Modeling Study on NOx Reduction Strategies for Biodiesel

advertisement

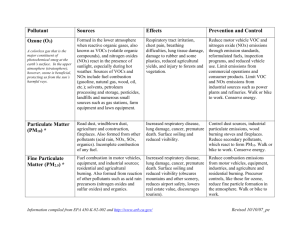

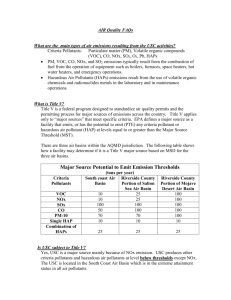

FINAL TECHNICAL REPORT IEC Grant No.: 06-05a Title: NOx Emissions From Biodiesel Burned in Utility Generators – Modeling Principal Investigator: Song-Charng Kong Grantee Organization: Mechanical Engineering Department, Iowa State University __________________________________ Signature of PI Public Abstract This study performed computer modeling of diesel/biodiesel combustion in large stationary engines used for utility generation. This work is part of the IEC project awarded to Iowa Association of Municipal Utilities on burning biodiesel in utility generators. The present modeling study used stack test results to calibrate computer models that have been developed for diesel combustion and emissions simulation. The purpose of this study is to use the model as a tool to explore NOx reduction strategies when biodiesel blends are used in large diesel engines. Two engines were modeled in this study, including a Caterpillar engine (2 MW) in Winterset facilities and a Fairbanks Morse engine (2 MW) in Story City facilities. After model validation, parametric studies were performed to investigate effects of fuel injection timing and exhaust gas recirculation on NOx emissions reduction. Model results indicate that NOx can be reduced by retarding the injection timing or increasing exhaust gas recirculation rates. On average, a 20 ~ 25% reduction in NOx emissions can be achieved by retarding injection timing for 5 crank angle degrees. On the other hand, a 25 ~ 35% reduction in NOx can also be achieved per 10% exhaust gas recirculation rates. Model results indicate that both strategies can be effective. However, exhaust gas recirculation requires extensive hardware modifications, in particular for large diesel engines. Therefore, retarding injection timing appears to be a more feasible means to reduce NOx emissions from burning biodiesel blends in large utility generators. i Table of Contents 1. Introduction…………………………………………………………………… 1 1.1 NOx Emissions from Biodiesel Combustion …………………… 2 2. Project Objective ………………………………………………….………… 2 3. Computer Models …………………………………………….……………… 3 4. Modeling Caterpillar Engine at Winterset Facilities ………………..…… 5 4.1 Engine Geometry and Conditions ……………………….……… 5 4.2 Model Calibration ………………….. ……………………………. 6 4.3 Parametric Study ………………………………………………….. 8 5. Modeling Caterpillar Engine at Winterset……………..…………………… 11 5.1 Engine Geometry and Conditions ……………………….……… 11 5.2 Model Calibration …………………………………………………. 11 5.3 Parametric Study ………………………………………………….. 14 6. Summary ………………………………..…………..………………………… 16 7. References………………………………………………………………...…… 17 ii 1. Introduction This work is part of the IEC project awarded to Iowa Association of Municipal Utilities (IAMU) on burning biodiesel in utility generators. The present work is a modeling study to complement the engine test that would be carried by IAMU at both Winterset and Story City municipal facilities. Particulate matters (PM) and nitrogen oxides (NOx) are the two major pollutants of diesel engines and can cause adverse effects on the environment and human health. Soot from diesel engines can cause as much as a quarter of all global warming by reducing the ability of snow and ice to reflect sunlight (Sato et al., 2003). On the other hand, NOx is a major pollutant of concern as a component of smog and acid rain, contributing to the formation of ground-level ozone and contributing to the greenhouse effect. When biodiesel is used in the engine, it is known that biodiesel combustion produces less PM emissions but more NOx emissions. Previously published literature has been focusing on laboratory engines or transit buses. Modeling study of large diesel engines for utility generation is not available and is the subject of study in this work. Biodiesel can displace petroleum-based fuels and contribute to bioeconomy. However, the increase in NOx emissions due to biodiesel combustion can limit its application. In Iowa, NOx is the limiting pollutant for stationary diesel generators. While generator permit types vary, a typical Iowa Department of Natural Resources (IDNR) air permit (Iowa Administrative Code, 2005), for example, allows a generator to operate up to a certain number of hours per year, or to burn a certain number of gallons of fuel, based on the expected emissions of NOx predicted from emissions factors (AP-42 factors, EPA 2005) for