1024 Dynamic - KMML-The Kerala Minerals and Metals Limited

advertisement

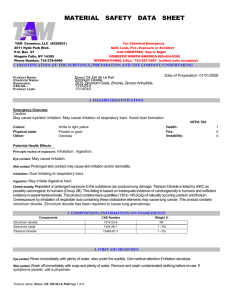

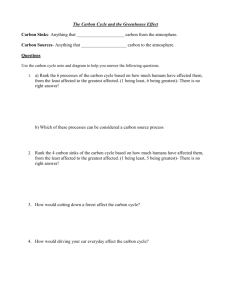

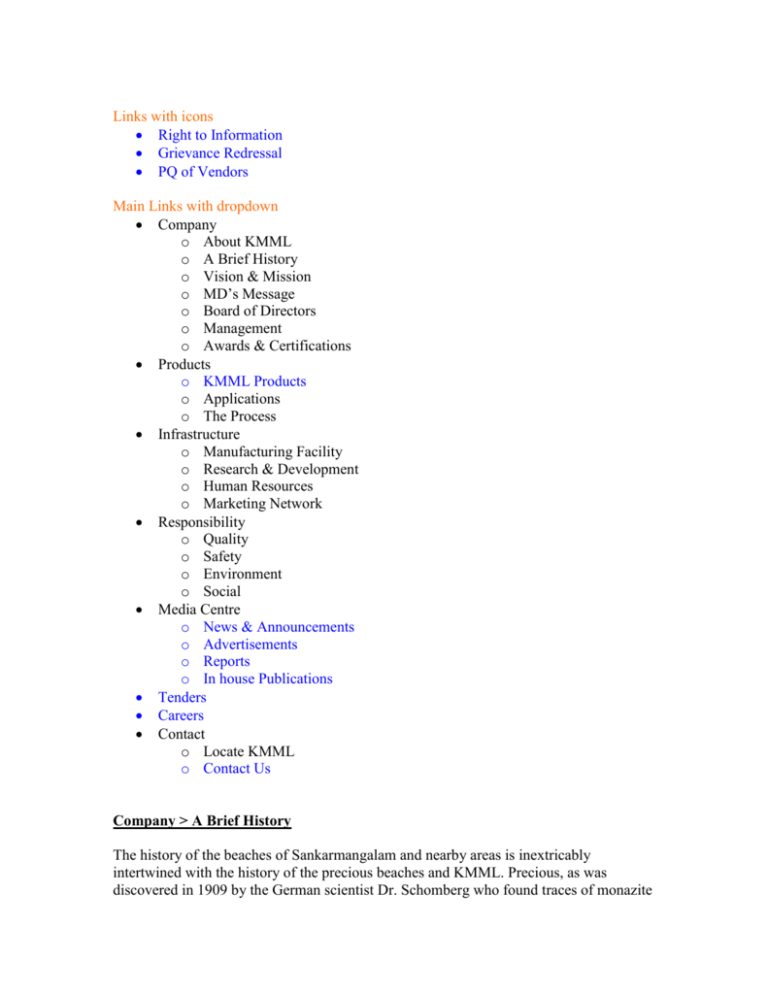

Links with icons Right to Information Grievance Redressal PQ of Vendors Main Links with dropdown Company o About KMML o A Brief History o Vision & Mission o MD’s Message o Board of Directors o Management o Awards & Certifications Products o KMML Products o Applications o The Process Infrastructure o Manufacturing Facility o Research & Development o Human Resources o Marketing Network Responsibility o Quality o Safety o Environment o Social Media Centre o News & Announcements o Advertisements o Reports o In house Publications Tenders Careers Contact o Locate KMML o Contact Us Company > A Brief History The history of the beaches of Sankarmangalam and nearby areas is inextricably intertwined with the history of the precious beaches and KMML. Precious, as was discovered in 1909 by the German scientist Dr. Schomberg who found traces of monazite in the sand flakes on the imported coir from Sankaramangalam. The beaches with a wealth of rare earth minerals became the centre of scientific attraction. By 1932, a visionary private entrepreneur established the F. X. Perira and Sons (Travancore) Pvt. Ltd, the forerunner to KMML. During the course of time, KMML changed hands three times over. In 1956 it was taken over by the state government and was placed under the control of the industries department. The unit was subsequently converted as a limited company in 1972 by the name of ‘The Kerala Minerals and Metals Ltd.’ Today, with over 2000 employees and a range of products, KMML has become part and parcel of local and international life. Products > KMML Products The Kerala Minerals and Metals Ltd (KMML) is the world’s first fully integrated Titanium Dioxide plant. KMML is also India’s first and only manufacturer of Rutile Grade Titanium dioxide by chloride process. KEMOX RC 822 from KMML is a multiple application pigment, which is in great demand in the world market. We also produce other grades of Titanium Dioxide pigments like RC 800 PG, RC 800, RC 802, RC 813, RC 822 and RC 808. Minerals like Zircon and Monazite are used in the development of Nuclear Technology. We manufacture Iron oxide bricks from the waste Iron Oxide, which is used for building purpose. The KMML Titanium pigments are reputed for their high degree of gloss, tint retention capacities and ease of dispersion. KMML Product Range: o Titanium Dioxide Pigment (Rutile) KEMOX RC 800 KEMOX RC 813 KEMOX RC 802 KEMOX RC 808 KEMOX RC 822 KEMOX RC 800 PG o Titanium Tetra Chloride o Ilmenite o Rutile o Leucoxene o Zircon o Sillimenite o Monazite o Iron Oxide Bricks KEMOX RC 800 CHLORIDE PROCESS TITANIUM DIOXIDE RUTILE TITANIUM DIOXIDE General Description Kemox RC 800 is a low oil absorption medium durable alumina treated rutile titanium dioxide pigment produced by the chloride process. It has high gloss producing properties for interior trade sale paints and industrial coatings. It exhibits high brightness excellent tint strengths in gloss and semi-gloss enamels. Applications Kemox RC 800 is recommended for printing inks, high gloss coating, industrial coating, low abrasivity pigment for letterpress gravure polyamides and exterior applications where maximum chalk resistance is not required. Typical Properties Titanium Dioxide (min) % Rutile Content (min) % Specific Gravity Bulk Density (g/cc) Treatment Oil absorption (max) pH 95 99 4.1 0.88 Al 18 g oil/100 g pigment 5.0 to 8.0 Volatile matter at 105ºC (%) Average particle size microns, (Microtrac) Grit (325 mesh) % max ISO 591 Clause 0.5 0.30 to 0.35 0.004 R2 Packaging 25 kg multi wall paper bags Did you know? Find here all you need to know about Titanium dioxide > Slide Show 1. Titanium dioxide (TiO2), also referred to as Titania, is a substance as old as the earth itself. 2. Titanium dioxide is readily mined in its purest form from beach sand. The beaches of Sankarmangalam and nearby areas in Kollam are inextricably intertwined with the history of this substance and KMML. 3. Dr. Schomberg, a German Scientist, discovered in 1909 traces of monazite in the sand flakes on the imported coir from Sankaramangalam. The beaches with a wealth of rare earth minerals became the centre of scientific attraction. 4. KMML is the world’s first fully integrated Titanium dioxide plant. Established in 1932 as F. X. Perira and Sons (Travancore) Pvt. Ltd., by a visionary private entrepreneur, it was taken over by the State Government in 1956, and became a public limited company in 1972 in the name ‘The Kerala Minerals and Metals Ltd. (KMML)’. 