Assignment 2 – Quantum Physics

advertisement

HPH412 Instrumentation

Transducers

Transducers are electric or electronic devices that transform energy from one manifestation into another. Most people, when they

think of transducers, think specifically of devices that perform this transformation in order to gather or transfer information, but

really, anything that converts energy can be considered a transducer.

Transducers that detect or transmit information include common items such as microphones, Geiger meters, potentiometers,

pressure sensors, thermometers, and antennae. A microphone, for example, converts sound waves that strike its diaphragm into

an analogous electrical signal that can be transmitted over wires. A pressure sensor turns the physical force being exerted on the

sensing apparatus into an analog reading that can be easily represented. While many people think of transducers as being some

sort of technical device, once you start looking for them, you will find transducers everywhere in your everyday life.

Most transducers have an inverse that allows for the energy to be returned to its original form. Audio cassettes, for example, are

created by using a transducer to turn the electrical signal from the microphone pick-up – which in turn went through a transducer to

convert the sound waves into electrical signal – into magnetic fluctuations on the tape head. These magnetic fluctuations are then

read and converted by another transducer – in this case a stereo system – to be turned back into an electrical signal, which is then

fed by wire to speakers, which act as yet another transducer to turn the electrical signal back into audio waves.

Other transducers turn one type of energy into another form, not for the purpose of measuring something in the external

environment or to communicate information, but rather to make use of that energy in a more productive manner. A light bulb, for

example, one of the many transducers around us in our day-to-day lives, converts electrical energy into visible light. Electric

motors are another common form of electromechanical transducer, converting electrical energy into kinetic energy to perform a

mechanical task. The inverse of an electric motor – a generator – is also a transducer, turning kinetic energy into electrical energy

that can then be used by other devices.

As in all energy conversions, some energy is lost when transducers operate. The efficiency of a transducer is found by comparing

the total energy put into it to the total energy coming out of the system. Some transducers are very efficient, while others are

extraordinarily inefficient. A radio antenna, for example, acts as a transducer to turn radio frequency power into an electromagnetic

field; when operating well, this process is upwards of 80% efficient. Most electrical motors, by contrast, are well under 50%

efficient, and a common light bulb, because of the amount of energy lost as heat, is less than 10% efficient.

A transducer is a device, usually electrical, electronic, electro-mechanical, electromagnetic, photonic, or photovoltaic that

converts one type of energy or physical attribute to another for various purposes including measurement or information

transfer (for example, pressure sensors).

The term transducer is commonly used in two senses; the sensor, used to detect a parameter in one form and report it in

another (usually an electrical or digital signal), and the audio loudspeaker, which converts electrical voltage variations

representing music or speech, to mechanical cone vibration and hence vibrates air molecules creating acoustical energy.

Types of transducers

This list is confined to the narrower definition of the term.

Electromagnetic:

o Antenna - converts electromagnetic waves into electric current and vice versa.

o Cathode ray tube (CRT) - converts electrical signals into visual form

o Fluorescent lamp, light bulb - converts electrical power into visible light

o Magnetic cartridge - converts motion into electrical form

o Photodetector or Photoresistor (LDR) - converts changes in light levels into resistance changes

o Tape head - converts changing magnetic fields into electrical form

o Hall effect sensor - converts a magnetic field level into electrical form only.

shokoi@msu2008

1

Electrochemical:

o pH probes

o Electro-galvanic fuel cell

Electromechanical (electromechanical output devices are generically called actuators):

o Electroactive polymers

o Galvanometer

o MEMS

o Rotary motor, linear motor

o Vibration powered generator

o Potentiometer when used for measuring position

o Load cell converts force to mV/V electrical signal using strain gauge

o Accelerometer

o Strain gauge

o String Potentiometer

o Air flow sensor

Electroacoustic:

o Geophone - convert a ground movement (displacement) into voltage

o Gramophone pick-up

o Hydrophone - converts changes in water pressure into an electrical form

o Loudspeaker, earphone - converts changes in electrical signals into acoustic form

o Microphone - converts changes in air pressure into an electrical signal

o Piezoelectric crystal - converts pressure changes into electrical form

o Tactile transducer

Photoelectric:

o Laser diode, light-emitting diode - convert electrical power into forms of light

o Photodiode, photoresistor, phototransistor, photomultiplier tube - converts changing light levels

into electrical form

Electrostatic:

o Electrometer

Thermoelectric:

o RTD Resistance Temperature Detector

o Thermocouple

o Peltier cooler

o Thermistor (includes PTC resistor and NTC resistor)

Radioacoustic:

o Geiger-Müller tube used for measuring radioactivity.

o Receiver (radio)

- A transducer is an electronic device that converts energy from one form to another. Common examples

include microphones, loudspeakers, thermometers, position and pressure sensors, and antenna.Although not

generally thought of as transducers, photocells, LEDs (light-emitting diodes), and even common light bulbs are

transducers.

Efficiency is an important consideration in any transducer.Transducer efficiency is defined as the ratio of the power output in

thedesired form tothe total power input. Mathematically, if P represents thetotal powerinput and Q represents the power

output in the desired form, thenthe efficiency E,as a ratio between 0 and 1, is given by:

E = Q /P

shokoi@msu2008

2

If E% represents the efficiency as apercentage, then:

E% = 100Q/P

No transducer is 100-percent efficient; some power isalways lost in the conversion process. Usually this loss is manifested

in the form ofheat. Some antennas approach 100-percent efficiency. A well-designed antennasupplied with 100 watts of

radio frequency (RF) power radiates 80 or 90 watts in the form of an electromagnetic field.A few watts are dissipated as

heat in the antenna conductors, the feed lineconductors and dielectric, and in objects near the antenna. Among the

worsttransducers, in terms of efficiency, are incandescent lamps. A 100-watt bulb radiates onlya few watts in the form of

visible light. Most of the power is dissipated as heat; a small amount is radiated in the UV (ultraviolet) spectrum.

Measuring Strain with Strain Gauges

Overview

1. This tutorial is part of the National Instruments Measurement Fundamentals series. Each tutorial in this

series will teach you a specific topic of common measurement applications by explaining theoretical

concepts and providing practical examples.This tutorial introduces and explains the concepts and

techniques of measuring strain with strain gauges.

What Is Strain?

Strain is the amount of deformation of a body due to an applied force. More specifically, strain (e) is defined as the fractional

change in length.

Strain can be positive (tensile) or negative (compressive). Although dimensionless, strain is sometimes expressed in units

such as in./in. or mm/mm. In practice, the magnitude of measured strain is very small. Therefore, strain is often expressed

as microstrain (me), which is e x 10-6.

