Compliance Checklists

advertisement

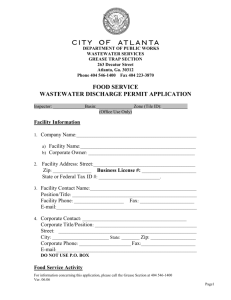

ALULINE GROUP COMPLIANCE DEPARTMENT Compliance Checklist Inspection Checklist Installation Checklist Inspector:________________________ Signature:________________________ Date:___________________________ Time Inspection Started:_____________ Time Inspection Completed:__________ Establishment:____________________________ Address:________________________________ Contact Name:___________________________ Phone:_________________________________ BMP, (Best management practice.) Inspection Checklist Number Item Description 1. The establishment has implemented a training program to ensure that BMPs are followed. 2. "No Grease" signs are posted in appropriate locations. 3. The establishment recycles waste cooking oil and can provide records of this. 4. Water temperatures at all sinks, especially the pre-rinse sink before the mechanical dishwasher or the sinks in the three. Measure and record temperature. 5. The establishment "dry wipes" pots, pans, and dishware prior to rinsing and washing. 6. Food waste is disposed of by recycling or solid waste removal and is not discharged to the grease traps or interceptors. 7. Grease trap(s) is cleaned regularly. Note and record the frequency of cleaning. 8. Grease trap cleaning frequency is documented on a maintenance log 9. Grease interceptor does not contain greater than 1/3 the depth in grease accumulation. Estimate and record amount of grease in interceptor. 10. Grease interceptor does not contain greater than 1/4 the depth in sediment accumulation. Estimate and record amount of sediment in interceptor if possible. 11 Outdoor grease and oil storage containers are covered and do not show signs of overflowing. 12. Grease and oil storage containers are protected from discharge to storm drains. Field Data (where appropriate) Compliance Status1 13. Absorbent pads or other materials (not free flowing material such as Alusorb) are used to clean up any spills or leakages that could reach the storm drain. 14. Storm drain catch basins show no signs of grease or oil. 15. The roof shows no signs of grease and oil from the exhaust system. 16. Exhaust system filters are cleaned regularly, which is documented by cleaning records. Note and record frequency of cleaning. NOTES ALULINE GROUP COMPLIANCE DEPARTMENT Inspector:________________________ Establishment:____________________________ Signature:________________________ Address:_______________________________ Date:__________________________ Contact Name:__________________ Time Inspection Started:___________ Phone:_________________________________ Time Inspection Completed:_________ Installation Checklist Number Item Description 1. Each grease trap serves not more than four single compartment sinks of the same depth. Grease trap is sized based upon the number of fixtures discharging to it. 2. Grease traps has a water seal of not less than two inches in depth or the diameter of its outlet, whichever is greater. 3. No food waste disposal unit or dishwasher is connected to or discharges into any grease trap. 4. Waste from toilets or toilet hand-wash/ urinals do not discharge to the grease interceptor. 5. W (Dishwashe any grease trap.) 6. The vertical distance between the fixture outlets and grease trap weirs is as short as practical. 7. Grease interceptor is as close as practical to the fixtures served. 8. Each fixture connected to a grease trap is provided with an approved type flow control or restricting device installed in a readily accessible and visible location. Devices shall be designed so that the flow through the device or devices at no time exceeds the rated capacity of the grease trap or interceptor. 9. Each fixture discharging into a grease trap or interceptor is individually trapped and vented in an approved manner. 10. Each grease trap and interceptor is fitted to properly vented pipe system to allow air circulation throughout the entire drain system. 11 Grease interceptor is easily accessible for inspection and cleaning and access does not require the use of ladders or the removal of bulky equipment. 12. Location of grease interceptor is shown on approved building plans. Drawings of interceptor are complete and show all dimensions, 13. Grease interceptor is installed Location shall meet the approval of the Local Authority. 14. Grease interceptor serves a single business establishment. is not discharged to any grease trap. is not discharged to Compliance Status1 15. Grease interceptor has a minimum of two compartments and 50mm diameter fittings designed for grease retention. The compartments shall be separated by partitions or baffles that extend above the water level. The inlet compartment shall be 70% of the total interceptor capacity 16. The outlet fittings shall be a baffle tee (or similar flow device) that extends above the water level and to within 100mm of the bottom of the interceptor. The outlet tee out of a sample box shall extend at least 100mm below the water surface. Flow between the separate compartments is through a baffle or bend that extends down to the bottom of the interceptor. 17 There shall be a minimum of open vent space above the water level to the top of the interceptor. The airspace has a minimum capacity equal to 10% of the grease interceptors liquid volume. . 18. The grease interceptor should have at least 300 sq mm of surface area for every 180 ltr of liquid capacity. 19. All waste enters the interceptor through the inlet pipe. 20. Grease interceptor cover is air-tight and should provide full access opening. 21. Grease interceptors located in areas of pedestrian or vehicle travel are adequately designed to support the imposed loads. 22 A sample box may be provided on the outlet side of the grease interceptor. This is recommended and may be required so that the Water Company can periodically sample the effluent quality. 