Blottnitz - Civil and Environmental Engineering

advertisement

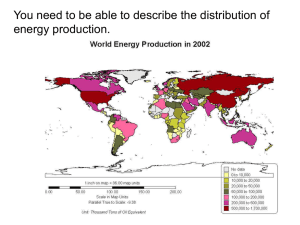

Accepted for Publication in the Journal of Cleaner Production (1 March 2006) A review of assessments conducted on bio-ethanol as a transportation fuel from a net energy, greenhouse gas, and environmental life-cycle perspective Harro von Blottnitz* Chemical Engineering Department, University of Cape Town, Private Bag, 7701 Rondebosch, South Africa e-mail: hvb@chemeng.uct.ac.za and Mary Ann Curran Environmental Protection Agency, National Risk Management Research Laboratory, Cincinnati, Ohio 45268 USA e-mail: curran.maryann@epa.gov * Corresponding author Abstract Interest in producing ethanol from biomass in an attempt to make transportation ecologically sustainable continues to grow. In recent years, a large number of assessments have been conducted to assess the environmental merit of biofuels. Two detailed reviews present contrasting results: one is generally unfavourable, whilst the other is more favourable toward fuel bio-ethanol. However, most work that has been done thus far, to assess the conversion of specific feedstocks to biofuels, specifically bio-ethanol, has not gone beyond energy and carbon assessments. This study draws on 47 published assessments that compare bio-ethanol systems to conventional fuel on a life-cycle basis, or using life cycle assessment (LCA). A majority of these assessments focused on net energy and greenhouse gases, and despite differing assumptions and system boundaries, the following general lessons emerge: i) make ethanol from sugar crops, in tropical countries, but approach expansion of agricultural land usage with extreme caution; ii) consider hydrolysing and fermenting lignocellulosic residues to ethanol; and iii) the LCA results on grasses as feedstock are insufficient to draw conclusions. It appears that technology choices in process residue handling and in fuel combustion are key, whilst site-specific environmental management tools should best handle biodiversity issues. Seven of the reviewed studies evaluated a wider range of environmental impacts, including resource depletion, global warming, ozone depletion, acidification, eutrophication, human and ecological health, smog formation, etc., but came up with divergent conclusions, possibly due to different approaches in scoping. These LCAs typically report that bio-ethanol results in reductions in resource use and global warming; however, impacts on acidification, human toxicity and ecological toxicity, occurring mainly during the growing and processing of biomass, were more often unfavourable than favourable. It is in this area that further work is needed. Keywords: bio-ethanol, life cycle assessment, energy balance, greenhouse gas, sustainable transportation Accepted for Publication in the Journal of Cleaner Production (1 March 2006) 1. Introduction Ethanol derived from biomass is often advocated as a significant contributor to possible solutions to our need for a sustainable transportation fuel. Kim and Dale [1] estimated that the potential for ethanol production is equivalent to about 32% of the total gasoline consumption worldwide, when used in E85 (85% ethanol in gasoline) for a midsize passenger vehicle. Such a substitution immediately addresses the issue of reducing our use of non-renewable resources (fossil fuels) and the attendant impacts on climate change, especially carbon dioxide and the resulting greenhouse effect, but it does not always address the notion of overall improvement. For instance, it is well understood that the conversion of biomass to bio-energy requires additional energy inputs, most often provided in some form of fossil fuel. The life cycle energy balance of a biofuel compared to conventional fossil fuel should be positive, but depending on the processing choices, the cumulative fossil energy demand might, at times, only be marginally lower or even higher than that of liquid fossil fuels (e.g., [2, 3]). Also, ethanol in gasoline may result in decreased urban air quality, and be associated with substantive risks to water resources and biodiversity [4]. Bio-based systems have other possible ecological drawbacks. Agricultural production of biomass is relatively land intensive, and there is a risk of pollutants entering water sources from fertilisers and pesticides that are applied to the land to enhance plant growth. A very large number of researchers have recognised this conundrum and have attempted to analyse bio-ethanol systems in an effort to describe their environmental sustainability and to determine whether bio-based fuels, i.e. biofuels, are helping us achieve the goal of providing environmentally sustainable transportation. Two recent reviews have attempted to summarise the findings. One focused on ethanol alone and presents generally unfavourable recommendations [4]; the other review looked at biofuels more generally and presented more favourable results for ethanol but cautioned with respect to some of its environmental impacts [5]. It must be noted that a number of studies that looked specifically at the North American corn-to-ethanol route, were very critical as to its environmental sustainability [3, 6, 7]. Whilst the issue of sustainability is complicated, one that encompasses human and environmental health as well as societal needs, it is clear that our efforts to identify solutions should be broad in scope to avoid shifting problems from one place to another [8]. A large number of authors have studied liquid biofuel production systems, both current and projected, with the aim of determining whether the currently accepted premise that such systems contribute to environmental sustainability is valid. In this paper we review previous evaluations of bio-ethanol (as a transportation fuel) that used life cycle thinking or life cycle assessment as the basis for the evaluation. It is assumed that the reader has a fundamental knowledge of bio-ethanol production systems, so such background information is not provided here. The paper begins with a brief review of the study approach, then provides an overview of the evaluations that were found in a search of the open literature, and concludes with a summary of key findings and recommendations both for policy on bio-ethanol projects, and for further studies. Accepted for Publication in the Journal of Cleaner Production (1 March 2006) 2. Approach used in this study 2.1 Objective The objective of the study was to review recent evaluations of bio-ethanol, made from varying feedstocks for use as a transportation fuel, compared to conventional fuels on a life cycle basis. The effort consisted of a literature search and a desk study, followed by an analysis of the methods and assumptions used, and findings obtained to detect if any trends could be identified in the results when viewed by the type or location of the feedstock. 