When a bar is strained with a uniaxial force, as in Figure 1, a phenomenon known as Poisson Strain causes the girth of the

bar, D, to contract in the transverse, or perpendicular, direction. The magnitude of this transverse contraction is a material

property indicated by its Poisson's Ratio. The Poisson's Ratio n of a material is defined as the negative ratio of the strain in

the transverse direction (perpendicular to the force) to the strain in the axial direction (parallel to the force), or n = e T/e.

Poisson's Ratio for steel, for example, ranges from 0.25 to 0.3.

The Strain Gauge

While there are several methods of measuring strain, the most common is with a strain gauge, a device whose electrical

resistance varies in proportion to the amount of strain in the device. The most widely used gauge is the bonded metallic

strain gauge.

The metallic strain gauge consists of a very fine wire or, more commonly, metallic foil arranged in a grid pattern. The grid

shokoi@msu2008

3

pattern maximizes the amount of metallic wire or foil subject to strain in the parallel direction (Figure 2). The cross sectional

area of the grid is minimized to reduce the effect of shear strain and Poisson Strain. The grid is bonded to a thin backing,

called the carrier, which is attached directly to the test specimen. Therefore, the strain experienced by the test specimen is

transferred directly to the strain gauge, which responds with a linear change in electrical resistance. Strain gauges are

available commercially with nominal resistance values from 30 to 3000 Ω, with 120, 350, and 1000 Ω being the most

common values.

Figure 2. Bonded Metallic Strain Gauge

It is very important that the strain gauge be properly mounted onto the test specimen so that the strain is accurately

transferred from the test specimen, through the adhesive and strain gauge backing, to the foil itself.

A fundamental parameter of the strain gauge is its sensitivity to strain, expressed quantitatively as the gauge factor (GF).

Gauge factor is defined as the ratio of fractional change in electrical resistance to the fractional change in length (strain):

The Gauge Factor for metallic strain gauges is typically around 2.

Strain Gauge Measurement

In practice, the strain measurements rarely involve quantities larger than a few millistrain(e x 10 -3). Therefore, to measure

the strain requires accurate measurement of very small changes in resistance. For example, suppose a test specimen

undergoes a strain of 500 me. A strain gauge with a gauge factor of 2 will exhibit a change in electrical resistance of only 2

(500 x 10-6) = 0.1%. For a 120 W gauge, this is a change of only 0.12 W.

To measure such small changes in resistance, strain gauges are almost always used in a bridge configuration with a voltage

excitation source. The general Wheatstone bridge, illustrated below, consists of four resistive arms with an excitation

voltage, VEX, that is applied across the bridge.

shokoi@msu2008

4

Figure 3. Wheatstone Bridge

The output voltage of the bridge, VO, will be equal to:

From this equation, it is apparent that when R1/R2 = R4/R3, the voltage output VO will be zero. Under these conditions, the

bridge is said to be balanced. Any change in resistance in any arm of the bridge will result in a nonzero output voltage.

Therefore, if we replace R4 in Figure 3 with an active strain gauge, any changes in the strain gauge resistance will

unbalance the bridge and produce a nonzero output voltage. If the nominal resistance of the strain gauge is designated as

RG, then the strain-induced change in resistance, DR, can be expressed as DR = R G·GF·e. Assuming that R1 = R2 and R3 =

RG, the bridge equation above can be rewritten to express VO/VEX as a function of strain (see Figure 4). Note the presence

of the 1/(1+GF·e/2) term that indicates the nonlinearity of the quarter-bridge output with respect to strain.

Figure 4. Quarter-Bridge Circuit

Ideally, we would like the resistance of the strain gauge to change only in response to applied strain. However, strain gauge

material, as well as the specimen material to which the gauge is applied, will also respond to changes in temperature. Strain

gauge manufacturers attempt to minimize sensitivity to temperature by processing the gauge material to compensate for the

thermal expansion of the specimen material for which the gauge is intended. While compensated gauges reduce the

thermal sensitivity, they do not totally remove it.

By using two strain gauges in the bridge, the effect of temperature can be further minimized. For example, Figure 5

illustrates a strain gauge configuration where one gauge is active (RG + DR), and a second gauge is placed transverse to

the applied strain. Therefore, the strain has little effect on the second gauge, called the dummy gauge. However, any

changes in temperature will affect both gauges in the same way. Because the temperature changes are identical in the two

shokoi@msu2008

5

gauges, the ratio of their resistance does not change, the voltage VO does not change, and the effects of the temperature

change are minimized.

Figure 5. Use of Dummy Gauge to Eliminate Temperature Effects

The sensitivity of the bridge to strain can be doubled by making both gauges active in a half-bridge configuration. For

example, Figure 6 illustrates a bending beam application with one bridge mounted in tension (R G + DR) and the other

mounted in compression (RG - DR). This half-bridge configuration, whose circuit diagram is also illustrated in Figure 6, yields

an output voltage that is linear and approximately doubles the output of the quarter-bridge circuit.

Figure 6. Half-Bridge Circuit

Finally, you can further increase the sensitivity of the circuit by making all four of the arms of the bridge active strain gauges

in a full-bridge configuration. The full-bridge circuit is shown in Figure 7.

Figure 7. Full-Bridge Circuit

The equations given here for the Wheatstone bridge circuits assume an initially balanced bridge that generates zero output

when no strain is applied. In practice however, resistance tolerances and strain induced by gauge application will generate

some initial offset voltage. This initial offset voltage is typically handled in two ways. First, you can use a special offsetnulling, or balancing, circuit to adjust the resistance in the bridge to rebalance the bridge to zero output. Alternatively, you

can measure the initial unstrained output of the circuit and compensate in software.

shokoi@msu2008

6

The equations given above for quarter, half, and full-bridge strain gauge configurations assume that the lead wire resistance

is negligible. While ignoring the lead resistances may be beneficial to understanding the basics of strain gauge

measurements, doing so in practice can be a major source of error. For example, consider the 2-wire connection of a strain

gauge shown in Figure 8a. Suppose each lead wire connected to the strain gauge is 15 m long with lead resistance R L

equal to 1 W. Therefore, the lead resistance adds 2 W of resistance to that arm of the bridge. Besides adding an offset

error, the lead resistance also desensitizes the output of the bridge.

You can compensate for this error by measuring the lead resistance R L and accounting for it in the strain calculations.

However, a more difficult problem arises from changes in the lead resistance due to temperature fluctuations. Given typical

temperature coefficients for copper wire, a slight change in temperature can generate a measurement error of several me.

Using a 3-wire connection can eliminate the effects of variable lead wire resistance because the lead resistances affect

adjacent legs of the bridge. As seen in Figure 8b, changes in lead wire resistance, R L2, do not change the ratio of the bridge

legs R3 and RG. Therefore, any changes in resistance due to temperature cancel each other.