23. Grease interceptor is permanently and legibly marked with the manufacturer's name of trademark, model number certification mark. NOTES Instructions for form: 1. Completely fill out general information. 2. For items that require some measurement of field data, the inspector should obtain the necessary data or information and record it under the column titled, "Field Data." 3. For all items marked in violation, note the fact that the establishment contact was notified of the violation and the contact's response. 1 An entry should be made for each item using the following codes: "C" – Compliance with the item "V" – Violation of the item (provide explanation in the notes) "NA" – Not applicable (provide explanation in the notes) "NC" – Not checked (provide explanation in the notes) Property of Aluline Compliance Department ALULINE GROUP COMPLIANCE CHECKLIST Frequently Asked Questions About Grease: Is grease a problem? What is a grease trap and how does it work? What is a grease interceptor? How do I clean my grease trap? Can you recommend a maintenance schedule? Do I have a grease trap? Do I need a grease trap? Is the grease trap I have adequate? What if I don’t install a grease trap? Who determines if I need a grease trap or interceptor? How can I get in compliance? What are the criteria for inspecting grease traps? Is Grease/Oil a problem? In the sewage collection and treatment business, the answer is an emphatic YES! Grease/Oil is singled out for special attention because of its poor solubility in water and its tendency to separate from the liquid solution. Large amounts of oil and grease in the wastewater(FOG)cause trouble in the collection system pipes. It decreases pipe capacity and, therefore, requires that piping systems be cleaned more often and/or some piping to be replaced sooner than otherwise expected. Oil and grease also hamper effective treatment at the wastewater treatment plant adding to operating costs. Grease/Oil in a warm liquid may not appear harmful. But, as the liquid cools, the grease or fat/oil congeals and causes nauseous mats on the surface of settling tanks, digesters, and the interior of pipes and other surfaces which may cause a shutdown of wastewater treatment units. Problems caused by wastes from restaurants and other grease-producing establishments have served as the basis for regulations governing the discharge of grease/oil (FOG) to the sewer system. This type of waste has forced the requirement of the installation of preliminary treatment facilities, commonly known as grease traps or interceptors. What is a grease trap and how does it work? A trap is a small reservoir built into the wastewater piping a short distance from the grease/oil producing area. Baffles in the reservoir retain the wastewater long enough for the grease/oil to congeal and rise to the surface. The grease/oil can then be removed and disposed of properly. What is a secondary underground grease interceptor? An interceptor is a specially designed tank with a minimum capacity of between 1000lt and 3000lt located on the exterior of the building. The trap includes a minimum of two compartments, and flow between each compartment is through a fitting designed for grease/oil retention. The capacity of the interceptor provides adequate residence time so that the wastewater has time to cool, allowing any remaining grease not collected by the internal traps time to congeal and rise to the surface where it accumulates until the interceptor is cleaned. How do I clean my grease trap? Refer to Grease Trap and Interceptor Maintenance. Can you recommend a maintenance schedule? All grease interceptors should be cleaned at least once per month. Some establishments will find it necessary to clean their traps more often than twice per month. If the establishment is having to clean it too often, the owner should consider implementing “Removal at Source Programme” or installing a larger trap or interceptor. Do I have a grease trap? If the establishment is uncertain whether it has a grease trap, the owner should contact the Local Drainage Department or Water/Compliance Company for the community served. Do I need a grease trap? Any establishment that introduces grease or oil into the drainage and sewage system as this can cause line blockages or hinder sewage treatment must install a grease trap or interceptor. Larger interceptors are usually required for high volume restaurants (full menu establishments operating 16 hrs/day and/or serving 500+ meals per day) and large commercial establishments such as hotels, hospitals, factories, or school kitchens. Grease traps are required for small volume (fast food or take-out restaurants with limited menus, minimum dishwashing, and/or minimal seating capacity) and medium volume (full menu establishments operating 8-16 hrs/day and/or serving 100-400 meals/day) establishments. Is the grease trap I have adequate? The regulations requires that Grease Trap have a capacity to meet eu standard or as per Water Companies Compliance Inspectors recommendation. The size of the trap depends upon the number of fixtures connected to it. The size will also depend largely upon the maintenance schedule. If a grease trap or interceptor is not maintained regularly it will not provide the necessary grease removal. The establishment should work out a specific cleaning schedule that is right for the establishment. All grease traps need to have the grease cleaned out periodically and no one likes to do the job. It is a dirty job. Running extremely hot water down the drain only moves the problem down stream. It does not go away. Catch the grease/oil at the source! This is the most economical means to reduce all costs. What if I don’t