Pipe Flow (Matlab)

advertisement

1 -זרימה

)(עבודת בית

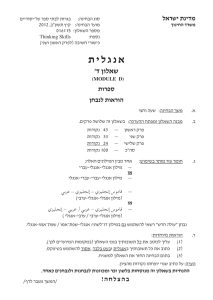

:להלן הנתונים עבור תוכנית המחשב לחישובי זרימה בצינור

input data:

p1

p2

v1

v2

z1

z2

ha

hr

hm

d

l

vis

e

sw

q

- gauge pressure at point 1 in kilopascals:

0.0

- gauge pressure at point 2 in kilopascals:

0.0

- velocity 0 if essentially zero, otherwise 1.0:

0.0

- velocity 0 if essentially zero, otherwise 1.0:

1.0

- elevation at point 1 in meters:

80.0

- elevation at point 2 in meters:

60.; 50.; 40.; 30.; 20.;

- energy added between points 1 and 2 in kilowatts: 0.; 50.; 100.;

- energy removed between points 1 and 2 in kilowatts:

0.

- minor losses between points 1 and 2 in meters:

0.;

- diameter of a pipe in millimeters:

from 300. – to 400. (delta=20 mm)

- length of a pipe in meters:

1000

- kinematic viscosity in m^2/s:

0.406e-6

- pipe material roughness in meters; zero for smooth: 0.0005

- specific weight of a fluid in kilonewtons/m^3:

7.05

- flow rate in m^3/s:

0. (unknown!)

.( בתחום הנתוןd) ( עבור כל קוטרq) ( חשב את הספיקהz1-z2) עבור כל, ha עבור כל

. q q(d) את התוצאות יש להציג באמצעות גראפים

.' שבוע ימים לאחר המבחן מועד א:מועד האחרון להגשת העבודה

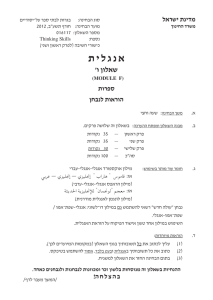

Shalom,

The attached is the Matlab program cpipe.m.

Input

0.0

0.0

0.0

1.0

39.0

0.0

67.0

0.0

0.0

300.

90.0

1.0e-6

0.000045

9.8

0.0

p1

- gauge pressure at point 1 in kilopascals

p2

- gauge pressure at point 2 in kilopascals

v1

- velocity - 0 if essentially zero, otherwise 1.0

v2

- velocity - 0 if essentially zero, otherwise 1.0

z1

- elevation at point 1 in meters

z2

- elevation at point 2 in meters

ha

- energy added between points 1 and 2 in kilowats

hr

- energy removed between points 1 and 2 in kilowats

hm

- minor losses between points 1 and 2 in meters

d

- diameter of conduit in millimeters

l

- length of conduit in meters

vis - kinematic viscosity in m^2/s

e

- conduit material roughness in meters; zero for smooth

sw

- specific weight of fluid in kilonewtons per m^3

q

- flow rate in m^3/s, =0 if unknown

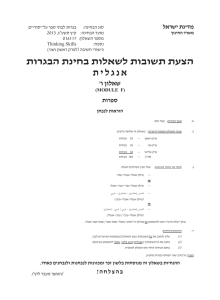

%The program:

%

program cpipe, should be named cpipe.m

%

%

this program computes the flow rate or the required conduit

%

diameter. the international system of units is used.

%

the application of the program is limited to cases involving

%

a single pipe with constant diameter.

%

%

this program is based on solution of the bernoulli equation.

%

accordingly, certain data must be entered for each of two points

%

in a pipe system. however, both the velocity at point 1 and the

%

velocity at point 2 are not considered as known values initially.

%

%

%

%

%

if either value of velocity is essentially zero (such as at a

reservoir or tank surface) - enter 0 (zero) for that velocity or

for both velocities if both are essentially zero, otherwise - enter

1.0 for all other velocities.

pi = 4.*atan(1.0);

factor = 1000; % factor to convert mm into m

%-------------------------------------------------------------------------%

%

Input Data

p1=0; % gauge pressure at point 1 in kilopascals

p2=0; % gauge pressure at point 2 in kilopascals

v1=0; % velocity = if essentially zero, otherwise 1.0

v2=1; % velocity = if essentially zero, otherwise 1.0

z1=39; % elevation at point 1 in meters

z2=0; % elevation at point 2 in meters

ha=67; % energy added between points 1 and 2 in kilowats

hr=0; % energy removed between points 1 and 2 in kilowats

hm=0; % minor losses between points 1 and 2 in meters

d=300; % diameter of conduit in millimeters

l=90; % length of conduit in meters

vis=1e-6;

