LEED Strategies – specific to site anaylsis phase

advertisement

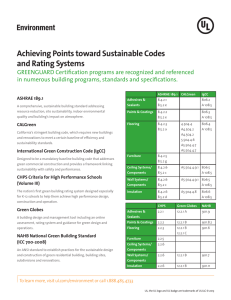

LEED Strategies The following is a cumulative list of LEED strategies from which we feel are achievable objectives for the new U.S. Land Port of Entry for Warroad, Minnesota. This list is a starting point that represents our current thoughts on achievable goals to reach a LEED silver rating. It will change and evolve throughout the process as the design progresses. Tracking this evolution through each phase will assure that we are on target for our goal. Listed below are the LEED sections and specific credits we feel are possible on this project as well as our initial strategies on achieving these credits. SUSTAINABLE SITES SS Credit 4.2 Alternative transportation Provide suitable means for securing bicycles with convenient changing and shower facilities for 5% of building occupant. We are currently providing locker rooms and showers in the male and female restrooms. We only need to add bike rack to achieve this credit. SS Credit 5.1: Site Development: Protect or Restore Habitat Minimize construction intrusion into wetlands to the north of the site. If required to gain wetlands credits, restore drain tile field to the northwest of the site to wetlands. Bank credits for any construction intrusion on wetlands to the north of the site Verify that some area of site can be restored. SS Credit 5.2: Site Development: Maximize open space Reduce development footprint (building, access, road) to exceed the local zoning’s open space requirement for the site by 25%. Verify what local zoning and or nearest local zoning requirements are for this site. Reduce from this requirement. SS Credit 6.1: Stormwater Design: Quantity and Quality Control Site is surrounded by soils with low-percolation capacity and high-water table. Wetlands to the north of the site also require protection from polluted site runoff water. Runoff from roads contribute large quantities of heavy metals (Lead, Copper, Chromium and Zinc), hydrocarbons and small and large particulate matter to adjacent hydrological systems. Contaminants accumulate on road surfaces during dry periods, and are picked up by the next rainfall and quickly moved to the storm water system. ‘First flush’ concentrations of pollutants can be very high, especially after long periods with no rain or snow fall. Because of the high degree of variability in rainfall events (intensity, duration and frequency) design of storm water treatment system must be designed to work for a wide range of loading rates. Methods Reduction of on-site storm water by use of permeable paving systems and reduction of impermeable surface on-site ‘First flush’ treatment of site runoff water before sending water off-site Install concrete permeable paving system Reduces annual runoff volume by 60 to 100 percent Runoff water infiltrates into shallow groundwater, replicating predevelopment hydrology Reduces nutrient and pollutant loads entering the storm water network Permeable pavements will function for up to 20 years Permeable systems must be constructed in areas free of disturbed soil and regularly maintained Permeable paving systems require a regular maintenance regime of sweeping to keep void spaces within the paving system open Normal maintenance, like street sweeping once a year, keeps the system operating as designed Iowa State has conducted research on cold weather performance of concrete paving Properly designed concrete mixes can withstand a high number of freeze-thaw cycles without degrading The addition of sand to the concrete mix design can increase longevity and structural strength SS Credit 6.2: Stormwater Design: Quality Control This may be possible and would require treatment systems to remove 80% of the average annual post development total suspended solids(TSS), and 40% of the average annual post development total phosphorous(TS), by implementing best practices. SS Credit 7.1: Heat Island Effect: Non-Roof Lighter paving colors. Light colored paving can reduce ambient temperatures at paving surfaces by 10 to 12 degree F. These measurements typically involve concrete versus bituminous paving surfaces. Most measurements and research has taken place in large urban areas, and relatively small paving areas, like the border station, may not see such drastic reductions in ambient temperature. Any reduction in surrounding exterior ambient temperatures can reduce cooling load inside the building. SS Credit 7.2: Heat Island Effect: Roof A green roof can reduce typical roof run-off loads by 60 to 80%. A green roof can reduce peak flow (by holding water within the roff growing medium) from larger rainfall events by 85%. Typically a green roof can delay discharge of roof storm water for 2 hours, before it flows into the site storm water system. The use of a green roof will reduce the size of site storm water system, and site impacts on a tight site. A green roof can reduce cooling and heating load in a building. Studies have shown that green roof maximum surface temperatures averaged 11 degrees F higher in the winter and more than 30 degrees F lower in the summer. Greens roofs in cold climates can reduce energy consumption by 10 percent in the winter months. The use of a green roof reduces temperature fluctuations on the roof membrane, extending the life span of the roof system. SS Credit 8: Light Pollution Reduction Full cut-off lighting fixtures for site lighting, including vehicle travel areas to conform to Dark Skies initiatives and reduce light pollution. Use low voltage LED exterior lighting (typically 50,000 to 100,000 hour life-cycle for white LED lamps). Safety cannot be compromised for lighting. WATER EFFICIENCY WE Credit 1.2: Water Efficient Landscaping: No Potable Water Use or No Irrigation Use native planting so that no irrigation system need to be installed on site, and no site water is used for irrigation. Rain water collection for use in irrigation system WE Credit 2: Innovative Waste Water Treatment This credit states that we need to reduce use of municipally provided potable water for building sewage conveyance by a min of 50%, or treat 100% of wastewater on site to tertiary standards. We need to verify how this credit works in relation to water source