Saucer SDS

advertisement

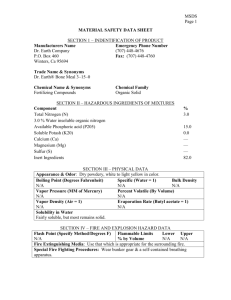

Anderson Saucers MDS – 2015 - Denton Plastics MSDS for Polypropylene Anderson Saucers – MSDS -2015 - MATERIAL SAFETY DATA SHEET 1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION PRODUCT NAME: PRODUCT CODE: PRODUCT DESCRIPTION: FORMULA: MSDS DATE: Denton Plastics, Inc. 18811 NE San Rafael St. Portland, OR 97230 2. Polypropylene None established Intended for various plastic molded products N/A June 2005 MANUFACTURER/SUPPLIER EMERGENCY TELEPHONE NUMBERS Emergency Number: 503-257-9945 Non-Emergency Number: 503-257-9945 Monday-Friday 8 - 5 PST COMPOSITION/INFORMATION ON INGREDIENTS The following chemicals may exceed the OSHA Hazard Communication or Canadian Controlled Products Regulations criteria for listing: INGREDIENT NAME Polypropylene Copolymer CAS # 9003-07-0 EXPOSURE LIMITS OSHA1 PEL ACGIH TLV (As Particulates (As Particles Not Otherwise Not Otherwise Regulated) Specified) 15 mg/m3 (T) 5 mg/m3 (R) CONC % 100 10 mg/m3 (I) 3 mg/m3 (R) OSHA PELs are current as of this revision (2005). ACGIH TLVs were published in 2005. Exposure limits are expressed as 8-hour time weighted average limits in milligrams per cubic meter of air. (T) = Total Particulate; (R) = Respirable Particulate; and (I) = Inhalable Particulate February 6, 2016 Page 1 of 7 Anderson Saucers MDS – 2015 - Denton Plastics MSDS for Polypropylene 3. HAZARDS IDENTIFICATION HAZARDOUS MATERIAL INFORMATION SYSTEM (HMIS) Health: 0 Fire: 1 Reactivity: 0 Hazard Scale: 0=Minimal 1=Slight 2=Moderate 3=Serious 4=Severe *=Chronic Hazard EMERGENCY OVERVIEW Low hazard for usual industrial or commercial handling. Pellets may present a slipping hazard. Burning or thermal decomposition may produce toxic vapors that may cause discomfort to the eyes, skin, and respiratory tract. Skin contact with molten material will cause burns. ROUTES OF ENTRY: Inhalation, eye contact, skin contact INHALATION: Inhalation of airborne particulate may lead to mechanical irritation of the respiratory tract and mucous membranes. Vapors and fumes from molten or burning polyethylene may cause respiratory irritation, headache or nausea. SKIN CONTACT: Mechanical irritation or abrasion from pellets or powder. Molten material will cause skin burns and may adhere strongly to the skin. Not expected to be a skin absorption hazard. EYE CONTACT: Contact with particulate may cause mechanical irritation or tearing. Vapors and fumes from burning material may cause irritation. INGESTION: Not a likely route of entry. Not expected to be toxic by ingestion. CARCINOGENICITY: NTP: Not listed IARC: Group 3: Not classifiable as to carcinogenicity to humans (polypropylene) OSHA: Not listed MEDICAL CONDITIONS GENERALLY AGGRAVATED BY EXPOSURE: Conjunctivitis of the eye, dermatitis of the skin, asthma, and respiratory diseases. 4. FIRST AID MEASURES INHALATION: If irritation occurs, remove to fresh air. If not breathing, give artificial respiration. Seek medical attention if symptoms or irritation persist. February 6, 2016 Page 2 of 7 Anderson Saucers MDS – 2015 - Denton Plastics MSDS for Polypropylene SKIN: Wash thoroughly with soap and water consistent with good hygiene practice. If contact with molten product occurs, flush with large volumes of cold water. If molten material adheres to the skin, do not attempt to remove. Cool quickly with water and obtain medical attention. EYE: Immediately flush with copious amounts of water for at least 15 minutes, carefully lifting eyelid to expose the eye to contact with the water. Remove contact lens, if present, and repeat flush. For contact with molten material, treat as for skin burns. If any symptoms or irritation persist, contact a physician. INGESTION: Not expected to be toxic by ingestion. Do not induce vomiting; give large quantities of water or milk. If any symptoms or irritation persist, contact a physician. 