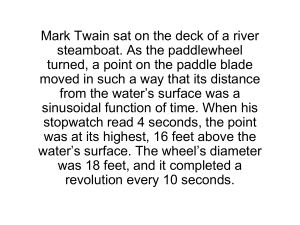

Fig.3. Frequency-velocity dependence

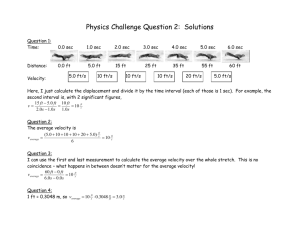

advertisement

THE APPLIED ASPECTS OF CALCULATION METHOD OF TEMPERATURE IN THE PROCESSES OF SCANNING PLASMA TREATMENT. Anahov S.V., Fominych S.I. Urals state technical university, Ekaterinburg, Russia. Here is considered the way of surface hardening of metals by scanned heat source, presenting as plasma jet (the arc). It is offered the method of counted calculation of the heat spreading process by means of equations of Fourier problem for periodic surrface source. The presented results of analysis of this model are given in the manner of approximation formulae and diagrams. Change of cycle warm-up fluctuations is revealed in the contrast with frequency of scan, unevenness of hardening depth and effect of subsurface layer cycling hardening. The scanned heat source, how the studies have shown, is an efficient facility in the row of problems of surface heat - and electric conductive materials treatment. However, brought in literature accounting schemes of warm-up fields for thermal methods of influence (lazer, electronic - beam, plasma and electro - arc ), as a rule, reduce the problem to simplifieded decisions, not using in their own calculation frequency scan factor. Some authors neglect the frequency of scan already at frequencies 12 - 15 Hz, then authors of the other works suggest to use the working frequencies not below several hundreds hertz. Presented work is a continuation conducted by authors of studies and development of strategy of heat calculations of sine scan [ 1 ] in motivation of offer about velocity linearization of transverse fluctuations for prevention of effects uneven hardening on width of zone of termal influence and structured spottiness on depth. Let us assume that the heat source by power q, moving on the surface of semiinfinite space at the speed of Vx for axis OX and revocable-onward at the speed of Vy=4Lf for axis OY – the "saw" law of scan with frecuency f and amplitude L (fig.1). Fig.1. Scheme of the heat source movement. Obviously, that on the strength of periodicity of process, in rolling field, connected with source, process of spreading the heat does not reach the quasistationary condition and its reasonable to consider in still coordinate system, connected with the warmed body. Within the range of amplitudes y < 0.8L given model can be used and for calculation of sine scan. We shall consider that velocity Vy enough great (fair at frequencies over 1 Hz) and neglect heat flows toward OX. To use the principle of imposition for continuously moving source we shall consider the 2 - 23 thermal constants, describing the process independent from the temperature. Thereby, temperature in point (x,y,z) in the coordinate system, connected with body, shall consider as temperature imposition, caused by action in given point fastly moving on axis OY source with orderly - circular sharing the heat and in points, periodically removable comparatively it on the distance pVyTr and Vxtr ( p,x ) on axis OY ( Tr = f1 - period of scan, p - number of period; tr( p,x ) = Tr(( 2p + 1 - x/L )/2 ): 2 z ( y Vy k Tr ) 2 exp[ ] exp[ ] n qf 4a ( t k Tr ) 4a ( t t 0 k Tr ) T( x, y, z, t ) [ 8L k 0 t k Tr t t 0 k Tr ( 1) 2 2 z ( y Vy k tr (l, x )) exp[ ] exp[ ] m 4a ( t k tr (l, x )) 4a ( t t 0 k tr (l, x )) ] t k tr (l, x ) t t 0 k tr (l, x ) l0 where t0 = d2/48a - time constant, - factor of thermal conductivity; a – factor of themperature conductivity; d - diameter of heat spot; q - efficient power of heat source; n = [ t/Tr ] - 1; m = n, under (t - Tr[t/Tr])>Tr/2; and m= n-1, under (t Tr[t/Tr])Tr/2. Given strategy of calculation easy can be applying to study of the other scan laws, including sine law, allowing with a linearization determined by inaccuracy to velocities of scan in determined ranges on width of heat treatment zone. Herewith temperature imposition, taking into account aftereffect removable for primary heat sources, must be recorded with provision for typical of given scan law of temporal parameters of cycling process such as Tr, tr(p,x) etc. At the analysis of given models was expected that surface treats without melting in order to avoid the change of the subsurface layer structure. So the process was analysed within the range of parameters: d = 2..10 mms, L = 4..15 mms, Vx = 0.01..0.5 м/c, f = 5..1000 Hz, q = 2 kW( the typical heat power plasma jet, calculated in [ 3 ]. Thermal constants were selected for structures, subjected to