coming from on-site well. WE Credit 3.1: Water Use Reduction: 20% Reduction The intent is to reduce load on the Border Station septic system, and reduce water use. Grey water recycling system for non-potable water in commercial and secondary buildings toilet rooms Waterless urinals to replace ultra-low flow urinals generate a further reduction of 0.5 gals per flush. Based on 30 uses per day a waterless urinal can reduce the septic load by 11,000 gals per fixture per year. Two-stage flush valves for water reduction Ultra low-flow shower heads (0.8 to 1.5 gals per minute vs. 2.5 gals per minute). ENERGY & ATMOSPHERE EA Credit 1: Optimize Energy Performance Reduce energy costs compared to the energy cost budget for regulated energy components by 30% for 4 points. EA Credit 2: On-Site Renewable Energy Wind generated power for mains or backup system. Quiet Revolution QR2.5 vertical turbines require an average wind speed of 9mph to generate 4,000KwH to 7,000KwH of power per year. Photovoltaics EA Credit 3: Enhanced commissioning This is an added cost and is in addition to Fundamental Building commissioning. EA Credit 4: Enhanced refrigerant management Install base building level HVAC and refrigeration equipment and fire suppression systems that do not contain HCFC’s Halon. EA Credit 5: Measurement and Verification Long term continuous measurement of performance of systems. Recommended sub-metering of lighting and panels and mechanical motor panel EA Credit 6: Green Power Engage in a two year contract to purchase power generated from renewable sources. Roseau Electric has a relationship with Minnkota Power of Grand Forks, North Dakota who supplies wind power for a slight increase in monthly billing for this region. They stated that they should have alternative power available for purchase to this location by the completion of our project. MATERIALS & RESOURCES MR Credit 2.1: Construction waste management Recycle and reuse 50% of construction, demolition and land clearing waste. If relocation of homes occurs, this should count towards this credit. We will need to verify once project is registered. MR Credit 2.2: Construction waste management Recycle and reuse an additional 25% of construction, demolition and land clearing waste. If relocation of homes occurs, this should count towards this credit. We will need to verify once project is registered. MR Credit 3.1: Materials Reuse Specify salvage or refurbished materials for 5% of building materials. Materials will be from other resources. Source and quantity need to be recorded. Include origin and cost of salvaged materials. MR Credit 4.1: Recycled Content 10% Specify 25% of building materials that contain in aggregate weighted average of 20% post consumer recycled content or a min. weighted average of 40% post-industrial recycled content material. Concrete Mix Designs: Utilize a minimum 40% post-industrial recycled materials to replace cement with materials such as fly ash and/or ground granulated blast furnace slag. Steel Reinforcement and Structural Steel: Utilize 100% post consumer recycled metals. Driven Piles: Utilize recycled pipe such as used gas lines or rejected oil casings. MR Credit 5.1: Regional Materials Specify a minimum of 20% of building materials that are manufactured regionally within a radius of 500 miles. MR Credit 6: Rapidly Renewable Materials Specify rapidly renewable building materials for 5% of total building materials. MR Credit 7: Certified Wood Specify 25% of building materials that contain in aggregate weighted average of 20% post consumer recycled content or a min. weighted average of 40% post-industrial recycled content material. Wood Framing: Certify products specified to be made from certified wood comply with forest certification requirements. INDOOR ENVIRONMENTAL QUALITY IEQ Credit 1: Outdoor Air Delivery Monitoring Install a permanent carbon dioxide monitoring system that provides feedback IEQ Credit 2: Increased Ventilation Air change effectiveness greater than or equal to .9 as determined by ASHRAE 129-1997 IEQ Credit 3.1: Construction IAQ Management Plan, during construction During construction meet or exceed the minimum requirements of the sheet metal and air conditioning national contractors association and protect stored on-site or installed absorptive materials from moisture damage, and replace all filtration media prior to occupancy. IEQ Credit 3.2: Construction IAQ Management Plan, before occupancy Conduct a minimum two-week flush out with new filtration media at 100% or base line indoor air quality testing IEQ Credit 4.1: Low-Emitting Materials Meet or exceed VOC limits for adhesives, sealants, paints, composite wood products, and carpet systems IEQ Credit 4.2: Low-Emitting Materials Paints or coatings must meet or exceed the VOC and chemical component limits of green seal requirements IEQ Credit 4.3: Low-Emitting Materials Carpet systems must meet or exceed the carpet and rug Institute Green Label Indoor Air Quality Test Program IEQ Credit 4.4: Low-Emitting Materials Composite wood and agrifiber products must contain no added urea-formaldehyde resins. IEQ Credit 5: Indoor Chemical & Pollutant source Minimize cross contamination of regularly occupied areas by chemical pollutants. IEQ Credit 6.1: Controllability of systems Provide one operable window and one lighting control zone per 200sf for all occupied areas within 15 feet of the perimeter wall Daylight harvesting lighting schemes are planned for project. IEQ Credit 6.2: Controllability of systems Provide controls for each individual for airflow, temp. and lighting for 50% of the non-perimeter, regularly occupied areas. Use an expandable temperature range for building occupants Occupancy sensors in each zone to control airflow in areas, AHU control and set-points. IEQ Credit 7.1: Thermal Comfort Comply with ASHRAE standard 55-1992, addenda 1995 Use VAV for office instead of CAV with reheat IEQ Credit 8.1: Daylight & Views Minimum daylight factor of 2% in 75% of all space occupied for critical visual tasks IEQ Credit 8.2: Daylight & Views Direct line of sight to vision glazing form 90% of all regularly occupied spaces INNOVATION AND DESIGN PROCESS IEQ Credit 1.1: Innovation in design To be determined Instantaneous water heaters for low-use areas