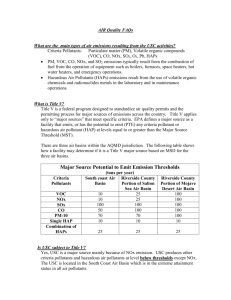

2003-360-C M-1 PSD - the Oklahoma Department of Environmental

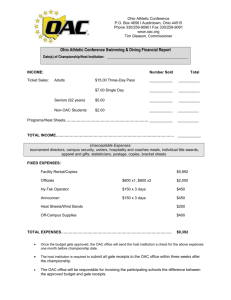

advertisement