Figure 8. 2-Wire and 3-Wire Connections of Quarter-Bridge Circuit

Signal Conditioning for Strain Gauges

Strain gauge measurement involves sensing extremely small changes in resistance. Therefore, proper selection and use of

the bridge, signal conditioning, wiring, and data acquisition components are required for reliable measurements. To ensure

accurate strain measurements, it is important to consider the following:

Bridge completion

Excitation

Remote sensing

Amplification

Filtering

Offset

Shunt calibration

Bridge Completion – Unless you are using a full-bridge strain gauge sensor with four active gauges, you will need to

complete the bridge with reference resistors. Therefore, strain gauge signal conditioners typically provide half-bridge

shokoi@msu2008

7

completion networks consisting of high-precision reference resistors. Figure 9 shows the wiring of a half-bridge strain gauge

circuit to a conditioner with completion resistors R1 and R2.

Figure 9. Connection of Half-Bridge Strain Gauge Circuit

Excitation – Strain gauge signal conditioners typically provide a constant voltage source to power the bridge. While there is

no standard voltage level that is recognized industry wide, excitation voltage levels of around 3 and 10 V are common.

While a higher excitation voltage generates a proportionately higher output voltage, the higher voltage can also cause larger

errors because of self-heating.

Remote Sensing – If the strain gauge circuit is located a distance away from the signal conditioner and excitation source, a

possible source of error is voltage drop caused by resistance in the wires connecting the excitation voltage to the bridge.

Therefore, some signal conditioners include a feature called remote sensing to compensate for this error. Remote sense

wires are connected to the point where the excitation voltage wires connect to the bridge circuit. The extra sense wires

serve to regulate the excitation supply through negative feedback amplifiers to compensate for lead losses and deliver the

needed voltage at the bridge.

Amplification – The output of strain gauges and bridges is relatively small. In practice, most strain gauge bridges and strainbased transducers will output less than 10 mV/V (10 mV of output per volt of excitation voltage). With 10 V excitation, the

output signal will be 100 mV. Therefore, strain gauge signal conditioners usually include amplifiers to boost the signal level

to increase measurement resolution and improve signal-to-noise ratios.

Filtering – Strain gauges are often located in electrically noisy environments. It is therefore essential to be able to eliminate

noise that can couple to strain gauges. Lowpass filters, when used in conjunction with strain gauges, can remove highfrequency noise prevalent in most environmental settings.

Offset Nulling – When a bridge is installed, it is very unlikely that the bridge will output exactly zero volts when no strain is

applied. Slight variations in resistance among the bridge arms and lead resistance will generate some nonzero initial offset

voltage. Offset nulling can be performed by either hardware or software:

1. Software Compensation – With this method, you take an initial measurement before strain input is applied, and use this

offset to compensate subsequent measurements. This method is simple, fast, and requires no manual adjustments. The

disadvantage of the software compensation method is that the offset of the bridge is not removed. If the offset is large

enough, it limits the amplifier gain you can apply to the output voltage, thus limiting the dynamic range of the measurement.

2. Offset-Nulling Circuit – The second balancing method uses an adjustable resistance, a potentiometer, to physically adjust

the output of the bridge to zero. By varying the resistance of potentiometer, you can control the level of the bridge output

and set the initial output to zero volts.

Shunt Calibration – The normal procedure to verify the output of a strain gauge measurement system relative to some

shokoi@msu2008

8

predetermined mechanical input or strain is called shunt calibration. Shunt calibration involves simulating the input of strain

by changing the resistance of an arm in the bridge by some known amount. This is accomplished by shunting, or

connecting, a large resistor of known value across one arm of the bridge, creating a known DR. The output of the bridge can

then be measured and compared to the expected voltage value. The results are used to correct span errors in the entire

measurement path, or to simply verify general operation to gain confidence in the setup.

Strain Gages and the Wheatstone Bridge

The metal foil strain gages used in this lab are resistors with a nominal (unstrained) resistance of 120 ohms. As

they are put in tension, their resistance increases; as they are compressed, their resistance decreases. The

Wheatstone bridge provides a way to convert these changes in resistance to changes in voltage, which are easy to

work with. These voltages can be conditioned, transmitted, or stored digitally.

Figure 1: Wheatstone Bridge Circuit

Figure 1 shows a Wheatstone bridge configuration.

Four resistors are connected in an end-to-end fashion.

The input or excitation voltage is connected to the bridge between top and bottom nodes of the circuit.

The output is the difference between the voltage at the left node and the voltage at the right node.

An excitation voltage is required to convert the change in resistance (in the legs of the bridge) to a change in

voltage at the output of the bridge.

For the bridge shown, the output voltage is expressed as

Figure 2: equation (1)

When building a Wheatstone bridge with strain gages, all four resistors have the same nominal value. Bridges can

be built in the following configurations:

Quarter Bridge-One strain gage and three fixed resistors

Half Bridge- Two strain gages and two fixed resistors

Full Bridge- Four strain gages

shokoi@msu2008

9

Figure 3: Quarter Bridge Configuration

Quarter Bridges

Figure 3 illustrates a quarter bridge configuration. The quarter bridge has one active leg, i.e., one leg with a

changing resistance. From equation (1) above we can derive an expression for the output voltage as a function of

the resistance change ∆R:

Figure 4: equation (2)

Half and Full Bridges

Half bridge: two active legs, one in tension and one in compression. These legs are adjacent legs in the bridge.

Full bridge: four active legs, two in tension and two in compression. The gages in tension are on opposite legs of

the bridge.

Using equation 1 and Figure 1 as a guide, derive expressions for the output voltage of the half-bridge and fullbridge circuits.

Thought Question

A half bridge could be made with two gages in tension on opposite legs. When would this be useful? What would

be the main problem with doing this?

Figure 5: Half Bridge Configuration

shokoi@msu2008

10

Figure 6: Full Bridge Configuration

Resistance Temperature Detectors (RTDs)

What are RTDs?

Resistance Temperature Detectors or RTDs for short, are wire wound and thin film devices that measure temperature because

of the physical principle of the positive temperature coefficient of electrical resistance of metals. The hotter they become, the

larger or higher the value of their electrical resistance.

They, in the case of Platinum known variously as PRTs and PRT100s, are the most popular RTD type, nearly linear over a wide

range of temperatures and some small enough to have response times of a fraction of a second. They are among the most

precise temperature sensors available with resolution and measurement uncertanties or ±0.1 °C or better possible in special

desions.

Usually they are provided encapsulated in probes for temperature sensing and measurement with an external indicator,

controller or transmitter, or enclosed inside other devices where they measure temperature as a part of the device's function,

such as a temperature controller or precision thermostat.

