggested so the user should be able to find the one depending on his requirements. Mixing indices mostly use variance of the samples for their calculation. Variance is calculated based on the assumption that the distribution obtained is normal distribution. Keyword: V-Blender, Mixing, Froude. 2. Introduction However, the homogeneity of the final mixture relies on the nature of the mixing procedure used, type of the mixture as well as handling after mixing. Ideally speaking we want to achieve the random mixing step but any systematic mixing process is incapable of creating a completely random mixture since the likelihood of it re-ordering the particles increases with the degree of mixing. Mixing time is also very important variable as both mixing and demixing happen simultaneously initially with different rates but after some time an equilibrium point is reached where the mixing and de-mixing mechanisms are in balance and there is a natural cessation of mixing. So if we keep running the device demixing may dominate after some time and it will deteriorate the quality of the mixture. For different mixing devices, the equilibrium states will depend on the design of the device as well as the conditions at which the operations are taking place. In many cases it may not be possible to reach the desired mixing uniformity fundamentally as the process involves complex flow regions inside the mixer having significant different in properties, and there may be segregation due to some pattern formation or self-organisation due to the particle 2 shape ,size and density. To study the flows in the granular devices is very limited as there is no technology to visualize the mixing in the mixer itself especially for the large ones so the only option available is to remove the samples and analyse which has many limitations. But recent advances in discrete element modelling (DEM) have resulted in this method becoming a useful simulation tool that can provide detailed experimental information which cannot be observed during experiments. The flow properties of the powders depend on the flow properties of the mixture which can be obtained from the component properties. The selection of the mixer as well as the type of dominant mixing mechanism is decided by the properties of the mixture. Here we are basically focussing on the V-blender which is found to be more efficient in the pharmaceutical mixing compared to the other mixers. The flow regimes inside the mixer will be discussed along with the experimental observations such as the effect on the uniformity due to variables such as mixture flow properties, speed of mixing, size of mixer, loading pattern etc. Scale-up of the V-blender is discussed based on the experimental scale–up observations and some empirical relations which are used in the industry. A procedure is developed which is helpful in designing the experiments so that scale up can be done considering the critical variables of importance. 3. Understanding the Mixing The phenomenon of mixing is not completely understood but a lot of research has been done about the mechanisms involved in the mixing. There are a lot of devices available industrially and they can be grouped based on the mixing mechanism which is predominant inside them. Since mixing strongly depends on the properties of the materials to be mixed such as their shape, size and density there is a need to understand how these properties affect the flowability and thus the mixing. The problems associated with the mixing such as agglomeration and segregation also need to be looked upon and steps should be taken to avoid such problems. 2.1 Mixing mechanisms There are three main type of mixing mechanisms which regulate the mixing in devices. Though there is no such device which has only one type of mixing, most of them have either one or two of these three as the dominating mechanism which decide the rate and quality of the mixing. The three mechanisms of mixing are 2.1.1 Convection This mechanism arises due to the mixing of materials inside the mixer as large clumps. The motion of the vessel or the baffles inside the vessel force the material to move in form of clumps. In simple words baffles pick one large chunk of the materials from one place and put it at another place in the mixer thus leading to convection. The homogeneity at the macroscopic level is achieved due to the convective mixing. Surface area between the components is improved due to this mechanism. This mechanism is very fast compared to other mechanisms of mixing especially the diffusive mixing. 2.1.2 Diffusion This mechanism is responsible for the mixing at the length scale of the particle in the mixer. This should not be confused with the molecular diffusion in the fluids which has well defined equations. Rather it arises when the dense packed material is distributed over the surface by the mixer action and thus developing the new set of particleparticle contact. This method helps to achieve uniformity at the particle size scale so final mixing quality depends a lot on this mechanism. The mechanism is very slow and takes orders of magnitude more time than the convective mixing and so it is the rate determining mechanism of the mixing process. 2.1.3 Shear This mechanism is related to the convection, as clumps of the powder move in convection the velocity gradient is created between the region of two clumps. This region is called slip zone and here the velocity gradient is very high. In this region due to high shear strain the breaking of agglomerates take place and also the area of contact of two group of particles are extended here. This mechanism helps in mixing when the mixture is showing cohesive properties. But, phenomenon like percolation which cause demixing especially in non-cohesive mixtures take place in the slip zone. 3 2.2 Important component properties The selection of the mixer as well as mixing quality that can be achieved is mostly determined by the properties of the individual components such as shape, size, density and flowing properties. In this section the effect of the shape and cohesiveness is discussed, the effect due to density and the size will be covered in the section of problems related to the mixing and cohesion section. 