South Plant Grease Co-Digestion Study

advertisement

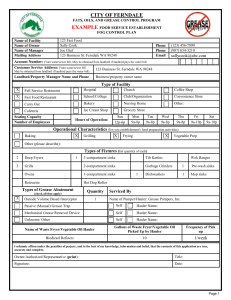

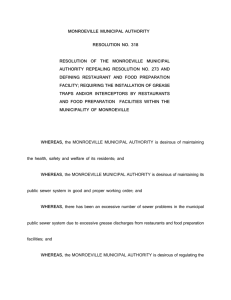

KING COUNTY & BROWN GREASE Local sewer agencies have a need to address restaurant grease trap waste. In response, there is the potential of a renewable energy fuel source and opportunity to invest in sustainable waste management technologies. Wastewater Treatment Division (WTD) 34 local jurisdictions feed wastewater to King County WTD’s system 3 major treatment plants serve 1.5 million across 420 sq. miles 600 employees manage the treatment of about 175 million gallons of sewage each day Our challenge: integrating sustainability into urban sanitation systems In Evaluation of Emerging Technologies Level of technology development Applicability to WTD system Potential benefits to WTD facilities or environment Potential impacts to WTD facilities or environment Potential for recovery of valuable resources Consistency with King County policies & directives A Business Need for Energy Management WTD represents 58% of all King County government’s facility energy use Target #1: Achieve a 10% normalized net reduction in energy use Target #2: Produce, use or procure renewable energy equal to 50% of use Target #3: Maximize the cost-effective conversion of waste to energy 2010 Wastewater Treatment Energy Use by Type WTD Already Produces 610,000 MMBtu’s of Digester Gas 5 South Plant Digester gas scrubbed. 20% of it used on site for process heat. 65% sold directly to PSE [85% use, 15% flared] West Point New cogen plant expected to generate 18,000+ mega-watt hours of ‘renewable energy’ every year, nearly 1/3 of the plants yearly electricity consumption Plant will use 60% of digester gas to produce electricity for sale to SCL – two engines, capable of producing 2.3 MW each (combined 4.6 MW installed power) 44% of digester gas energy used on-site for process needs including raw sewage pumping [total adds to >100% as cogen process also generates all process heat required for the plant] Why South Plant for Brown Grease? Relatively easier plant access for trucks visiting brown grease receiving site - must be self serve Centrally located in Renton Digester capacity Local Sewer Agencies’ Proposed Preferred Pumper Program If PPP moves forward: Potential for “new” brown grease coming on market Standardization and improved record-keeping helpful Would need public & private involvement to leverage resources/support beneficial reuse 2006: Food Waste Co-Digestion Study Benefits: Increased energy production Concerns: Uncertain supply with private composter contracting for restaurant food waste High onsite cost to unload and store incoming waste; screen out metals and glass; mix and grind Conclusions: 2006 report recommended looking at liquid waste as potentially more cost-effective WTD Approach to Study Experience available: nationally, agencies/consulting firms have implemented full-scale grease co-digestion projects Plants currently accepting brown grease by truck (partial list): Riverside, CA East Bay Municipal Utility District, CA Millbrae, CA Oxnard, CA Watsonville, CA So. Bayside Authority (Redwood City), CA Lincoln, NE Pinellas County, FL 2012: Brown Grease Co-Digestion Study Q1: How much brown grease can the current wastewater processing facilities manage? Q2: How much would an appropriately-sized brown grease receiving facility cost? Q3: What are the estimated operating costs and revenues? Q1: How much grease can current wastewater processing facilities manage? Capacity of solids processing facilities (digesters, biosolids mngt., etc.) - OK Capacity of biogas handling systems could be limited by waste gas burners - ?? Capacity of biogas-to-energy systems - OK Practical operational limit to daily truck deliveries onsite maximum 10–20 trucks/day Q2: How much would an appropriately-sized brown grease receiving facility cost? Representative site selected Identified facilities needed Truck offloading facilities, grease receiving tanks Screening, heating, mixing, pumping Modular design to facilitate expansion if needed Capital cost estimate: $2M Q3: Identify estimated operating costs and revenues Cost estimates prepared for facility to manage 15,000 - 30,000 gpd (10 – 20 trucks/day) Costs Cap’l recovery: ~$135,000/yr O&M cost: $400,000/yr to $500,000/yr Revenues Energy revenue: $100,000/yr to $200,000/yr Tipping fee required to break even Next Steps Market assessment – How much brown grease is currently being collected by haulers? – Can a sufficient quantity of grease be secured to recover costs? – Is the PPP moving forward? Further verify key grease co-digestion process assumptions Seek grant funding WTD Considerations Moving Forward Must be cost-effective for ratepayers Ability to help WTD meet energy targets Need assurances that supply won’t disappear Is this something better done by private sector? Brown grease can create storage and pumping issues Must be O&M cost neutral Ensure trucks don’t create safety & security issues Digester and scrubber capacity is not unlimited