hardening, as stainless steels. Counted calculation have revealled the typical for warm-up waves harmonic fluctuations in process of heating and cooling. So in the process of analysis of the general regularities a temperature was averaged on cycle of fluctuations. How the calculation have shown, velocity Vx renders the more essential influence on the temperature, than Vy and , accordingly, frequency of scan f. As can be seen from the fig. 2 , when the velocity Vx increases, maximum of the temperature Tmax 2500 V1 0 T, C is reached quicker, but at value Tmax falls. V2 2000 Average cooling velocity falls under Vx V3 increase, but average velocity of heating is V4 1500 changed small. The fig. 3 and fig. 4 show 1000 frequency-speed dependencies of time tmax of maximum temperature and values Tmax 500 achievement. Time tmax falls with the scan frequency increase, but value Tmax increases. 0 1 10 Presented dependen-cies is possible to t, sec Fig.2. Temperature dependance of velocity aproximate ( R2 = 0.95 ): Vx (V1=1 sm/sec, V2=4 sm/sec, V3=10 sm/sec, V5=50 sm/sec; f=500 Hz) 2 - 24 Tmax = Tmf 0.08 exp( -0.2 Vy f -0.1 ) (2) tmax = tm f -0.11 exp( -0.6 Vy f 0.03 ) where Тm = 2040.5 K and tm = 42.5 sec in the given range of parameters. 2500 12 tmax, tmax, c c 10 2000 5 5 20 20 100 100 1000 1000 8 1500 6 1000 4 500 2 0 0.01 0,04 0,08 0,15 0,3 0,45 0,6 V, m/sec Fig.3. Frequency-velocity dependence of time tmax achievment (5, 20, 100, 1000 Hz). 0 0.01 0,04 0,08 0,15 0,3 0,45 0,6 V,m/sec Fig.4. Frequency-velocity dependence of temperature Tmax (5-1000 Hz). Using the pict.4, it is possible to define the limiting velocities and frequencies of scan required for hardening. So, at velocities Vx = 0.2 m/sec, scan frequency must be more than 50 Hz, but at velocities Vx more 0.3 m/sec hardening effect disappears. At velocities less 0.005 m/sec occurs the melting of the metal surface. Termal cycle of average temperature in the point of heating is in the form similar with the cycle of heating by evenly driving source (fig. 2). The velocity of heating decreases in the process from (14)103 K/sec at the initial moment to 0.5 K/sec ( at the average 150200 K/sec), cooling velocity reaches the maximum (100300 K/sec) through 310 sec after passing tmax, but the temperature falls to 373 K during 1.52.5 min. However, if for evenly moving source such dependency is conditionned by unevenness of isothermal process before and after source in rolling 18 V1 z,mm field, then in our case such 16 V2 temperature sharing is caused by 14 V3 influence of heat affects distant V4 12 from considereded points, which 10 8 slow the cooling process. The 6 velocity of heating is defined, 4 basically, heat affect from primary 2 passing of heat source, when 0 essential role renders the heating 1,5 2 5 8 10 12 spot geometry and heat power q, kW distribution in that (fig.5). Fig.5. Hardening depth z dependence of the sorce power q and velocity V (V1=4sm/sec, 2 - 25 V2=8 sm/sec, V3=15 sm/sec, V4=30 sm/sec) When the spot diameter increases the heating temperature decreases by the law: T T0 T0 t0 exp( 0.2 ) , exp( 0.2d / t ) = t t t (3) and reaches Tmax later: tmax = 0.94 d + 4.1, (4) where [ d ] - mm. The essential role of scan effect reveals itself at fluctuations of temperature in the process of heating and cooling. The typical peculiarities are: 1)2 different peaks with periodicity, corresponding to scan periodicity, at the initial period of heating, caused by double imposition of warm-up waves with different periods; 2)disappearance of the 2-nd peak at the following periods of heating and cooling, caused by reduction of influence of 2 cycling processes difference for distant waves; 3)amplitudes fluctuations decrease in the course of time ( from 250400 K at the initial moment to 60100 K at the cooling period 15-20 sec after - at frequencies before 100 Hz ); 4) amplitudes fluctuations decrease when the frequency of scan increases by the law T~ f -0.5. Fluctuations of temperature Т ~ 400 K exist only at frequencies less then 15 Hz that is a condition for prevention of the effect of hardened layer tempering. Pict.4 defines frequency - speed limits of the arising effect in the processes of surface hardening. The influence of the source power and velocities Vy on hardening depth is showed on the pict.5. The hardening depth increases with growing of the power q and falls with the velocities Vy increase. Herewith under Vy> 0.3 m/sec and q<5 kW, Vy>0.15 m/sec and q<2 kW hardening effect disappears. When scan frecuency increase, the hardening