Lecture 1

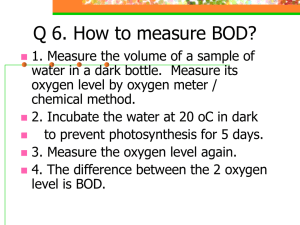

advertisement

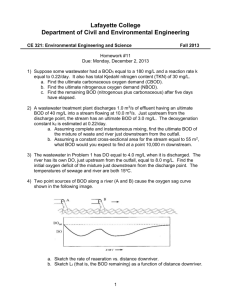

Lecture 1 Outline: Introduction and motivation Beyond optimality: shadow prices, sensitivity Introduction and motivation A. Motivation for water resources planning/management/analysis 1. Water: to much, too little, too polluted 2. Result: people demand certain quality and quantity of water at various times and locations 3. How is demand satisfied? a. Structural solutions: design/construct/operate/remove facilities b. Nonstructural solutions: improve management 4. Who makes decisions? a. Final decision - public officials, elected politicians b. Role of water resources planner/engineer/scientist: provide a number of reasonable alternatives for decision-makers to consider B. Water resource systems analysis as a discipline 1. Characteristics a. An attempt to apply quantitative methods to planning and management of water resources b. Concerned more with policy than with basic physics, chemistry, etc. of water c. Uses existing knowledge about physical processes and incorporates questions of economics and broader policy goals d. Helps define and evaluate in a detailed manner numerous alternatives that represent various possible compromises among conflicting groups, values, management objectives e. Not trying to identify the best objectives or assumptions, but rather good decisions, given stated objectives and assumptions, where there are many alternative decisions that may satisfy objectives, and the best decision is not obvious. f. A synthesis of insights and methods from several different disciplines: engineering and science; economics and planning; operations research and applied mathematics. 1 Table: Focus and tools used in different disciplines for water resource management. DISCIPLINE ENGINEERING, SCIENCE TOOLS MODELS, OBSERVATIONS FOCUS PHYSICAL CONSTRAINTS ECONOMICS, PLANNING RESOURCE VIEW, BENEFIT MEASURES OBJECTIVE FUNCTIONS OPERATIONS RESEARCH, APPLIED MATHEMATICS OPTIMIZATION METHODOLOGY SOLUTION PROCEDURES 2. Classic tools a. Optimization Techniques (Mathematical Programming) (1) LP (2) DP (3) IP/Mixed IP-LP (4) NonLP/Search techniques b. Economic Analysis (1) Traditional cost-benefit evaluations of water resources projects as investments (2) input/output models - economic impacts of projects (3) multiobjective analysis - tradeoffs, utility theory 3. Example applications a. River basin development - water supply, hydropower, flood protection, recreation b. Capacity expansion of facilities c. Conjunctive use of water d. Reservoir operations e. Water quality management f. Infrastructure maintenance g. Design of field sampling programs h. Allocation of limited resources to water pollution mitigation 2 I. Beyond optimality: Information provided by an LP solution 1. A solved example 2. Shadow prices 3. Sensitivity analysis A Solved Example A. Problem statement (Refer to Figure 2.10) There are two wastewater treatment plants (at Sites 1 and 2) discharging to a river upstream from a recreational area (Site 3). The existing levels of dissolved oxygen all below those required by DoE at Sites 2 and 3 are as follows: --------------------------------------------Site 2 3 --------------------------------------------Existing DO (mg/L) 3 2 Desired DO (mg/L) 7 6 --------------------------------------------What fraction of BOD should be removed from each waste stream at Sites 1 and 2 such that the total treatment costs are minimized? Plant 1 Plant 2 3 The following information is known: (1) The amount of BOD to be treated at Plant 1 is 200 kg/d. (2) The amount of BOD to be treated at Plant 2 is 100 kg/d. (3) For each kg of BOD removed (not discharged into the river) at Plant 1, the DO at Site 2 (just upstream of 2) improves by 0.025 mg/L and the DO at Site 3 improves by 0.0125 