MiniVol 8 hour run SOP

advertisement

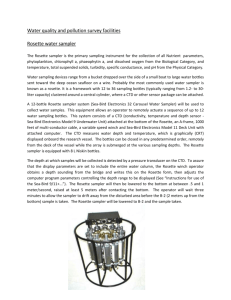

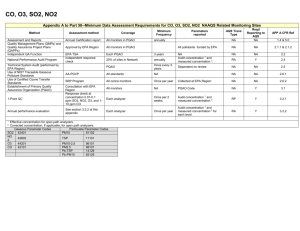

MiniVol Feb. 11-12, 2004 TAMS Assessing Ambient Air Quality using the MiniVol Sampler Objectives Participants will: 1. Gain experience in quantitative collection of airborne particulates. 2. Keep a Data Record Sheet. 3. Be able to explain how to use the MiniVol sampler. 4. Understand that weather conditions can influence the concentration of airborne particulates. 5. Calculate the ambient air concentration of PM10 in an 8-hour period. Background Information In some areas, suspended particulate matter is the most significant contributor to air pollution. Mass concentration is defined as the total mass of particulate matter per volume of air, usually expressed in micrograms per cubic meter (g/m3). Measurements include all particles with a mean diameter of 10 micrometers (PM10) or smaller (PM2.5). The MiniVol consists of a vacuum pump that is calibrated to draw in a fixed volume of air of 5.0 liters per minute (L/min). Air is drawn through a particle size separator and then through a fiberglass or Teflon filter which acts as a barrier to particles. Particle size separation is achieved by impaction. The average concentration of particulate matter per cubic meter of air can be calculated by weighing the filter before and after the sampling run, and correlating the particulate weight to the volume of air drawn through the pump. To accommodate for the 8-hour sample run, the filter will be pre-dried and pre-weighed. 8 hour SOP MiniVol Feb. 11-12, 2004 TAMS Setting up the sample run At the monitoring site: 1. Ensure that the sampler is upright and at least 30 centimeters from any obstacle to air flow. 2. Remove the filter holder assembly from the plastic bag and attach it to the quick connect located at the top of the MiniVol sampler. 3. Pressing the two silver buttons on the sampler, lift the pump and timer assembly up and rest it on the edge of the sampler casing, using the triangular mount stand. Take care not to pull the connecting wire loose or jar the pump hose fittings. Hold the top cap and do NOT grasp the center of the circuit board. 4. To obtain the beginning flow rate, press the On/Auto/Off button twice to start the pump. On the display, a horizontal bar should be above the word “On.” 5. Wait 30-45 seconds to allow the flow rate to stabilize then record the reading on your Data Record Sheet. If the flowmeter indicates zero or a very low reading, see a workshop instructor for assistance. NOTE: the “thresh” indicator light will always be on when the sampler is attached to a power source. 6. Press the ON/AUTO/OFF button twice to stop the pump. 7. Press the ON/AUTO/OFF button once to set the timer to the “Auto” mode. 8. Confirm that the correct local time is displayed on the screen. If not, see workshop instructor for assistance. 9. To set the timer, press the PROG button once. 1ON will appear near the lower left corner of the display indicating that the power-on time for the first cycle is ready to be programmed. 10. Press the HOUR and MIN buttons to enter the power-on time for the first cycle. 11. Press the WEEK button to select the desired day. NOTE: When more than one day is displayed, it means you are programming the sampler to have the same power-on time for all days. Be careful to choose just one day. 12. After you have entered the power-on time and date for the first cycle, press the PROG button once. 1OFF now appears on the display to indicate that the power-off time for the first cycle is ready to be programmed. 13. Press the HOUR and MIN buttons to enter the power-off time. 14. Press the WEEK button to select the desired day. Be careful not to select the same day as the power-on day. 15. Press the CLOCK button to return to the real-time clock display. 16. Place the pump and timer assembly back into the sampler body. Press the two silver buttons and allow assembly to fall into place. 17. Record the following information on your Data Record Sheet: MiniVol identification numbers (sampler and battery) Start Time and Date Elapsed Time (beginning) – located on top of timer assembly Ambient Temperature Barometric Pressure Note any other observations at site (clear skies, cloudy, rainy, snow, smog, nearby fires, etc.) 8 hour SOP MiniVol Feb. 11-12, 2004 TAMS Completing the sample run At the monitoring site: 1. Make sure the MiniVol has completed its sampling run. If so, wait for the sampling run to end. 2. Pressing the two silver buttons on the sampler, lift the pump and timer assembly out by the top cap and rest it on the edge of sampler body using the triangular mount stand. Take care not to pull the connecting wire loose and hold the top cap. 3. Check the sampler face plate for any error lights. If an error exists, notify the workshop instructor. 4. Verify the correct time and day of week on the display. 5. To obtain the ending flow rate, press the ON/AUTO/OFF button once to start the pump. 6. Allow the flow rate to stabilize then record your reading on the Data Record Sheet. 7. Press the ON/AUTO/OFF button twice to stop the pump. 8. Record the following information on your Data Record Sheet: MiniVol identification numbers (sampler and battery) End Time and Date Elapsed Time (ending) – located on top of timer assembly Ambient Temperature Barometric Pressure Any other observations at site (clear skies, cloudy, rainy, snow, smog, nearby fires, etc.) 9. Place the pump and timer assembly back into the sampler body. Press the two silver buttons and allow the assembly to fall into place. Disconnect the filter holder assembly from the MiniVol female quick-disconnect. Calculating the PM concentration Since this is an abbreviated training and time does not allow for participants to post-dry and post-weigh the filters, weights will be given to participants to complete the calculations. Questions/Discussion 1. Why must the filter be dry before weighing it? 2. How could weather affect the measurement? 3. Was the weather conducive to an inversion? 8 hour SOP MiniVol Feb. 11-12, 2004 TAMS DATA RECORD SHEET for MINIVOL AIR SAMPLER Initial Equilibration Filter Identification Number: Beginning Time: Beginning Date: Pre-Sampling Information Equilibration End Date: Equilibration End Time: Initial Filter Weight: Elapsed Time (Start): Sample Start Time: Sample Start Date: Sampler ID: Sampler Battery ID: Flow Rate: Ambient Temperature: Barometric Pressure: Observations/Comments: Post-Sammpling Information Sample End Date: Sample End Time: Flow Rate: Ambient Temperature: Barometric Pressure: Elapsed Time (End): Observations/Comments: Post-Sampling Equilibration Filter Identification Number: Beginning Date: Beginning Time: Equilibration End Date: Equilibration End Time: Final Weight of Dry Filter: 8 hour SOP MiniVol Feb. 11-12, 2004 TAMS CALCULATION SHEET for MINIVOL AIR SAMPLER 1. Calculate total particulate weight (in grams) as follows: Final Weight of Dry Filter - Initial Weight of Dry Filter = grams - Total Particulate Weight grams grams 2. Calculate total time sampler ran (in minutes): total hours x 60 minutes/hour = minutes 3. Calculate average flow rate for the sampling period (in L/min): Initial Flow Rate + Final Flow Rate = L/min 2 4. Calculate volume of air sampled (in liters): Flow Rate L/min x Time = Volume Sampled x minutes = liters = g 5. Convert particulate weight from grams to micrograms: grams x 1 x 106 g/gram 6. Convert volume of air sampled from Liters to Cubic Meters: Liters x 1 m3 1 x 103 liters = m3 7 Calculate average particulate concentration (in g/m3): Particulate Weight g 8 hour SOP ÷ ÷ Volume of Air Sampled = Average Particulate Concentration m3 = g/m3