5. FIRE FIGHTING MEASURES FLASH POINT: N/A AUTO IGNITION TEMPERATURE: Not established FLAMMABLE LIMITS: N/A HAZARDOUS COMBUSTION PRODUCTS: Carbon dioxide, carbon monoxide, oxides of nitrogen, and organic chemicals such as methane, ethane, acrolein, organic acids, alcohols, ketones and aldehydes. The smoke may contain polymer fragments or toxic and/or irritating chemicals depending on combustion conditions. FIRE AND EXPLOSION HAZARD: When heated to decomposition, may emit toxic vapors and fumes. An electrostatic charge can potentially build up when pouring pellets. Grounding of equipment is recommended. EXTINGUISHING MEDIA: Dry chemical, foam, carbon dioxide, or water spray. SPECIAL FIRE FIGHTING PROCEDURES: Material will not burn unless pre-heated. Use water to cool fire exposed containers. Use self-contained breathing apparatus to avoid exposure to the products of combustion. 6. ACCIDENTAL RELEASE MEASURES: SPILL OR LEAK PROCEDURES: Pellets present slipping hazard on hard surfaces. Molten material presents a burn hazard. Wear appropriate personal protective equipment. Scoop or sweep up pellets or collect with vacuum equipment. Avoid generating dust. Dispose of in accordance with applicable federal, state/provincial, and local regulations. If material enters a sewer or waterway, notify responsible authorities. 7. HANDLING AND STORAGE: February 6, 2016 Page 3 of 7 Anderson Saucers MDS – 2015 - Denton Plastics MSDS for Polypropylene HANDLING AND STORAGE PRECAUTIONS: Fixed equipment, as well as transfer containers and equipment, should be grounded to prevent accumulation of static charge. Store in cool, dry, well-ventilated area away from heat, strong oxidizing agents, and ignition sources. 8. EXPOSURE CONTROLS/PERSONAL PROTECTION: EYE PROTECTION: Use goggles (ANSI Z87.1) if generating dust. Wear chemical splash goggles and face shield when possibility exists for eye and face contact due to splashing or spraying of molten material. SKIN PROTECTION: None normally required other than that for personal hygiene. To reduce exposure, work clothing should be left at the workplace. If there is potential for contact with hot/molten material, wear heat-resistant clothing and footwear. RESPIRATORY PROTECTION: Not normally needed. A NIOSH/MSHA-approved air-purifying respirator with dust/mist filters or organic vapor cartridges/canisters should be used when airborne particulate or vapor concentrations are expected to exceed exposure limits. Use a positive pressure air-supplied respirator if there is any potential for an uncontrolled release, exposure levels are not known, or other circumstances exist where air-purifying respirators may not provide adequate protection. ENGINEERING CONTROLS: Good general ventilation should be sufficient to control airborne levels under normal conditions. If user operations generate dust, fumes, vapors or mist, use process enclosures, local exhaust ventilation, or other engineering controls to control airborne levels below recommended exposure limits. 9. PHYSICAL AND CHEMICAL PROPERTIES: PHYSICAL STATE: APPEARANCE ODOR: BOILING POINT: MELTING POINT: pH: SOLUBILITY IN WATER: SPECIFIC GRAVITY: % VOLATILE BY WEIGHT: VAPOR PRESSURE: VAPOR DENSITY: 10. Solid White to off-white pellets None N/A Not determined N/A Insoluble 0.88 to 0.92 (water=1) N/A N/A N/A REACTIVITY/STABILITY: February 6, 2016 Page 4 of 7 Anderson Saucers MDS – 2015 - Denton Plastics MSDS for Polypropylene STABILITY: Stable at normal temperatures and storage conditions CONDITIONS OF REACTIVITY: None known HAZARDOUS POLYMERIZATION: Will not occur INCOMPATIBILITIES: Strong oxidizing agents. Avoid temperatures above 600°F. Product can decompose at elevated temperatures. DECOMPOSITION PRODUCTS: Carbon dioxide, carbon monoxide, oxides of nitrogen, and organic chemicals such as methane, ethane, acrolein, organic acids, alcohols, ketones and aldehydes. The smoke may contain polymer fragments or toxic and/or irritating chemicals depending on combustion conditions. 