The Advantages of RTDs

The advantages of RTDs include stable output for long period of time, ease of recalibration and accurate readings over

relatively narrow temperature spans. Their disadvantages, compared to the thermocouples, are: smaller overall temperature

range, higher initial cost and less rugged in high vibration lenvironments.

shokoi@msu2008

11

They are active devices requiring an electrical current to produce a voltage drop across the sensor that can be then measured

by a calibrated read-out device.

RTD Error Sources

The lead wires used to connect the RTD to a readout can contribute to their measurement error, especially when there are long

lead lengths involved, as often happens in remote temperature measurement locations. Those calculations are straight forward

and there exist 3-wire and 4-wire designs to help minimize or limit such errors, when needed.

Often the lead error can be minimized through use of a temperature transmitter mounted close to the RTD. Transmitters

convert the resistance measurement to an analog current or serial digital signal that can be sent long distances by wire or rf to

a data aquisition or control system and/or indicator.

RTDs, as mentioned above, work in a relatively small temperature domain, compared to thermocouples, typically from about 200 °C to a practical maximum of about 650 to 700 °C. Some makers claim wider ranges and some construction designs are

limited to only a small portion of the usual range.

Insulation resistance is always a function of temperature and at relatively high temperature the shunt resistance of the

insulator introduces errors into measurement. Again, error estimates are straight forward, provided one has a good estimate of

the thermal properties of the insulator.

Insulator material such as powdered magnesia (MgO), alumina (Al2O3) and similar coumpounds are carefully dried and sealed

when encapsulated in probes along with an RTD element.

ASTM has standards related to insulation resistance testing to help determine the performance of such sealed probes,

specifically E 1652-00.

RTDs Other Than Platinum

RTDs can be made cheaply in Copper and Nickel, but the latter have restricted ranges because of non-linearities and wire

oxidation problems in the case of Copper.

Platinum is the preferred material for precision measurement because in its pure form the Temperature Coefficient of

Resistance is nearly linear; enough so that temperature measurements with precision of ±0.1 °C can be readily acheived with

moderately priced devices. Better resolution is possible, but equipment costs escalate rapidly at smaller error levels.

All RTDs used in precise temperature measurements are made of Platinum and they are sometimes called PRTs to distinguish

them.

Standard Platinum RTDs(SPRTs)

The ITS-90 (International Temperature Scale of 1990- used as a worldwide practical temperature scale in national metrology

labs like NIST, NPL et al) is made up of a number of fixed reference points with various interpolating devices used to define the

scale between points. A special set of PRTs, called SPRTs, are used to perform the interpolation in such labs over the ranges

13.8033 K (Triple point of Equilibrium Hydrogen) to the Freezing point of Silver, 971.78 °C.

Platinum RTD Output Equation

ASTM Standards E 1137 for Industrial Platinum Resistance Thermometers specifies that the resistance-temperature

relationship for such devices for the range 0 °C to 650°C, to within the tolerances given below, will be described by the

equation:

R(t) = Ro1 + At +Bt2]

shokoi@msu2008

12

Where:

t = temperature (to ITS-90), °C,

R(t) = resistance at temperature t,

Ro = resistance at 0°C

A = 3.9083 * 10-3(°C), and,

B = -5.775 * 10-7(°C-2).

More details and the equation for -200 °C to 0°C as well as the inverse, temperature as a function of resistance are

provided in the standard.

In Europe, the former German DIN standard, DIN 43760, had been the major, recognised source for RTD properties.

Not withstanding this fact, the British have long had standard BS 1904:1964. Both recognize the 0.003850

temperature coefficient for platinum RTDs. Now the IEC adminiters the "DIN" standard as IEC Standard 60751.

The Callendar-Van Dusen equation and others are used to correct for the nonlinearity of the resistance-temperature

relationship for very high accuracy measuments, such as those performed in a metrology or calibration laboratory

1. Recommended Use Limits and Tolerances:

In the USA, ASTM Specification E1137 "Standards Specification for Industrial Platinum Resistance Thermometers" gives

many details and specifications for them over the range from -200 °C to 650°C.

It defines two RTD grades, A and B with a resistance-temperature relatiionship that has the following tolerances:

Grade A Tolerance = ±[0.13 +0.0017 *|t|] °C

Grade B tolerance =±[0.25 +0.0042 *|t|] °C

where |t| is the absolute value of the RTD's temperature in °C.

Below are examples of these tolerances for a nominal 100 ohm (at 0°C) Platinum RTD. The actual ASTM document

includes more examples.

RTD Classifications And Tolerance Limits per ASTM E1137

Grade A

Grade B

Limits

Limits

Temperature Degrees C

°C

Ohms °C

-200

0.47 0.20

1.1

0

0.13 0.05

0.25 0.10

100

0.30 0.11

0.67 0.25

400

0.81 0.28

1.9

0.66

650

1.24 0.40

3.0

0.94

The DIN Standard recognizes three different tolerance classes, they are:

DIN Class A tolerance: ±[0.15 + 0.002*|t|] °C

DIN Class B tolerance: ±[0.30 + 0.005*|t|] °C

DIN Class C tolerance: ±[1.20 + 0.005*|t|] °C

shokoi@msu2008

Ohms

13

0.47

Our RTD vendor lists are long and spread over several pages, arranged alphabetically by company.

Thermocouples (TCs)

Thermocouples are among the easiest temperature sensors to use and obtain and are widely used in science and industry.

They are based on the Seebeck effect that occurs in electrical conductors that experience a temperature gradient along their

length. They are "simple", rugged, need no batteries, measure over very wide temperature ranges and more. They have their

quirks, too, like everything else. The solution to thermocouple uses and problems lies in the details of a given application.

Have a read through, click on the key topics below to get more detail about the thermocouple (TC), how it works, color codes,

recommended use limits and thermocouple standards. There is a link to an excellent article on how they work and notes on

using thermocouples from a well-known expert on them.

Don't forget to check our temperature references pages for the many additional publications that provide a wealth of

information on the theory and application of these very popular and rugged temperature sensors. The applications are where

the seasoned TC user and the novice part company and the one with know-how usually acheives the desired result. If all else

fails to impress you to be thorough and careful with thermocouples, consider these few facts:

1.

Thermocouples measure their own temperature. You must infer the temperature of the obect of interest by being

certain there is no heat flow between them when you take the measurement. That's easier than it sounds in some

case.

2.

Thermocouples can err in reading their own temperature, especially after being used for a while, or if the insulation

between the wires loses its resistance due to moisture or thermal conditions, or there are chemical, nuclear radiation

or mechanical effects with the immediate surroundings.

3.

Beware of electrical hazards using thermocouples, they are electrical conductors, even refractory oxide sheathed

models at high temperatures; should they contact another source of electricity, they can kill you!

4.