specific fuels combined with manufacturer data about engine performance. There are no emissions factors calculated for biodiesel blends and there have not until recently been any emissions tests on large stationary engines used for electricity generation. The lack of emissions data from large diesel generators has been a significant barrier to utilities wanting to burn biodiesel. The present modeling study is intended to help determine strategies to reduce NOx emissions from utility generators burning biodiesel blends. The present computer code consists of various 1 physical and chemistry models to describe the in-cylinder spray combustion process. Multidimensional simulation will be performed including the simulation of flow turbulence, spray dynamics, vaporization, mixing and chemical reactions within the engine cylinder. This work will use stack test results to calibrate computer models that have been developed for diesel combustion and emissions simulation. 1.1 NOx Emissions from Biodiesel Combustion It has been suggested that the increase in NOx is due to injection timing differences caused by the low compressibility of biodiesel. Research that used spray chamber testing showed one crank angle degree shift in using B100, i.e., actual start of injection is earlier (Szybist and Boehman, 2003). The shift in injection timing resulted in an earlier ignition by 4 crank angle degrees that caused a higher combustion temperature in the cylinder and produced more NOx emissions. Other research indicates that the increase in NOx emissions is due to the lack of soot radiation that causes a higher flame temperature in the cylinder when oxygenated fuel is used, such as biodiesel (Mueller, 2005). In any case, various NOx reduction strategies have been proposed including retarding the injection timing setting, intake charge cooling, fuel additive and blending, and the use of exhaust gas recirculation (EGR) to lower the combustion temperature (Yoshimoto and Tamaki, 2001; McCormick et al., 2002; Szybist et al., 2003). For instance, a recent study by Minnesota Center for Diesel Research demonstrated that charge-air cooling (from 90 to 40 degree C) was very effective at reducing NOx emissions (by 25%) in a utility engine (Zarling et al., 2004). The updated engine performance model will be used to suggest NOx reduction methods for the test engines. The suggested methods will be examined to consider the feasibility of the engine hardware. 2. Project Objective The goal of the present modeling study is to use the test data collected from the stack tests, performed by IAMU, to calibrate the engine model. The calibrated model will be used to predict 2 effects of injection timing and related engine operating parameters on NOx reduction. Potentially the model can also be used to predict emissions from other engine geometries in the future. It is also hoped that the model results, together with stack test data, will provide information to utilities and regulators to better evaluate their options for controlling NOx emissions. We disseminate the results from this project through research papers and technical meetings. 3. Computer Models The computer code consists of various models to describe the in-cylinder fluid dynamics and chemical reaction processes. The models have been developed over the pasts few years and have been validated mainly for on-high vehicle engines (Kong et al., 1995; Kong et al., 1999; Kong et al., 2002). This study will further validate the model predictions using large diesel engines in power plants that have different geometries and operating conditions. The computer code was designed to simulate engine combustion that is a transient (due to piston motion), multiphase (due to liquid spray and gas phases) and turbulent (due to high piston speed) process with chemical reactions. The major models include the spray atomization, drop-wall impingement, wall heat transfer, piston-ring crevice flow, combustion, and NOx and soot formation and oxidation models (Kong et al., 1995; Kong et al., 1999). The RNG k- turbulence model was used for in-cylinder flow simulations using the standard values for turbulence parameters as those derived originally. The combustion model uses multi-step chemical kinetics to describe the low-temperature autoignition chemistry and high-temperature flame chemistry that are both important to diesel engine. The reaction chemistry and flow solutions were coupled by using a characteristics time approach. The turbulence also affects the combustion by property transport, wall heat flux, etc. Details of the model can be found in the original literature (Kong et al., 1995). The extended Zeldovich NO mechanism was used to simulate the NO emission process. The effect of OH radical on NO formation is also considered through the reactions, as listed below. 