% kinematic viscosity in m^2/s

e=0.000045; % conduit material roughness in meters; zero for smooth

sw=9.8;

% specific weight of fluid in kilonewtons per m^3

q=0;

% flow rate in m^3/s, =0 if unknown

%-------------------------------------------------------------------------g = 9.807;

p1sw = p1/sw;

p2sw = p2/sw;

% friction coefficient initial guess

ff = 0.02;

%

%

for i=1,11 %do 333

d = 200 + (i-1)*50;

% d is known, find q

if v1>0.0001

v1 = 1/2/g;

end

if v2>0.0001

v2 = 1./2./g;

end

for j=1:10000

hf = ff*l/d*factor/2/g; %105

hat = ha/sw;

hrt = hr/sw;

% flow rate q first guess

q = 0.001;

vtry = (q/(pi*(d/factor)^2/4))^2;

try1 = p1sw+vtry*v1+z1+hat/q-hrt/q-(p2sw+vtry*v2+z2+hf*vtry);

for n=1:10000

q = q + 0.001;

vtry = (q/(pi*(d/factor)^2/4))^2;

try2 = p1sw+vtry*v1+z1+hat/q-hrt/q-(p2sw+vtry*v2+z2+hf*vtry);

if try1*try2>0

try1 = try2;

else

q = q - 0.0005;

break

end

end

v = q/(pi*(d/factor)^2/4);

rn = d/factor*v/vis;

ed = e/d*factor;

% compute friction coefficient

f=rough(ed,rn); % call rough

diff = abs(f-ff);

if diff<0.0001 % goto 104

break

else

ff = f;

continue %goto 105

end

end

if v1>=0.0001 % 104

v1 = v;

end

if v2>=0.0001

v2 = v;

end

% writing input and output on screen

fprintf('

\n')

fprintf('

sample analysis for a closed conduit carrying fluid \n')

fprintf('--------------------------------------------------------\n')

fprintf('

\n')

fprintf('

input data: \n')

fprintf('

\n')

fprintf('

pressure at point 1 = %4f kPa \n',p1)

fprintf('

pressure at point 2 = %4f kPa \n',p2)

fprintf('

elevation at point 1 = %4f m \n',z1)

fprintf('

elevation at point 2 = %4f m \n',z2)

fprintf('

actual energy added between points 1 and 2 = %4f m \n',hat)

fprintf('

actual energy removed between points 1 and 2 = %4f m \n',hrt)

fprintf('

minor losses between points 1 and 2 = %4f m \n',hm)

fprintf('

length of conduit = %4f m \n',l)

fprintf('

conduit material roughness = %4f mm \n',e*factor)

fprintf('

fluid viscosity = %4f m^2/s \n',vis)

fprintf('

\n')

fprintf('

computed data: \n')

fprintf('

\n')

fprintf('

flow rate will be %4f m^3/s \n',q)

fprintf('

velocity at point 1 = %4f m/s \n',v1)

fprintf('

velocity at point 2 = %4f m/s \n',v2)

fprintf('--------------------------------------------------------\n')

% writing output in a file: out.txt

fid = fopen('out.txt','w');

fprintf(fid,'computed data: ');

fprintf(fid,'%1f\n flow rate will be %4f m^3/s ;\n',q);

fprintf(fid,'%1f\n velocity at point 1 = %4f m/s ;\n',v1);

fprintf(fid,'1f\n velocity at point 2 = %4f m/s ;\n',v2);

fclose(fid);

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%

% function rough, should be saved separately as rough.m

%

function f=rough(ed,rn)

if rn<2000

f = 64/rn;

return

end

% friction coefficient quess

f = 0.006;

try1 = 1/sqrt(f)+2*log10(ed/3.7+2.51/rn/sqrt(f));

for i=1:10000

f = f + 0.00001;

try2 = 1./sqrt(f)+2.*log10(ed/3.7+2.51/rn/sqrt(f));

if try1*try2>0

try1 = try2;

else

f = f - 0.000005;

return

end

end

======================================================================

output:

sample analysis for a closed conduit carrying fluid

--------------------------------------------------input data:

pressure at point 1 =

0.0 kpa

pressure at point 2 =

0.0 kpa

elevation at point 1 =

39.0 m

elevation at point 2 =

0.0 m

actual energy added between points 1 and 2

= 67.0m

actual energy removed between points 1 and 2 = 0.0m

minor losses between points 1 and 2 = 0.0 m

diameter of conduit = 300.0 mm

length of conduit =

90.0 m

conduit material roughness = 0.045 mm

fluid viscosity = 0.000001000 m^2/s

computed data:

flow rate will be 0.951 m^3/s

velocity at point 1 = 0.00 m/s

velocity at point 2 = 13.46 m/s

===================================================================