Surface modification using amphiphilic cyclodextrins

advertisement

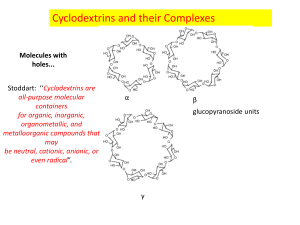

Publikationstitel: Surface modification using amphiphilic cyclodextrins Konference: 2nd European Cyclodextrin Conference, Asti, Italien, Oktober 2011 Abstrakt: Surface modification using amphiphilic cyclodextrins Ludmilla Lumholdt1,2, Lars Damgaard Løjkner1, Ronnie Nielsen1,2 and Kim Lambertsen Larsen1 1 Section of Chemistry, Department of Biotechnology, Chemistry and Environmental Engineering, Aalborg University, DK-9000 Aalborg, Denmark 2 Amphidex A/S, DK-9220 Aalborg Ø Modification of materials, e.g. textiles, with cyclodextrins (CDs) in order to obtain new functionalities, e.g. controlled release of fragrances or removal of malodours, has been the subject of many studies the past years1,2. Traditionally, the grafting of CDs onto relatively inert materials such as polypropylene (PP) has required long reaction times, harsh organic solvents and/or advanced equipment3-5, thus impeding the overall production process of the final product as well as raising the production costs. Here, we present a new, simple and fast method for the functionalization of textiles with CDs requiring only basic equipment (spray or kiss-roll) and limited amounts of non-harmful organic solvent. The method relies on the self-assembly of amphiphilic CDs on the surface of the material. Amphiphilic CDs are CDs modified with hydrophobic hydrocarbon chains rendering the molecule amphiphilic and allowing them to form nanoparticles in solution as well as self-assembled layers on appropriate surfaces. This class of CDs can be produced by various routes and several one-step synthesis routes have been developed. The simple self-assembly process has proven to yield permanent hydrophilic (in aqueous solution) multilayers retaining the inclusion complex forming properties of the CD and the mechanical properties of the fabric (e.g. PP). This novel process enables the production of CD functionalized surfaces with minimal change to existing production lines and with nearly no solvent residue. Due to the simple process the method is not surface specific and no advanced synthesis steps are needed for the modification unlike most commercial available modification processes. 1. 2. 3. 4. 5. B. Martel, M. Morcellet, D. Ruffin, F. Vinet, M. Weltrowski, J Incl Phenom Macro, 2002, 44, 439. M. H. Lee, K. J. Yoon, S. W. Ko, J Appl Polym Sci, 2000, 78, 1986. P. Le Thuaut, B. Martel, G. Crini, U. Maschke, X. Coqueret, M. Morcellet, J App Polym Sci, 2000, 77, 2118. S. M. Gawish, S. R. Matthews, D. M. Wafa, F. Breidt, M. A. Bourham, J App Polym Sci, 2007, 103, 1900. A. Yahiaoui, T. L. O'Connell, D. L. Myers, I. Bolian, Charles Edward, in US patent no. 6613703, USA, 2003.