3 By invoking the steady-state assumption for N radical and using equilibrium approach for O, H and OH radicals, the formation rate of NO can be obtained as in the following. O + N2 N + O2 N + OH NO + N NO + O NO + H R |S |T 2 1 NO / K12 O2 N 2 d NO 2 k1 f O N 2 dt 1 k1b NO / k2 f O2 k3 f OH d U |V i|W (1) Soot emissions are predicted using a phenomenological soot model. Two competing processes are considered in this model, namely soot formation and oxidation. The rate of change of soot mass M s within oxidation rate a computational cell is determined from the soot formation rate M sf and soot M so . dM s dM sf dM so dt dt dt (2) The formation rate uses an Arrhenius expression and the oxidation rate is based on a carbon oxidation model, described as dM sf dt Af M fv P 0.5 exp E RT (3) dM so 6Mwc M s RTotal . dt s Ds (4) Based on the current combustion model, fuel was used as the soot inception species in Eq. (3). The pre-exponential constant Af was adjusted accordingly for the present implementation and also to account for the fuel effects, i.e., regular diesel vs. biodiesel blends. On the other hand, the soot oxidation rate is determined by the Nagle-Strickland-Constable model that considers carbon oxidation by two reaction pathways whose rates depend on surface chemistry of two different reactive sites, as in Eq. (4). 4 The combustion and emissions chemistry in the present model was calibrated based on the test data to account for the characteristics of biodiesel blends. The calibrated was then used to perform parametric study for NOx reduction. 4. Modeling Caterpillar Engine at Winterset Facilities 4.1 Engine Geometry and Conditions The engine is a Caterpillar 3516B engine. The specification is listed in Table 1. The baseline condition has a start-of-injection (SOI) timing of –10 ATDC (after top-dead-center). The parametric study includes sweeps of EGR and SOI. The engine was run at full load conditions with 1,825 kW output. The fuel injector has 8 nozzle holes such that the computational domain only uses 1/8 of the entire cylinder to take advantage of symmetry, as indicated in Fig. 1. The computational domain contains one fuel spray plume as will be seen in the following figures. Table 1 Caterpillar 3516B engine specifications Bore × Stroke 170 mm × 190 mm Compression Ratio 14:1 Displacement 69 L for 16 cylinders Connecting Rod Length 392.5 mm Engine power and speed 185 kW at 1800 rpm BSFC 204.7 g/kW-hr Modeling cases: (1) Baseline 0% EGR, SOI= –10 ATDC (2) 0% EGR SOI= –10, –5, 0, 5 ATDC (3) SOI= –5 ATDC EGR=0, 5, 10, 15% 5 Cylinder head Computational domain Piston surface Figure 1 Combustion chamber and the computational domain in this study. 4.2 Model Calibrations for Baseline Case The present three-dimensional computational fluid dynamics (CFD) model is capable of simulating fuel spray combustion and emissions inside the engine cylinder. Figure 2 shows the distributions of liquid fuel spray and combustion temperature on a cross section in the cylinder. The fuel spray experiences atomization and vaporization, and the fuel vapor mixes with air such that combustion occurs in the cylinder. It is seen that the fuel spray is surrounded by the combustion flame as expected in the real engine combustion process. The predicted spray and combustion processes seem very realistic as compared with existing literature. Figure 2 Model results of in-cylinder fuel spray and combustion temperature distributions on a cross section inside the combustion chamber. The fuel spray is surrounded by the high temperature combustion flame. 