2.2.1 Particle shape The shape of the particle is very important in particle industries as the properties of the final product depends critically on the shape of the components. For e.g. in pharmaceutical industry the shape of the API (active pharmaceutical ingredient) governs the rate of dissolving the drug in the body and so is of paramount importance. Shape of the particle should not change while mixing. The shape vary dramatically with the feed and to account for that in modelling is daunting task and we have not been able to completely take into account the effect of shape on mixing for different shapes. Spherical particles have low resistance to shear compared to more angular or blocky particles. So where the flow regime and mixing patterns for realistic particle assemblies depart significantly from that of spheres the prediction of the mixing rates correctly is a major problem. For characterising the effects of shape on particulate flows and microstructures angularity and aspect ratio are important parameters. Angularity leads to tighter packing as neighbours lose their ability to freely roll over each other. Elongated particles which have high aspect ratio lead to complicated interlocking of the microstructure and restrict the flow and also generate complex force network within the system. In order to mimic the flow behaviour of particles of more complex shapes rolling and sliding friction coefficients are used, but this is unable to account for the many important aspects such as the packing fraction and the extent of dilation of granular bed in slip zones. Shape plays an important role in determining packing efficiency, strength of a microstructure, flowability and segregation. 2.2.2 Cohesivity There are two types of powder behaviour, cohesionless and cohesive. There are different set of problems faced while mixing these different type of powders. To make the matter more complicated the given powder can behave as cohesive at some conditions and cohesionless at some other conditions. This can arise either from a spatial variation of the velocity field in a mixer or from the system containing materials of a range of sizes, densities or surface properties. Two types of forces compete to decide which type of behaviour a powder is going to show the forces between the particles and the force of the gravity. If the force of gravity dominates it shows cohesionless behaviour and if the interparticle forces dominate cohesive behaviour is seen. 2.2.2.1 Cohesionless materials These are the materials for which the force of gravity dominates the interparticle forces and these have the tendency to flow freely. The biggest problem in mixing such type of powders is that of the segregation. It has been seen that large difference in size causes materials to segregate and for the rotating drums the size ratio above 1.2 tend to segregate. Since segregation is main problem for such kind of materials so even after the mixing is complete special care should be taken so that segregation is avoided during downstream processing and transport. For cohesionless materials important mixing mechanisms are convective and diffusive, shear mixing which is mainly used for breaking of agglomerates is largely unimportant for the mixing of such powders. So for the selection of the mixer for such powders one with the dominant mixing mechanism as convective should be chosen so that the rate of mixing is fast. 2.2.2.2 Cohesive materials These are the materials in which the inter-particle forces dominate the force of the gravity and hence the flow inside the mixers require more amount of the force. These kind of the powders agglomerate while mixing and the size of agglomerate depends on the relative strength of the interparticle forces over gravity. Shear mixing is very important for such mixtures to break the agglomerates and the selection of the mixer should be accordingly. Mostly the mixers for cohesive materials have baffles or rods inside which provide the impact to break the agglomerates. These are the basic forces responsible for cohesion: 4 • Surface tension – Surface tension is significant when there is solid liquid interface considering the solid-solid mixing it is largely unimportant. But even in solid-solid mixing additives are added and then surface tension should be taken into account. • Electrostatic forces – These forces arise when solids are in rubbing contact of each other. They charge each other via movement of electrons from one species to other and a potential difference is developed between them. But these forces are magnitudes of order smaller than the der Walls forces. • Van der Waals forces - The van der Waals forces are related to electromagnetic fluctuation phenomena in solids. These forces originate when the random movement of electrons on a particle's surface momentarily concentrate to form dipoles which, in turn, are attracted to other dipoles nearby. The van der Waals forces are only noticeable when the particles can come sufficiently close together, at separation distances of the order of the size of a molecule, 0.2 to 1 nm. Whilst the gravitational force is proportional to the cube of the particle diameter, the van der Waals force is proportional to the diameter and, therefore, the magnitude of the attractive van der Waals force becomes negligible compared with that of the body force when the particle size exceeds a certain value (of the order of a few microns) . The most important parameter determining the van der Waals attraction force is the interparticle separation distance which is affected by the surface roughness and the presence of spacers (small molecules or fines adsorbed) on the particle surface. 