install a grease trap? If the establishment uses grease and oil in food preparation, it will eventually encounter a maintenance problem with a blocked drain/sewer line. The blockage can create a sewer backup situation and ultimately a potential health problem in the establishment or further down line to Public. Someone will have to pay for removing the blockage & the subsequent clean-up. If the problem is in the building sewer line, then the establishment has direct responsibility for paying for the clean-up. If the blockage or restriction is in the public sewer main and it can be proven that the establishment is the cause of the blockage, then the establishment may have to pay for the public sewer to be cleaned. Blocking a Public sewer system is also a violation of the regulations & can result in heavy fines, clean-up costs even a jail sentence for perpetrators . Compliance Inspector will report this contravention for action and may also call in Food & Health Inspectors Who determines if I need a grease trap or interceptor? When waste pretreatment is required by the Water Company, an approved grease trap or interceptor shall be installed according to the regulations. The rules of the Water Act & Building regulations states clearly that protection of sewer system is property owners responsibility Your designer will also assist your establishment in determining if a grease trap or interceptor is required. All administrative authorities prohibit the discharge of materials that can solidify and create blockages in the wastewater collection system or treatment plants. The Health Department/Water Companies makes periodic inspections to see that no health problems exist due to improperly maintained grease interceptors. These rules will be enforced if a problem exists. How can I get in compliance? The establishment should contact its local Compliance /company/Inspector The establishment will be asked to provide a risk assessment & drawing showing drainage system & protection installed to protect main public sewer system .This will require approval & stamp of compliance inspector to obtain a permit for the grease trap. This will enable the proper jurisdiction to assist the establishment in cleaning schedules and advise them of any problem showing up in the wastewater collection system. A grease interceptor permit will be required regardless of whether the establishment has an existing trap or is installing a new one. What are the criteria for inspecting grease traps? All food service establishments suspected of causing problems to the collection system or treatment facilities will be inspected. Some agencies use the following criteria to inspect grease traps: Percent of Trap Filled Trap Condition 25 Good 25 – 50 Fair >50 Poor If the trap is in FAIR condition, the establishment should be advised to keep an eye on the maintenance schedule. The cleaning frequency may need to be increased. If the trap is in POOR condition, the establishment should be issued a compliance order to have it cleaned immediately. The establishment should then be required to contact the issuing authority within 30 days to verify that the grease interceptor has been properly cleaned & produce a maintenance plan or contract from approved cleaning contractor. ALULINE GROUP COMPLIANCE DEPARTMENT Best Management Practices (BMPs) Prevent Blockages in the Sanitary Sewer System Properly Grease Traps and Interceptors to Prevent Introduction into the Sanitary Sewer System Prevent Fats, Oil, and Grease From Entering Ponds/Lakes and Streams Through the Storm Drain System Prevent Blockages in the Sanitary Sewer System BMP Reason For Benefits to Food Service Establishment Pretreatment Inspection Tips Train kitchen staff and other employees about how they can help ensure BMPs are implemented. People are more willing to support an effort if they understand the basis for it. All of the subsequent benefits of BMPs will have a better chance of being implemented. Talk to the establishment manager about the training program that he/she has implemented. Post "No Oil/ Grease" signs above sinks and on the front of dishwashers. Signs serve as a constant reminder for staff working in kitchens. These reminders will help minimize grease discharge to the traps and interceptors and reduce the cost of cleaning and disposal. Check appropriate locations of "No Oil/ Grease" signs. Use water temperatures less than 60° C in all sinks, especially the prerinse sink before the mechanical dishwasher. Temperatures in excess of 60° C will dissolve grease, but the grease can recongeal or solidify in the sanitary sewer collection system as the water cools. The food service establishment will reduce its costs for the energy – gas or electric – for heating the water. Check boiler or hot water heater discharge temperature. There are many waste oil recyclers One National Organization A.C.O.R.N. Will advise on members in your area. The food service establishment will be paid for the waste material and this may reduce cost of disposal Obtain waste disposal records The mechanical dishwasher requires a minimum temperature of 60° C, but the Best practice advice do-not discharge the dishwasher to grease traps. Recycle waste cooking oil. Measure the temperature of the hot water being discharged from the closest sink. Confirm records with waste recycle company. "Dry wipe" pots, pans, and dishware prior to dishwashing. The grease and food that remains in pots, pans, and dishware will likely go to the landfill. By "dry wiping" and disposing in garbage receptacles, the material will not be sent to the grease traps and interceptors. This will reduce the amount of material going to grease traps and interceptors, which will require less frequent cleaning, reducing maintenance costs. Observe dishwashing