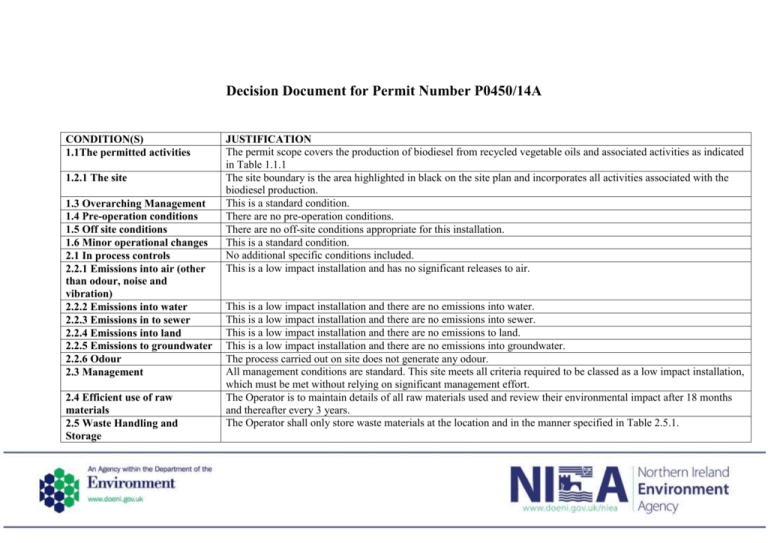

Decision Document for Permit Number P0450/14A

advertisement

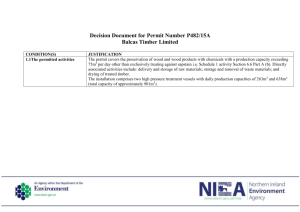

Decision Document for Permit Number P0450/14A CONDITION(S) 1.1The permitted activities 1.2.1 The site 1.3 Overarching Management 1.4 Pre-operation conditions 1.5 Off site conditions 1.6 Minor operational changes 2.1 In process controls 2.2.1 Emissions into air (other than odour, noise and vibration) 2.2.2 Emissions into water 2.2.3 Emissions in to sewer 2.2.4 Emissions into land 2.2.5 Emissions to groundwater 2.2.6 Odour 2.3 Management 2.4 Efficient use of raw materials 2.5 Waste Handling and Storage JUSTIFICATION The permit scope covers the production of biodiesel from recycled vegetable oils and associated activities as indicated in Table 1.1.1 The site boundary is the area highlighted in black on the site plan and incorporates all activities associated with the biodiesel production. This is a standard condition. There are no pre-operation conditions. There are no off-site conditions appropriate for this installation. This is a standard condition. No additional specific conditions included. This is a low impact installation and has no significant releases to air. This is a low impact installation and there are no emissions into water. This is a low impact installation and there are no emissions into sewer. This is a low impact installation and there are no emissions to land. This is a low impact installation and there are no emissions into groundwater. The process carried out on site does not generate any odour. All management conditions are standard. This site meets all criteria required to be classed as a low impact installation, which must be met without relying on significant management effort. The Operator is to maintain details of all raw materials used and review their environmental impact after 18 months and thereafter every 3 years. The Operator shall only store waste materials at the location and in the manner specified in Table 2.5.1. Decision Document Part A Q57/15 Version 1 2.6 Waste recovery and disposal The operator is to maintain details of all waste materials disposal routes, quantity and review their environmental impact after 18 months and thereafter every 3 years. The operator must submit a report on energy consumption annually, and shall maintain an energy management system 2.7 Energy Efficiency and operate the plant with a view to continuous improvement of energy efficiency. Standard conditions used. The process hall is inside and totally contained and there are no external storage areas. 2.8 Accident prevention and control This is a standard noise and vibration condition. 2.9 Noise and vibration There are no specific monitoring requirements associated with this permit, due to the absence of emissions. 2.10 Monitoring This is a standard condition. Satisfactory site closure plan submitted with application. 2.11 Closure and Decommissioning Not applicable 2.12 Multi Operator installations Not applicable 2.13 Transfer to effluent treatment plant IMP 1 – to contain any spillage of methanol IMPROVEMENT IMP 2 – to contain any spillage of waste cooking oil PROGRAMME IMP 3 – to contain any spillage of biodiesel CONSULTEE COMMENTS Comments and measures in permit where applicable Response from HSC indicated that if the applicant carries out all the mitigation measures during the construction and HSC Public Health Agency operational phases as outlined in the application then the public health effects would be minimal and the Public Health Agency would have no immediate concerns regarding adverse health effects of the facility related to IPPC issues. Newtownabbey Borough Council indicated that residential properties in Aylesbury and Blackrock may potentially be District Council sensitive receptors but that no complaints had been received to date. Response from Northern Health and Social Services Board indicated that the main concerns in relation to this facility Food Standards Agency were pre-acceptance/acceptance procedures for waste, storage/spillages throughout site, emissions throughout site and training all covered under conditions in the permit. The Board stated based on the information made available, provided that the applicant operates and maintains the site in accordance with the relevant guidelines, it is unlikely that there will be unacceptable effects on the human food chain. Page 2 of 3 Decision Document Part A No additional consultees required. Others ( list) IMPACTS ON THE ENVIRONMENT European sites ASSIs Other environmental receptors People Q57/15 Version 1 There are no European sites which may be affected by the installation. There are no ASSI’s within 2 kilometres of the installation. This is a Low Impact Installation, i.e. an installation that has a potential for only low environmental impact, meeting the requirements of “Criteria for determining whether an installation can be classified as low impact” with regard to Management Techniques, Raw Materials, Techniques to prevent and reduce waste arising and emissions, Groundwater Regulations, Waste Production, Energy Consumption, Accident Prevention, Noise, Emissions of polluting substances and Odour and as such does not pose a significant threat to environmental receptors. The installation is a low impact installation located inside a building in Central Park Industrial Estate, Mallusk, Newtownabbey, with the nearest neighbouring dwelling some 200 metres away. The installation is unlikely to cause odour or noise nuisance due to its location inside a building, distance from other dwellings and the fact that it is a low impact installation Completed by: NIEA – Industrial Pollution & Radiochemical Inspectorate Date: 21st January 2015 Page 3 of 3