C1a-13_Titanium

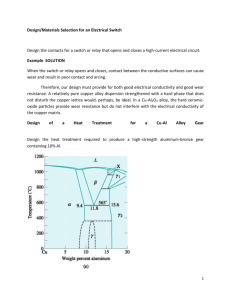

advertisement

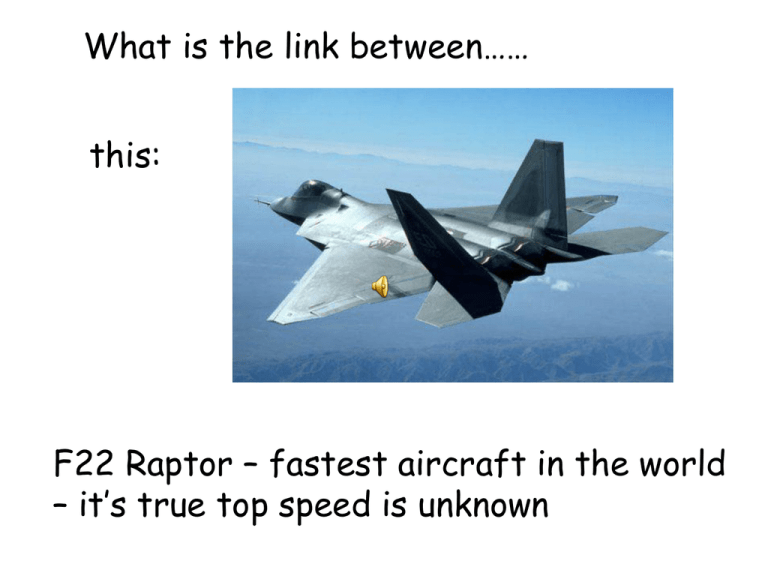

What is the link between…… this: F22 Raptor – fastest aircraft in the world – it’s true top speed is unknown … and this? artificial hip replacements Both the Raptor and hip replacement joints are made from the metal Titanium Titanium is a transition metal – where in the Periodic Table would you find it? Titanium Properties of titanium: • VERY STRONG – as strong as steel but 45% lighter • RESISTS CORROSION – more resistant to acids and alkalis than aluminium, iron and magnesium • LOW DENSITY – so LIGHT and EASY TO SHAPE • VERY HIGH MELTING POINT 1800oC • CAN WITHSTAND EXTREMES OF TEMPERATURE when ALLOYED with aluminium and vanadium Uses of titanium: • It’s strength, light weight and resistance to corrosion make titanium alloy a good material to use in biomedical components e.g. hip replacements It’s resistance to corrosion means titanium alloy is used to make: • ship parts that would be exposed to seawater, e.g. hulls and propeller shafts • structural components in chemical plants Because of its strength combined with light weight, titanium alloy is also used to make: military armour plated vehicles Aircraft e.g. the Raptor Titanium alloy can withstand very high temperatures so it is commonly used in structural components in: • aircraft • satellites • spacecraft Extraction of titanium: • Titanium is not found as an element – it is extracted from its ore rutile in the Kroll process • In rutile, titanium is found as titanium dioxide, TiO2 • Because titanium is more reactive than carbon, it cannot be extracted in a blast furnace using carbon • Titanium dioxide is covalently bonded so cannot be extracted from its ore by electrolysis • 99% of world’s titanium is produced by the Kroll process: Titanium dioxide Titanium chloride TiO2 heated with carbon and chlorine Titanium Reaction with molten magnesium displaces titanium Why don’t we use titanium more often if it is so useful? • Titanium is the 4th most abundant metal on Earth, after aluminium, iron and magnesium but it is VERY EXPENSIVE • Pure titanium costs £8,000 per tonne • Titanium alloy costs £20,000 - £30,000 per tonne • Compared to aluminium and steel alloys which cost £1,000 - £2,000 per tonne • Cleaner, quicker and cheaper method, the Fray process, now developed in which electrolysis is used to ‘suck out’ the oxygen from titanium dioxide, leaving a porous sponge of titanium metal • Metals other than titanium now being extracted by this process • Process also allows alloys to be produced directly from mixtures of oxides e.g. mixture of TiO2 and Nb2O5 gives superconducting alloy NbTi