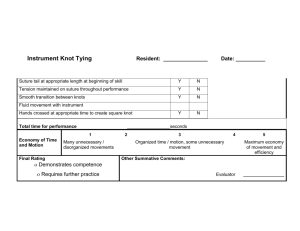

8.3 Implementation Requirements

advertisement