2.3 Mixing devices There are mainly two categories of the mixing devices. First one is rotating shell devices in which the shell rotates and the material slopes inside the mixer, and mixes due to action of gravity. Diffusion and the shear are the main mixing mechanisms here. These are available in various geometries, a few examples of such devices are given in Table 1(S. No. 1-4). Table 1 Different types of mixers and their description S. No. 1. 2. 3. 4. 5. 6. 7. Name of the mixer Drum Mixer Octagonal Double cone V blender Centrifugal Mixer Ribbon mixer Orbiting Screw mixer Mixing Mechanism Materials Suited Comments Diffusion Free flowing Cleaning is easy. Slightly cohesive Suited for continuous operation. Free flowing Ensures good quality of mixture. Slightly cohesive Very less RPM is required. Shear and Diffusion Free flowing Easy to clean. Slightly cohesive Can be sealed during operation. Shear and Diffusion Free flowing Better performance than the other rotating shell devices. Shear and convection Cohesive Shear and convection Slightly cohesive or Cohesive Less RPM and less time required. Convection and diffusion Free flowing Confined to batch operation. Diffusion Slightly cohesive Removes agglomerates. Hard to clean. Wide range of materials handling. Reduces segregation. 5 The second kind of the mixers are in which the shell is kept stationary and inside there are blades and impellers which rotate. These are suitable for the mixing of cohesive powders as the main mixing mechanism is the shear and convection. These are highly effective in breaking of the agglomerates. Some examples of such type of mixers are in Table 1(S. No. 5-7). For any mixing operation selection of the blender is done considering that, ideally the mixer should be able to achieve the acceptable blend uniformity in reasonable time and without damaging the product. But there are many other factors which should be kept in mind in selection, design and operation of the equipment. In general mixer should be dust tight, require low energy and can be cleaned and discharged easily. The surface of the mixer should be such that it does not react with the components of the mixture and it should not resist the flow of the components to be mixed. It should be designed such that taking samples is easy for the determination of the quality of the mixture and also the samples taken should be sufficient enough to represent the whole batch. While operating the mixer if one component is in very small amount which is the case of APIs in pharmaceutical industry first a preblend of higher percentage should be made and it should be mixed with main components in next step to get the desired percentage. Segregating mixtures should be dealt with addition of some appropriate liquid to increase the cohesiveness. Particle damage, reduction of size should be monitored during the operation along with the conditions of blender such as temperature and pressure. The way mixer is started and stopped also affects the product quality and when the material is discharged care should be taken so that it does not segregate. 2.4 Mixing problems There are two important problems which should be addressed while doing the mixing: Segregation and Agglomeration, while segregation occur as the mixture is more flowing in nature, the existence of the agglomeration is due to cohesive nature of the mixture. As the presence of these can heavily deteriorate the quality so there is a need to control these via controlling the process conditions and variables. 2.4.1 Segregation In the process where the particles move relative to each other the difference in size, shape or density leads to the separation of bulk mass into different regions each region containing one of the components in amounts more than it’s overall percentage. It has been seen that particle size is most dominating factors of all which causes segregation. Segregation is seen in case of free flowing mixtures but sometimes the agglomerates in cohesive powders also tend to segregate. There are some mechanisms of segregation 2.4.1.1 Inter particle Percolation In the convective movement of chunks while mixing there is a small thin layer of particles (usually 10 particle diameter in thickness) between the two blocks which are moving with different velocity, the region is called the failure zone. The failure zone has more mobility due to velocity gradient and particles move in different directions based on difference in size, shape, density etc. but the particle size is seen to be most deterministic factor. In failure zone smaller particles move downwards and larger ones move in the direction of the increasing strain rate. 2.4.1.2 Trajectory segregation This mechanism can cause segregation when the particle travel through the air or when they are freely falling and simultaneously have horizontal component of velocity. When stokes law is applied the particle is seen to travel the horizontal distance proportional to the square of the diameter. So the particles with more diameter travel more and segregation occurs. 