ENVIRONMENTAL ASSESSMENT SHEET

advertisement

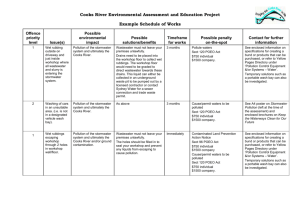

Cooks River Environmental Assessment and Education Project ENVIRONMENTAL ASSESSMENT CHECKLIST A.1 Inspection date: _________________________________________________________________________ A.2 Assessment officer: ______________________________________________________________________ A.3 Assessment number: _____________________________________________________________________ B. PROPERTY DETAILS B.1 Company name: _________________________________________________________________________ B.2.1 Property address: (number/street) _________________________________________________________ B.2.2 Suburb: ______________________________________ B.2.3 Postcode __________________________ B.3.1 Postal address: (number/street/PO Box) ____________________________________________________ B.3.2 Postal suburb: _________________________________ B.3.3 Postcode __________________________ Contact person: B4.1 Title: ________________ B4.2 First name: ______________________________________ B4.3 Surname: _____________________________________________________________________________ B.5 Position: _______________________________________________________________________________ B.6 Phone no:______________________________ B.7 Fax No: _____________________________________ C. BUSINESS CLASSIFICATIONS C.1 Nature of business: _______________________________________________________________________ C.2 ANZSIC Code:__________________________________________________________________________ C.3 How long has your business been operating at this location? ______________________________________ C.4 What business types were previously on site? __________________________________________________ C.5 ANZSIC Code(s) of previous business(es): ____________________________________________________ C.6 In which LGA is this business located? _______________________________________________________ C.7 In which sub-area is this business located? ____________________________________________________ C.8 Is the business located near sensitive receptors? ________________________________________________ C.9 Property identification number: _____________________________________________________________ TIPS – Licensing 1.1.1 May require a licence for generation/transport of waste or distribution of a product, e.g. ozone depleting substances. 1.2.4 A premises will require a Sydney Water Trade Waste Agreement for any industrial discharge to the sewer. 1.2.6 Wastesafe monitors and licences the removal and disposal of waste from businesses grease traps. Sydney Water gives a book of dockets to each trade waste customer’s nominated contractor, which is used to keep track of the waste from their grease traps. The program is designed to stop waste being illegally dumped into sewers, rivers or drains. For more information contact your local sewerage authority. 1.2.7 The PURE Code of Practice is a national voluntary guideline for management and disposal of liquid wastes from photographic film and paper processors including photo labs, X-ray and graphic arts. Everybody who regularly drains these liquid types to sewer must send a PURE data sheet to Sydney Water. The main aims of the program include avoiding over-replenishment of chemicals, limiting washwater, using chemicals of lower toxicity and using only approved disposal methods. For more information contact your local sewerage authority. 1.3.1 These may include inspection of boilers, compressors, spray booths or handling of hazardous substances. 1.3.2 Refer to the guidelines in the table on Dangerous Goods (page 4). 1.4.1 These systems must be registered with Council for health and safety reasons associated with legionnaire’s disease. Examples include evaporative coolers and cooling towers. 1.5.1 R12 equipment is no longer permitted. This has been replaced by 134A. TIPS – Property Details C.4 May have inherited previous contamination problems. C.7 Sub-area may be sub-catchment, industrial estate, etc. C.8 Sensitive receptors may include open drains, creeks, rivers, wetlands, and schools. 