P209 - World Journal of Engineering

advertisement

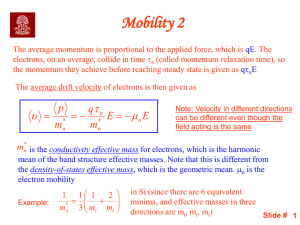

World Journal Of Engineering Formation of InAs Nanowire by Solid Source Reaction: A promising material as the high mobility channel for nanoelectronics Yu-Lun Chuch§,*, Alexandra C. Ford†, and Ali Javey† Abstract- InAs nanowires have been actively explored as the channel material for high performance transistors owing to their high electron mobility and ease of ohmic metal contact formation. In present study, the InAs NWs are simply synthesized by using solid source reaction approaches. The nanowires show superb electrical properties with electron mobility >3000 cm2/Vs and ION/IOFF ~104. The detailed current-voltage (I-V) for individual InAs NWs with different radius at different temperatures is reported, enabling the direct assessment of electron mobility as a function of NW diameter. The fundamental kinetics of the Ni/InAs alloying reaction is explored with the Ni diffusion reported as the rate determining step with diffusion activation energy of ~1 eV/atom. The uniformity of the grown InAs nanowires is further demonstrated by large-scale assembly of parallel arrays of nanowires on substrates for high performance. BACKGROUND1 Semiconductor nanowires, especially for Si1 and Ge2 nanowires, have been spent much attention on acquiring the best performance. However, low electron mobility of Si limits the device performance. Recently, by using the bandgap lineup concept, Ge/Si core-shell, which confines electrons transported along the axial direction, opens a route of realizing the highest device performance for Si-based nanowire.3 III-V compound semiconductor nanowires are the best candidate materials for high speed and low power devices due to the extremely high electron mobility.4 InAs nanowires have been reported to have promising high speed nanodevices application due to (1) low effective mass and small bandgap, resulting in the high electron mobility and (2) high electron gas accumulated at the surface of NW owing to Fermi level pinning above the conduction band after contacting with metal electrode.5 In present study, InAs NWs are simply synthesized by using solid source reaction approaches. The detailed microstructure and I-V behavior will be analyzed. Of particular interest is the dependence of the carrier mobility on InAs NW radius, especially since smaller NWs are highly attractive for § Department of Materials Science and Engineering, National Tsing Hua University, Hsinchu, Taiwan 300, ROC . † Department of Electrical Engineering and computer Sciences, University of California at Berkeley, Berkeley, CA, 9720, USA. *contacting author, ylchueh@mx.nthu.edu.tw). phone:+886-3-5715131ext33965;E-mail: the channel material of nanoscale transistors as they enable improved electrostatics and lower leakage currents. Therefore, the detailed current-voltage (I-V) for individual InAs NWs with different radius at different temperatures is reported, enabling the direct assessment of electron mobility as a function of NW diameter. On the other hand, one of the major challenges associated with nanowire devices, and all nanoscale devices in general, is the development of nanoscale and ohmic Source/Drain (S/D) contacts. To address this challenge, developing and characterizing metal/InAs alloys with low resistivity and abrupt interfaces as the contact material to InAs is of major interest. Here, we report the formation and materials properties of NixInAs/InAs/NixInAs heterojuction and NixInAs NWs by using a simple solid source reaction of Ni with InAs NWs at annealing temperatures of 220-300 ℃ in different ambient conditions. The diffusion kinetics of Ni atoms inside InAs NWs and the electrical properties of the fabricated devices with ohmic NixInAs contacts are investigated in detail. MATHERIALS AND METHODS The growth furnace consisted of two independently controlled temperature zones, one for the solid source and the other for the sample. Ni nanoclusters used for InAs nanowire growth were obtained by thermal annealing (800-900ºC) of thin Ni films (thermally evaporated) on Si/SiO2 (50 nm thermally grown) substrates in a hydrogen environment. After the thermal annealing process, the sample temperature was decreased to 470-550 ºC, and InAs NWs were grown for ~1 hr by vaporization of InAs solid source (source temperature 720ºC. The pressure was maintained constant at ~1 torr. InAs NWs were harvested in an ethanol solution by a gentle sonication process, and drop-casted on a p+Si/SiO2 (~50 nm, thermally grown) substrate. Metal source/drain (S/D) contacts were then defined by photolithography, Ni evaporation (~50 nm thick), and lift-off. To ensure an ohmic contact formation, a 5 sec HF etch (~0.1%) was applied immediately prior to the Ni contact evaporation to remove the native oxide on the exposed NW surfaces. The surface morphology was examined by a field-emission scanning electron microscope (JSM-6500F), operated at 15 kV. In order to prepare the TEM specimen, all samples were sonicated in ethanol and then dispersed in copper grid supported by a holy carbon film. A field-emission transmission electron microscope (JEM-2100 F), operated at 200 kV, with a point-to-point resolution of 0.17 nm and equipped with an energy dispersion spectrometer (EDS) was used to characterize the microstructures and chemical compositions. 