2.4.1.3 Free Surface segregation This is related to interparticle percolation and trajectory segregation. To understand this phenomenon consider a mixture having one component in small amount and the mixture is poured to form a heap. It is found that the minor component in the heap is either close to the top or towards the bottom of the slope (Drahun & Bridgwater, 1983). If the minor component is smaller than the bulk, the minor component is found near the top of the heap. This arises from the percolation of small particles through the deforming array of larger ones. If the minor component is 6 larger than the bulk, then it is found at the bottom of the heap. Here the large particles float on the surface of the small ones to the bottom of the heap. If the velocity of the particles onto the top of the heap is increased, then a smaller minor component is found near the bottom of the heap and a larger minor component at the top. The greater momentum of the individual particles when impacting on the surface is the important factor. Smaller particles are reflected off large ones into the space above the free surface and bounce over the free surface to the bottom, with surface avalanches being avoided. In the case of the minor component being large, particles then get buried in the heap and avoid the action of the surface avalanches. There is a significant effect of particle density. More dense particles of the same size as the bulk are found at the top of the heap and less dense ones at the bottom. 2.4.1.4 Elutriation segregation This happens when one of the components has size less than 50 micrometre. While mixing when the air passes through the bed of particles it may be possible that the velocity of air is more than the terminal velocity of smaller particle and thus they form a suspension in the air and remain there hampering the mixing. 2.4.2 Agglomeration The problem of agglomeration occurs in the cohesive powders. Here the interparticle forces are strong enough so that particles bond with each other and form large chunk called agglomerates. The chunk size is seen to be directly proportional to the surface tension and inversely proportional to the product of density and acceleration due to gravity. 4. Sampling and Assessment There are generally two types of methods for studying the quality of mixing first one is to take out samples from different locations at different times to analyse it and the second is in which material remains in the container and using some techniques it is analysed. In the first type sometimes probes can be inserted rather than taking out the samples, use of the optic fibre probes hold the potential to do that but due to several issues their use is not widespread(Kaye, Brushenko, Ohlhaber, & Pontarelli, 1969). The second type of study mainly relies on the free surface or transparent surface photographs. These methods cannot be used for 3-D study of mixing. But now with the help of DEM (discrete elemental method) it is now possible to tack the motion of each and every particle, but this method is computation expensive and so is not used for the large systems. The two methods of thief sampling and the DEM are discussed below3.1 Thief Sampling and Statistical analysis Earlier this method mostly used the scoops to take out the samples but Keye developed a more consistent equipment in 1997which reduced the errors in the sampling. It consists of a first cylindrical tube with a conical base, there being a number of holes drilled in a line along the wall in the axial direction. There is a second cylindrical tube of external diameter slightly smaller than the inner diameter of the first tube. It is split apart internally into a number of axial compartments, with a handle on the end. There are holes, drilled in the wall of this inner cylinder, these having the same spacing as those in the first tube. To carry out sampling, the smaller tube is inserted into the larger with the three sets of holes out of alignment. The device is inserted into the mixture with the holes of the outer tube on the top. The inner tube is then rotated so the two sets of holes are aligned. Material falls into each of the three compartments. The inner tube is then rotated again to take the holes out of alignment and the whole assembly is withdrawn. The next task is to characterize the samples taken, for that each sample is first analysed for it’s components and then spread in the compositing is determined by using the variance. The formulae for the variance are for the two components system but in case of the multicomponent mixtures that can be applied by taking compound of interest as the one component and rest as the other. There are two reference states of variance which correspond to the completely unmixed state and completely mixed state, these can be calculated by the equation (1) and (2) respectively 7 σo2 = x(1−x) (1) σr2 = x(1−x)/N (2) Where x is the fraction of component in the original mixture σo2 is the variance of unmixed state and σr2 is the variance of completely mixed random state. Now for the samples taken at the intermediate time variance can be calculated using the equation 1 𝑛 𝜎 2 = (𝑛−1) ∑𝑙̇=1(𝑦ⅈ − 𝑦)2 (3) Where 𝜎 2 is the variance of the intemediate samples, n is the number of the sample taken and y i is the mass concentration of main component in sample i.Once we know all the variances the task remaining is to find the mixing uniformity and for that a lot of mixing indices are described in the literature. There is no such best index and selection of index depends on the user and the conditions of the operation and product specification. The method in which the thief sample is used to take out the material is used widely in most of the places. But there are a number of issues related to using a sample probe – it is slow and has to be followed by some measurement techniques, insertion of the probe causes the material to displace thus changing the composition and microstructure near the probe. Also many samples are needed to give a sufficiently reliable estimate of σ 2. The taking and analysis of these samples in itself can prove to be very tedious. Also the movement of components in the thief is with different velocities and causes seperation. The force necessary to the probe in the bulk can be appreciable which may lead to comapction and partcle attrition. Also it violates two golden rules of sampling i.e. to sample a moving powder and sampling the entire stream rather than sampling the parts of stream. Considering the problems related to thief sampling and the inherent error it adds to the results there is need of more precise technique to analyze the powders. 