2 Cooks River Environmental Assessment and Education Project 1. LICENSING 1.1 Environment Protection Authority Yes No 1.2.1 Is wastewater generated on site? Yes No 1.2.2 Is wastewater discharged to sewer system? Yes No 1.1.1 Is the licence current? N/A 1.1.2 Licence no.: ________________________________________ 1.2 Sydney Water 1.2.3 Does the business have any of the following equipment: Grease Trap Settling Tank Oil/Water Separator Silver Recovery Unit Underground Waste Pit Other Wastewater Pretreatment Equipment Yes No N/A 1.2.6 Is the business part of the Wastesafe Program? Yes No N/A 1.2.7 Is the business part of the PURE Program? Yes No N/A 1.3.1 Are there any obvious occupational health and safety issues on site? Yes No Yes No 1.4.1 Are there any regulated systems registered with Council? Yes No 1.4.1.1 Water cooling system? Yes No 1.4.1.2 Warm water system? Yes No Other? Yes No 1.2.4 Is the Trade Waste Agreement current? 1.2.5 Trade Waste Agreement No.: ___________________________ 1.2.8 Water Meter Serial Number: ____________________________ 1.3 WorkCover NSW 1.3.2 Is the Dangerous Goods licence current? N/A 1.3.3 Licence No.:_________________________________________ 1.4 Council 1.4.2 Other matters to be referred internally: ______________________________________________________ 1.5 Other Licences/Additional Information 1.5.1 Is the business licensed by the Motor Vehicle Repair Industry Council to carry out air conditioning repairs? Yes 1.5.2 No N/A Other Licences/Additional Information: __________________________________________________ _________________________________________________________________________________________ Cooks River Environmental Assessment and Education Project 3 TIPS – On Site Storage and Management of Materials (Dangerous Goods) Material type Fuels (flammables) Examples Units L/Kg/m3 Petrol, alcohol, ether Quantity Hazard L >100 F Other flammable fuels/solvent Kerosene, mineral turpentine L >1 000 F Combustible Fuels (category one) Diesel, heating oils L >50 000 in single tank C Combustible Fuels (category two) Engine oil, olive oils L Unlimited quantity permitted C Solvents/Degreasers Thinners, lacquers, methylated spirits, sodium hypochlorite (general purpose bleach), methylene chloride (degreaser rollers),some car wax & shine, acetone, carbon disulfide L >100 F/C/P Paints/Inks/Dyes (S&O/B) Solvent &/or oil based L >100 C/F Paints/Inks/Dyes (W/B) Water-based L Unlimited quantity permitted P Liquefied flammable gas A licence is required for any premises where LPG is decanted for sale Kg >300 F LPG connected for use (e.g. to a stove, heater) Liquefied flammable gas LPG (not connected for use and not for sale but only used in-house - (e.g. reserve cylinders for later use, cylinders for filling forklift cylinders). Kg >150 F Compressed flammable gas Acetylene, hydrogen 'G' size ~ 7m3 of compressed flammable gas 'E' size ~ 3.5m3 of compressed flammable gas m3 >60 F Non flammable & non-toxic gases - (Cryogenic gases) Liquid oxygen, liquid nitrogen m3 >600 N/F & N/T Non flammable & non-toxic gases (Non-cryogenic gases) Compressed oxygen, nitrogen, argon, air m3 Unlimited quantity permitted N/F & N/T Liquefied poisonous gases Chlorine, anhydrous ammonia, sulfur dioxide (if premises open to the general public, e.g.'municipal swimming pool', a license is required to keep any amount on the premises) Kg Any quantity where premises open to public (e.g. municipal swimming pool) P Premises not open to the public >50 Flammable solids & reactive Nitrocellulose, some magnesium, aluminium & other Substances Combustible solids metal powders, sulfur, desensitised explosives, activated Solids dangerous when wet charcoal, matches, hexamine Kg >25 F Combustible solids Aluminium alkyls, diethyl, sodium sulfide, hydrosulfite, scrap celluloid, some metal powders, fibres & paper containing vegetable oils, & self-heating liquids & solids Kg >100 C Oxidising agents A license is required for any quantity of ammonium chlorate stored on site Kg >0 CV Corrosive Substances Sulfuric acid, hydrochloric acid, sodium hydroxide Kg/L >500 CV NOTE: A Dangerous Goods Licence is required for quantities stored on site at