practices. Dispose of food waste by recycling and/or solid waste removal. Some recyclers will take food waste for Composting. In the absence of such recyclers, the food waste can be disposed as solid waste in landfills by designated waste disposal companies. Recycling of food wastes will reduce the cost of solid waste disposal. Inspect grease traps and interceptors for food waste accumulation. Solid waste disposal of food waste will reduce the frequency and cost of grease trap and interceptor cleaning. Confirm the recycler or solid waste removal company with the establishment manager. ALULINE GROUP COMPLIANCE DEPARTMENT Properly Maintain Grease Traps and Interceptors to Prevent Introduction into the Sewer System BMP Reason For Benefits to Food Service Establishment Witness all grease trap or interceptor cleaning/maintenance activities to ensure the device is properly operating. Grease trap/interceptor cleaning companies may take shortcuts. If the establishment manager inspects the cleaning operation and ensures it is consistent with the procedures in the section on Grease Trap and Interceptor Maintenance they are more assured of getting full value for their money. The establishment will ensure it is getting value for the cost of cleaning the grease trap or interceptor. Otherwise the establishment may be paying for cleaning more often than necessary. Clean under-sink grease traps regularly. Under-sink grease traps have less volume than grease interceptors. If grease traps are more than 50% full when cleaned weekly, the cleaning frequency needs to be increased. Weekly cleaning of undersink grease traps by the establishment’s own maintenance staff will reduce the cost of cleaning the grease interceptor. If the establishment does not have a secondary grease interceptor, and the undersink grease trap is the only means of preventing grease from entering the sanitary sewer system when the maintenance is not adequate the Water Company may require installation of a Secondary grease interceptor. Regular cleaning by staff using sinks will encourage less debris from being discharged into traps This will extend the length of the cleaning cycle for grease interceptors that the establishment maintains. Pretreatment Inspection Tips None. Visually inspect the contents of the under-sink grease trap. Inspect cleaning records. Clean grease interceptors routinely. Grease interceptors must be cleaned routinely to ensure that grease accumulation does not cause the interceptor to operate poorly. The cleaning frequency is a function of the type of establishment, the size of the interceptor, and the volume of flow discharged by the establishment. Keep a maintenance log. The maintenance log serves as a record of the frequency and volume of cleaning the interceptor. It is required by the pretreatment programme to ensure that grease trap/interceptor maintenance is performed on a regular basis. Routine cleaning will prevent blocking of the sewer line between the food service establishment and the public sewer system. If the line blocks, the sewer line may back up into the establishment, and the business will need to employ a company to jet it. Interceptor should have no more than 1/3 the depth as grease, and, Interceptor should have no more than 1/4 the depth as sediment, and No more than 25% of the depth should be a combination of grease (top) and sediment (bottom). The maintenance log serves as a record of cleaning frequency and can help the establishment manager optimize cleaning frequency to reduce cost. Inspect maintenance log. Provide the establishment with a sample maintenance log if it does not have one. Confirm the maintenance log has the waste disposal company identified. ALULINE GROUP COMPLIANCE DEPARTMENT Prevent Fats, Oil, and Grease From Entering Rivers, Lakes, Creeks Through the Storm Drain System BMP Reason For Benefits to Food Service Establishment Pretreatment Inspection Tips Cover outdoor grease and oil storage containers. Bund to ensure no oil can enter surface water drain Uncovered grease and oil storage containers can collect rainwater. Since grease and oil float, the rainwater can cause an overflow onto the ground. Such an overflow will eventually reach the stormwater system and nearby streams. The discharge of grease and oil to the storm drain system will degrade the water quality of receiving streams by adding biological and chemical oxygen demand to the stream. Locate oil /grease disposal and storage containers and keep away from storm drain inlets. The farther away from the drain, the more time someone has to clean up spills or drainage prior to entering the storm drain system. The discharge of grease and oil to the storm drain system will degrade the water quality of receiving streams by adding biological and chemical oxygen demand to the stream. Be aware of oil and grease dripped on the ground while carrying waste to the waste bins, as well as oil and grease that may "ooze" from the waste bins. Discharge of grease and oil to the storm drain might also result in legal penalties or fines. Use absorbent pads or other material in the storm drain if grease containers must be located nearby. Absorbent pads and other materials can serve as an effective barrier to grease and oil entering the storm drain system. The discharge of grease and oil to the storm drain system will degrade the water quality of receiving streams by adding biological and chemical oxygen demand to the stream. Discharge of grease and oil to the storm drain might also result in legal penalties or fines. Check the nearest gully and drainage areas for signs of grease and oil. Routinely clean kitchen exhaust system filters. If grease and oil escape through the kitchen exhaust system, it can accumulate on the roof of the establishment and eventually enter the storm