Oh, Yes..Thermocouples DO NOT MEASURE AT THE JUNCTIONS! They can't, it is physically impossible to have a

temperature gradient at a point. Also the Electric Field Strength (i.e. volts/meter) at such an impossible condition

would be infinite, sufficient to tear the materials apart. So, if you want to understand TCs better, start with the very

basics; learn about the Seebeck Effect and how thermocouples really work!

What is a Thermocouple?

Thermocouples are pairs of dissimilar metal wires joined at least at one end, which generate a net thermoelectric voltage

between the the open pair according to the size of the temperature difference between the ends, the relative Seebeck

coefficient of the wire pair and the uniformity of the wire-pair relative Seebeck coefficient.

Thermocouple Types

There are many, many types of thermocouples but only a small number have been standardized to the point

of having distinct calibration tables, color codes and assigned letter-designations that are recognized world

wide. The ASTM Standard E230 provides all the specifications for most of the common industrial grades,

including letter designation, color codes (USA only), suggested use limits and the complete voltage versus

temperature tables for cold junctions maintained at 32 °F and 0 °C. Needless to say there are other

thermocouple standards around the world and the color codes can and do vary in places.

Note that there are about three or four "classes"of thermocouples. Although no one really calls them

classes, they really are.

shokoi@msu2008

14

There are:

1.

2.

3.

4.

The home body class (called base metal),

the upper crust class (called rare metal or precious metal),

the rarified class (refractory metals) and,

the exotic class (standards and developmental devices).

In most countires all but the most exotic class are codified by a letter designation.

The home bodies, at least in the USA, are the Types E, J, K, N and T.

The upper crust are: types B, S, and R, platinum all to varying percentages .

The exotic class includes several tungsten alloy thermocouples usually designated as Type W (something)

Thermistors

THERMal resISTORS

Thermistors are special solid temperature sensors that behave like temperature-sensitive electrical resistors. No surprise then

that their name is a contraction of "thermal" and "resistor". There are basically two broad types, NTC-Negative Temperature

Coefficient, used mostly in temperature sensing and PTC-Positive Temperature Coefficient, used mostly in electric current

control.

There's even more history of the name and development of thermistors and facts about some key NTC parameters at the Kele

Electronics website, just be prepared for some strong opinions about one brand of thermistor.

They are mostly very small bits of special material that exhibit more than just temperature sensitivity. They are highlysensitive and have very reproducible resistance Vs. temperature properties.

During the last 60 years or so, only ceramic materials (a mix of different metal oxides) was employed for production of NTC

thermistors. In 2003, AdSem, Inc. (Palo Alto, CA) developed and started manufacturing of Si and Ge high temperature NTC

thermistors with better performance than any ceramic NTC thermistors.

Thermistors, since they can be very small, are used inside many other devices as temperature sensing and correction devices

as well as in specialty temperature sensing probes for commerce, science and industry.

Some of those new-fangled digital medical thermometers that get stuck in one's mouth by a nurse with an electronic display in

her other hand are based on thermistor sensors. They are probably inside your cell phone, automobile, stereo and television,

too, but you'd never know it unless you were an engineer or visited here.

Thermistors typically work over a relatively small temperature range, compared to other temperature sensors, and can be very

accurate and precise within that range, although not all are.

Thermistor Terminology

A glossary slightly modified from that given in a US government publication: MIL-PRF-23648D. Note that the term being

described is in bold typeface.

A thermistor is a thermally sensitive resistor that exhibits a change in electrical resistance with a change in its temperature.

The resistance is measured by passing a small, measured direct current (dc) through it and measuring the voltage drop

produced.

The standard reference temperature is the thermistor body temperature at which nominal zero-power resistance is

specified, usually 25°C.

The zero-power resistance is the dc resistance value of a thermistor measured at a specified temperature with a power

dissipation by the thermistor low enough that any further decrease in power will result in not more than 0.1 percent (or 1/10 of

the specified measurement tolerance, whichever is smaller) change in resistance.

shokoi@msu2008

15

The resistance ratio characteristic identifies the ratio of the zero-power resistance of a thermistor measured at 25°C to that

resistance measured at 125°C.

The zero-power temperature coefficient of resistance is the ratio at a specified temperature (T), of the rate of change of

zero-power resistance with temperature to the zero-power resistance of the thermistor.

A NTC thermistor is one in which the zero-power resistance decreases with an increase in temperature.

A PTC thermistor is one in which the zero-power resistance increases with an increase in temperature.

The maximum operating temperature is the maximum body temperature at which the thermistor will operate for an

extended period of time with acceptable stability of its characteristics. This temperature is the result of internal or external

heating, or both, and should not exceed the maximum value specified.

.

The maximum power rating of a thermistor is the maximum power which a thermistor will dissipate for an extended period

of time with acceptable stability of its characteristics.

The dissipation constant is the ratio, (in milliwatts per degree C) at a specified ambient temperature, of a change in power

dissipation in a thermistor to the resultant body temperature change.

The thermal time constant of a thermistor is the time required for a thermistor to change 63.2 percent of the total difference

between its initial and final body temperature when subjected to a step function

The resistance-temperature characteristic of a thermistor is the relationship between the zero-power resistance of a

thermistor and its body temperature.

The temperature-wattage characteristic of a thermistor is the relationship at a specified ambient temperature between the

thermistor temperature and the applied steady state wattage.

The current-time characteristic of a thermistor is the relationship at a specified ambient temperature between the current

through a thermistor and time, upon application or interruption of voltage to it.

The stability of a thermistor is the ability of a thermistor to retain specified characteristics after being subjected to designated

environmental or electrical test conditions.

Thanks for visiting; there's more info at the links highlighted below.

Radiation Thermometers (RTs)

Radiation Thermometers (Pyrometers, if you will) are non-contact temperature sensors that measure

temperature from the amount of thermal electromagnetic radiation received from a spot on the object of

measurement. This group of sensors includes both spot or "point" measuring devices in addition to line

measuring radiation thermometers, which produce 1-D and, with known relative motion, can produce 2-D

temperature distributions, and thermal imaging, or area measuring, thermometers which measure over an

area from which the resulting image can be displayed as a 2-D temperature map of the region viewed.

These are significant devices in all their manifestations because they enable improvements in processes,

maintenance, health and safety that save both lives and money. They are used widely in many

manufacturing process like metals, glass, cement, ceramics, semiconductors, plastics, paper, textiles,

coatings, and more.

They enable automation and feedback control that boost productivity while improving yield and product

quality.

shokoi@msu2008

16

They save lives and improve safety in fire-fighting, rescues, and detection of criminal activities. In hospitals,

nursing homes and home care, they have enabled a new , quick and reliable method to monitor and

measure human body temperatures with one second time response.

In reliability and maintenance needs from building heating to electrical power generation and distribution,

they save downtime and help optimize practices. Without these devices, our lives would be vastly different,

much like the status of the 1950's and 60's.