these values 4 Cooks River Environmental Assessment and Education Project 2. ON SITE STORAGE AND MANAGEMENT OF MATERIALS 2.1 Types of liquids/gas/solids stored on site. (e.g. fuels, solvents, paints and detergents) Material type Units L/Kg/m3 Annual use quantity Stored quantity Types of storage Storage acceptable Yes/No Primary hazard Secondary hazard Fuels (flammable) Fuels (combustible) Oils / Lubricants Solvents / Degreasers Paints / Inks / Dyes Adhesives Detergents / Cleaning Agents Liquid Foodstuffs Photographic/Printing Chemicals Gases (flammable) Gases (non-flammable) Solids Other Hazard type: C = Combustible Liquids; CV = Corrosive; E = Explosive; F = Flammable; G = Gases; M = Miscellaneous; O = Oxidising Substances; P = Pollutant; R = Radioactive; T = Toxic 2.2 Is there a fuel service on site? Yes No 2.3 Are there underground storage tanks on site? Yes No 2.4 Have non-operating tanks been properly decommissioned? Yes No N/A 2.5Are all materials (especially liquids) adequately contained? Yes No N/A 2.6 Is spill clean up equipment stored on site? Yes No N/A 2.7 Are there adequate supplies of spill clean up materials and equipment? Yes No N/A 2.8 Is there sufficient awareness of spill response procedures? Yes No N/A 2.9 Are the necessary MSDSs available? Yes No N/A 2.10 Is there fire-fighting equipment? Yes No 2.11 Is fire equipment checked and maintained? Yes No 2.12 Materials Management Comments: _________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ Cooks River Environmental Assessment and Education Project 5 TIPS – General Waste Management 3.3 Some common bin volumes are 0.24m3 (wheelie bin), 1.5m3, 2m3, 3m3, 4m3, 4.5m3. 3.4 It is illegal to dispose of any liquids into general waste bins. There is a risk to the environment via liquids leaking from the bin or truck, or leachate at the landfill site. 3.5 Licenced waste/recycling contractors are those which require a licence from the Environment Protection Authority for the transport/disposal of the waste. For example any liquid wastes, asbestos, clinical wastes or hazardous materials. TIPS – On Site Storage and Management of Materials 2.1 Refer to the guidelines in the table on Dangerous Goods (page 4). Acceptable storage requirements may include bunding, the gradient of the floor or proximity of storage area to doorway or drain. 2.4 If an underground storage tank has not been used for 6 months, i.e. nothing in or out, one of three things may be done: a) the tank may be removed from the ground, b) it may be filled with an acceptable material, or c) apply to WorkCover NSW for a 2 year exemption to fill it with liquid so it can be reused later. Either way, WorkCover NSW need to be contacted. 2.5 Adequate containment may include bunding, the gradient of the floor, proximity of liquids to drains or workshop entrance or valve locks for tanks. 2.6 Spill clean up equipment may range from sawdust, rags, a broom and a biodegradable cleaning product to a professional spill kit depending on the types of materials dealt with on the site. 2.8 Are all staff aware of procedures and where equipment is kept or is one person responsible for spill emergencies. 2.9 Under the OH&S (Hazardous Substances) Regulation 1996, all employers using hazardous and dangerous goods in the workplace are required to provide appropriate and accessible Material Safety Data Sheets. 6 Cooks River Environmental Assessment and Education Project 3. GENERAL WASTE MANAGEMENT 3.1 Does the business generate/separate any of the following categories of solid waste? Waste generated M3/month Waste recycled Paper/board Yes No Yes No 0–1 1-3 3–10 >10 Mixed glass Yes No Yes No 0–1 1-3 3–10 >10 Metals Yes No Yes No 0–1 1-3 3–10 >10 Plastic Yes No Yes No 0–1 1-3 3–10 >10 Timber Yes No Yes No 0–1 1-3 3–10 >10 Cloth offcuts Yes No Yes No 0–1 1-3 3–10 >10 Green waste Yes No Yes No 0–1 1-3 3–10 >10 Food waste Yes No Yes No 0–1 1-3 3–10 >10 Commercial/demolition Yes No Yes No 0–1 1-3 3–10 >10 Other waste Yes No Yes No 0–1 1-3 3–10 >10 3.2 Does the business generate any of the following categories of liquid waste? Waste generated Waste recycled Oils Yes No Yes No N/A Brake fluids