2.2 Scope of the search An online search of publicly-available papers and reports was conducted to find studies that have been published in recent years (1996 – 2004). The focus of the search was on ethanol from biomass for use as a transportation fuel (a gasoline replacement). The search included completed, published assessments that claimed to be life-cycle based and that were environmental in nature. Cost analyses were not part of the main focus of the study. Only those reports that are available in English were subjected to further analysis; 47 reports were included in the analysis. This area of research is still of significant interest worldwide and studies on biofuels continue to be conducted. Although additional studies have been published since the completion of the literature search, this paper includes the assessments that were available at that time. 2.3 Defining the life cycle Life cycle management is quickly becoming a well-known and often used approach for environmental management. A comprehensive environmental assessment of an industrial system needs to consider both upstream and downstream inputs and outputs involved in the delivery of a unit of functionality. A life cycle approach involves a cradle-to-grave assessment, where the product is followed from its primal production stage involving its raw materials, through to its end use. The diagram in Figure 1 illustrates a generic biofuel lifecycle scheme; it shows the main sub-processes, and identifies the flows of importance for describing environmental performance. INSERT FIGURE 1 The main stages A to E can be studied in order to determine the holistic performance of the system, depending on the goals of the study. It is at this point that differences in studies that are called life cycle assessments can be seen. Some studies include cradle-to-grave boundaries but evaluate limited input or output data. Most often, studies on energy and carbon balances, as well as greenhouse gas emissions, are found in the literature. The goal of a life cycle assessment (LCA), on the other hand, is to model all potential impacts to human health and the environment across all media - air, water and solid waste (see Appendix at the end of the paper for a longer discussion on LCA). A distinction can then be made between studies that are life-cycle based versus those that aim to be fuller life cycle assessments. 3. Overview of published studies The on-line literature search led to a recent review study that was conducted by the Institute for Energy and Environmental Research (IFEU) with a similar objective [5]. This study analyzed and compared all international, publicly-accessible publications about biofuels that Accepted for Publication in the Journal of Cleaner Production (1 March 2006) are currently used for transportation (e.g., bio-diesel and bio-ethanol as well as those potential fuels like biomass-to-liquid, BTL). The literature search uncovered additional references that were not part of the IFEU review. The integration of these efforts resulted in 47 publications, in English, that address bio-ethanol (see Table 1). Note that whilst several studies encompassed the entire life cycle as depicted in Figure 1, many studies did not extend beyond ethanol production. It was nevertheless possible to compare studies with such differing system boundaries, at least for the carbon and energy analyses, by developing a spreadsheet to reflect all the E and C streams in Figure 1. For those studies that exclude life cycle stages such as fuel distribution, storage and combustion (in use), it was then assumed that the carbon and energy flows associated with these stages were similar to results documented in other studies. To date, the emphasis in life cycle based studies of bio-ethanol has strongly, but not exclusively, focused on North America and Europe, and the few full LCAs completed also do not cover the full range of possible or promising options. INSERT TABLE 1 4. Key results from selected bio-ethanol system assessments Results are discussed in three categories of special interest to the question of environmental sustainability: (1) reducing dependence on fossil fuels through energy balance assessments; (2) reducing emissions of greenhouse gases (GHGs), and (3) reducing health and environmental impacts throughout the life cycle. Each interest area is discussed in more detail in the following sections. 4.1 Energy balance assessments Almost all studies on biofuels consider the question as to whether such fuels achieve the desired net effect of lowering the amount of fossil fuel needed to propel standard and nearfuture vehicles powered by spark-ignition internal combustion engines. As discussed in the appended methodological discussion on energy assessments, a variety of indicators has been developed for this purpose, and it is important to norm these to the few most appropriate ones. The IFEU review [5] does this well. Whilst this type of analysis is often inspired by the controversial results of Pimentel on ethanol from corn in the United States (e.g., [9]), the bulk of the studies report moderate to strong fossil fuel substitution effects for bio-ethanol systems. This is evident from Figure 2 and Table 2, that present results for two of the most commonly used energy balance indicators. 4.1.1 Net replaced fossil energy This indicator can be reported relative to the achieved transportation effect (e.g., per kilometre driven) or relative to the land area used, as is done in Figure 2. It must be noted that no additional land is needed when by-products (e.g., molasses) or lignocellulosic residue are used as feedstock for fermentation. In this regard, for these latter feedstocks, Figure 2 indicates the potential amounts of replaced fossil energy per hectare of land, but this is not an additional land requirement as it is for the food crops in the lowest section of the figure. Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Of the possible sources of bio-ethanol, sugar crops are most land-efficient in replacing fossil energy, and here tropical sugarcane significantly outperforms sugar beet in temperate regions. Our interpretation of the Brazilian studies (at about 250 GJ/hectare-annum) appears somewhat less conservative than that of Quirin et al. [5], which may be due to the inclusion of by-product electricity credits. Starch crops, such as maize (corn), potatoes, wheat and rye, replace significantly less fossil energy. The IFEU study [5] reports a range of 35-50 GJ/ha.a; studies which we are citing compare well with this range, at 35-40 GJ/ha.a for potato and wheat [10], and a projected 27-56 GJ/ha.a for wheat and rye winter crops [11]. An unusually high result is reported by Hanegraaf et al [12], who reported 124 GJ/ha.a for winter wheat, but yielding heat and power in addition to ethanol. For corn in North America, our analysis of the definitive USDA study [13] yields a fossil energy replacement of 38 GJ/ha.a – a number of much debate, although its poor performance relative to the sugar crops is not doubted by any commentators. INSERT FIGURE 2 For ethanol made from a waste product taken to carry no environmental burden, a fossil energy replacement can also be determined on a per hectare basis. However, in interpreting these, it must be remembered that this is not the additional land area needed, but rather an additional bio-energy contribution that can potentially be harnessed from land already in use. Results will differ on a case-by-case basis, depending on how efficiently wastes and byproducts are already used, and how the industrial systems are configured. The two diverging results for molasses illustrate this: the Indian case yielding 30 GJ/ha.a is for a distillery fully integrated into a sugar mill, where excess low pressure steam is used; whereas the South African case yielding 5 GJ/ha.a is for a distillery distant from sugar mills, relying on coal and grid electricity for its energy needs. For ethanol from lignocellulosic feedstocks, the contribution to fossil