Some confusion exists about this whole class of sensors for a variety of reasons. Not the least of these

reasons is the variety of names given to the devices in this class, e.g.: Optical Pyrometers, Radiation

Pyrometers, Total Radiation Pyrometers, Automatic Infrared Thermometers, Ear Thermometers, Continuous

Radiation Thermometers, Line-Scanners, Thermal Imaging Radiometers, Infraducers, Infracouples,

Fibreoptic Thermometers, Gold Cup Pyrometers, Surface Pyrometers, Ratio Pyrometers, Two-Color

Pyrometers, Infra-Snakes, or something similar. There are few standards, especially ones relating to

nomenclature. The term used in most of them to technically describe these devices is "Radiation

Thermometer".

If you are seeking information or more knowledge about any of the following, you are at the right page.

Then, too, the mysterious terms like emissivity, blackbody and spectral crop up so often that the average

engineer unskilled in them can get fully turned in circles very quickly.

Radiation Thermometer Types and Construction

There are numerous types of Radiation Thermometers (Pyrometers, if you will) available on the market. In

general, they can be broken down into four broad categories:

Spot measuring thermometers

Ones that are intended to measure the temperature of a spot at some distance. These are the most

common types. They can be further subdivided by whether they are intended for portable (handheld) use or fixed mounting; they can also be classified according to their technical type, i.e whether

they collect and measure thermal radiation in a single spectral region, "single waveband devices,"

sometimes known as "spot radiometers".

Devices measuring in two wavebands simultaneously are called Two Color Thermometers

(pyrometers) or Ratio Thermometers.

Single waveband radiation thermometers can be classified by the wavebands or center wavelength of

the measuring waveband. So, too, they can be given distinctive names by their developer, to help

differentiate among brands in some way, e.g "Automatic Optical", "Hot Spot" " Cyclops".

Then, too, there are specialized variations for well defined uses such as the medical unit used to

measure the temperature of humans by inserting a small probe on one end of a unit into the outer

part of the ear canal, called (not surprisingly) The IR Ear Thermometer.

Optical pyrometers

The oldest and original hand-held optical temperature sensor which was believed to be the only true,

accurate method to measure temperature without contact. Although they have been around for

about 100 years and have today nearly vanished from industry and science. They are unique and

deserve a mention on their own. In some organizations and publications they are called disappearing

filament pyrometers because of the principle upon which their operation is based: the use of the

human eye (and later a photocell circuit) to detect a balance in brightness between a lamp filament

and the object of measurement in a narrow visible wavelength passband.

shokoi@msu2008

17

Optical pyrometers, with few exceptions measured the brightness or spectral radiance temperature

of the target. These devices are usually limited to object temperatures above incandescence,

typically above about 700°C.

Line measuring thermometers.

These sensors measure a linear region over a defined angular range. If there's an object of sufficient

temperature covered by that angle, then the device produces a linear trace along the line "seen" by

the sensor. Some line measuring thermometers are connected to computers in such a way, that if

the object moves perpendicular to the measured line, a series of temperature profiles can be

connected together to form a sample of the two-dimensional temperature distribution on the object.

Area measuring thermometers (or Quantitative Infrared Thermal Imagers)

If one wants a two dimensional temperature map of a surface, a Quantitative Thermal Imager is

often the first choice. These are instrument systems that have been developed from Thermal

Imagers. If you don't know about them, check out the James Cameron film "Predator" starring

Arnold Schwartzenegger. The Predator's view of our world was created using a real thermal imager.

Thermal Imagers themselves are very sophisticated instruments, but the right models in the hands

of a skilled user can find water trapped between sheets of roofing material on a flat roof, or tell if the

refractory brick insulation in a high temperature furnace or kiln has gone bad!

Some Thermal Imager models are even claimed to be capable of looking through walls and clothing.

Indeed, some units enable fire fighters to see better in thick smoke to locate victims and uncooled

hot spots. Many rescues have been attributed to them and most fire-fighting organizations in the

USA have been acquiring units designed especially for the kinds of conditions they can encounter.

Another remarkable set of uses have been developed by Law Enforcement in North America. At our

last check there were something like 11 or 12 "approved" uses of Thermal Imagers described by the

Law Enforcement Thermography Association, a group that trains professionals in the successful use

of these devices.

THis technology has taken a giant step forward with the development of many competing kinds of focal

plane array sensors now entering the market, and,

The large volume production (high volume means lower unit prices) of some models for uses in

automobiles, e.g. night vision devices are now available on some car models.

Piezoelectric sensor

shokoi@msu2008

Piezoelectric disk used as a guitar

pickup

18

A piezoelectric disk generates a voltage when deformed (change in shape is greatly exaggerated)

A piezoelectric sensor is a device that uses the piezoelectric effect to measure pressure, acceleration, strain or force by

converting them to an electrical signal.

Applications

Piezoelectric sensors have proven to be versatile tools for the measurement of various processes. They are used

for quality assurance, process control and process development in many different industries.

From the Curies’ initial discovery in 1880, it took until the 1950s before the piezoelectric effect was used for industrial

sensing applications. Since then, the utilization of this measuring principle has experienced a constant growth and can be

regarded as a mature technology with an outstanding inherent reliability. It has been successfully used in various critical

applications as for example in medical, aerospace and nuclear instrumentation.

The rise of piezoelectric technology is directly related to a set of inherent advantages. The high modulus of elasticity of

many piezoelectric materials is comparable to that of many metals and goes up to 105 N/m². Even though piezoelectric

sensors are electromechanical systems that react on compression, the sensing elements show almost zero deflection. This

is the reason why piezoelectric sensors are so rugged, have an extremely high natural frequency and an excellent linearity

over a wide amplitude range. Additionally, piezoelectric technology is insensitive to electromagnetic fields and radiation,

enabling measurements under harsh conditions. Some materials used (especially gallium phosphate or tourmaline) have an

extreme stability over temperature enabling sensors to have a working range of up to 1000°C. Tourmaline shows

pyroelectricity in addition to the piezoelectric effect; this is the ability to generate an electrical signal when the temperature of

the crystal changes. This effect is also common to piezoceramic materials.