11. TOXICOLOGICAL INFORMATION: LD50: LC50: REPRODUCTIVE TOXICITY: TERATOGENICITY: MUTAGENICITY: CARCINOGENICITY: CHRONIC EXPOSURE: SENSITIZATION TO PRODUCT: 12. Not determined Not determined None listed None listed None listed See Section 3 See Section 3 Not expected ECOLOGICAL INFORMATION: Not expected to be acutely toxic but maybe mechanically harmful to wildlife if ingestion is attempted. Keep out of waterways. No bio concentration is expected. Polymer is expected to photo degrade in sunlight but remain in soil as an inert material. 13. DISPOSAL CONSIDERATIONS: Not an RCRA hazardous waste. Recovery and reuse, rather than disposal, should be the ultimate goal of handling efforts. Dispose according to local, state/provincial, and federal regulations. EPA Waste Codes: N/A for product 14. TRANSPORT INFORMATION: February 6, 2016 Page 5 of 7 Anderson Saucers MDS – 2015 - Denton Plastics MSDS for Polypropylene D.O.T. SHIPPING NAME: TECHNICAL SHIPPING NAME: D.O.T. HAZARD CLASS: U.N/N.A. NUMBER: SPECIAL SHIPPING INFORMATION: TDG Classification: ICAO/IATA Classification: IMDG Code: 15. N/A N/A N/A N/A N/A Not controlled under TDG (Canada) Not controlled under ICAO/IATA Not regulated as a hazardous material for transportation. REGULATORY INFORMATION: Users should comply with applicable OSHA and RCRA and other state and federal regulations, including (but not limited to) 29 CFR 1910.1000 (air contaminants), 29 CFR 1910.1200 (hazard communication), and 40 CFR 262 (hazardous waste). OSHA Hazard Communication Rule, 29 CFR 1910.1200: Not considered hazardous in product form. See components listed in Section 2 with accompanying notes. TSCA Inventory Status: All components of this product are listed in the U.S. Environmental Protection Agency Toxic Substances Control Act Chemical substance Inventory. SARA Title III Sect. 302 Extremely Hazardous Substances / CERCLA Hazardous Substances: This material contains no Reportable Quantity (RQ) Substances. SARA Title III Sect. 311/312 Hazard Classes: Fire Hazard: No Acute Health Hazard: No Reactive Hazard: No Chronic Health Hazard: No Release of Pressure: No SARA Title III Sect. 313 Toxic Chemicals: None California Prop 65: No components are known to the State of California to cause cancer and developmental effects. NJ Right to Know Law: No components are on the New Jersey Workplace Hazardous Substance List. MA Right to Know Law: All components have been checked for inclusion on the Massachusetts Substance List (MSL). Those components present at the de minimus concentration have been identified in Section 2 of the MSDS. PA Right to Know Law: All components have been checked for inclusion on the Pennsylvania Hazardous Substance List. Those components present at the de minimus concentration have been identified in Section 2 of the MSDS. Canadian Status: Not controlled under WHMIS. February 6, 2016 Page 6 of 7 Anderson Saucers MDS – 2015 - Denton Plastics MSDS for Polypropylene 16. OTHER INFORMATION: MSDS STATUS: VERSION NUMBER: PREPARED BY: Replaces MSDS dated September 2000 3.0 Paul Carlson Associates, Inc. Milwaukie, Oregon (503) 652-6040 Denton Plastics has prepared this information based on its reasonable review of available information. Underlying information was not created or prepared by Denton Plastics. Although Denton Plastics provides this information as a public service, it does not represent or warrant the accuracy, completeness, or applicability of the information contained herein. Denton Plastics does not warrant the fitness of the product for any particular use. All employers using the product should perform all review and testing and take all precautions required to protect their employees from any hazards associated with use of the product. February 6, 2016 Page 7 of 7