CE 428 Trickling fil.. - Iowa State University

advertisement

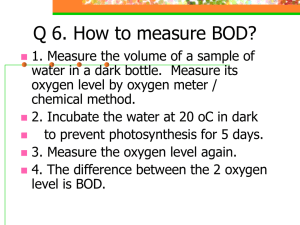

CE 428 Water and Wastewater Design Trickling Filters Dr. S.K. Ong has been in use for nearly 100 years for the treatment of municipal wastewater consist of a media bed (crushed rocks, plastic, redwood, etc.) over which wastewater is continuously distributed. Wastewater is distributed using a rotary distributor providing an uniform load over the filter surface. Most common devices consist of two or four arms. They are driven by the reaction of the wastewater flowing out of the distribution nozzles. These devices require a minimum pressure head of 24 ins., measured from the center of the arm. Air supply is from natural air circulation Microogranisms attached themselves to the sold surface of the media. They are generally heterotropic and facultative bacteria. They grow into a dense biofilm on the surface. Organics/substrate and oxygen will diffuse into the biofilm, CO 2 will diffuse out. As the biofilm grows thicker, oxygen will be utilized before it reaches the media-biofilm interface. Anaerobic and endogeneous decay conditions will occur at the interface and attachment is weakened. The biofilm is washed out. This phenomenon is called sloughing. It is usually a function of the hydraulic and organic loading. Trickling Filters are classified based on the hydraulic loading rates - low, intermediate or standard, high rate or super-high rate (see Table 9-1) In addition, the filters have different types of recirculation (see Figure 9-2). Design of Trickling Filters No universal equation available for the design of trickling filters. Most equations are semi-empirical. The following equation known as the Schultz-Germain formula is shown to be adequate (Equation 9-19 in Metcalf and Eddy book) Se Q exp K 20 D T Si A where Se Si n = total BOD5 of settled effluent filter (mg/L) = total BOD5 applied to filter (mg/L) = r k20 D QT A n = recirculation rate (fraction) = treatability constant corresponding to a specific filter media of depth D at 20 o C (gal/min)0.5/ft = depth of filter (ft) = volumetric flow rate (Q + rQ) = surface area of filter = constant 0.5 0.5 D S k 2 k1 1 1 To estimate treatability constants at different depths use: D 2 S2 Where k2 = treatability constant corresponding to a filter at depth D2 k1 = treatability constant corresponding to a filter at depth 6.1 m and influent BOD of 150 mg/L D1 = 6.1 m (20 ft) packing depth (m) D2 = site specific depth of second filter (m) S1 = 150 g BOD/m3 S2 = site specific influent BOD concentration, g BOD/m3 For K at different temperatures, use Arrhenius equation kT = k20 T-20 where = 1.035 Table 9 - 6 k values for Germain equation Type of wastewater k value (L/s)0.5/m2 Domestic 0.210 Fruit canning 0.181 Meat packing 0.216 Refinery 0.059 Sugar processing 0.351 Synthetic diary 0.170 Textile mill 0.107 ___________________________________________________ Example - Trickling Filter Design Design a trickling filter tower using plastic packing to treat wastewater from a rural community. Given the following: Average year round domestic flow Average year-round domestic BOD5 Desired effluent BOD5 Temperature: May - Oct Jan. = 2.5 mgd (9,460 m3/d) = 220 mg/L = 30 mg/L = 20o C = 10o C Treatability constant k25/D20 = 0.1 (gal/min)0.5/ft2 (derived from treatability studies using a 20 feet deep test filter) Recirculation, r = 1.0 Assume two towers with depth of 20 feet media. Compute area needed at summer and winter months. Compute Si S o rS e 220 (1)(30 ) 125 mg / L 1 r 1 1.0 QT per filter = Q + rQ = 2.5 x 10 6 + (1)(2.5 x 106)/2 gal/day = 1736 gal/min Need to correct the treatability constant for temperature (note don’t have to correct the k for depth as design depth is similar with treatability studies) Summer Months k20/D20 = k25/D20 T-25 = (0.1) (1.035)20-25 = 0.084 Surface area needed for summer 1/ n Se ln Si A Q k D T / D 20 1 / 0 .5 30 ln 125 1,732 (0.084 )( 20 ) 2 1249 .8 ft Winter Months k10/D20 = k25/D20 T-25 = (0.1) (1.035)10-25 = 0.060 Surface area needed for winter 1/ n Se ln Si A Q k D T / D 20 1 / 0 .5 30 ln 125 1,732 (0.060 )( 20 ) 2 2449 .6 ft Winter controls Diameter = 55.8 feet. Select 60 ft. Check: Hydraulic loading = 1732/2449 = 0.71 gal/min/ft 2 = 1018 gal/d/ft2 (high rate filters) Organic loading = (9460 x 103 L/day) x 125/20 x 2449 = 24143 mg BOD/d/ft3 = 0.053 lb/d/ft3 = 53 lb/d/1000 ft3 Design Data for Combined BOD Removal and Nitrification in Trickling Filters Empirical design approaches based on pilot- and full-scale plants are generally used to guide nitrification designs in view of the difficulty in predicting biofilm coverage area and thickness. BOD Loading Rate For rock trickling filters: For 90 % nitrification efficiency, BOD loading should be less than 0.08 kg BOD/m3/d (5 lb BOD/1000 ft3/d) At a loading rate of 0.22 kg BOD/m3/d (14 lb BOD/1000 ft3/d), about 50% nitrification efficiency is expected. BOD Surface Loading Rate Instead of using volumetric BOD loading values, BOD loading based on packing surface area (not cross-sectional area) can be used. Nitrification efficiency was found to be similar for both rock and plastic packing at similar BOD surface loading rate. For > 90% ammonia removal, surface loading rate should be less than 2.4 g BOD/m 2/d. Volumetric Oxidation Rate Oxidation of BOD and ammonia in trickling filters with plastic packing can be characterized by a volumetric oxidation rate defined as: VOR where [So 4.6( NO x )]Q V(10 3 g / kg) VOR = volumetric oxidation rate (kg/m3/d) So = influent BOD concentration (g/m3) NOx = ammonia-nitrogen oxidized (g/m3) Q = influent flowrate (m3/d) V = packing volume (m3) VOR varied from 0.75 to 1.0 kg/m3/d Okey and Albertson relationship Okey and Albertson found a linear relationship between the specific nitrification rate and the influent BOD/TKN for combined systems. See Figure below. The regressed equation which is 25% below the mean of the observed data is given by Ra = 0.82 (BOD/TKN)-0.44 Ra = nitrification rate (g N/m2/d) BOD/TKN = influent BOD to TKN ratio (g/g) From Ra the surface area needed can be determined. Influent BOD/TKN

![Crisis Communication[1] - NorthSky Nonprofit Network](http://s2.studylib.net/store/data/005428035_1-f9c5506cadfb4c60d93c8edcbd9d55bf-300x300.png)