energy replacement is of a similar magnitude to that of the starch crops. Our interpretation of studies on sugarcane bagasse, corn stover and wheat straw here agrees well with the range reported by Quirin et al. [5], at 25-90 GJ/ha.a. It is important to note that the three studies we refer to are all for waste lignocellulosic material. Dedicated energy cropping (e.g., of grasses) is a future possibility that needs to be considered too. 4.1.2 Energy yield ratios The ratios relating energy output of the resultant biofuel to the fossil energy input into its production are also often used to test the sensibility of making a particular product. Table 2 summarises our analysis of key studies for a range of feedstocks and locations in this regard. Again, the tropical sugarcane-based ethanol production outperforms that from starch crops in temperate regions by a significant margin. Several commentators have questioned whether the energy yield ratio for ethanol from corn in the US is at all positive, though the balance of evidence seems to indicate it is, if only marginally [13]. INSERT TABLE 2 Accepted for Publication in the Journal of Cleaner Production (1 March 2006) In the case of molasses utilization, the two studies which we cite yield very diverging ratios – the physical differences between the two cases have already been discussed above; in addition, it is probable that the Indian study has neglected several non-factory inputs of fossil energy into the system. In the case of utilization of lignocellulosic wastes through hydrolysis and fermentation, the cited studies all project very encouraging bio-energy yields in relation to the required fossil energy inputs. Concerning the effectiveness of bio-ethanol to replace fossil energy, Quirin et al. [5] have concluded that the desired effect is generally achieved, and our more limited review confirms this. It is, however, also clear that tropical sugarcane-based production is most effective from this vantage point. 4.2 Greenhouse gas assessments With scientific evidence now increasingly mounting that climate is changing, and that this can be attributed to the large-scale use of fossil fuels, the potential of biofuels to deliver transportation energy in a carbon-neutral way is receiving increasing attention. Most studies on bio-ethanol systems have thus, also investigated at least their CO2 balance, and often also those of the other major greenhouse gases methane and nitrous oxide. Again, a multitude of different indicators are used, and results are often not immediately comparable. 4.2.1 Avoided CO2 equivalent emissions from bio-energy systems Closely related to the replaced fossil energy indicator is the avoided emission of greenhouse gases (GHGs). It is dominated by CO2 flows, but the nature of the replaced fossil fuels (coal, oil, gas) does introduce a degree of divergence from the energy indicator, as these fuels are characterised by different fossil carbon intensities. Careful accounting for the two next important GHGs, i.e. CH4 and N2O, may exacerbate this variation, with global warming potentials of 21 and 310 times those of CO2 respectively. Again, the avoided CO2 indicator can be derived relative to a kilometre driven, or to the land area used. Figure 3 presents the results of our limited evaluation of avoided GHG emissions per hectare cropped and year, for the same studies as in Figure 2, and compares our results with those by Quirin et al. [5]. INSERT FIGURE 3 Sugar-based production systems again achieve much higher effects per hectare of cropped land than starch-based systems, and tropical sugarcane is again by far the most efficient crop. Our analysis yields a much higher figure for avoided GHGs than that of Quirin et al. [5], again because of our inclusion of the substitution effect of bio-based process heat and electricity. For the other feedstocks, our interpretation of the selected studies agrees well with the more general results of Quirin et al [5]. 4.3 Health and environmental impact assessments Only seven of the reviewed studies listed in Table 1 evaluate impacts that are more expansive in scope than the studies described in the previous sections. Whilst these studies Accepted for Publication in the Journal of Cleaner Production (1 March 2006) all account for energy (as resource demand), CO2 and greenhouse gas emissions, they go beyond these measures and include additional impact indicators. As each of these studies had a somewhat different objective and therefore, also a different scope, we have not attempted to harmonise the results as in the previous sections, but have opted to rather individually summarise each of them in the following paragraphs and in Table 3. Full citations are included in the references section. INSERT TABLE 3 Table 3 summarises the findings of these seven LCA studies by indicating for 13 impact categories and 6 related inventory categories whether the study reports an increased or decreased impact for bio-ethanol compared to conventional fuel. A dash indicates no change. In cases where only inventory data were provided, the relevant impact category was applied and interpreted as an increase, decrease or no change. As one scans across the lines of this table, it becomes evident that there is not much consensus on the environmental benefits of fuel bio-ethanol beyond the broad agreement that they do avoid to some extent the use of fossil energy carriers, and consequently also reduce GHG emissions. Kadam (2002). Environmental benefits on a life cycle basis of using bagasse-derived ethanol as a gasoline oxygenate in India [14]. Feedstock: Bagasse Location: India Basis: 1 dry tonne of bagasse to produce 10% by volume ethanol in gasoline (E10). System description: The study compares the conventional practice of burning bagasse in the field and using conventional fuel (Scenario 1) to a hypothetical process of converting bagasse into ethanol for use in E10 (Scenario 2). Boundaries include bagasse transport, ethanol production, use and excess electricity. Impacts: - Non-renewable resource depletion - Greenhouse effect - Air acidification - Eutrophication - Human toxicity - Waste generation - Air odour Findings: The author concludes that there are significant benefits in diverting excess bagasse to ethanol production as opposed to the current practice of open-field burning. Scenario 2 leads to a decrease in carbon monoxide, hydrocarbons, SOx, NOx, particulates, carbon dioxide, methane and fossil fuel consumption. COD (from ethanol raw material production) is significantly higher. Non-methane hydrocarbons are from ethanol production. Lime, ammonia & sulphuric acid occur only in Scenario 2. Electricity credits result in negative CO2 and CH4 emissions and lower solid waste. Kaltschmitt, Reinhardt & Steltzer (1997). Life cycle analysis of biofuels under different environmental aspects [10]. Feedstock: Sugar beet, wheat, and potato Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Location: Germany Basis: 1 hectare System description: This study compared bio-based systems, including cultivation and harvesting of raw materials, through energy use, to fossil systems, including mining and processing of raw materials through energy use. Impacts: - Finite energy - Global warming potential (CO2 equivalents) - Nitrous oxide - Acidification potential - Sulphur dioxide - Nitrogen oxide Findings: The study shows some clear ecological advantages of bio-ethanol over fossil fuels, such as