Principle Strain Sensitivity V/µ* Threshold µ* Span to threshold ratio

Piezoelectric 5.0

0.00001

100,000,000

Piezoresistive 0.0001

0.0001

2,500,000

Inductive

0.001

0.0005

2,000,000

Capacitive 0.005

0.0001

750,000

One disadvantage of piezoelectric sensors is that they cannot be used for true static measurements. A static force will result

in a fixed amount of charges on the piezoelectric material. Working with conventional readout electronics, not perfect

insulating materials, and reduction in internal sensor resistance will result in a constant loss of electrons, yielding a

decreasing signal. Elevated temperatures cause an additional drop in internal resistance; therefore, at higher temperatures,

only piezoelectric materials that maintain a high internal resistance can be used. Anyhow, it would be a misconception that

piezoelectric sensors can only be used for very fast processes or at ambient conditions. In fact, there are numerous

applications that show quasi-static measurements while there are other applications that go to temperatures far beyond

500°C.

shokoi@msu2008

19

Piezoelectric sensors are also seen in nature. Dry bone is piezoelectric, and is thought by some to act as a biological force

sensor.12

Principle of operation

Depending on how a piezoelectric material is cut, three main modes of operation can be distinguished: transverse,

longitudinal, and shear.1

Transverse effect

A force is applied along a neutral axis (y) and the charges are generated along the (x)

direction, perpendicular to the line of force. The amount of charge depends on the

geometrical dimensions of the respective piezoelectric element. When dimensions a, b,

c apply,

A diagram is

Cx = dxyFyb / a,

where a is the dimension in line with the neutral axis, b is in line with the charge

needed in this

generating axis and d is the corresponding piezoelectric coefficient.3

article

Longitudinal effect

The amount of charge produced is strictly proportional to the applied force and is independent of size and

shape of the piezoelectric element. Using several elements that are mechanically in series and electrically

in parallel is the only way to increase the charge output. The resulting charge is

Cx = dxxFxn,

where dxx is the piezoelectric coefficient for a charge in x-direction released by forces applied along xdirection (in pC/N). Fx is the applied Force in x-direction N and n corresponds to the number of stacked

elements .

Shear effect

Again, the charges produced are strictly proportional to the applied forces and are independent of the

element’s size and shape. For n elements mechanically in series and electrically in parallel the charge is

Cx = 2dxxFxn.

In contrast to the longitudinal and shear effects, the transverse effect opens the possibility to fine-tune sensitivity on the

force applied and the element dimension.

Electrical properties

Schematic symbol and electronic model of a piezoelectric sensor

A piezoelectric transducer has very high DC output impedance and can be modeled as a proportional voltage source and

filter network. The voltage V at the source is directly proportional to the applied force, pressure, or strain. 2 The output signal

is then related to this mechanical force as if it had passed through the equivalent circuit.

Frequency response of a piezoelectric sensor; output voltage vs applied force

A detailed model includes the effects of the sensor's mechanical construction and other non-idealities.3 The inductance Lm is

due to the seismic mass and inertia of the sensor itself. Ce is inversely proportional to the mechanical elasticity of the

sensor. C0 represents the static capacitance of the transducer, resulting from an inertial mass of infinite size. 3 Ri is the

insulation leakage resistance of the transducer element. If the sensor is connected to a load resistance, this also acts in

parallel with the insulation resistance, both increasing the high-pass cutoff frequency.

shokoi@msu2008

20

In the flat region, the sensor can be modeled as a voltage source in series with the sensor's capacitance or a charge

source in parallel with the capacitance

For use as a sensor, the flat region of the frequency response plot is typically used, between the high-pass cutoff and the

resonant peak. The load and leakage resistance need to be large enough that low frequencies of interest are not lost. A

simplified equivalent circuit model can be used in this region, in which Cs represents the capacitance of the sensor surface

itself, determined by the standard formula for capacitance of parallel plates.34 It can also be modeled as a charge source in

parallel with the source capacitance, with the charge directly proportional to the applied force, as above.2

Sensor design

Metal disks with piezo material, used in buzzers or as contact microphones

Based on piezoelectric technology various physical quantities can be measured; the most common are pressure and

acceleration. For pressure sensors, a thin membrane and a massive base is used, ensuring that an applied pressure

specifically loads the elements in one direction. For accelerometers, a seismic mass is attached to the crystal elements.

When the accelerometer experiences a motion, the invariant seismic mass loads the elements according to Newton’s

second law of motion F = ma.

The main difference in the working principle between these two cases is the way forces are applied to the sensing elements.

In a pressure sensor a thin membrane is used to transfer the force to the elements, while in accelerometers the forces are

applied by an attached seismic mass.

Sensors often tend to be sensitive to more than one physical quantity. Pressure sensors show false signal when they are

exposed to vibrations. Sophisticated pressure sensors therefore use acceleration compensation elements in addition to the

pressure sensing elements. By carefully matching those elements, the acceleration signal (released from the compensation

element) is subtracted from the combined signal of pressure and acceleration to derive the true pressure information.

Sensing materials

Two main groups of materials are used for piezoelectric sensors: piezoelectric ceramics and single crystal materials. The

ceramic materials (such as PZT ceramic) have a piezoelectric constant / sensitivity that is roughly two orders of magnitude

higher than those of single crystal materials and can be produced by inexpensive sintering processes. The piezoeffect in

piezoceramics is "trained", so unfortunately their high sensitivity degrades over time. The degradation is highly correlated

with temperature. The less sensitive crystal materials (gallium phosphate, quartz, tourmaline) have a much higher – when

carefully handled, almost infinite – long term stability.

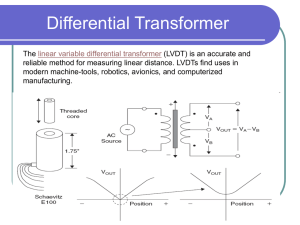

THE LINEAR VARIABLE DIFFERENTIAL TRANSFORMER (LVDT)

shokoi@msu2008

21

The Linear Variable Differential Transformer (LVDT) is a displacement measuring

instrument and is not a strain-based sensor.

The LVDT models closely the ideal Zeroth-order displacement sensor structure at low

frequency, where the output is a direct and linear function of the input.

The LVDT is a variable-reluctance device, where a primary center coil establishes a

magnetic flux that is coupled through a mobile armature to a symmetrically-wound

secondary coil on either side of the primary.

Two components comprise the LVDT: the mobile armature and the outer transformer windings. The

secondary coils are series-opposed; wound in series but in opposite directions.

When the moving armature is centered between the two series-opposed secondaries, equal magnetic flux

couples into both secondaries and the voltage induced in one half of the secondary winding is balanced and

180 degrees out-of-phase with, the voltage induced in the other half of the secondary winding.

The balanced condition provides total cancellation of secondary voltages and therefore zero voltage output.

When the moveable armature is displaced from the balanced condition, more magnetic flux will couple into

one half of the secondary than into the other producing an imbalance voltage output at the primary coil

excitation frequency. The output voltage of the LVDT is therefore a direct function of the displacement of the

mobile magnetic armature. The LVDT is, by definition, a transformer and requires an oscillating primary coil

input.

The DC LVDT is provided with onboard oscillator, carrier amplifier, and demodulator circuitry. The AC LVDT

requires these components externally. Due to the presence of internal circuitry, the DC LVDT is temperature

limited operating from typically -40 C to +120 C.

