Treatment of industrial flue gases to control Global Warming

advertisement

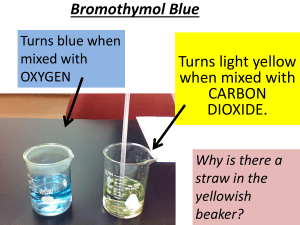

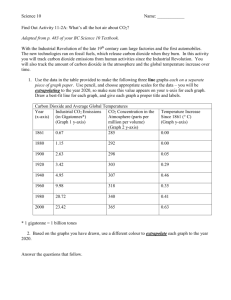

TREATMENT OF INDUSTRIAL FLUE GASES TO CONTROL GLOBAL WARMING AND PURIFICATION OF WASTE WATER BY TREATED FLUE GASES S.S.pendhari.Gharda institute of technology,Lavel. e-mail: pendhrisandeep@gmail.com S.P.Korde. Gharda institute of technology,Lavel. e-mail: kordesnehal@rediffmail.com S.V.Sutar. Gharda institute of technology,Lavel. e-mail: sutarsandesh@gmail.com Abstract : Due to prominent increase in deforestation for industrial development and outlet of waste fluid and flue gases from industries has increased GLOBAL WARMING. The system of purification of industrial waste water via treated flue gases prove advantageous in improving GREEN TECHNOLOGY .Thus we can able to treat the flue gases and using the same flue gas for the treatment of industrial waste water.The CO2 is absorbed from flue gases which undergoes demolecularization. Demolecularization of carbon dioxide involves conversion of CO2 to CO by electric potential and demolecularization of CO with hydrogen to form carbon and water. Carbon thus produced can be dried and powdered to form activated carbon. This activated carbon can be used for the treatment of industrial effluent waste water. Keywords : Global warming, Green technology, Purification of industrial waste water via treated flue gases, Demolecularization of carbon-di-oxide, Ativated carbon. INTRODUCTION: Forests are the treasures of our earth. But, man started to destroy forests and the scientists are giving call to save forest. By cutting trees the temperature will raise enormously, which causes harm to the whole mankind. Due to prominent increase in deforestation for industrial development and outlet of waste fluid and flue gases from industries has increased GLOBAL WARMING. So we are in condition to tackle the problem of global warming which leads to blindness, skin cancer, etc. Nowadays we are carrying mineral bottles along with us, in future we have to carry oxygen cylinders. In the air, the carbon dioxide content should be 330 ppm (parts per million). WORLD SITUATION DUE TO INCREASE IN CO2: According to the current position, the level of carbon dioxide is approximately 370ppm. About 7 giga tons/year of CO2 is emitted worldwide, and that is expected to double between 2030 and 2050. However, types of CO2 emissions vary, and not all can be economically separated or sequestered. Examples of CO2 sources are automobiles, natural gas enrichment, large diesel/gas internal combustion engines, coal/gas-fired boilers and turbines in power plants, and gas turbine driven machinery including compressors in refineries, chemical plants, gas plants, and others. In future the level of carbon dioxide will be as follows, In 2025, from 405ppm to 460ppm In 2050, from 445ppm to 640ppm In 2100, from 540ppm to 970ppm The current temperature level is 40 degree Celsius… In future the temperature will be, For 2025, the temp level will be 0.4 to 1.1 degree For 2050, the temp level will be 0.8 to 2.6 degree For 2075, the temp level will be 1.4 to 5.8 degree 1.The global warming will lead to changes in the rainfall pattern in many areas ,thereby affecting the distribution of vector – borne disease like malaria, filariasis, elephantiasis etc., 2. A rapid shrinking of the world's glaciers and polar ice caps is occurring. 3. A rise in sea levels is occurring as the ice and snow melt. You may not see this effect of sea level rise where you live, but down here in Louisiana, it is very apparent if you go into the marsh. 4. Due to glacier and ice cap melting in the northern hemispheres, the water of the North Atlantic has become much fresher in terms of salinity. "So what," you say. The Gulf Stream requires very salty water in the Arctic ocean sinking and flowing south for the system to work properly. The system may not work if Arctic water loses too much of its salinity. While such an event would not destroy civilization as we know it, it would put a few kinks in it for those living on the affected coasts. 5. Agriculture crop yields have decreased in some instances. Some think a significant decrease in corn crop yields has already occurred. Just when we were counting on surplus corn crops to produce ethanol fuel. 6. Violent weather is more frequent and unpredictable. The number of hurricanes occurring each year is forecast to increase and the storms will be more violent. Some experts say this happened in 2005 as New Orleans and the Gulf Coast were devastated. INDUSTRIES THAT EMITS CO2: Industries are one of the major responsible for pollution especially air and water pollution. Carbon dioxide is main responsible for global warming. Some of the major industries leaving out carbon dioxide are as follows, Cement and lime industry, which gives out carbon dioxide durig calcinations and roasting. Chloro-alkali industry, on manufacturing soda ash, caustic soda and chlorine gives out carbon dioxide. Gelatin and other bio industries, which removes carbon from organic raw material gives out carbon as carbon dioxide. Fermentation industries, which manufactures ethyl alcohol from molasses produce basically 0.76 ton/ ton of ethyl alcohol. Petroleum industry, on cracking of crude oil leaves out enormous amount of carbon dioxide. Thermal and coal power plant produces enormous amount of carbon dioxide during generation of electric power. Also many other industries which applies combustion process to generate heat evolutes flue gases. The CO2 content of flue gases depend on the fuel properties. Coal generates 18-20% CO2 (and up to 30 wt-% ash), natural gas can vary from 2 to 30% CO2, with a pipe line specification limit of up to 3% CO2 Thus we comes to conclusion that green house gas carbon dioxide is main responsible for global warming. Industries are major responsible for carbon dioxide emission. So Carbon dioxide