6 NOx Soot TDC 20 ATDC 50 ATDC Figure 3 Model results of soot and NOx distributions on a cross section for a sequence of times. The cylinder axis is located at the left boundary of each plot and only half of the cylinder cross section is shown. The present model also includes the chemical kinetics for NOx and soot formation. Figure 3 shows the distributions of soot and NOx on the cross section for a sequence of timing. It is seen that the NOx forms at the region where there is high combustion temperature since NOx is sensitive to temperature. Soot is formed in the leading edge of the spray plume where the fuel-air mixture is rich. The soot cloud is then moved by the in-cylinder flow in a counterclockwise direction to the squish region later in the engine cycle. Part of the in-cylinder soot will oxidize later in the engine cycle, as will be seen in Fig. 4. Since the experimental emissions data are available for B0, the model was further calibrated for this baseline condition. Figure 4 shows the history of in-cylinder soot and NOx emissions in lb/MMBTU to be consistent with the engine data. The predicted emissions at exhausts valve 7 open (approximately 120 ATDC) are compared with the engine-out stack measurements. In the present model formulation, the kinetics rate constant for soot formation was adjusted such that the engine-out PM emissions was matched. On the other hand, no model constants were adjusted in the NOx model while the NOx emissions was already well predicted. More engine conditions using biodiesel blends will be modeled once the experimental data are available. 0.06 5 0.05 Engine Data PM (lb/MMBTU) NOx (lb/MMBTU) 4 3 Model Prediction 2 Model Prediction 0.03 0.02 Engine Data 0.01 1 0 -100 0.04 0 -100 -50 0 50 -50 0 50 100 Crank Angle (ATDC) 100 Crank Angle (ATDC) Figure 4 History of in-cylinder soot and NOx emissions. The predicted emissions at exhausts valve open are compared with the engine-out stack measurements. 4.3 Parametric Study Parametric study was performed to investigate effects of EGR and SOI on NOx and soot emissions. Note that using EGR or retarding SOI are the most common and effective methods to reduce NOx emissions. This is because the two methods can reduce the combustion temperature inside the cylinder leading to lower NOx emissions. Figure 5 shows the predicted NOx and soot emissions, cylinder pressure history and peak cylinder pressure for various SOI conditions. It is seen that, as injection timing is retarded, the cylinder pressure decreases resulting in lower NOx emissions but higher soot emissions due to lower combustion temperatures. An average of 20% reduction in NOx emissions can be achieved by retarding injection timing for 5 crank angle degrees. 8 10 200 Soot Variation (%) NOx Variation (%) 0 -10 -20 -30 -40 150 100 50 -50 0 -60 -50 -70 -10 -5 0 5 -10 10 -5 0 Cylinder Pressure and Heat Release Rate vs. Crank Angle CAT 3500 Full Load 1800 rpm 0% EGR 10 Peak Cylinder Pressure vs. SOI CAT 3500 Full Load 1800 rpm 0% EGR 15.0 15 1500 1250 SOI-5 EGR 0% SOI-10 EGR 0% 10 1000 750 5 500 250 Heat Release Rate (J/deg) SOI 0 EGR 0% Peak Cylinder Pressure (Mpa) SOI 5 EGR 0% Cylinder Pressure (Mpa) 5 SOI (ATDC) SOI (ATDC) 10.0 5.0 0.0 0 0 -60 -40 -20 0 20 40 -10.0 -5.0 60 0.0 5.0 10.0 SOI (dATDC) Crank Angle (dATDC) Figure 5 Predicted NOx and soot emissions, cylinder pressure history and peak cylinder pressure for 0% EGR with various SOI. On the other hand, EGR is another effective means of reducing NOx emissions. The EGR rate is defined as the ratio of re-inducted exhaust gas to the total intake charge. EGR [%] mEGR 100 mintake (5) It is an indication of how much exhaust gas is re-inducted to the intake. If exhaust gas is not reinducted into the intake, the EGR rate will be zero. It is known that the specific heat (Cp and Cv) of H2O and CO2 (exhaust) are higher than O2 and N2 (fresh air). If part of the exhaust gas is directed to the intake and displacement some of the fresh air, the overall specific heat of the incylinder mixture will be higher. Since the energy release from combustion is the same, a higher specific heat will result in lower gas temperature rise during combustion. Therefore, NOx production can be reduced due to low combustion temperature. 9 10 50 40 Soot Variation (%) NOx Variation (%) 0 -10 -20 -30 30 20 10 -40 0 -50 -60 -10 0 5 10 15 20 0 5 10 EGR (%) Cylinder Pressure and Heat Release Rate vs. Crank Angle CAT 3500 Full Load 1800 rpm SOI -5 dATDC SOI-5 EGR 10% SOI-5 EGR 15% 10 1250 1000 750 5 500 250 0 Heat Release Rate (J/deg) Cylinder Pressure (Mpa) SOI-5 EGR 5% Peak Cylinder Pressure (MPa) 1500 SOI-5 EGR 0% -20 0 20 40 10.0 8.0 6.0 4.0 2.0 0.0 0 -40 20 Peak Cylinder Pressure vs. EGR CAT 3500 Full Load 1800 rpm SOI -5 dATDC 12.0 15 -60 15 EGR (%) 60 0.0 5.0 Crank Angle (dATDC) 10.0 15.0 EGR (%) Figure 6 Predicted NOx and soot emissions, cylinder pressure history and peak cylinder pressure for SOI= –5 ATDC with various EGR. Figure 6 shows the predicted engine data of using different levels of EGR. Results are consistent with the understanding of EGR that NOx emissions decrease with increased EGR. Approximately a 35% reduction in NOx by increasing EGR by 10% was predicted. It is of interest to note that NOx emissions decrease significantly while the engine cylinder pressure does not decrease noticeably. Also note that the increase in soot emissions by using EGR is not as significant as retarding the injection timing. Note that the stack test data for B20 and B100 are recently available and the modeling is currently being performed for the two biodiesel blends. Modeling results will be presented in the final report as the parametric study data are available for B20 and B100. 