conserving fossil energy sources and reducing global warming potential, but bio-ethanol also has some definite disadvantages; in particular N2O and NOX emissions are higher. SO2 emissions and, correspondingly, acidification potential show no discernible change. Puppan (2002). Environmental evaluation of biofuels [15]. Feedstock: Sugar beet, winter wheat, and potato Location: Germany Basis: Summary of a German study on E5 fuel versus gasoline [16]. System description: Not provided Impacts: - Depletion of abiotic resources - Climate change - Stratospheric ozone depletion - Acidification - Human & Ecotoxicity Findings: For the bio-ethanol portion of the paper, Puppan cites a German study [16] that shows that E5 (5% ethanol) fuel has lower impacts for depletion of abiotic resources and climate change, but higher impacts for stratospheric ozone depletion (acidification and human toxicity impacts were mostly unchanged). Puppan states that the LCA study proved the environmental benefit of biofuels during the combustion in the engine, but also emphasised the environmental drawbacks that occur during the agricultural phase, such as pollution of ground and groundwater by fertilisers and pesticides as well as the creation of monocultures. Puppan concludes that it is apparent that the net environmental impact significantly depends on the agricultural conditions. Reinhardt & Uihlein (2002). Bio-ethanol and ETBE (ethyl tertiary butyl ether) versus other biofuels for transportation in Europe: an ecological comparison [17]. Feedstock: Sugar beet, wheat and potato Location: Europe Basis: Per kilometre System description: Accepted for Publication in the Journal of Cleaner Production (1 March 2006) The study includes fertiliser, fuel, and pesticide production; cultivation; sugar extraction; ethanol production; and consumption (use in the vehicle). Impacts: - Resource demand (natural gas, mineral coal, brown coal, uranium ore) - Greenhouse gas emissions (CO2, CH4, N2O) - Acidification - Eutrophication - Photochemical smog (N2O) - Human toxicity (reported as LCI) - Eco toxicity (reported as LCI) Findings: For all life cycle comparisons, resource demand and greenhouse gas effect are in favour of biofuels, whereas most of the other parameters are in favour of the fossil fuels. Ethanol from sugar beets has advantages over wheat and potato. Hu et al (2004). Economics, environment, and energy life cycle assessment of automobiles fueled by bio-ethanol blends in China [18]. Feedstock: Cassava Location: China Basis: 200,000 kilometre driving distance System description: Cassava, from the Guangxi Province, is converted to E85 fuel for use in a 5-passenger vehicle. Impacts: The environmental impacts are reported as inventory releases of CO2, CO, hydrocarbons (HC), NOx, and particulate matter (PM). Findings: The cassava-based E85 fuel has lower life cycle CO2, CO, HC, and PM pollutants than gasoline fuel; however, it has higher NOx emissions. The combined environment indicator is calculated to be 20% lower for bio-ethanol. Sheehan et al (2004). Energy and environmental aspects of using corn stover for fuel ethanol [19]. Feedstock: Corn stover Location: USA (Iowa) Basis: 1 hectare of land and 1 kilometre travelled using 85% ethanol in gasoline (E85) versus gasoline. System description: Sheehan describes a hypothetical system of using corn stover to make E85. The processes include stover production & collection; transport; ethanol production; distribution; and use. The system also includes the gasoline system, with which the ethanol is blended, from crude oil extraction through use. Impacts: - Fossil energy use - Greenhouse gas emissions - Air quality (ozone precursors; CO; NOx) - Land use (soil health) - Cost Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Findings: Findings are presented in the paper for a few key metrics: - Fossil energy use is 102% and greenhouse gas emissions are 113% lower for E85. - 2.91 MJ/km avoided non-renewable energy. - Air quality impact is mixed with emissions of CO, NOX, and SOX substantially higher. NOX emissions result mainly from farm soil. SOX emissions result from the combustion of lignin residue at ethanol plants. Hydrocarbon ozone precursors are reduced. - Stover can be removed from the field whilst maintaining or increasing soil carbon. Tan & Culuba (2002). Life-cycle assessment of conventional and alternatives fuels for road vehicles [20]. Feedstock: Cellulosic agricultural waste using enzymatic hydrolysis and fermentation Location: Philippines Basis: Per kilometre System description: The LCA encompasses extraction of raw materials and energy resources; conversion of these resources into the desired product; the utilization of the product by the consumer; and the disposal, reuse, or recycling of the product after its service life. Impacts: - Resource depletion (oil, coal, natural gas) - Human toxicity potential (PM10) - Nutrification - Photochemical ozone - Acidification - GWP (CO2, CH4, N2O) - Air emissions (VOC, CO, NOX, PM10, SOX) Findings: For Scenario A, using Philippine Department of Energy projections for the year 2009, the use of bio-ethanol in place of gasoline is expected to yield significant gains particularly with respect to fossil fuel depletion and greenhouse gas emissions. The total impacts for bioethanol are significantly lower than those of gasoline, primarily due to sharp reductions in CO2 emissions (and global warming potential) and fossil fuel consumption. Tan & Culuba state that impacts of biofuels in other impact categories remain roughly comparable to those of conventional fuels (Table 1 shows acidification, nitrification and human toxicity potentials that are slightly larger and photochemical oxidation potential slightly less than conventional fuel). 5. Findings and Recommendations Published life cycle based assessments of the sustainability of bio-ethanol systems have investigated a wide variety of feedstocks (as presented in Table 1). An array of different metrics has been used to convey their results, sometimes complicating comparisons. Methods have varied from simple energy and carbon accounting to attempts to be more inclusive in addressing sustainability. Much of the focus has been to determine if the use of biomass to make fuel is a net loss or a net gain regarding energy input versus output. Two factors emerge as dominating the energy performance of bio-ethanol systems: crop/climate productivity, and nature of the feedstock. With regard to both of these, it is highly significant that both tropical sugar crops (by far the most productive) and cellulosic Accepted for Publication in the Journal of Cleaner Production (1 March 2006) feedstocks (potentially most sustainable and abundant), have, to date, received the least amount of attention in bio-ethanol sustainability assessments that go beyond energy and carbon analysis. The overriding conclusion of the studies that looked at energy balances was that the use of bio-ethanol in place of conventional fuels or as an additive leads to a net gain. That is, the prevailing data indicate that it takes less energy to make and distribute ethanol than can be delivered by the fuel. The results of the studies that evaluated other environmental impact categories beyond energy and greenhouse gases were mixed. Acidification, human toxicity and ecological toxicity impacts, mainly occurring during the harvesting and processing of the biomass, were more often unfavourable than favourable for bio-ethanol. The IFEU study had similar findings and concluded that for all life cycle comparisons, resource demand and GHG effect are in favour of biofuels, whereas most of the other parameters they evaluated are in favour of fossil fuels [17]. Our recommendations for future sustainability assessments of bio-ethanol are: 1. It is not necessary to repeat detailed energy and GHG assessments. Depending on crop and geographical location, in many cases it will be possible to obtain a sufficiently reliable estimate from previous work (e.g., [5] or from the Biomitre website [21]). 