Sujet 91-2 Proposés pour une Allocation de Recherche

advertisement

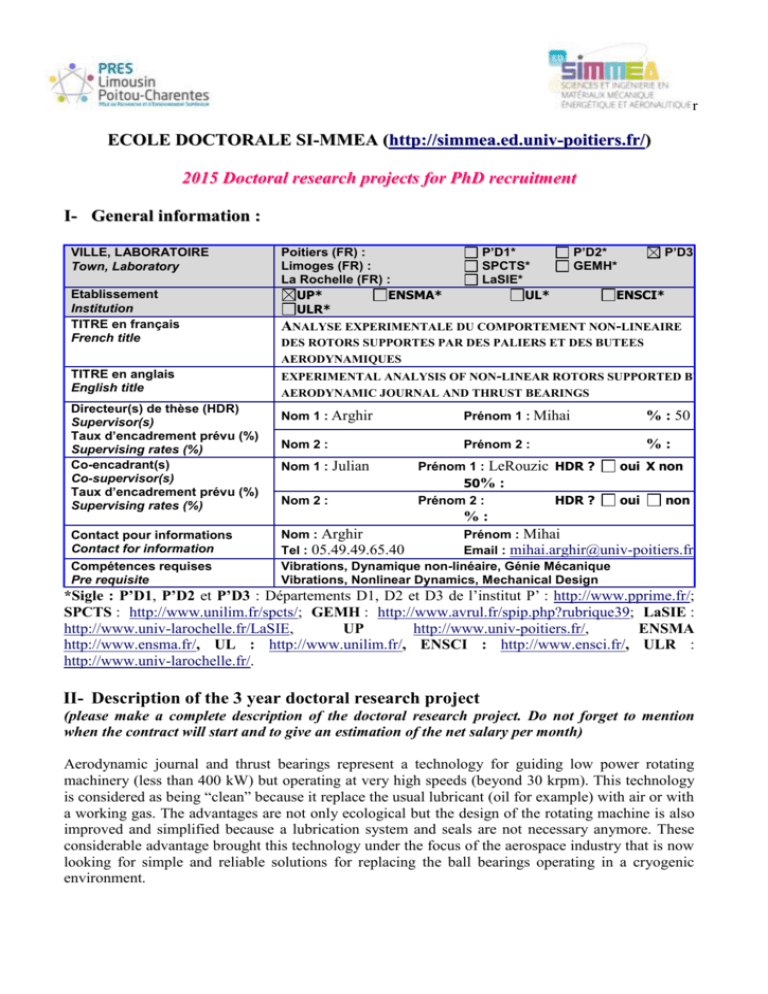

r ECOLE DOCTORALE SI-MMEA (http://simmea.ed.univ-poitiers.fr/) 2015 Doctoral research projects for PhD recruitment I- General information : VILLE, LABORATOIRE Town, Laboratory Etablissement Institution TITRE en français French title TITRE en anglais English title Directeur(s) de thèse (HDR) Supervisor(s) Taux d’encadrement prévu (%) Supervising rates (%) Co-encadrant(s) Co-supervisor(s) Taux d’encadrement prévu (%) Supervising rates (%) Contact pour informations Contact for information Compétences requises Pre requisite Poitiers (FR) : P’D1* P’D2* P’D3* Limoges (FR) : SPCTS* GEMH* La Rochelle (FR) : LaSIE* UP* ENSMA* UL* ENSCI* ULR* ANALYSE EXPERIMENTALE DU COMPORTEMENT NON-LINEAIRE DES ROTORS SUPPORTES PAR DES PALIERS ET DES BUTEES AERODYNAMIQUES EXPERIMENTAL ANALYSIS OF NON-LINEAR ROTORS SUPPORTED BY AERODYNAMIC JOURNAL AND THRUST BEARINGS Nom 1 : Arghir Prénom 1 : Mihai % : 50 Nom 2 : Prénom 2 : %: Nom 1 : Nom 2 : Julian Prénom 1 : LeRouzic HDR ? 50% : Prénom 2 : HDR ? oui X non oui non %: Nom : Arghir Prénom : Mihai Tel : 05.49.49.65.40 Email : mihai.arghir@univ-poitiers.fr Vibrations, Dynamique non-linéaire, Génie Mécanique Vibrations, Nonlinear Dynamics, Mechanical Design *Sigle : P’D1, P’D2 et P’D3 : Départements D1, D2 et D3 de l’institut P’ : http://www.pprime.fr/; SPCTS : http://www.unilim.fr/spcts/; GEMH : http://www.avrul.fr/spip.php?rubrique39; LaSIE : http://www.univ-larochelle.fr/LaSIE, UP http://www.univ-poitiers.fr/, ENSMA http://www.ensma.fr/, UL : http://www.unilim.fr/, ENSCI : http://www.ensci.fr/, ULR : http://www.univ-larochelle.fr/. II- Description of the 3 year doctoral research project (please make a complete description of the doctoral research project. Do not forget to mention when the contract will start and to give an estimation of the net salary per month) Aerodynamic journal and thrust bearings represent a technology for guiding low power rotating machinery (less than 400 kW) but operating at very high speeds (beyond 30 krpm). This technology is considered as being “clean” because it replace the usual lubricant (oil for example) with air or with a working gas. The advantages are not only ecological but the design of the rotating machine is also improved and simplified because a lubrication system and seals are not necessary anymore. These considerable advantage brought this technology under the focus of the aerospace industry that is now looking for simple and reliable solutions for replacing the ball bearings operating in a cryogenic environment. r Research activities on this topic are developed since 2005. They enabled the continuous developement of these technology from both theoretical and experimental standpoints: original theoretical models for journal bearings were developed and two rotordynamic test rigs were build. A first test rig is dedicated to the analysis of an horizontal rotor supported on aerostatic hybrid journalbearings and/or aerodynamic foil journal bearings. The second test rig consists of a vertical rotor suported by ball beraings mounted with a dead band clearance and by aerostatic bearings of Lomakin type. Both test rigs are entrained by air driven, Pelton turbines. Work to be performed: New aerodynamic foil bearings will be designed and will need intensive testing on the rig using an horizontal rotor. The goal of the tests will be the measurement of the start-up torque, of the top speed and the appropriate description of the non-linear dynamic response of the rigid rotor guided by these bearings. The data acquisition and parameter identification methods used up to now will need to be consolidated. The second step of the experimental activity will be the analysis of the response of a flexible rotor suported on foil journal bearings. Up to now only rigid rotors were tested and the behavior of flexible rotors is not much documented in the literature. It is also a demand of the industry that must be dealt with great care and free of any commitement. The test rig using a vertical flexible rotor showed a very complex non-linear responses. The origins of these non-linearities are the dead band clearance of the ball bearings and the internal damping of the rotor stemming from its complex design. Up to now only the first aspect was analyzed and taken into account in simulations. The goal of the work will be the combined analysis of both aspects (dead band clearance of the ball bearings and internal damping) by using a commercial rotordynamic code and confronting experimental findings with theoretical results.