The AC LVDT is able to tolerate the extreme variations in operating temperature that the internal circuitry of

the DC LVDT could not tolerate. Typically, LVDT’s will be excited by a primary carrier voltage oscillating at

between 50 hertz and 25 Kilohertz with 2.5 Kilohertz as a nominal value. The carrier frequency is generally

selected to be at least 10 times greater than the highest expected frequency of the core motion.

The external housing of the LVDT is fabricated of material having a high-magnetic permeability therefore

desensitizing the device from the effects of external magnetic fields.

No sensing spring element exists within an LVDT and therefore, the output of the sensor is hysteresis-free.

Some LVDT displacement measuring sensors are, however, provided with internal armature return springs

to allow profile measurement. When there exists no direct contact with the moving armature is allowed no

mechanical wear results. The provision of linear bearings to prevent armature to coil structure contact and

to limit wear can greatly extend LVDT operating life expectancies.

The strong relationship between core position and output voltage yields a sensor design that shows

excellent resolution, limited more by the associated circuitry than the sensing method.

The internal core of the LVDT is generally constructed of an annealed nickel iron alloy with the hightemperature limitations of the device limited to the curie point of the core and the winding insulations used.

shokoi@msu2008

22

The thermal response characteristics of the LVDT are excellent for static and quasi-static thermal

environments due to the physical and electrical symmetry of these devices. The physical symmetry also

contributes to excellent zero repeatability over time and temperature. Most thermal-sensitivity shift errors

result from the significant thermal coefficient of resistance (TCR) of the copper transformer windings. With

increasing temperature, the primary coil resistance will increase causing a decrease of the primary current

in the constant-voltage-excited case and therefore decreasing the magnetic flux generated and voltage

output correspondingly.

The use of constant-current excitation will ensure a constant primary flux regardless of the coil resistance.

Since the equivalent circuit of the constant-current source is a voltage source with an infinite series

resistance, the use of a low-TCR resistance, in series with the primary, will function in much the same

manner as the piezoresistive span-compensation resistor by causing the primary voltage to increase as a

function of temperature thus offsetting the TCR-induced losses. The use of the series low-TCR resistor in the

primary circuit allows the constant-voltage source to appear to the LVDT as a constant-current source.

Other thermally-active methods may also be used to compensate for the primary winding TCR by causing

the primary voltage to increase, with rising temperature, in proportion to the increase in the primary coil

resistance. The temperature coefficient of magnetic permeability is another contributor to the thermalsensitivity shift and is compensated out as a net effect by the means described above. Within approximately

2 seconds of power application the LVDT oscillator and demodulator circuitry will stabilize sufficiently for

dynamic measurement.

Due to self-heating of the primary coil, warm-up times for high precision static measurement are

comparable to strain gaged sensors and are dependent upon the thermal stability of the measuring

environment.

Important factors for the specification of Linear Position Sensors.

Determine the displacement

The length of displacement that needs to be measured will most likely determine the type or range of

sensors available (rod, slide or cable operated).

Consider the mounting of the sensor

Can the sensor be mounted close to the movement, integrated within the equipment, or will it need to be

situated away from the moving part?

Consider the aftachment method

The attachment between the sensor and the moving part can either be a fixed mechanical interface or a

spring biased probe that follows the moving surface.

Vibration conditions

Careful consideration needs to be given to the impact of vibration on the sensor, and whether this can be

detrimental to operation and life. This factor may determine the type of sensing element to select contacting or non-contact.

Shock conditions

High levels of shock can seriously affect the operation of a sensor, either permanently damaging the device

or degrading the output, so careful selection of a device that can withstand this treatment is important.

Temperature variation or extremes

Extremes of temperature (hot or cold) need to be considered, and whether the sensor will be required to

operate within its specification at these extremes or just survive under storage conditions. Some sensor

technologies are particularly susceptible to changes in temperature, resulting in drifting output signals,

which could be mistaken by a control system as a valid movement of a machine part.

shokoi@msu2008

23

Resistance to ingress of particles and liquids

Environmental protection of the sensor may be required where it is operating in harsh conditions, to stop

the ingress of harmful particles or liquids that may damage the sensor. Protection to lP68 can be specified in

some specialist designs, but IP66 is normally readily available as an option on standard models.

Corrosion resistance

Protection from the effects of corrosive materials may be required. A sensor that has been manufactured

using corrosion-resistant materials (such as stainless steels or engineering polymers) will be necessary in

these applications.

Hazardous areas

If the application is in an area where explosive gases are present, then consideration must be given to

selecting a sensor that has been specially designed, tested and approved to be safe to operate in this

environment.

Sensor life

The duty cycle of the application being measured is important when selecting the type of sensor to use. A

typical benchmark for linear potentiometers is 200 million operations, but a really heavy-duty cycle may be

better suited to a sensor that uses technology operating on a non-contacting principle, although this can

have an impact on cost.

Accuracy

The accuracy of the sensor is determined by a combination of the output signal conformity ('linearity' or

'non-linearity') and the temperature coefficient of the sensor. Overall system accuracy should be considered

over the operating temperature range of the equipment.

Sensor resolution

The resolution of a sensor is the smallest measurable change in the output signal. Most linear position

sensors now use technologies that provide virtually infinite resolution; this is normally stated in sensor

manufacturers' technical data.

Repeatability

The ability of the sensor to provide repeatable signals is of paramount importance. Sensor manufacturers

will quote a figure for the deviation in indicated position when a point along a stroke length is approached

repeatedly from the same direction. This factor is often confused with the sensor resolution.

Hysteresis

This is the difference in indicated position for the same point when reached from opposing directions. This

may be an important factor to consider but most linear position sensors have minimal or negligible values.

Power supply available

An important factor to consider is the supply requirement to the sensor. Most operate on values within the

range of 5VDC to 3OVDC.

Output signal required

The output from the sensor can vary, but can be DCV, ACV, DCmA or a range of digital signals (such as TTL,

R5232 or CAN). The control interface to the sensor will usually determine the type of signal required to be

specified.

EMC/EMI

The ability of a sensor to withstand operation in electrically noisy environments has become more important

since the introduction of European regulations on EMC/EMI. CE marks ensure testing and compliance with

regulations.

Cost of ownership

A factor often overlooked when selecting a position sensor is the cost of ownership over a period of time.

shokoi@msu2008

24

Selecting a sensor on price alone may compromise the reliability of a system, particularly if constant failure

involves service costs, downtime and lost production.

Product availability

Sensors that are readily available from stock or manufactured within days of ordering can provide a

considerable advantage to project development times. Additionally, holding spare parts to support aftersales is virtually eliminated.

Supplier experience

Do not underestimate the value of asking suppliers about their experience.

shokoi@msu2008

25