special conditions

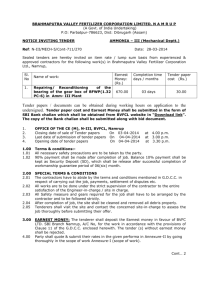

advertisement