3.2 Discrete Element Modelling (DEM) The challenges associated with the development of computational models for industrial blenders is their large size and the particles inside them can be as small as few microns and can have very complex shapes. To accomodate for complex shapes and such size ranges is not feasible. In DEM approach, particles are permitted to suffer minute deformations, and these small deformations are used to calculate elastic, plastic and frictional forces between particles. The motion of particles is described by the Newton’s laws of motion. This model can handle multiple contacts which are of importance in modelling quasi-static systems. Newton’s laws are applied to describe both the velocity and rotation of each particle, which are mostly taken to be spherical, the equations are solved for velocities and trajectories. The models describing the inter-particle forces are generally linear ones. When considering the torque balances on a particle, it is argued that rolling friction is also needed. Rolling friction accounts for the energy dissipation associated with rolling of particles on each other or on other contact surfaces. Cohesive forces due to van der Waals’ forces, electrostatic effects, steric forces and capillary action can also be included. The method can be used for particles of shapes other than spheres but this makes calculations much slower. Each particle in the flow is tracked and all collisions between particles and between particles and boundaries are modelled. The particles are allowed to overlap and the extent of overlap is used in conjunction with a contact force law to give instantaneous forces from knowledge of the current positions, orientations, velocities and spins of the particles. Here we used the simplest of the force laws which is the linear spring-dashpot model. A search grid is maintained which keeps list for all neighbouring interactions between particle-partile and particle-wall which can result in collision in a given time period. The forces are calculated using the contact force model and then summed over to form the net force and net torque which when put in the Newton’s laws of motion gives the position,speed and orientation of particles. 5. V-Blender Case Study 8 The V-Blender (also known as a twin shell blender) is one of the most commonly used tumbling blenders. It has been seen that it’s performance is better than a lot of blenders like drum blender, bin blender etc. It offers short blending time and efficient blending. The mechanism of mixing in the V-blender is seen to be convection and diffusion. Diffusion leads to the uniformity at the length scale of the blender. Therefore when precise blend uniformity is reqiuired V-Blenders are used. They also show excellent mixing when one of the components is in very small amount like API in pharmaceutical industry. A V-blender uses a V shaped mixing vessel for batch mixing. Each arm of the V has a cylindrical cross-sectional shape and there is typically an access port at the bottom of the V for filling and discharge of the particulates. This is sealed during mixing operation. The blender has a horizontal shaft attached to the V and the blender rotates around this shaft. The configuration is symmetric to reflection in a vertical plane through the V. The advantages of using the V-Blender is that the particle size reduction and attrition is minimized and loading and discharge of material is easy. Cleaning of the Blender is also easy and there are no chances of product contamination. Next section talks about the flow pattern inside the blender and the effect of various paramters like rotation rate, vessel size, time of operation, vessel fill level on the performance of blender. Different mixtures have different flowing properties which lies between free flowing and cohesive so the next section is divided into two parts and mixing of both type of powders are discussed seperately. 4.1 Free flowing mixtures in V-Blender In this section various experimental results are discussed along with the DEM of blender for free flowing powders. 4.1.1 DEM of free flowing powder in V-Blender In the DEM analysis of the scaling of the blender the data was analysed by ##for the blenders of the volume 1.8 litre to the volume 210 litre. DEM modelling of industrial scale mixers for coarser materials (mm scale) is now feasible, but mixing of finer powders (10μm to 1 mm) is Table 1 Table 2 mixing rate with scale up still not feasible at the industrial scale. The experiment was performed for the free flowing particels. The particles used had a mean size of 2.75 mm with a range of 0.25 mm above or below this size. The same particle sizes are used in all the different scale mixers. The solid packing fraction was 0.5564. The particle density was 1500 kg/m3 and the blenders were filled to 50.1% by volume. The physical length of blender and the number of particles in the model for each blender scale are given in Table 1. As the blender rotates slowly around its horizontal axis the free surface