2. Studies should be selected to fill the critical gaps: full life cycle assessments are needed on ethanol from tropical sugar crops, and on 2nd generation bio-ethanol from cellulosic cropped feedstocks, such as perennial grasses or short rotation forests. 3. The assessments must be cradle-to-grave, as significant air quality impacts may be associated with the bio-ethanol used in internal combustion engines. 4. Attention must be paid to gathering the data needed for the disputed environmental categories of acidification, eutrophication, photochemical smog, human and ecotoxicity, as well as land use and its effects on biodiversity. Put another way, the safeguard subjects of human and ecological health need to feature more prominently next to those of climate change and resource depletion concerns. 5. Data gaps for life cycle assessments of corn to bio-ethanol in the United States should be addressed and filled, to address shortcomings of studies, to date, in accordance with recommendations 3 and 4. 6. Conclusion Moving toward sustainability requires a re-thinking of our systems of production, consumption and waste management and an increased awareness of the need to avoid shifting of problems, as often occurs with isolated measures. The ecological advantages should outnumber, or outweigh, the disadvantages to the environment and human health. Numerous studies have been done in recent years evaluating the life cycle impacts of bioethanol, and there is now strong evidence that all bio-ethanol production is mildly to strongly beneficial from a climate protection and a fossil-fuel conservation perspective. Fuel ethanol produced from sugar crops in tropical settings appears by far the most efficient in these categories from a land-use perspective. However, whilst over 40 studies have been life cycle based, only seven were identified which could be said to approach life cycle Accepted for Publication in the Journal of Cleaner Production (1 March 2006) assessments. These studies do not, of course, cover the full range of possible feedstocks and geographies, and their results in the standard impact categories diverge. Further assessments should thus, take energy and carbon performances as understood, work on the less studied but highly promising feedstocks and locations outside Europe and North America, and pay more attention to the safeguard subjects of human and ecological health. We caution against basing fuel production policy on environmental sustainability studies that are life cycle based in the sense of extending from the crop to the wheel, but that ignore issues other than fossil fuel depletion and GHG emissions; such practices are likely to result in detrimental shifting of burdens. Disclaimer This research was supported in part by the U.S. Environmental Protection Agency through its Office of Research and Development. This paper has not been subjected to Agency review and therefore does not necessarily reflect the views of the Agency, and no official endorsement should be inferred. References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Kim, S. and B.E. Dale, Global potential bioethanol production from wasted crops and crop residues. Biomass and Bioenergy, 2004. 26(4): p. 361-375. von Blottnitz, H., E. Theka, and T. Botha. Bio-Ethanol as octane enhancing fuel additive in Southern Africa: an examination of its “environmental friendliness” from a life cycle perspective. in National Association for Clean Air Annual Conference, 23-25 October, 2002. 2002. Durban, South Africa. Pimentel, D., Ethanol fuels: energy balance, economics, and environmental impacts are negative. Natural resources research, 2003. 12(2): p. 127-134. Niven, R.K., Ethanol in gasoline: environmental impacts and sustainability review article. Renewable and Sustainable Energy Reviews, 2005. 9(6): p. 535555. Quirin, M., et al., CO2 mitigation through biofuels in the transport sector – status and perspectives, main report. 2004, Institute for Energy and Environmental Research (IFEU): Heidelberg, Germany. Patzek, T.W., Thermodynamics of the corn-ethanol biofuel cycle. Critical Review in Plant Sciences, 2004. 23(9): p. 519-67. Berthiaume, R., C. Bouchard, and M.A. Rosen, Exergetic evaluation of the renewability of a biofuel. Exergy, An International Journal, 2001. 1(4): p. 256268. Curran, M.A. Achieving sustainability through life cycle strategies: keynote address. in Waste & Recycle Annual Conference. 2004. Fremantle, Autralia. Pimentel, D., The limits of biomass utilization, in Encyclopedia of pyhsical science and technology, third edition. 2001. p. 159-71. Kaltschmitt, M., G.A. Reinhardt, and T. Stelzer, Life cycle analysis of biofuels under different environmental aspects. Biomass and Bioenergy, 1997. 12(2): p. 121-134. Accepted for Publication in the Journal of Cleaner Production (1 March 2006) 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. Rosenberger, A., et al., Improving the energy balance of bioethanol production from winter cereals: the effect of crop production intensity. Applied Energy, 2001. 68(1): p. 51-67. Hanegraaf, M.C., E.E. Biewinga, and G. van der Bijl, Assessing the ecological and economic sustainability of energy crops. Biomass and Bioenergy, 1998. 15(45): p. 345-355. Shapouri, H., J. Duffield, and M. Wang, The energy balance of corn ethanol: an update. Agricultural Economic Report No 813, USDA, Editor. 2002. Kadam, K.L., Environmental benefits on a life cycle basis of using bagassederived ethanol as a gasoline oxygenate in India. Proc S Afr Sug Technol 2002. 75: p. 358-62. Puppan, D., Environmental evaluation of biofuels. Periodica Polytechnica Ser. Soc. Man. Sci 2002. 10(1): p. 95-116. Steltzer, T., Biokraftstoffe im vergleich zu konventionellen kraftstoffen – Lebensweganalysen von umweltwirkungen, research report. 1999, University of Stuttgart, Institut für energiewirtschaft und rationelle energieanwendung: Stuttgart, Germany. Reinhardt, G. and A. Uihlein, Bioethanol and ETBE versus other biofuels for transportation in Europe: an ecological comparison, in The 114th International Symposium on Alcohol Fuels (ISAF XIV). 2002: Phuket, Thailand. Hu, Z., et al., Economics, environment, and energy life cycle assessment of automobiles fueled by bio-ethanol blends in China. Renewable Energy, 2004. 29(14): p. 2183-2192. Sheehan, J., et al., Energy and environmental aspects of using corn stover for fuel ethanol. Journal of Industrial Ecology, 2004. 7(4): p. 117-46. Tan, R.R. and A.B. Culuba, A life cycle assessment of conventional and alternative fuels for road vehicles, in InLCA. 2002: Seattle, Washington. Biomitre. BIOmass based climate change MITigation through Renewable systems. [cited; Available from: http://www.joanneum.at/biomitre/. Prakash, R., A. Henham, and I. Krishnan Bhat, Net energy and gross pollution from bioethanol production in India. Fuel, 1998. 