evolved from industries can be controlled by demolecularization method. PROCESS DESCRIPTION: The principle steps involved in this process are Absorption of carbon dioxide from flue gases using calcium hydroxide (slaked lime). Separation of carbon dioxide from absorbent by means of calcination. Demolecularization of carbon dioxide to form carbon and oxygen by electrolysis process. FLOWSHEET: ABSORPTION OF CO2 IN ABSORPTION COLUMN: The flue gases which evolves from industries mainly contains CO2, H2S and SO2. Carbon dioxide is major constituent of flue gases. Also it is major responsible for global warming. So it should be removed and treated from other flue gases. We use alkaline solution to absorb the carbon dioxide from the flue gases. On analysis we conclude that calcium hydroxide (slaked lime) is one of the best absorbers of carbon dioxide. Calcium hydroxide is stored in absorption column as batch-wise process. Then flue gases is send into the absorption column where carbon dioxide alone is captured and absorbed by the calcium hydroxide. Since calcium hydroxide is very good absorber of carbon dioxide, it does not include the absorption of any other constituents of flue gases such as SO2, H2S, etc. Flue gases are allowed into the absorption column till the complete conversion of calcium hydroxide into calcium carbonate. The calcium carbonate formed is then sent into the calciner. Ca(OH)2 + CO2 CaCO3 + H2O SEPARATION OF CO2 BY CALCINATION: Calcium carbonate is introduced into calciner, which is 3-8 metres in diameter and 10-25 metres high. It is lined with refractory brick and covered with sheet steel outside for strength and prevention of gas leakage. Temperature of 8250C is maintained in the calciner chamber by means of hot gases. At this temperature calcium carbonate decomposes to calcium oxide (CaO) and carbon dioxide (CO2). CaCO3 CaO + CO2 The calcium oxide thus formed is separated and sent to the lime slaker where it mixes with water to form calcium hydroxide (Ca(OH)2) at 1500C. Thus calcium hydroxide is recovered back. This recycled calcium hydroxide can be used again and again for absorption of carbon dioxide from flue gases. So it is a batch-wise process. Carbon dioxide thus evolved is sent to electrolysis chamber for demolecularization to produce carbon and oxygen. DEMOLECULARIZATION OF CO2 : Demolecularization of carbon dioxide involves two steps. They are, 1. Conversion of CO2 to CO by electric potential of 15-20kW. 2. Demolecularization of CO with hydrogen to form carbon and water. STEP 1: Carbon dioxide is then sent to electrolytic chamber, where carbon dioxide is converted to carbon monoxide (CO) by treating with steam. High-temperature cells are very efficient compared with other electrolysis methods as they produce more oxygen and carbon monoxide from a given amount of electricity. This is because at high temperatures water and carbon dioxide can be split into synthesis gas (hydrogen + carbon monoxide) and oxygen using the heat, and the SOEC* cell is thereby self-cooling: The heat which is inevitably produced when electricity runs through something – this is needed for the electrolytic process. Moreover, it is possible to utilise the heat which is often available as surplus heat from, for example, power stations and industry. This can be achieved by high electric potential of 15-20Kw. *(SOEC - SOLID OXIDE ELECTROLYTIC CELL) CO2 + H2O H2 + CO + O2 SOLID OXIDE ELECTROLYTIC CELL: CO2 CO + O2- H2O H+ + OH- OH- + O2- + H+ O2 + H2 STEP 2: Then carbon monoxide and hydrogen virtually reacts at very increased temperature to give carbon and water. This can achieved by increasing the temperature to1500K and at high electric potential. CO + H2 C + H2 O Carbon thus produced can be dried and powdered to form activated carbon. This activated carbon can be used for the treatment of industrial effluent waste water. APPLICATION OF CARBON PRODUCED: As Fertilizer for Plants: The carbon produced can be converted into useful products in many ways. One is carbonic acid (H2CO3). The carbonic acid, formed as a result of the reaction is released in to the earth via artificial root system. The carbonic acid absorbed by the soil. Products for pest and disease control of the plant, the metabolism of plants is specifically stimulated and encouraged so that storage in the plants of surplus nutrients is avoided and their health and resistance is improved. C + 3H2O H2CO3 + 2H2 For Treatment of Industrial Waste Water: Another one is activated carbon. If the carbon is converted to activated carbon and used in WATER TREATMENT. The effluent, coming out from the biological treatment plant, is mixed with carbon which comes via artificial root in a content-aeration tank. After some time, the water is allowed to store in a clarification tank, where the carbon particles get settled at the bottom of the tank. Since the carbon particles are very fine, a coagulant such as polyelectrolyte is added to aid the removal of the carbon particles. The spent carbon is regenerated by passing it into the regenerating column and is used again for the process. Finally the water is filtered by passing it through the filtration column. FLOWSHEET FOR TREATMENT OF EFFLUENT WASTE WATER: CONCLUSION: Thus this method gives good air and useful products of carbon like carbonic acid as good manure for soil and in water treatment which will give pure water. It is a simple and cheapest method to save earth from global warming. Also it is the best method to control carbon dioxide emission from industries. REFERENCES Bullis, K. (2009, October). Capturing carbon dioxide through cement production. Technology Review, 112(5) E.S., Yeh, S., Hounsell, D.A., and Taylor, M.R., Experience curves for power plant emission control technologies, Int. J. Energy Technology and Policy, Vol. 2, Nos. 1/2, 2004 The Economist (2009) Trouble in store - Carbon capture and storage, Mar 5th 2009, The Economist print edition