changes its angle until it reaches the angle of failure of the material which then avalanches down the slope settling at the angle of repose. Each increment of rotation causes some particles to exceed the angle of failure leading to continuous avalanching from across the high side of the blender. In the first half revolution the avalanching flow is directed down into the angled cylindrical sections of the blender shell. In the second half of the revolution particles flow down the slope in the direction of rotation but also converge back towards the middle of the blender as the particles pack into the apex region. It was seen that both type of mixing mechanisms i.e. convective and diffusive mixing were present and the 9 mixing in each arm was very fast compared to the cross arm mixing suggesting that the flow pattern developed was symmetrical in nature. Also the mixing rate initially was high which keep on decreasing with time asymptotically which suggests that to acheive complete uniformity may take very long time. From the mixing rates summarised in Table 2 it is clear that the rate of mixing does change with increasing scale when the speed of the mixer was scaled to maintain the same Froude number. For this V-blender, scaling up the volume by 31.6 times has led to a halving of the mixing rate when measured in revolutions. 4.1.2 Flow pattern and Circulation Intensity ## performed Positron Emission Particle Tracking (PEPT) study for mixing of 3 mm large cohesionless particles in V-blender with the operating conditions summerized in table 3. The motion showed some trends of the rotating drums , it has a convective component driven by vessel rotatin and a diffusive component driven by gravity. The circulation in the left arm was in the anti-clockwise direction when the fill percentage is relatively low (20% and 28%), whereas the direction of the flow reverses at a greater fill (46%). It is also apparent that at the intermediate fill of 34% fill, the motion is much less ordered. Although mixing within a single arm is considered to be very fast compared to mass transfer between arms, the convective mixing mechanism can be Table 3 suppressed at intermediate fills and hence reduces the quality of mixing within the arms. The change of the direction of the flow due to the free volume available in the arms. The rotation of the vessel can be divided into two steps: the division step and the combination step. During the division step, the surface particles move towards the two ends of the arms under the influence of gravity. When the fill level is relatively low, the trajectories of the particles in the surface flow region are closer to the plane of symmetry of the V-mixer than those in the high fill level condition. During the combination step, the surface particles move towards the joint of the V-mixer. The trajectories of the particles in the surface flow region are closer to the bottom of the arm when the fill level is relatively low. It is therefore the surface flow regime which determines the direction of the circulation. The flow in the arm reverses as the fill level increases and the occurrence of the flow reversal is system-dependent. Circulation intensity is the term which is calculated using the velocity vectors at the different positions in each cross section and it represents the rate of mixing. When the shaft rotational speed increases, an increase of the particle circulation intensity was observed.The dependence of the circulation intenstiy on rotation rate was quadratic. This is the expected result if the circulation intensity is controlled by the kinetic energy of the particles and their mean velocity is directly proportional to the rotational speed of the mixer. The inertia of the particles is then roughly proportional to the square of the rotational speed. As the fill level increases, the circulation intensity decreases dramatically. There is a minimum value of the circulation intensity and this occurs approximately where the flow reversal occurs. This again suggests that the convective mixing mechanism is hindered at intermediate fills. 4.1.3 Effect of fill level Fill level as discussed changes the circulation intensity and thus the rate of mixing. So operations should not be performed with the ~50% fill as at that point the convection is hampered and the rate of mixing is very slow. Fill level along with the rotation rate basically decides the type of segregation which may occur in the blender. There are normally 4 types of segregating pattern - stripes, inverse-stripes, small-out and big-out. In general operations are performed for fill level ranging from 40 % to 80 %. 10 Table 4 Experiment for loading pattern effect determination Figure 1 Different segregating patterns in V-blender 4.1.4 Effect of Loading pattern There are three types of loading pattern – Top-bottom, Front-back and Left-Right loading patterns. As can be seen in Fig. 2, all three curves exhibit a similar profile that is a rapid decrease with time followed by a slow transition leading to an asymptotic plateau. The loading profiles have a critical influence on the evolution of the RSD. The system with the front-back loading profile shows the fastest RSD decrease. The system with the top–bottom loading profile follows closely, the asymptotic plateau being attained after about 60 rotations (120 s). The system with the worst mixing efficiency is the one with the right–left loading profile, for which the asymptotic plateau was not yet reached after 60 revolutions. One can explain the differences obtained for these three loading profiles by the fact that the convective transport between the two arms of the V-blender is slower than that within any of its arms. Consequently, in the case of a right–left loading profile, the mixing of the two phases comes from the (convective and diffusive) mass transfer across the plane of symmetry of the blender, that is between its two arms, and the overall mixing dynamics is then slower than in the case of a front–back or top–bottom loading profile for which the (convection-dominated) mass transfer mainly occurs within each of these arms. It is also seen that the loading profile not only affects the rate of the mixing but it also affects the asymptotic value of the variance i.e. the best mixing that possibly can be achieved also depends on the loading pattern. 