Yes No Yes No N/A Solvent Yes No Yes No N/A Coolant Yes No Yes No N/A Oily sludge Yes No Yes No N/A Other Yes No Yes No N/A 3.3 Volume of general waste generated by the business each month Bin volume _______ _______ _______ Number of bins Collection frequency 1 2 3 4 5 other____ > monthly daily monthly fortnightly weekly other/month__________ 1 2 3 4 5 other____ > monthly daily monthly fortnightly weekly other/month__________ 1 2 3 4 5 other____ > monthly daily monthly fortnightly weekly other/month__________ Yes No N/A 3.5 Is the premises serviced by ‘licensed’ waste/recycling contractor(s)? Yes No N/A 3.6 Have there been any instances of illegal dumping on the site? Yes No 3.7 Is there effective waste management on site? Low Medium High 3.8 Is there any evidence of ground contamination (e.g. visual stains, odours, affected vegetation) Yes No N/A 3.9 Are good housekeeping practices being used on these premises: Low Medium High 3.4 Are there any liquids disposed of into the waste bin/s? 3.10 General waste management comments: ______________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ Cooks River Environmental Assessment and Education Project 7 TIPS – Air Emissions Management Air treatment devices may include filters, exhaust systems, dust collectors fitted to machinery or appropriate ventilation. 8 Cooks River Environmental Assessment and Education Project 4. STORMWATER MANAGEMENT 4.1 Is there any evidence of, or potential for, stormwater pollution from the following on site activities/operations? YES Evidence of stormwater pollution Activity NO Potential for stormwater pollution Forecourt washing Yes No Yes No Hosing out of workshop Yes No Yes No Equipment washing/high pressure cleaning outside Yes No Yes No Discharge of waste water/liquids into SWDs Yes No Yes No Disposal of solid wastes into SWDs Yes No Yes No Debris in SWDs Yes No Yes No Storage of contaminated parts in an open area Yes No Yes No Other Yes No Yes No 4.2 Are the occupiers aware of their stormwater drainage system? Low Medium Awareness High 4.3 Stormwater Management Comments: __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ _________________________________________________________________________________________ 5. AIR EMISSIONS MANAGEMENT Yes 5.1 Does the business have any air emissions leaving the premises? Type of air emission leaving premises No Air treatment device in place and properly maintained Smoke Yes No N/A Yes No N/A Spray painting emission Yes No N/A Yes No N/A Dust Particles Yes No N/A Yes No N/A Fumes/Vapours Yes No N/A Yes No N/A Ozone depleting gas Yes No N/A Yes No N/A Sand blasting emission Yes No N/A Yes No N/A Odour Yes No N/A Yes No N/A Steam Yes No N/A Yes No N/A Other Yes No N/A Yes No N/A 5.2 Air Emissions Management Comments: ______________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ Cooks River Environmental Assessment and Education Project 9 TIPS – Noise Management 6.0 EPA guidelines developed in January 2000 provide details of the offensive noise test. This is a subjective assessment carried out by an authorised officer. Noise measurements are not required by the legislation (POEO) to determine whether a noise is offensive however there are a series of factors to consider when using the test. This list is not exhaustive and you do not have to answer all the questions before deciding that a noise is offensive. Is the noise loud either in an absolute sense, or relative to other noise in the area? Does the noise include any tones or impulses and any fluctuations in volume? Does the noise occur at times (such as the evening or night) when unreasonable interference with comfort or repose is likely? Where is the noise heard and is it likely to adversely affect people’s activities (including relaxing, speaking and sleeping)? Is the noise likely to be intrusive (That is, how much does the noise exceed the background noise level)? Is the noise typical of activities normally conducted in the area? Are the volume and character of the noise typical of the type of activity in question? How many people are affected? TIPS – Water and Energy Use 7.1.1 Measures may include sky lights, timer switches, low energy lighting, updated equipment. 