depth has a small decrease. For calculation of hardening depth in presented range of the temperature it is possible to use the approximation formula ( R2 = 0.93 ): z = Aqf -0.3exp(-0.75 Vxf -0.2 q -0.5 ) , (5) where A = 3.10.7, [ q ] - kW, [ f ] - Hz, [ z ] - mm. When the heatihg spot diameter increases, the hardening depth increases as: z = 0.24 Ln ( d ) + 3.06, (6) where [ d ] – mm. This fact is connected with the increase of the time of temperature maximum tmax achievement and, accordingly, general time of heating. For the rest regularities of heat processes on depth ( for the average per cycle temperature ) are similar with the laws of the heat waves spreading. The authors indicated in the work [ 1 ] , the disadvantage effect of unevenness of hardening depth on the zone width of termal influence reveals at the sine scan law. The analysis of data of linear scan velocity hardening is indicative of essential 2 - 26 reduction of this effect, which shows at the frequencies 520 Hz only and at the initial moments of heating ( t 2 sec ). Herewith at the frequencies ~ 50 Hz difference of the temperature forms 35 K at the amplitude L = 15 mms, in contrast with L = 4 mms. At the frequency f = 5 Hz temperature with the increase of the amplitude decreases, but influence of amplitude quickly fades in the course of time ( from 230 K at t = 0.2 sec to 1 K after 20 sec, L decreases from 4 to14 mms ) as: T = 245 t -1.5 (7) The character of unevenness at the initial moments is similar as at the sine scan law: the low temperature - on axis of heating, but depends on velocities Vy: at the velocity Vy ~ 0.1 m/sec amplitude distribution is even, but at the lesser velocity small reduction of the temperature from axis to edges of the heating zone. Presented model of calculations was checked by hardening at different regimes of cylindrical samples (hardness of steel before hardening 170 - 180 HRB). Velocity of the rotation of sample N ( the period of rotation Ts ) was defined according to calculation data for Vx min ( N < Vx min/ D), where D – diameter of the sample. In the case that the processing of sample was on the big surface area, the plasma - arc torch moved by the sample with the velocity Vs, sufficient to provide the overlapping of zones of heat influence ( VsTs < 2L ). The calculation have shown that under given regimes processing does not occur any effect of tempering. Temperature in the zone of overlapping was defined by equation; Tp(x,y,z,t) = T(x,y,z,t) + T(x,VsTs-y,z,t-Ts) (7) Table 1 shows sufficient influence of treatment regime on the depth and hardness of the layer. So, small heat power of the arc in 1-st series of experiments did not give any hardening effect, but reduction of depth and hardness in the 7-th serieses in contrast with 6 series caused by increase of the linear velocity Vy. The divergences between experimental and accounting data form 10-20% that is given by inaccuracy of experiment and admissions, used in counted model. Table 1. Hardening regimes D=78 mm D = 93 mm, L = 240 L = 275 mm. mm. 3 4 5 24 22 22 250 260 250 Type of the sample D = 78 mm, L = 255 mm. Seral number Arc voltage,V Arc current,A Rotation frequency N, min-1 Velocity Vs, mm/rot ( mm/sec) Number of passes 1 20 175 2 28 300 12.5 5.5 (0.92) 1 12.5 5.5 (0.92) >30 12.5 5.5 (0.92) 7.5 9 1.5 Scan amplitude L, mm Region of overlapping, mm Hardeninf HB (HRC) Hardening depth, mm (accounting) 170-180 300-311 (0) (33-35) 1.5 (1.2) D = 91.5 mm, L = 225 mm. 6 24 300 7 24 300 12.5 3.5 (0.6) >30 12.5 3.5 (0.6) >30 16 3.5 (0.6) 1 20 3.5 (0.6) 30 9 5 1.5 5.5 1.5 8 1 5 1 230 - 250 (27-30) 0.8 (0.8) 400-430 (40-46) 1.2 (1.0) 250(30) after polishing 480-500 (50-54) 1.8 (1.4) 300-311 (33-35) 1.2 (1.0) 230 2 - 27 Summary. 1.The model for counted calculation of the temperature in still field for heat source with linear scan velocity with account of frequency factor have been proposed. 2.The results of this models analysis: diagrams and approximation formulae for calculation of the temperature, time of heating, hardening depths, depending on the parameters of process were presented. 3.The change of the warm-up fluctuations cycling in the process of heating and cooling in the contrast with frequency of scan was revealed. 4.The essential reduction of hardening unevenness effect on width of zone of termal influence was revealed. Publications: 1.Method of the temperature fields accounting in the process of plasma scan hardening. S.V. Anahov, Yu. A. Pyckin, S.I. Fominych. High Temperature (TVT), 1994. V.32. P.40-43. 2 - 28