11 Figure 2 Figure 3 4.1.5 Effect of rotation rate There is a critical speed which, if approached will diminish blending efficiency considerably. As the revolutions per minute increase, the centrifugal forces at the extreme points of the blender will exceed the gravitation forces required for blending. Consequently the powder shall tend to gravitate to the outer walls of the blender shell. As the size of the blender increases, the rotational speed decreases usually in proportion to the peripheral speed of the blender extreme. V-Blenders are designed to operate at 50% to 80% of the critical speed. Three flow regimes (tumbling, partial-inertia, and centrifugal) were characterized for the V-blender rotating at variable speeds##. The first mode of particle motion was dominated by tumbling motion, characterized by particles cascading from one end of the shell to the other, with the mixture splitting and reforming during each rotation. A gradual transition to the second mode of particle motion began at about 70 rpm. In this regime, the mixer rotated too fast for all the particles to complete tumbling from one end of the shell to the other. Since all particles did not reach the end of the shell, some became airborne as they fell from a position no longer supported by the vessel to another location that was supported. As the rotation rate increased, a gradual shift toward the third mode of particle motion occurred, which was totally dominated by particle inertia. In Figure 4, results are compared for 8, 16, and 24 rpm. The data shows that rotation rate exerts little influence on the mixing process; in all cases, the evolution of the standard deviation is independent of rotation rate and can be expressed solely as a function of the total number of revolutions (which is the properly nondimensionalized mixing time). All these data are for the tumbling flow regime in which all the industrial mixers run. Qualitative observations indicate that this tumbling motion, which is gravity driven, is largely independent of the rotation rate for low enough Fr numbers. Particles within one shell are mixed relatively quickly by convective rearrangement during the tumbling motion. Mixing between shells occurs more slowly, as particles cross from one shell to the other only as 12 Table 5 the mixture is reassembled. Hence, the important factor determining the overall extent of mixing is the total number of times the mixture splits and reforms, rather than the rotation rate. In terms of total mixing time, however, the rotation rate is very important, because tripling the rotation rate from 8 to 24 rpm produces a uniform mixture three times as fast. 4.2 Cohesive mixtures in V-Blender An experiment was performed for the mixing of the MgSt with microcrystalline cellulose in V-blender, the conditions are given in table 5. MgSt is widely used powder lubricant in the pharmaceutical industry. 4.2.1 Effect of blender fill volume Blending performance, as characterized by the asymptotic RSD value, decreases as the fill volume increases, which complies with what is generally observed in the case of free-flowing and cohesive powders in tumbling blenders. The deleterious effect of fill volume on mixing performance can be explained here by the decrease in shear stress per unit volume. It was seen that the MgSt concentration has little impact on mixing performance. Therefore, the impact of the fill volume on MgSt mixing performance is related to the shear stress per unit volume alone. 4.2.2 Effect of loading profile Loading profile has little impact on the mixing time at similar fill levels. Note that previous results from the literature have shown that the difference between axial (diffusive) and radial (convective) mixing rates in tumbling blenders, which can be as high as an order of magnitude for free-flowing powders, is much less important in the case of cohesive powders. The relative lack of influence of the loading profile on mixing performance in the case of cohesive powders may be caused by three factors: relatively slow radial mixing, relatively fast axial mixing, or the overriding importance of shear mixing with respect to the previous two mechanisms. 4.2.3 Effect of blender rotational speed Unlike the free flowing powders the cohesive powders are greatly affected by the rotation rates, both in terms of the RSD value at a given time and the asymptotic RSD value. Not only does the RSD value decrease more quickly at high rpm, but the final RSD value is also lower than that obtained at low RPM, as expected. 4.2.4 Other factors Cohesion effects are less dominant in the larger vessels so when scale up is done the cohesion effects keep on decreasing. The reason is simple: Although cohesive forces are surface effects, the gravitational and convective 13 forces that drive flow in powder blenders grow proportionally to the vessel volume. Thus, as the blender’s scale increases, gravitational and convective forces increase, thereby overwhelming cohesive forces. The characteristic “chunk” size of a cohesive powder flow is a property of the material, and thus to a first approximation it is independent of the blender size. The dependence of the chunk size on properties of powder is already discussed in the cohesive materials section. As the blender size increases, the chunk-to-blender size ratio shrinks, thus reducing the effect of cohesion. Pre blend composition has seen to greatly affect the mixing performance so the order in which the components are added in the blender also affect the mixing quality. 