drain system when it rains. The discharge of grease and oil to the storm drain system will degrade the water quality of receiving streams by adding biological and chemical oxygen demand to the stream. Inspect roof (if safely accessible) for signs of oil and grease. Discharge of grease and oil to the storm drain might also result in legal/action/ penalties or fines. Discharge of grease and oil to the storm drain might also result in legal penalties or fines. Property of Aluline Compliance Department Observe storage area for signs of oil and grease. Inspect containers for covers. Remove covers to ensure containers have not overflowed and do not have excess water. Observe storage area for signs of oil and grease. Inspect the closest drain for signs of accumulated grease and oil. Require absorbent pads if the basin is within 20 feet of grease containers, or if there are signs of grease in the catch bund at any distance. Require a maintenance schedule and records for cleaning exhaust filters. Cleaning is usually by washing, which will discharge the grease to the interceptor where it can be controlled. ALULINE GROUP COMPLIANCE CHECKLIST Fats, Oil and Grease Haulers and Recyclers Note: Compliance Debt. Licensed septic haulers not included on this list can also pump out grease traps and interceptors and deliver the waste to wastewater treatment plants. The disposal company must submit a written request to the appropriate regional Compliance office for every new site that they wish to haul from and the Compliance Inspectors for region will approve this action by letter. Hauler/Recycler and Location Phone Number Acceptance Criteria Picks up and recycles cooking oil. Provides storage container for oil. Picks up and recycles cooking oil. Provides storage container for oil. Picks up and recycles cooking oil. Provides storage container for oil. Picks up and recycles cooking oil. Provides storage container for oil. Accepts grease trap/interceptor waste from disposal companies. Has own treatment/reclaim system. Pumps out grease traps and interceptors. Picks up and recycles cooking oil. Provides bunded tank for oil. ALULINE GROUP COMPLIANCE DEPARTMENT Prohibitions Relating to Discharge of Fats, Oil, and Grease DO NOT… Basis Do not discharge fats, oil, and grease into sinks/drains/toilets as this will cause an obstruction to the flow in a sewer, or pass through or cause interference at a wastewater treatment facility. Grease can solidify and trap other solid particles to completely block the wastewater collection system. Do not discharge grease, improperly shredded garbage, animal guts or tissues, paunch manure, bones, hide, hair, fleshing, or entrails. These materials in combination or alone can cause blockages and other operations and maintenance problems in the wastewater collection and treatment system. Do not discharge wastewater with temperatures in exc to any grease traps. This includes water from mechanical dishwashers that have a minimum required temperature of . Temperatures in excess of 60° C will dissolve grease, but the grease can re-congeal and cause blockages further downstream in the sanitary sewer collection system as the water cools. Note: High temperature water, such as from a dishwasher, is discharged to the remotely-located grease interceptor, if there is one. The remote location and the high volume of the interceptor allows the water time to cool so that there is not a problem with dissolving grease and moving it further downstream. The high volume also provides dilution of the detergents in the dishwasher waste. Do not discharge waste from a food waste disposal unit to any grease traps. The food waste will greatly reduce the capacity of the grease trap for retaining grease and can cause worse problems with blockages. (Special tanks that can be cleaned by waste disposal truck are advised) Do not discharge caustics, acids, solvents, or other emulsifying agents. Though emulsifying agents can dissolve solidified grease, the grease can re-congeal further downstream in the sewer pipework system. Caustics, acids, and solvents can have other harmful effects on the wastewater treatment system and can be a hazard to employees working in the wastewater distribution system. Do not discharge fats, wax, grease or oils containing substances that will become viscous between The temperatures shown are temperatures that can occur in the wastewater collection and treatment system. If these substances congeal, solidify, or become too viscous, they can cause blockages and other operations and maintenance problems. Do not clean equipment outdoors in an area where Water can flow to the gutter, storm drain, or street. Grease and dirt will be washed off the equipment and enter the storm drain system and flow to nearby streams. ALULINE GROUP COMPLIANCE DEPARTMENT Preventing Water Pollution PROPER HANDLING OF FATS, OILS AND GREASE WATER POLLUTION PREVENTION TIPS FOR THE FOOD SERVICE INDUSTRY Why Is Water Pollution Prevention Important? It’s in everyone’s best interest to reduce the amount of chemicals, hazardous substances and food wastes that flow into the sewer system. It’s good for the earth, it’s good for our pocket books and it’s good for our communities. Waterways are fragile environmental systems that need our care and protection. Over the last 50 years, local governments and businesses have made tremendous investments in Sewage Treatment Plants to keep pollution out of lakes, streams and rivers. But just because the facilities are in place doesn’t mean we can ignore our responsibilities toward our waterways. It’s critical that in homes and businesses we pay attention to the impact of our actions on water quality. Sewer Systems. The fundamental reason we have to be careful about what goes into sewer systems is that even the best sewage treatment facility has limitations. S.T.Ps are designed primarily to handle sanitary or domestic sewage. Bacteria provide “treatment” by breaking down organic matter in the water. We need to remember that: • Treatment facilities can’t treat all the many chemicals/medications we dispose of, so substances may pass untouched into the environment. This may threaten fish, wildlife and vegetation, as well as people using polluted water sources for drinking and recreation. • Some chemicals can destroy the bacteria in the treatment process – leaving the facility useless. This not only endangers the environment – it means tremendous expense to community /Higher water bills. 