209 World Journal Of Engineering RESULTS dNP ~ 10 nm (from 1.5 nm Ni film) (d) (c) dNP ~ 27 nm dNW ~ 38 nm (from 3 nm Ni film) (e) (f) Figure 1 (a) AFM images and NP diameter distribution histograms for Ni particles resulting from the thermal anneal of (a) ~0.5 nm, (c) ~1.5 nm, and (e) ~3 nm Ni films at 850 ºC for 10 min. All AFM images show an area of 1 μm x 1 μm. (b) SEM images and nanowire diameter distribution histograms for InAs nanowires grown using Ni catalyst particles produced by the thermal anneal of (b) 0.5 nm, (d) 1.5 nm, and (f) 3 nm Ni films. SEM image insets clearly show the Ni catalyst tips at the ends of the nanowires, depicting the tip-based growth mechanism. (a) (b) 20000 2 ~422 (cm /Vs)/nm 7000 Mobility (cm /Vs) 6000 5000 2 2 8000 4000 3000 2000 1000 T =298 K T =50 K 16000 12000 8000 4000 0 0 5 10 15 Radius (nm) 20 5 10 15 Radius (nm) 20 Figure 2 (a) Mobility as a function of radius for more than 50 different devices with NWs ranging from 7-18 nm in radius post oxide subtraction. Over this NW radius range, the mobility linearly increases with radius, closely fitting the linear expression µn=422r-1180. (b) Temperature dependent electron transport properties for four NWs of different radius at temperatures of 50 and 298 K. (a) NiXInAs InAs 250 nm (b) 10 -5 10 -6 10 -7 10 -8 10 -9 10 (c) Ni NiXInAs L: 280 nm D: 30 nm 16 12 VDS=0.3 V 8 4 0 -4 -2 0 2 4 VGS (V) X Axis Title -4 -2 0 VGS(V) 2 Ni 200 nm Vd=0.3 V Vd=0.1 V Vd=10 mV -10 InAs 4 (d) 10 -4 10 -5 10 -6 10 -7 10 -8 10 -9 -6 L: 400 nm D: 36. 5 nm Vd=0.3 V Vd=0.1 V Vd=10 mV 12 8 4 0 IDS (μA) [5] dNW ~ 26 nm IDS(A) [4] (b) dNP ~ 14 nm IDS (A) [3] G. Zheng, W. Lu, S. Jin, C. M. Lieber, Adv. Mater. 2004, 16, 1890. D. Wang, Q. Wang, A. Javey, R. Tu, H. Dai, H. Kim, P. C. Mclntyre, T. Krishnamohan, K. Saraswat, C. Appl. Phys. Lett. 2003, 83, 2432. G. Liang, J. Xiang, N. Kharche, G. Klimeck, C. M. Lieber, M. Lundstrom, Nano Lett. 2007, 7, 642. Y. Li, J. Xang, F. Qian, S. Gradecak, Y. Wu, H. Yan, D. Blom, C. M. Lieber, Nano Lett, 2006, 6, 1468. T. Beyllert, L. E. Wernersson, , L. E. Froberg, L. Samuelson, IEEE Electr Device 2006, 72, 323. (a) IDS (μA) REFERENCES [1] [2] dNW ~ 23 nm (from 0.5 nm Ni film) Field-Effect Mobility (cm /Vs) Direct annealing Ni film with controllable thickness is a remarkably effective approach to control the diameter of Ni NPs with discrepancy below ~10 % for the growth of InAs NWs. Figure 1 shows the atomic force microcopy (AFM) images and corresponding particle diameter distributions of Ni particles formed by the thermal annealing of 0.5 nm (Fig. 1a), 1.5 nm (Fig. 1c), and 3 nm (Fig. 1e) Ni films at 850 ºC for 10 min. The NP diameters obtained from the 0.5, 1.5, and 3 nm films are 10±2, 14±3, and 26±5 nm, respectively. After InAs growth, Ni NPs can be clearly observed at the tip of most nanowires (Fig. 1), which is a distinct characteristic of the tipbased, VLS/VSS growth mechanism. The NW diameter shows a direct correlation with the catalytic NP diameter. Nanowire diameters of 23±6, 26±8, and 38±9 nm were obtained for 10, 14, and 26 nm NPs, respectively. The variation for the grown nanowires is 25-32% which is slightly larger than that of the NP distribution. Figure 2a illustrates the peak mobility as a function of InAs NW radius for more than 50 different FETs with r=7-18 nm. Over this NW radius range, the mobility linearly increases with radius with a slope of ~422 (cm2/Vs)/nm. In an effort to shed light on the source of mobility degradation for smaller NWs, temperature-dependent electron transport measurements were conducted, as shown in Figure 2b, indicating a linear enhancement of the peak electron mobility from ~6,000 to 16,000 cm2/Vs as the temperature is reduced from 298 K to 200 K. Below ~200K, minimal change in the mobility is observed, which is attributed to the surface roughness scattering caused by acoustic phonon and/or surface/interface trap states. Figure 3 shows how the device improvement as the bulk Ni contacts (fabricated by e-beam lithography) replaced by NixInAs NW contacts. Data clearly illustrates the advantage of using nanoscale contacts for improved electrostatics. Vd=0.3 V -4 -2 0 2 4 6 VGS (V) X Axis Title -3 0 VGS (V) 3 6 X Axis Title Figure 3. (a) SEM image of a short channel, back-gated FET formed by using the InAs metallization approach, with nanoscale NixInAs contacts. The channel length is ~280 nm. (b) The corresponding IDS-VGS behaviors at VDS=10 mV, 0.l V and 0.3 V. Inset shows the linear scale IDS-VGS at VDS=0.3V. (c) SEM image of a short channel, back-gated FET fabricated by electron-beam lithography, with bulk Ni contacts. The channel length is ~400 nm. (d) The corresponding IDS-VGS behaviors at VDS=10 mV, 0.1 V, and 0.3 V. Inset shows the linear scale of IDS-VGS at VDS=0.3V. 210