mg/L. (for Plant 1 only) (4) For each kg of BOD removed (not discharged into the river) at Plant 2, the DO at Site 3 improves by 0.025 mg/L. (for Plant 2 only) (5) A minimum of 30% removal of BOD at each site is required by DoE. (6) Due to technology limitations, at most 95% of the BOD can be removed at the plants. (7) Suppose the cost of BOD removal is Tk. 2* per fraction of BOD removed at Plant 1 and Tk. 1* per fraction of BOD removed at Plant 2. (1* = 100,000) B. Problem formulation 1. Decision variables Let x1 = fraction of BOD removed by Plant 1 from waste stream at Site 1 (x1 x 100 = % removal; e.g. x1 = 0.25 means 25% removal) Let x2 = fraction of BOD removed by Plant 2 from waste stream at Site 2 2. Objective function We want to minimize the cost of treatment subject to a number of given constraints. We can specify an “objective function” which is a function of the decision variables, for which we seek an optimal value. For this case, the objective function is a cost function, and is a function of unknowns x1 and x2. We seek to minimize this cost function, i.e., find the least-cost combination of x1 and x2. Let z = the total cost of treatment. We want to minimize z, i.e.: minimize z = 2 x1 + 1 x2 3. Constraints We must specify mathematically the restrictions and assumptions described in the problem. a. Water quality criteria Site 2: 3 mg/l + (0.025 mg/l/kg)(200 kg) x1 7 mg/l (existing DO) + (Plant 1 contribution) (target) or x1 0.8 Site 3: 2 mg/l + (0.0125 mg/l/kg)(200 kg) x1 + (0.025 mg/l/kg)(100 kg) x2 6 mg/l (existing DO) + (Plant 1 contribution) + (Plant 2 contribution) (target) or x1 + x2 1.6 4 b. Limits on fractions of BOD removed (1) Regulatory constraints (at least 30% removal) x1 0.3 (redundant since x1 0.8; x1+x2 1.6) x2 0.3 (2) Technology constraints (at most 95% removal) x1 0.95 x2 0.95 c. Non-negativity constraints x1 0 (redundant since x1 0.8; x1+x2 1.6) x2 0 C. Graphical representation of decision space (See Figure 2.11.) We want to determine all combinations of x1 and x2 that simultaneously satisfy the constraints and then determine the optimal combination of x1 and x2 to minimize the objective function. Draw constraints 5 D. Finding the problem solution 1. Superimpose the objective function and find combinations of x1 and x2 that give rise to the lowest value of z. z = 2x1 + x2 Search points that give unique optimal solutions (corners/extremas): Upper right: x1 = x2 = 0.95 => z = 2(0.95) + 1(0.95) = 2.85 Lower left: x1 = 0.8, x2 = 0.8 => z = 2(0.8) + 1(0.8) = 2.40 (x2 = 1.6 – x1 = 1.6 - 0.8) The least-cost solution is: z = 2.4 (x 100,000 Taka) = Tk. 240,000 where x1 = 0.8 x2 = 0.8 i.e., 80% of the BOD must be removed at each site. Plant 1: 0.8 (200) = 160 kg/day BOD must be removed Plant 2: 0.8 (100) = 80 kg/day BOD must be removed Superimpose Objective Function 6 2. What if the cost coefficients were reversed such that: z = x1 + 2 x2 (Tk. 1* for Plant 1, Tk. 2* for Plant 2) Then the solution is: Upper right: x1 = x2 = 0.95 => z = 1(0.95) + 2(0.95) = 2.85 Lower right: x1= 0.95, x2 = 0.65 => z = 1(0.95) + 2(0.65) = 2.25 The least-cost solution is now: z = 2.25 (x 100,000 Taka) = Tk. 225,000 where x1 = 0.95 x2 = 0.65 We see from this example that the optimal solution is always located at one of the extrema of the solution space - this is true for all LP problems. New Objective Function 7 3. What if the objective function coefficients were both 1.0 such that: z = x1 + x2 The least-cost solution is now: z = 1.6 But in this case there are infinite combinations of x1 and x2 that satisfy the objective function because this objective function, at its optimal value, coincides with a constraint. x1 + x2 = 1.6 8

![Crisis Communication[1] - NorthSky Nonprofit Network](http://s2.studylib.net/store/data/005428035_1-f9c5506cadfb4c60d93c8edcbd9d55bf-300x300.png)