2 • If the facility receives too much of one type of waste at a time, it will not be able to process the organic matter. Again, this creates environmental hazards, and the Water Company may need to invest in greater treatment capacity thus adding to our bills. • Some chemicals in the sewage treatment system put system employees at risk. Exposure to chemicals can cause health problems, and some substances may cause explosions and fires. How the Food Service industry can affect Sewer Systems Every commercial cooking operation produces waste products of food, oils and grease (FOG). On a small scale, we all know what can happen when heated grease congeals in kitchen pipes – the pipes block up, blocking passage of liquid and creating unsanitary backups into the kitchen on a larger scale, the same thing can happen to sewer systems. Most blockages in wastewater collection systems can be traced to FOG. The result can have damaging effects throughout the system, creating sewage spills, manhole overflows or backups into homes and businesses. Too much grease and oil also can create the need for increased maintenance of pipelines, increasing costs to all customers. Restaurant personnel often use chemicals during clean-up that can impact the sewage treatment system – and ultimately lakes, streams or rivers. It’s always best to reduce chemical use, and make sure those chemicals you do use are friendly to the environment. Storm Sewers In most communities, storm drains flow directly into waterways without passing through a treatment plant. Anything in the storm drain – from leaves to motor oil – can contribute to water pollution. Why Is Water Pollution Prevention Important? Whenever grease or oil receptacles are stored outside, there is a chance of spills or overflows that will be collected by storm drains. Food product contamination in rivers and streams can interfere with the water’s nutrient balance and affect the health of fish vegetation and wildlife. Cleaning chemicals washed into storm drains can also impact water quality, as can debris from outdoor eating areas. Leaves, grass and motor oil from parking lots can also be washed into the storm drains and have a negative impact on rivers and streams. Grease and oil escaping through the exhaust system will be collected in rain water and carried into the sewers and waterways. How Can Pollution Prevention Help Businesses’ Bottom Line? Many businesses find that taking steps to prevent pollution – including keeping FOG materials out of the sewer system – saves money. • Keeping FOG out of your drains will reduce the likelihood of grease related plumbing problems. • An establishment causing a FOG spill to the storm sewer may be eligible for fines. • Fats, oils and grease can often be recycled, reducing waste disposal costs. • Water Companies will bill a business for excess sewer cleaning costs, if the agency can trace the source of the problem to that establishment. • Ultimately, we all pay if we need to build more treatment system capacity. We all save by keeping materials out of the sewer system. 1. Post “No Grease” signs above sinks and in front of dishwashers. Frequent reminders can help educate employees about the importance of keeping FOG out of sinks and drains. 2. Dry wipe pots, pans and dishes Get as much oil and grease as possible off the cookware before it hits the water. Send it into the trash for disposal in the landfill waste system. 3. Recycle waste cooking oil and other food wastes. Call your local compliance inspectors for businesses in your area that collect and recycle cooking oil. 4. Use lower water temperatures Water over 60 C will dissolve grease, sending it down the drain in wastewater. Inevitably, this grease will congeal – either in your pipes or in the public sewer system. 5. Install and properly maintain grease traps and interceptors Government and local laws require restaurants to install and maintain grease traps, interceptors or both, depending on the size and type of the food service. Contact your local planning department your local Water Company to find out your requirements and to make sure you are in compliance with all regulations. Some rules for maintenance are: 6. Clean under sink grease traps regulary. If grease traps are more than 50 percent full after one week, increase how frequently you clean the trap. You also may want to consider ways to reduce the amount of FOG reaching the sink drain. 5 7. Have large interceptors cleaned at least twice a year. It may be necessary to have interceptors cleaned more often. If more frequent cleanings are needed, consider installing a better trap or an interceptor with larger capacity or using other techniques to keep FOG out of the drains. 8 Make sure maintenance is done correctly. At least one employee in each facility should be knowledgeable & trained regarding cleaning procedures for traps and interceptors. That employee should observe maintenance contractors, waste disposal companies and recyclers to make sure all procedures are carried out fully and effectively. 