6. Scale-Up Scale up of V-blenders is still not understood theoretically but there are some observations and empirical relations which should be used. For Scaling the V-Blenders the approach for the cohesive powders and non-cohesive powders are different. For each of them first of all the optimum point is to be determined experimentally. So based on the product requirements and the dependence of mixing on various variables (as discussed above) the experimental procedure should be designed. While designing the experimental procedure the following guidelines should be followed – The rotation speed of vessel should be kept between 40% to 80% of the critical speed which can be calculated by 𝑔 Critical Speed (ω) = √ 𝑅 (4) Where ‘g’ is acceleration due to gravity and R is vessel radius. Vessel radius is half of the height of the blender. For non-cohesive or free flowing mixtures the rotation rate does not affect the blending rate or blend quality, for these the number of rotations is the parameter is the deciding factor. Segregation pattern for free flowing mixtures is highly dependent on the rotation rates. Mixing flow mechanism of segregating mixtures changes with changing the RPM. In case of the cohesive mixtures the asymptotic variance value decreases with the increasing the rotation rate but as we come near to the critical speed the mixing performance deteriorates. On increasing the rotation rate the rate of the mixing in cohesive powders also increases. When deciding the loading pattern convective mixing should be prompted so that the rate is fast. Hence top-bottom or front–back loading should be promoted over the right–left loading. Major components (components having the highest percentages) should be loaded first. The components which have a very low percentage (<10 %) should be added carefully and in 2-3 steps not at once. All material should be loaded when the V-blender is inverted to ensure equal loading into both shells. The best method for loading is the front-back loading which is slightly better than the top-bottom loading, left-right loading should be avoided. For cohesive powders the loading profile is not significant and seen to have no effect on the mixing performance. All experiments should be performed between the 40-80 % of blender volume. In case of the non-cohesive or the free flowing mixture the fill level nearby of 50% should be avoided as at this fill level there is change in the flow pattern and the convective mixing is minimum and so is the rate. When convective mixing is minimum at the 50% fill level the circulation intensity is minimum. Segregation pattern is very sensitive to the fill level (1% change of fill level can change segregating pattern) and RPM so experiment should be done carefully. Rate of mixing decreases with increase in the fill level. Asymptotic value of the standard deviation increases with the increasing the fill level. Industrial suggested fill level for v-blender is 60 %. Now we know the optimum point for the system and also the flowing property of the system. So if the system is free flowing we can use Froude Number (Fr) approach or Rayleigh method. 𝐹𝑟 = 𝑤2𝑅 𝑔 (5) Where (w is the rotation rate, R is the vessel radius, and g is the acceleration from gravity) is often suggested for tumbling blender scale-up. While scaling the Froude number should be kept constant. This relationship balances 14 gravitational and inertial forces and can be derived from the general equations of motion for a general fluid. Rayleigh method is based on the particle surface velocities and is seen to be more reliable than the Froude number method. V=KR Ω2/3(g/d)1/6 Ω<30 RPM (6) V=KR Ω1/2(g/d)1/4 Ω>30 RPM (7) Where ‘V’ is particle surface velocity, ‘d’ is diameter of the particle, ‘Ω’ is rotation rate and ‘R’ is vessel radius. In Rayleigh method the particle velocity is kept constant. For the cohesive system the rates are not affected by the vessel size and time obtained from experimental optimum is also the optimum for the scaled case. 7. References Zhu, H. P., Zhou, Z. Y., Yang, R. Y., & Yu, A. B. (2008). Discrete particle simulation of particulate systems: a review of major applications and findings.Chemical Engineering Science, 63(23), 5728-5770. Cleary, P. W. (2009). Industrial particle flow modelling using discrete element method. Engineering Computations, 26(6), 698-743. Cleary, P. W., & Sinnott, M. D. (2008). Assessing mixing characteristics of particle-mixing and granulation devices. Particuology, 6(6), 419-444. Adam, S., Suzzi, D., Radeke, C., & Khinast, J. G. (2011). An integrated Quality by Design (QbD) approach towards design space definition of a blending unit operation by Discrete Element Method (DEM) simulation.European Journal of Pharmaceutical Sciences, 42(1), 106-115. Remy, B., Glasser, B. J., & Khinast, J. G. (2010). The effect of mixer properties and fill level on granular flow in a bladed mixer. AIChE journal, 56(2), 336-353. Jovanović, A., Pezo, M., Pezo, L., & Lević, L. (2014). DEM/CFD analysis of granular flow in static mixers. Powder Technology, 266, 240-248. Soda, R., Takagi, K., & Ozaki, K. (2014, January). Discrete Element Simulation for Magnetic-Aligned Compaction of Magnetic Powders. In TMS 2014 143rd Annual Meeting & Exhibition, Annual Meeting Supplemental Proceedings (p. 347). John Wiley & Sons.