10 20.0 5. Modeling Fairbanks Morse Engine at Story City Facilities 5.1 Engine Geometry and Conditions The present computer model was also used to simulate the combustion and emission process of the Fairbanks Morse engine in Story City facility. The engine geometry and operating conditions are provided by Fairbanks Morse Engine. The engine is a two-stroke engine and each cylinder has two opposed pistons compressing against each other, as shown in Fig. 7. The combustion chamber is at the middle section of the cylinder where the fuel injectors are located. Each cylinder has two fuel injector that produce hollow-cone sprays. The entire fuel injection process was modeled as well as the combustion process. Top piston Injector #1 Injector #2 Bottom piston Figure 7 Geometry and computational mesh of the Fairbanks Morse engine. 5.2 Model Calibrations The model was calibrated for the baseline case ( 720 rpm, 0% EGR). A sequence of combustion images with in-cylinder details (fuel spray distribution and combustion temperature) are shown in Fig. 8. It is seen that the two injectors issue fuel spray from the side the cylinder wall toward the center. Some of the liquid drops impinge on the piston surface while pistons are compressing against each other. Auto-ignition occurs at the leading edge of the spray plumes and temperature 11 rises causing liquid fuel continuing to vaporize. Soon after ignition, the entire fuel spray is engulfed in the flame. As time goes by, two flames merge and combustion spreads across the majority of the combustion chamber. The model predicts that combustion is still confined in the center of the combustion chamber with the present two-injector setup, as indicated by the high temperature contours. Figure 9 shows the predicted in-cylinder pressure and temperature histories. The ignition occurs near top-dead-center and the peak cylinder pressure occurs at the early stage of piston expansion. The predicted NOx and soot histories are also shown in Fig. 9. The model was calibrated using the stack test results. Comparisons of measured and predicted NOx and soot emissions for B0, B20 and B100 are shown in Fig. 10. The soot formation rate constant in Eq. (3) is adjusted for different fuel blends. 12 (No combustion yet) (Combustion has started) (Combustion of two fuel spray merges and spread over the combustion chamber.) Figure 8 Predicted fuel spray and combustion temperature in the cylinder at different views for a sequence of timing. 13 FM Engine FM Engine 6 Pressure Temp 70 35 60 5 NOx 1000 2 500 50 25 40 20 30 15 20 10 Soot 1 10 5 0 0 0 -100 -50 0 50 Soot (g/kg-f) 3 30 NOx (g/kg-f) 1500 4 Gas Temperature (K) Cylinder Pressure (MPa) 40 2000 0 100 -40 -20 Crank Angle (TDC) 0 20 40 60 80 100 Crank Angle (TDC) Figure 9 Histories of in-cylinder pressure, average combustion temperature, NOx and soot emissions. FM Engine FM Engine 3 NOx - Test NOx - Model Soot - Test Soot - Model 0.25 Emissions (lb/MMBTU) Emissions (lb/MMBTU) 2.5 0.3 2 1.5 1 0.5 0.2 0.15 0.1 0.05 0 0 0 20 100 0 Biodiesel Blend (%) 20 100 Biodiesel Blend (%) Figure 10 Comparisons of test data and model prediction for NOx and soot emissions after model calibration. 5.3 Parametric Study After model calibration for different fuel blends, parametric study was performed to investigate effects of EGR and SOI on NOx and soot emissions for B20 and B100. Results are shown in Fig. 11. By delaying the fuel injection timing from –5 ATDC to 0 ATDC, approximately 25% reduction in NOx can be obtained for both B20 and B100. Further retarding injection timing can benefit 14 NOx reduction for B20 but no further NOx reduction was predicted for B100. On the other hand, for using EGR, an average of 25% reduction in NOx per 10% EGR can be achieved. Such effects of EGR on the reduction in NOx are similar for both B20 and B100. Although EGR seems to be more effective and consistent in reducing NOx emissions for B20 and B100, the increase in soot emissions is more significant for