7.1.3 Measures may include recycling systems, mopping instead of hosing. 7.1.4 Specific examples of saving resources and materials. TIPS – Company Policy 8.4 10 This may be for use of the Internet as an educational tool or providing information posted by Council. Cooks River Environmental Assessment and Education Project 6. NOISE MANAGEMENT 6.1 What are the operating hours of the business? Monday to Friday Hours: ____________ Saturday Hours: ____________ Sunday Hours: ____________ 6.2 Is noise and/or vibration audible from outside of the premises boundaries? Yes No 6.3 Are there any noise mitigation measures provided? Yes No N/A 6.4 Noise Management Comments: _____________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ 7. WATER AND ENERGY USE 7.1 During the past few years, has the company implemented any measures to reduce: 7.1.1 Electricity use? Yes No N/A 7.1.2 Fuel consumption? (Diesel, Gas) Yes No N/A 7.1.3 Water use? Yes No N/A 7.1.4 Other? Yes No N/A 8.1 Has the company ever carried out an environmental review before? Yes No N/A 8.2 Does the company have an environmental management policy in place? Yes No N/A 8.3 Has the company ever taken any specific action to reduce the impact of its business operations on the environment? Yes No N/A 8.4 Does the company have access to the Internet? Yes No N/A 8. COMPANY POLICY Cooks River Environmental Assessment and Education Project 11 TIPS - Inspection Summary 9.3 Response letter type A - business is compliant with legislative controls. Response letter type B - business is indifferent in that they do not impact on the environment. Response letter type C - business has some minor issues to deal with (e.g. recycling). Response letter type D - business has issues relative to legislative breaches. 12 Cooks River Environmental Assessment and Education Project 9. INSPECTION SUMMARY 9.1 Overall summary: _______________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ 9.2 Contact person’s attitude: 1 poor 2 average 3 excellent 9.3 Response letter type: A B C Yes 9.4 Schedule of Works required? D No 9.5 Schedule of Works issues: Impact category Agreed completion date Issue 9.5.1 9.5.2 9.5.3 9.5.4 9.5.5 9.5.6 9.5.7 9.5.8 9.5.9 9.5.10 9.6 Follow up required? Yes No 9.7 Date follow up due: ______________________________________________________________________ Cooks River Environmental Assessment and Education Project 13 10. SITE PLAN 14 Cooks River Environmental Assessment and Education Project SITE PLAN Cooks River Environmental Assessment and Education Project 15 TIPS – Follow Up Inspection 11.3 A different solution or modification to a Schedule of Works issue or the issue is no longer applicable. For example bunding was requested and upon re-inspection it was found that the gradient of the floor is adequate to prevent any spill or leak leaving the premises. 11.4 New issues discovered upon re-inspection 11.5 Follow up letter type A - issues all addressed. Follow up letter type B - new issues discovered upon re-inspection. Follow up letter type C - outstanding issues not addressed. Follow up letter type D - no issues have been addressed. 16 Cooks River Environmental Assessment and Education Project 11. FOLLOW UP INSPECTION 11.1 Date of follow up: ____________________________________ 11.2 Completion of the Schedule of Works issues. Impact category Agreed completion date Issue Actual completion date 11.2.1 11.2.2 11.2.3 11.2.4 11.2.5 11.2.6 11.2.7 11.2.8 11.2.9 11.2.10 Yes 11.3 Schedule of Works issues refined as result of follow-up? Impact category No N/A Agreed completion date Issue 11.3.1 11.3.2 11.3.3 11.3.4 11.3.5 11.4 Additional issues to Schedule of Works as a result of follow-up? Impact category Yes No N/A Agreed completion date Issue 11.4.1 11.4.2 11.4.3 11.4.4 11.4.5 11.5 Follow up letter type: A 11.6 Is a second follow up required? B C Yes No Yes No D 11.7 Date second follow up due (if required): ___________________ 11.8 Refer to other in Council/Sydney Water/other organisation for further action? Cooks River Environmental Assessment and Education Project N/A 17