77(14): p. 1629-1633. Sheehan, J., et al., An overview of biodiesel and petroleum diesel life cycles, USDA and DoE, Editors. 1998, NREL. Elsayed, M.A., R. Matthews, and N.D. Mortimer, Carbon and energy balances for a range of biofuels options – final report. 2003, Prepared for the Department of Trade and Industry Renewable Energy Programme Unit of Sheffield Hallam University and Forest Research. de Carvalho Macedo, I., Greenhouse gas emissions and energy balances in bioethanol production and utilization in Brazil (1996). Biomass and Bioenergy, 1998. 14(1): p. 77-81. ISO, Environmental management – Life cycle assessment – principles and framework 14040. 1997, International Standards Organization, Geneva. Curran, M.A., Status of LCA as an environmental management tool. Environmental Progress, 2004. 23(4): p. 277-83. IEA, Analysis of biofuels. 2003, International Energy Agency. Accepted for Publication in the Journal of Cleaner Production (1 March 2006) 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. Graboski, M., Fossil energy use in the manufacture of corn ethanol. 2002, Prepared for the National Corn Growers Association. General Motors, Well-to-wheel energy use and greenhouse gas emissions of advanced fuel/vehicle systems – North American analysis. 2001. Schneider, U.A. and B.A. McCarl, Economic potential of biomass based fuels for greenhouse gas emission mitigation. 2001. Levelton Engineering Ltd., Assessment of net emissions of greenhouse gases from ethanol-blended gasolines in Canada: lignocellulosic feedstocks, R-2000-2. 2000, Cross-Sectoral Policy Development Division. Industry Performance and Analysis Directorate. Policy Branch. Agriculture and Agri-Food Canada. Wang, M., C. Saricks, and D. Santini, Effects of fuel ethanol use on fuel-cycle energy and greenhouse gas emissions, ANL/ESD-38, Argonne, Editor. 1999. Kavalov, B., et al., Biofuel production potentials of EU-candidate countries. Final report EUR 20835 EN Addendum to the final report 20836 EN. 2003, JRC. Jungmeier, G., S. Hausberger, and L. Canella, Treibhausgas-emissionen und kosten von transportsystemen - vergleich von biogenen mit fossilen treibstoffern. 2003. Schmitz, N., Bioethanol in Deutschland. Schriftenreihe (publication series), “Nachwachsende Rohstoffe (Regenerating Raw Materials)" Band 21. 2003. Igelspacher, R., Ganzheitliche systemanalyse zur erzeugung und anwedenung von bioethanol im verkehrssektor. (Holistic system analysis for the production and application of biofuels in the transport sector.). Financed by the Bavarian State Ministry for Agriculture and Forestry. Chair for Energy and Environmental Technologies at Institute for Energy Technology, TU München Prof. Dr.-Ing. U. Wagner, München. 2003, Technical University of Munich (TU München). (S&T)2, The addition of ethanol from wheat to GHGenius. 2003. EUCAR, CONCAWE, and JRC, Well-to-Wheels Analysis of Future Automotive Fuels and Powertrains in the European Context. 2003. LowCVP, Well-to-wheel evaluation for production of ethanol from wheat, WTW sub-group. 2004. Thrän, D. and M. Kaltschmitt, Status quo und potenziale der energetischen biomassenutzung in Deutschland- Wozu sollen welche biomassepotenziale genutzt werden? In: Bundesverband BioEnergie.V. und Fachagentur Nachwachsende Rohstoffe e.V. : Tagungsband: Ausbau der Bioenergie -im Einklang mit dem Natur- und Umweltschutz. Eine Standortbestimmung. 2004. ADEME/DIREM, Energy and greenhouse gas balances of biofuels in production chains in France – executive summary. 2002. Armstrong, A.P., et al., Energy and greenhouse gas balances of biofuels for Europe – an update, CONCAWE, Editor. 2002. Richards, I.R., Energy balances in the growth of oilseed rape for biodiesel and of heat for bioethanol. 2000, British Association of Bio Fuels and Oils (BABFO). Gover, M.P., et al., Alternative road transport fuels – a preliminary life-cycle study for the UK. 1996, Energy Technology Support Unit: Oxford. Patyk, A. and G.A. Reinhardt, LCA of bioethanol and ETBE. Internal report. 2002, Institute for Energy and Environmental Research (IFEU). Accepted for Publication in the Journal of Cleaner Production (1 March 2006) 47. 48. 49. 50. 51. 52. 53. 54. 55. 56. 57. 58. 59. Beer, T., et al., Life-cycle emissions analysis of alternative fuels for heavy vehicles. 2001, CSIRO. Schindler, J. and W. Weindorf, Well-to-wheel – ecological and economic assessment of vehicle fuels and motors. 2003: Nürnberg. Eyre, N., M. Fergusson, and R. Mills, Fuelling road transport: implications for energy policy. 2002, Energy Saving Trust (EST). General Motors, Well-to-wheel energy use and greenhouse gas emissions of advanced fuel/vehicle systems – a European study. Annex: Full background report - methodology, assumptions, descriptions, calculations, results. 2002. Enguidanos, M., et al., Techno-Economic analysis of bio-alcohol production in the EU – a short summary for decision-makers. 2002, JRC. Fromentin, A., et al., Caracterisation de filieres de production de bioethanol dans le contexte helvetique. Programme de recherche biomasse, annexes a rapport. 2000, Office Federal de l'Energie. Altmann, M., et al., Comparison of different motor concepts in individual traffic with regard to energy and fuel conservation. Prepared by LBST for the Bavaria State Ministry of Regional Development and Environmental Affairs. 2002. Bastianoni, S. and N. Marchettini, Ethanol production from biomass: Analysis of process efficiency and sustainability. Biomass and Bioenergy, 1996. 11(5): p. 411-418. Moreira, J.R., The Brazilian energy initiative – biomass contribution, in Biotrade Workshop. 2002: Amsterdam, The Netherlands. Enerstrat, CSR fuel ethanol lifecycle analysis. 2003, Prepared for CSR Sugar in association with APACE Research. Theka, E., Life Cycle assessment of ethanol produced from sugarcane molasses, masters thesis. 2003, University of Cape Town, Department of Chemical Engineering: Cape Town. GM, Well-to-wheel energy use and greenhouse gas emissions of advanced fuel/vehicle systems – a European study. Annex: Full background report methodology, assumptions, descriptions, calculations, results. 2002. Dreier, T., Ganzheitliche Bilanzerung von Grundstoffen und Halberzeugen (Holistic balancing of base materials and semi-finished products.) Teil V Biogene Kraftstoffe. 1999, Commissioned by the Bavarian Research Foundation/Research Centre for energy Management. Processed by Chair for Energy and Environmental Technologies at the TU München. Appendix: Energy analysis approaches: input versus output The energy analysis approach evaluates all the fossil fuel inputs in upstream processing steps like agriculture, transportation and processing, and these are compared against the delivered energy of the product biofuel. Referring to the terminology in Figure 1, the net energy available from a fuel, Ee, is equal to (EG-Ee1), where EG is the gross energy produced by the fuel during combustion and Ee1 is the total feedback energy in the fuel production process. Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Proposed in the literature are energy yield ratios, e.g., the ratio of gross energy output to energy input (Eg/Ei, when there is no fossil energy input as in the case described by Prakash et al [22] or Eg/(Ei+Eb+Ec+Ed) in the more general case). Similarly, a fossil energy ratio is proposed by Sheehan et al [23], defined as (Enet + Ecop)/ (EA + EB + EC + ED) To avoid any confusion, we will here call this the bio-energy yield to fossil energy input ratio (or ByFi ratio). This relates the energy retrieved from a product biofuel, weighed against the fossil energy input involved in its life cycle, particularly in its production and conversion, and the related upstream processes. It is observed that for fossil energy ratios greater than 1, the system approaches renewability, which is theoretically only feasible for no fossil energy requirements (ratio of infinity). It might be more useful to describe this ratio as a “bioenergy ratio,” as its value increases as the fossil energy input to the system decreases. The use of fossil energy replaced should also be of interest – especially when comparing liquid fuel options to other bioenergy scenarios, such as electricity generation, and it is reported more frequently in recent studies. This measure is the total energy needed to provide an equivalent of amount of gasoline less all fossil energy uses needed to produce the bio-ethanol: Avoided fossil energy = EE + Ecop – (EA+EB+EC+ED) Carbon balancing approaches Carbon dioxide is the key greenhouse gas responsible for environmental issues of climate change. The production and use of agro-based fuels, however, mitigates the presence of carbon dioxide in the atmosphere, because this carbon dioxide is used by the crops in photosynthesis, converting the carbon released back to biomass, in a complete carbon cycle. The emissions of CO2 from fossil energy use, and of other greenhouse gases (notably N2O in fertiliser manufacture and use, and CH4 from agricultural and processing operations), should remain as low as possible. These total CO2 equivalent emissions, documented in detail in the studies of Elsayed et al [24] and Sheehan et al [19] are: e 44 C A C B CC C D j GWPj X ij Ceq.emm. = 12 i a A related approach analyses avoided emissions, where the use of biomass used as fuel replaces a quantity of fossil fuel that may have been used, or improved efficiency in energy utilisation results in a reduction in fossil fuel use. The CO2 that may have resulted from its combustion is classified as “avoided emissions”, and these figures would vary depending on the energy savings calculated, as well as the measure of relativity on which they are based (e.g., per annum, per kWh electricity produced, per hectare of land, per kilometre travelled, etc) [25]. 44 C eq.emm. Avoided CO2 emissions (kg CO2eq.) = C E C cop 12 Life Cycle Assessment: Life Cycle Assessment (LCA) is a tool for the systematic evaluation of the environmental aspects of a product or service system through all stages of its life cycle. It provides a holistic, i.e. cradle-to-grave, approach to evaluate environmental performance by considering Accepted for Publication in the Journal of Cleaner Production (1 March 2006) the potential impacts from all stages of manufacture, product use (including maintenance and recycling), and end-of-life management. LCA provides an adequate instrument for environmental decision support. Life cycle assessment has proven to be a valuable tool to document the environmental considerations that need to be part of decision-making towards sustainability. A reliable LCA performance is crucial to achieve a life-cycle economy. The International Organization for Standardization (ISO), a world-wide federation of national standards bodies, has standardised this framework within the ISO 14040 series on LCA [26]. There are 4 basic elements involved in conducting an LCA: 1) Definition of the goal and scope of the study; 2) Identification and quantification of environmental loads involved; e.g., the energy and raw materials consumed, the air emissions, water effluents, and wastes generated (inventory); 3) Evaluation of the potential environmental impacts of these loads (impact assessment); and 4) Assessment of available options for reducing these environmental impacts (interpretation). Whilst LCA is not a single uniform approach at this time, life cycle impact assessment (LCIA) methodology seems to be converging on similar categories [27]. The ten most common are listed below with brief descriptions. In addition, odour, noise and radiation effects are sometimes included, but their occurrence is not as frequent. Typical LCIA practice employs mid-point modelling. Midpoint refers to the placement along the stressor-impact (cause-effect) chain where the impacts are modelled. For example, the inventory output data for different greenhouse gases is modelled to indicate potential global warming (expressed in CO2 equivalents, then added up), not the damage caused by climate change. In general this definition works, but it is not applicable to all impact categories. Especially, the categories of human health and ecological health are not considered to have a common midpoint in the cause-effect chain. This has led to the application of various modelling approaches to these categories. Although modelling to the endpoint results in a more environmentally-relevant and meaningful result, this level of detail would require impossibly large amounts of time, data, resources and knowledge of how to interpret the results. Analysis at a midpoint is an effective approach to LCIA in that it reduces the complexity of modelling by minimizing the amount of forecasting and effect modelling. It also results in simplifying communication of the results with fewer categories to report. Acidification Potential: Acidification results when sulphur dioxide and nitrogen oxides reach the atmosphere and react with water vapour to form acids. These acids fall to earth and can damage plants, animals, and structures. Acid deposition can occur through wet (e.g., rain, snow, sleet), dry, or cloud water deposition (e.g., fog). Acidification compares the capacity of substances to release hydrogen and is expressed in SO2 equivalents. Ecological Toxicity Potential: Ecotoxicity characterization provides a relative prediction of the potential of chemicals to cause harm to plant and animal life. Whilst determining an ecotoxicity potential for a single chemical in a known environment is a difficult task, expanding the list of chemicals and environments to which the modelling is applicable makes this task even more difficult, especially since impacts of the stressors on plant and animal species can have multiple components. A reference chemical is often selected for the comparison, e.g., 2,4-Dichlorophenoxyacetic acid (2,4-D), and thus the units of the ecotoxicity potentials are expressed in kg 2,4-D equivalents/kg emissions. Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Eutrophication Potential: Eutrophication occurs when fertilizers move from land to surface waters and cause an increase in the aquatic plant growth. This is followed by a chain of other events including fish death, decreased biodiversity, and foul odour and taste. The limiting nutrient is often phosphorus for freshwater systems and nitrogen for estuaries and coastal waters, and thus the location of the release often makes a significant impact on the relative potential for damage. Global Warming Potential: Global warming refers to the potential change in climate that may occur with increasing concentrations of “greenhouse gases” which trap heat that would have otherwise passed out of the earth’s atmosphere. Resultant effects may include increased droughts, floods, loss of polar ice caps, sea-level rise, soil moisture loss, forest loss, change in wind and ocean patterns, and changes in agricultural production. Greenhouse gases include carbon dioxide (CO2), methane (CH4), and nitrous oxide (NxO), as well as some compounds that are not naturally occurring (hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulphur hexafluoride (SF6), etc.). The impact of a greenhouse gas is compared to the warming potential of carbon dioxide, so global warming potential is expressed in units of CO2 equivalents. Human Toxicity Potential: Human toxicity characterization provides relative comparisons of a large number of chemicals which may have the potential to contribute to cancer or other negative human health effects. The focus of this category is not on the localised use of chemicals within a work environment, (e.g., industrial hygiene), but the long-term exposures to chemicals in the regional and global environment. Ozone Depletion Potential: Ozone depletion is the reduction of the protective ozone layer within the stratosphere caused by the emissions of ozone-depleting substances (such as freon, chlorofluorocarbons, carbon tetrachloride, methyl chloroform, etc.). Models often adopt the ozone depletion potentials published in the Handbook for the International Treaties for the Protection of the Ozone Layer where chemical scores are based on CFC-11 as the reference compound. Photochemical Ozone Creation Potential: Also known as ground-level smog, ozone is formed within the troposphere from a variety of chemicals including nitrogen oxides, carbon monoxide, methane, and other volatile organic compounds in the presence of high temperatures and sunlight. High concentrations of ozone lead to negative impacts on human health and the environment. POCP is often measured relative to ethylene and is expressed as C2H4 equivalents. Natural Resource Depletion: There are several ways currently being used to analyze resource use, but no method is currently recognised as the standard methodology. Resources are any naturally occurring material, such as ores and fossil energy sources. This category may also include land use and water use. Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Figure 1. Material flow and environmental interventions across the life cycle stages in a biofuel system Ea Ca Xe Xa Ce= carbon released from combustion Stage A: Production of Inputs Stage B: Agriculture & harvesting Cb Eb Enet Eint Xb Es Stage E: Combustion at consumer Cs = carbon fixed during biomass growth Solar energy input Xd Xc Stage C: Transport Cc Stage D: Ecop Conversion Process Ec Ea - Ed, E’e = fossil energy input Ca - Cd, C’e = carbon input from fossil energy Xa – Xe, X’e = emissions to the environment X’e Cd Ed E’e Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Figure 2. Agricultural land efficiency of bio-ethanol in replacing fossil energy for transportation 0 50 100 150 ligno-cellulose 200 250 300 IFEU (min) IFEU (max) Replaced fossil energy (GJ/ha.a) bagasse - India wheat straw - Great Britain corn stover - USA molasses - South Africa molasses - India corn - USA sugarbeet - Great Britain sugarcane - Brazil 0 50 100 150 200 Replaced fossil energy (GJ/ha.a) 250 300 Accepted for Publication in the Journal of Cleaner Production (1 March 2006) 0 5000 10000 15000 ligno-cellulose 20000 25000 30000 IFEU (min) IFEU (max) Avoided CO2eq. (kg/ha.a) bagasse - India wheat straw - Great Britain corn stover - USA molasses - South Africa molasses - India corn - USA sugarbeet - Great Britain sugarcane - Brazil 0 5000 10000 15000 20000 Avoided CO2 (kg/ha.a) Figure 3. Avoided GHG emissions for different bio-ethanol systems 25000 30000 Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Table 1. Studies of biomass-to-fuel ethanol categorised by feedstock, location and scope of the evaluation (energy/GHG or multiple criteria/LCA) Corn North America Europe Wheat North America Europe Potatoes Cassava Lignocellulose Australia Europe Farmed Feedstock Energy/GHG Multiple criteria/LCA Pimentel 2003 [3] IEA 2003 [28] Graboski 2002 [29] USDA 2002 [13] Berthiaume 2001 [7] Pimentel 2001 [9] GM 2001 [30] Schneider 2001 [31] Levelton 2000 [32] Wang 1999 [33] JRC 2003 [34] Jungmeier 2003 [35] Schmitz 2003 [36] TU München 2003 [37] IEA 2003 [28] (S&T)2 2003 [38] Elsayed 2003[24] EUCAR 2003 [39] JRC 2003 [34] Jungmeier 2003 [35] LowCVP 2004 [40] Schmitz 2003 [36] TU München 2003 [37] Thrän 2004 [41] ADEME 2002 [42] CONCAWE 2002 [43] Rosenberger 2001 [11] Richards 2000 [44] Hanegraaf 1998 [12] Gover 1996 [45] CSIRO 2001 [47] JRC 2003 [34] Schmitz 2003 [36] China Australia Hu 2004 [18] North America Europe IEA 2003 [28] Waste Feedstock Energy/GHG Multiple criteria/LCA Levelton 2000 [32] Sheehan 2004 [19] (corn stover ) (corn stover) Elsayed 2003 [24] (wheat straw) Levelton 2000 [32] (wheat straw) Kaltschmitt 1997 [10] Steltzer 1999 [16] IFEU 2002 [46] Kaltschmitt 1997 [10] Steltzer 1999 [16] IFEU 2002 [46] Hu 2004 [18] CSIRO 2001 [47] (wood) EUCAR 2003 [39] (wood) IEA 2003 [28] (unknown) Jungmeier 2003 [35] LBST 2003 [48] CONCAWE 2002 [43] (wood & grass) EST 2002 [49] (wood) GM 2002 [50] (crop residue) EUCAR 2003 [39] (wood & straw) LBST 2002 [53] (wood) Accepted for Publication in the Journal of Cleaner Production (1 March 2006) GM 2002 [50] (various) JRC 2002 [51] (wood & grass) Fromentin 2000 [52] Levelton 2000 [32] (switchgrass & hay) Philippines Sugarcane North America South America India Tan & Culuba 2002 [20] (agricultural) Bastianoni and Marchettini 1996 [54] Moreira 2002 [55] Macedo 1998 [25] Prakash 1998 [22] (molasses) Enerstrat 2003 [56] (molasses) CSIRO 2001 [47] (molasses) Theka 2003 [57] (molasses) Australia Sugar beet South Africa Europe Australia Elsayed 2003 [24] EUCAR 2003 [39] IEA 2003 [28] JRC 2003 [34] Jungmeier 2003 [35] Schmitz 2003 [36] Thrän 2004 [41] TU München 2003 [37] ADEME 2002 [42] CONCAWE 2002 [43] GM 2002 [58] LBST 2002 [53] Fromentin 2000 [52] FfE 1999 [59] Hanegraaf 1998 [12] CSIRO 2001 [47] Steltzer1999 [16] Kaltschmitt 1997 [10] IFEU 2002 [46] Kadam 2002 [14] (bagasse) Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Table 2. Bio-energy yield to fossil energy input ratios for bio-ethanol systems Feedstock and country Sugarcane, Brazil Sugarbeet, Great Britain Corn, USA Molasses, India Molasses, South Africa Corn stover, USA Wheat straw, Great Britain Bagasse, India Energy yield ratio 7.9 2.0 1.3 48 1.1 5.2 5.2 32 Accepted for Publication in the Journal of Cleaner Production (1 March 2006) Table 3. Common life cycle impact categories and inventory releases for bio-ethanol compared to conventional fuel from a review of recent literature (1996-2004) Kaltschmitt 1997 [10] Sugar beet Wheat Potato Germany Agricultural Feedstocks Puppan Reinhardt 2001[15] 2002 [17] Sugar beet Sugar beet Winter wheat Wheat Potato Potato Germany Europe Waste Feedstocks Hu 2004 [18] Cassava Kadam 2002 [14] Waste Bagasse Sheehan 2004 [19] Corn Stover Tan & Culuba 2002 [20] Agricultural Cellulosic Waste China India USA Philippines NA NA NA NA NA NA NA NA NA Resource Depletion Global Warming CO2 NA NA NA Acidification NA SOx NA NOx NA Eutrophication NA Human Toxicity NA CO NA NA NA NA NA NA NA NA NA NA NA NA Accepted for Publication in the Journal of Cleaner Production (1 March 2006) PM Ecological Toxicity NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA Photochemical Smog NA NA HC NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA Solid Waste NA Land Use Water Use Ozone Depletion Odour NA NA – Not Assessed – No significant change NA ↑ ↓ – Increased impact for bio-ethanol – Decreased impact for bio-ethanol NA NA NA NA NA NA NA NA