5. Crude Titanium dioxide is chemically processed to remove impurities such as iron, leaving the pure, white pigment available for use. 6. KMML is India’s first and only manufacturer of Rutile Grade Titanium dioxide by chloride process. 7. The chloride process produces TiO2 products by reacting titanium ores with chlorine gas. 8. Crude titanium dioxide is purified via titanium tetrachloride in the chloride process. In this process, the crude ore (containing at least 90% TiO2) is reduced with carbon, oxidized with chlorine to give titanium tetrachloride. This titanium tetrachloride is distilled, and re-oxidized with oxygen to give pure titanium dioxide. 9. The Titanium dioxide is then classified and surface treated with various chemicals, filtered and washed to remove the salts, sent to the dryer and then to the micronizer. The Titanium dioxide pigment (in powder form) is subsequently packaged. 10. The plant uses recycling and regeneration methods at various levels of processing, including acid regeneration, which ensures negligent pollution. Know TiO2 Titania exists in a number of crystalline forms the most important of which are anatase and rutile. Pure titanium dioxide does not occur in nature but is derived from ilmenite or leuxocene ores. It is also readily mined in one of the purest forms, rutile beach sand. These ores are the principal raw materials used in the manufacture of titanium dioxide pigment. The first step is to purify the ore, and is basically a refinement step. Either the sulphate process, which uses sulphuric acid as an extraction agent or the chloride process, which uses chlorine, may achieve this. After purification the powders may be treated (coated) to enhance their performance as pigments. Titanium dioxide is by far the most widely used white pigment. Titania is very white and has a very high refractive index (n=2.7) – surpassed only by diamond. The refractive index determines the opacity that the material confers to the matrix in which the pigment is housed. Hence, with its high refractive index, relatively low levels of titania pigment are required to achieve a white opaque coating. Properties of TiO2 & its Applications The high refractive index and bright white colour of titanium dioxide make it an effective opacifier for pigments. The material is used as an opacifier in glass and porcelain enamels, cosmetics, sunscreens, paper, and paints. One of the major advantages of the material for exposed applications is its resistance to discoloration under UV light. Titania acts as a photosensitiser for photovoltaic cells, and when used as an electrode coating in photoelectrolysis cells can enhance the efficiency of electrolytic splitting of water into hydrogen and oxygen. Even in mildly reducing atmospheres titania tends to lose oxygen and become sub stoichiometric. In this form the material becomes a semiconductor and the electrical resistivity of the material can be correlated to the oxygen content of the atmosphere to which it is exposed. Hence titania can be used to sense the amount of oxygen (or reducing species) present in an atmosphere. The photocatalytic activity of titania results in thin coatings of the material exhibiting self cleaning and disinfecting properties under exposure to UV radiation. These properties make the material a candidate for applications such as medical devices, food preparation surfaces, air conditioning filters, and sanitary ware surfaces. When deposited as a thin film, its refractive index and colour make it an excellent reflective optical coating for dielectric mirrors and some gemstones, for example "mystic fire topaz". TiO2 offers great potential as an industrial technology for detoxification or remediation of wastewater due to several factors. Highlights of TiO2 Titanium Dioxide is the most widely used white pigment because of its brightness, high refractive index, opacity and its strong UV light absorbing capabilities. Titanium Dioxide is used to provide whiteness and opacity to products such as paints, coatings, plastics, papers, inks, foods, medicines, toothpastes etc. Titanium Dioxide is used as a white food colouring, tattoo pigment and styptic pencils. In cosmetic and skin care products, titanium dioxide is used both as a pigment and a thickener. TiO2 pigments are inert, do not react with other materials and are thermally stable, non-flammable and non toxic.