9 Cover any grease and oil storage containers kept outdoors Open containers can collect rainwater and overflow, sending grease and oil into the storm water system and ultimately polluting local waterways.(consider use of bunds) 10 Keep grease/oil storage containers an adequate distance from storm drains. The farther away you keep these units from a gully, the more time there will be for someone to clean up a spill or leak before it reaches the surface drainage system. 11. Use absorbent pads inside storm drains to catch FOG that may leak into the catch basins. If grease/oil containers are within 20 feet of the gully, or if you detect signs of FOG near the gully, line the gully with an absorbent cloth or pad. Use absorbent pads or cloths to clean up any spills or leaks. How to Keep FOG out of the Sewer System 6 12. Keep kitchen exhaust filters clean. Grease and oil escaping through the exhaust system can accumulate on the roof, ultimately getting washed into the storm sewers/rainwater collection systems. Establish a routine schedule and a record-keeping system for cleaning exhaust filters. Make sure that wastewater from washing is routed into the interceptor, where oil and grease can be collected before it reaches the sewer system. 13. Be cautious about outside cleaning. Do not conduct outside cleaning activities where wastes can flow into storm drains. 14. Don’t throw wastewater down storm drains. Train employees and contractors to dispose of wastewater appropriately. Water used for mopping, for carpet cleaning and for washing hood filters should be disposed of through the sewer system – never in storm drains. To protect the water treatment plants & pipe systems, limit cleaning chemicals and use the least hazardous products available. How to Keep FOG out of the Sewer System ALULINE GROUP COMPLIANCE DEPARTMENT GREASE INTERCEPTOR CLEANING RECORD VERIFICATION FORM Facility Name:___________________________________________ Address: _______________________________________________ Service Company used: ___________________________________ DATE CLEANED BY WITNESSED BY LITRES PUMPED GREASE DISPOSAL BY REMARKS ALULINE GROUP COMPLIANCE DEPARTMENT What Happens to Your Recycled Used Oil Used oil, or 'sump oil' as it is sometimes called, should not be thrown away. Although it gets dirty, used oil can be cleaned of contaminants so it can be recycled again and again. There are many uses for recycled used oil. These include: Industrial burner oil, where the used oil is dewatered, filtered and dematerialized for use in industrial burners; Mould oil to help release products from their moulds (e.g. pressed metal products, concrete); Hydraulic oil; Bitumen based products; An additive in manufactured products; or Re-refined base oil for use as a lubricant, hydraulic or transformer oil. Once you have taken your used oil to your local collection facility, used oil collectors take the used oil and undertake some pre-treatment and recycling of the used oil or sell it to a specialized used oil recycler. Pre-treatment of used oil involves removing any water within the oil, known as dewatering. One way of doing this is by placing it in large settling tanks, which separates the oil and water. Further recycling steps include: Filtering & demineralization of the oil, to remove any solids, inorganic material and certain additives present in the oil, producing a cleaner burner fuel or feed oil for further refining; Propane de-asphalting to remove the heavier bituminous fractions, producing re-refined base oil; and Distillation to produce re-refined base oil suitable for use as a lubricant, hydraulic or transformer oil. This process is very similar to the process undergone by virgin oil. Pre-treatment or Dewatering Water is found in used oil as free water or bound water, for example in emulsions. The term dewatering is usually taken to mean the removal of free water. Where water has been emulsified with oil, the emulsion has to be "broken" with a demulsifier before the water can be separated from the oil. Dewatering is a simple process relying on the separation of aqueous and oil phases over time under the influence of gravity. The used oil is allowed to stand in a tank (raw waste oil) and free water drops to the bottom where it can be drained, treated (waste water treatment) and discharged appropriately to sewer or storm water depending on quality and local regulations Heating and stirring the used oil in a tank (A) and driving off the water through evaporation can speed up the dewatering process. The "dried" or dehydrated oil is then suitable for further processing or for use as a burner fuel. Filtering & Demineralization The purpose of filtering and demineralization is to remove inorganic materials and certain additives from used oil to produce a cleaner burner fuel or feed for re-refining. Used oil feedstock is transferred to a reaction tank (A) and mixed with a small quantity of sulphuric acid and heated to about 60oC. A chemical surface-active reagent, called a surfactant, is added to the reactor (A) and after stirring the mixture is allowed to stand. This allows the mixture to separate into two "phases" - i.e. oil and water-based or aqueous. The reagent causes the contaminants to accumulate in the aqueous phase, which settles to the bottom of the tank (A) and is drained off as slurry. This phase contains acid, used oil contaminants, including metals and some of the oil additives. The water is dried off; leaving a solid waste that must be disposed of. The demineralized oil is filtered (B) to remove suspended fine particles (to solid waste) and run off to storage (C) as a clean burner fuel. It can be further diluted or "cut" with a lighter petroleum product (called cutter stock) to produce a range of intermediate to light fuel oils depending on the fuel viscosity requirements of the burner. Propane De-asphalting The Propane