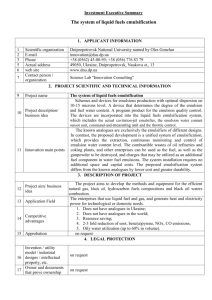

Under cavitation process, bubbles are formed

advertisement

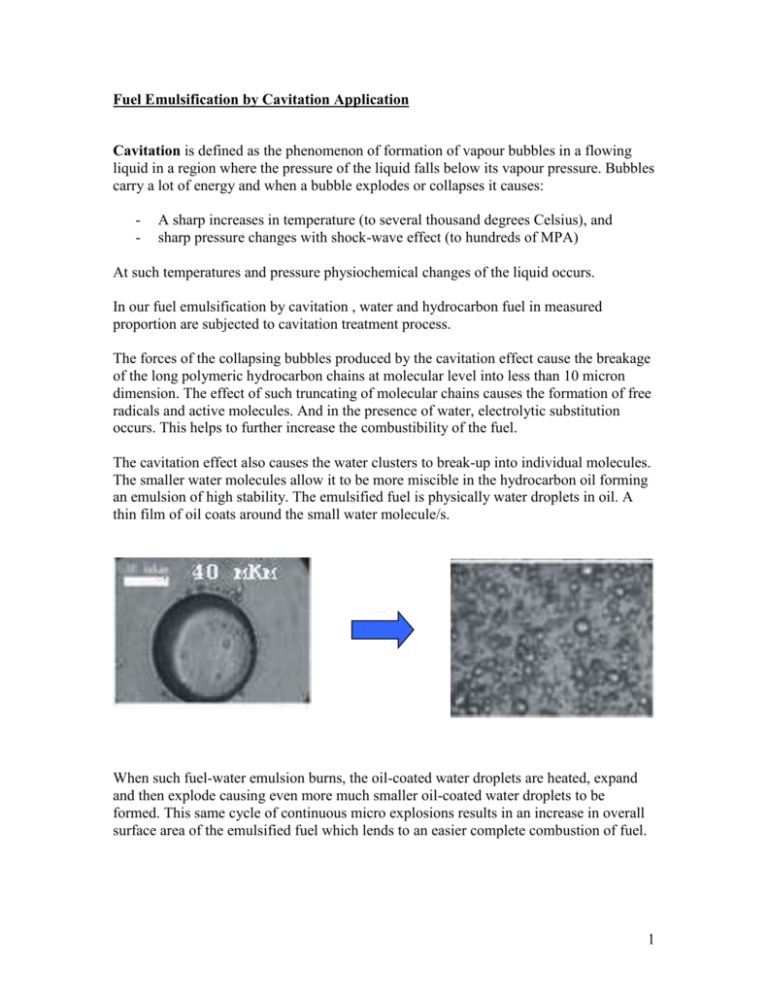

Fuel Emulsification by Cavitation Application Cavitation is defined as the phenomenon of formation of vapour bubbles in a flowing liquid in a region where the pressure of the liquid falls below its vapour pressure. Bubbles carry a lot of energy and when a bubble explodes or collapses it causes: - A sharp increases in temperature (to several thousand degrees Celsius), and sharp pressure changes with shock-wave effect (to hundreds of MPA) At such temperatures and pressure physiochemical changes of the liquid occurs. In our fuel emulsification by cavitation , water and hydrocarbon fuel in measured proportion are subjected to cavitation treatment process. The forces of the collapsing bubbles produced by the cavitation effect cause the breakage of the long polymeric hydrocarbon chains at molecular level into less than 10 micron dimension. The effect of such truncating of molecular chains causes the formation of free radicals and active molecules. And in the presence of water, electrolytic substitution occurs. This helps to further increase the combustibility of the fuel. The cavitation effect also causes the water clusters to break-up into individual molecules. The smaller water molecules allow it to be more miscible in the hydrocarbon oil forming an emulsion of high stability. The emulsified fuel is physically water droplets in oil. A thin film of oil coats around the small water molecule/s. When such fuel-water emulsion burns, the oil-coated water droplets are heated, expand and then explode causing even more much smaller oil-coated water droplets to be formed. This same cycle of continuous micro explosions results in an increase in overall surface area of the emulsified fuel which lends to an easier complete combustion of fuel. 1 It is well known that oil and water do not mix well. And in an engine, large clusters of water can be very corrosive and may cause damage on the long term. It is therefore to be highlighted that the proposed technology is not a water-fuel mixer or blender. Simple blending or mixing will only produce fuel emulsions with very low stability and in a short time, water separation from oil can be visibly observed. Our proprietary cavitation technology produces an emulsified fuel with long term stability. Laboratory samples of our Heavy Fuel Oil/Water emulsion produced more than 6 year ago, display no water-oil separation indicating high stability of the emulsion Benefits of Fuel Emulsification by Cavitation Effect 1. Pollution Reduction The combined effects of cavitation, both physical and chemical, gives rise to more complete combustion of fuel when burnt. A more complete combustion of fuel results in lower emissions of pollution exhaust. Specifically, complete combustion of fuel will lead to: 1. Reduction in Particulate Matter 2. Reduction in NOx 3. Lower concentration of Sulphur Dioxide Preliminary information gathered by Neftech Pte Ltd indicates significant reduction in the above, and more details will be made available as more tests are conducted. 2. Lower Maintenance Costs The other benefit of more complete combustion is cleaner engines. Cleaner burning results in less toxic by-products which causes engine corrosion which then requires higher maintenance costs. 3. Fuel Savings The most beneficial effect, and the most critical, is that better fuel combustion will lead to fuel savings. Tests carried out to-date on three container ships in the last twelve months have shown significant fuel savings . In this era of keen competition in the shipping industry and high fuel costs, this will be a welcome contribution to the bottom line. 2