EGR cases. In addition, considering the requirement in hardware modification to implement the EGR system, retarding the injection timing by 5 crank angle degrees seems to be a more feasible means for NOx reduction for burning biodiesel blends without significant penalty of soot emissions. B20 B100 20 60 10 40 Emission Variation (%) Emission Variation (%) Soot increase 0 -10 -20 -30 NOx reduction -40 Soot increase 20 0 NOx reduction -20 -50 -60 -40 -5 0 SOI (ATDC) 5 10 -5 0 B20 5 10 B100 150 150 100 100 Soot increase Emission Variation (%) Emission Variation (%) SOI (ATDC) 50 0 NOx reduction -50 Soot increase 50 0 NOx reduction -50 -100 -100 0 5 10 15 20 25 30 35 0 EGR (%) 5 10 15 20 25 30 35 EGR (%) Figure 11 Predicted NOx and soot emissions, cylinder pressure history and peak cylinder pressure for SOI= –5 ATDC with various EGR. 15 6. Summary The present computer models were validated by emissions test data for a Caterpillar engine and a Fairbanks Morse engine used in municipal facilities. Trends of soot and NOx emissions for different biodiesel blends are predicted by the model. Parametric studies were performed to investigate effects of fuel injection timing and exhaust gas recirculation on NOx emissions reduction. Model results indicate that NOx can be reduced by retarding the injection timing or increasing exhaust gas recirculation rates because both methods can create a lower combustion temperature environment that can reduce NOx formation. For the Caterpillar engine studied, an average of 20% reduction in NOx emissions can be achieved by retarding injection timing for 5 crank angle degrees. On the other hand, a 35% reduction in NOx can also be achieved per 10% exhaust gas recirculation rates. For the Fairbanks Morse engine, by delaying the fuel injection timing from –5 ATDC to 0 ATDC, approximately 25% reduction in NOx can be obtained for both B20 and B100. In using exhaust gas recirculation, an average of 25% reduction in NOx per 10% EGR can be achieved but with significant penalty in soot emissions. Model results indicate that both NOx reduction strategies can be effective. However, exhaust gas recirculation requires extensive hardware modifications to the intake and exhaust manifolds, the cost may be significant, in particular for large diesel engines. Therefore, it is concluded that retarding injection timing would be a more feasible means to reduce NOx emissions from burning biodiesel blends in large utility generators. 16 7. References EPA, Research Triangle Park, North Carolina, Compilation of Air Pollutant Emissions Factors, AP-42 Fifth edition, Volume 1, stationary point and and area sources, January 2005. Website: http://www.epa.gov/ttn/chief/ap42/index.html Iowa Administrative Code, Section 567, Chapters 20-32. Iowa Administrative Rules for Air Quality, 2005. Kong, S.C., Han, Z. and Reitz, R.D. “The Development and Application of a Diesel Ignition and Combustion Model for Multidimensional Engine Simulations,” Journal of Engines, Vol. 104, pp. 502-518 (1995). Kong, S.C. and Reitz, R.D. “Multidimensional Modeling of Diesel Ignition and Combustion Using a Multistep Kinetics Model,” J. Engng Gas Turbines Power, Vol.101, pp.781-789 (1993). Kong, S.C., Senecal, P.K. and Reitz, R.D. “Developments in Spray Modeling in Diesel and Direct-Injection Gasoline Engines,” Oil & Gas Science and Technology – Rev. IFP, Vol. 54, No. 2, pp. 197-204 (1999). McCormick, R.L., Alvarez, J.R., Graboski, M.S., Tyson, K.S. and Vertin, K. “Fuel Additive and Blending Approaches to Reducing NOx Emissions from Biodiesel,” SAE 2002-01-1658, 2002. Mueller, C., Private Communication, Combustion Research Facilities, Sandia National Laboratory, Livermore, CA, 2005. Sato, Mki., J. Hansen, D. Koch, A. Lacis, R. Ruedy, O. Dubovik, B. Holben, M. Chin, and T. Novakov. Global atmospheric black carbon inferred from AERONET. Proc. Natl. Acad. Sci. 100, 6319-6324, doi:10.1073/pnas.0731897100, 2003. Szybist, J.P. and A. L. Boehman “Behavior of a Diesel Injection System with Biodiesel Fuel,” SAE 2003-01-1039, 2003. 17 Szybist, J.P., Simmons, J., Druckenmiller, M., Al-Qurashi, K., Boehman, A.L. and Scaroni, A. “Potential Methods for NOx Reduction from Biodiesel,” SAE 2003-01-3205, 2003. Yoshimoto, Y. and Tamaki, H. “Reduction of NOx and Smoke Emissions in a Diesel Engine Fueled by Biodiesel Emulsion Combined with EGR,” SAE 2001-01-0649, 2001. Zarling, D.D., Bickel, K.L., Waytulonis, R.W. and Sweeney, J.R. “Improving Air Quality by Using Biodiesel in Generators,” SAE 2004-01-3032, 2004. 18