De-asphalting (PDA) process is an important pre-treatment step in the re-refining process producing de-asphalted lube-oil, which becomes a feedstock for the next step in a re-refining facility. The other output (which is also an input) is propane, which is recovered from both streams and re-used within the process. The PDA process relies on the greater solubility of the paraffinic and naphthenic (ie essentially the base oil) components versus the contaminated waste material in a stream of propane. The separation of the lubricating oil fraction from used oil is a continuous process and is conducted at ambient temperature when processing used oil. The used oil is pumped into the middle of the extraction column (A). Liquid propane is charged to the bottom of the column (A). The oil being heavier than propane, flows down the column (A); the propane rises in a counter-flow thus mixing the input streams within the column (A). The rising propane dissolves the more soluble lube oil components, which are carried out the top of the column (A) with the propane, and the propane insoluble material is removed from the bottom of the column (A). Propane is vaporized from both streams [ie., the de-asphalted lube-oil stream (B) and the waste stream (C)] in "stripper" units (B) and (C), then condensed and returned to the propane storage tank. The de-asphalted lube-oil component is feed for the next processing stage. The residuum (waste) component is mixed with bottoms from the vacuum distillation tower to produce an asphaltic material. Distillation Distillation (or Fractionation) is the physical separation of components of lubricating oil by boiling range. Depending on the type of distillation, the boiling ranges can produce gases and gasolines at the lower boiling points with heavy lubricating oils being distilled at higher boiling points. Distillation is the core process for a facility capable of producing re-refined base-oils to virgin base-oil quality. There are 2 types of distillation, atmospheric and vacuum. Atmospheric Distillation Atmospheric distillation is generally (but not always) considered a pre-treatment step for vacuum distillation and does not require de-watered feedstock. Atmospheric distillation is carried out at normal atmospheric pressure and with temperatures up to 300°C. Prior to the atmospheric distillation process, the feedstock can have undergone PDA treatment, but this is not an absolute pre-requisite. Atmospheric distillation is a relatively simple process separating lower boiling point liquids at ambient pressure. Used oil is heated (A) and charged to a distillation tower (B). Lower boiling point hydrocarbons present in the used oil (eg gases, petrol and solvents) and water are collected at the top of the tower (B). Some of these hydrocarbons can be condensed and collected for use as a fuel in the refining process. This process is only suitable for temperatures up to 300oC, as temperatures above this can lead to "thermal cracking" of the larger molecule (higher boiling point) hydrocarbons, ie. the actual lube oil molecules we are aiming to recover. After atmospheric distillation the oil usually undergoes vacuum distillation. Note that used oil can be sent directly from a "drying" process to a vacuum distillation unit without necessarily undergoing atmospheric distillation. However, it is generally accepted that water and lower boiling point hydrocarbon components be removed prior to vacuum distillation. Vacuum Distillation Vacuum distillation is considered the key process in used oil re-refining. If atmospheric distillation is utilized, the oil from the atmospheric distillation column is the feedstock for the vacuum distillation column. In vacuum distillation the feedstock can be separated into products of similar boiling range to better control the physical properties of the lube base stock "distillate cuts" that will be produced from the vacuum tower products. The major properties that are controlled by vacuum distillation are viscosity, flash point and carbon residue. The viscosity of the lube-oil base-stock is determined by the viscosity of the distillate in terms of its relative viscosity separation, eg. light, medium and heavy oil. The used oil feedstock (usually from the atmospheric distillation unit) is heated in a furnace (A) and flows as a mixture of liquid and vapour to the heated vacuum distillation column (B) where the vapour portion begins to rise and the liquid falls. Steam can be added to assist vaporization. A vacuum is maintained in the column (2-10 mm Hg) by a vacuum system connected to the top of the tower (B). By reducing the pressure, materials normally boiling at up to about 540oC at atmospheric pressure, can be vaporized without thermal cracking. As the hot vapours rise through the column (B), they cool and some condense to a liquid and flow back down the column. Similarly, some of the downward flowing liquids are re-vaporized by contacting the rising hot vapours. Special devices in the column allow this upward flow of vapours and downwards flow of liquids to occur continuously. At various points in the column (B), special trays, called draw trays, are installed which permit the removal of the liquid from the column. If three cuts or "fractions" of oil are required to produce light, medium and heavy base stocks, then three draw trays are positioned appropriately. This can be reduced to two draw trays if, for example, only 2 cuts or fractions are required. Some of the material does not boil even under this vacuum. This remains in the vacuum tower and is run out as the vacuum tower bottoms (VTBs). This material contains the heaviest molecules, including some lube oil additives and carryover contaminants not removed in the PDA process. (Note: not all re-refining plants have PDA units).