Selective position and alignment of single InAs self

advertisement

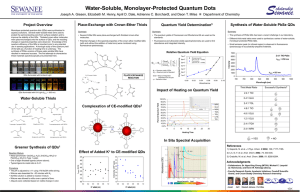

Selective Growth of InAs Quantum Dots on Patterned GaAs Substrate by Metal-Organic Chemical Vapor Deposition Tung-Po Hsieh1, Pei-Chin Chiu1, Yu-Chuan Liu1, Nien-Tze Yeh2, Wen-Jeng Ho2 and Jen-Inn Chyi1 1 Department of Electrical Engineering, National Central University, Chung-Li, Taiwan 32054, R.O.C. 2 Telecommunication Laboratories, Chunghwa Telecom Co., Ltd., Yang-Mei, Taiwan 326, R.O.C. Abstract We report selective growth of InAs self-assembled quantum dots (QDs) on nano-ridges (~25 nm) formed by wet chemical etching and epitaxial growth process. Two groups of QDs are observed across the patterned substrate, one on the planar surface and the other on top of the ridges. The QDs, which align one by one on the top of the ridges, are of an asymmetric shape along the [011] and [0-11] directions. The well resolved photoluminescence spectrum from these quantum dots exhibits two major peaks at 1.31 m and 1.24 m, which correspond to the ground state and the first excited state, respectively. Single quantum dot can also be formed on the top of nano-pillars prepared by the same technique. 1 The research of self-assembled quantum dots (QDs) formed by Stranski-Krastanov (SK) growth mode has been being of considerable interest in recent years. The self-assembled QDs is a promising candidate for the fabrication of quantum effect devices such as QD transistors1, QD lasers2-3, QD infrared photodetectors4, and single photon sources5-6. However, precise positioning of QDs on the substrate, which is required for many device applications, is difficult due to the random distribution nature of SK growth mode. A number of approaches7-13, including patterned process and strain engineering, has been proposed to cope with this problem. However, most of these approaches are either too complicated or too difficult to produce QDs of high optical quality consistently. In this paper, we report QDs formed by selective epitaxial growth process on nano-scale mesa, which is prepared using conventional photolithography and wet chemical etching. It demonstrates the feasibility of producing QDs on patterned substrates without using costly and low throughout technique, such as e-beam lithography. The samples were grown by low-pressure metal-organic chemical vapor deposition (MOCVD) in a vertical reactor using conventional metal-organic and hydride sources, including trimethylindium (TMIn), trimethylgallium (TMGa), and arsine (AsH3). Before the epitaxial growth, (100) 2° off (111)A Si-doped GaAs 2 substrates were patterned to form ridges along both [011] and [0-11] directions by g-line photolithography. Ridges of 1 to 3 m wide were obtained by etching the substrates in an NH4OH/H2O2 solution. The final upper width of the ridge, which was determined by the thickness of the GaAs buffer layer, could be tuned from 30 nm to 300 nm. InAs QDs were then deposited on the patterned substrates after the growth of the buffer layer. The growth temperatures were 650 oC for the GaAs buffer layer, and 500 oC for the InAs QDs and cap layer, respectively. The V/ III ratios were 100 for GaAs and 3 for QDs. The QDs were grown at a growth rate of 0.1- monolayer (ML)/s with a total nominal thickness of 3 MLs. The surface morphology and mesa facet were observed by scanning electron microscopy. Some of the samples have a GaAs cap layer on top of the QDs so that photoluminescence measurements can be carried out to characterize their optical properties. Shown in Fig. 1(a) is the as-etched ridge along [011] direction. The upper width of the ridge, on which the quantum dots are deposited, varies with the thickness of the GaAs buffer layer. It decreases with increasing buffer layer thickness. Fig. 1(b) shows the shape of a ridge after the growth of a 0.2 m-thick buffer layer. Nano-size ridges (25 to 50 nm) with smooth (100) top facet and (111)B inclined facets for the selective growth of quantum dots can thus be obtained reproducibly. InAs QDs grown on the patterned substrate can be characterized into two 3 groups, i.e. those on the planar surface and those on the top (100) surface of the ridges. Fig. 2(a) shows the InAs QDs grown on the planar surface. These QDs are of lens shape and have a density of about 2.4x1010 cm-2. Capped by a layer of GaAs, the QDs exhibit a strong photoluminescence at room temperature as shown in Fig. 2(b). Note that the spectrum comes from the QD ensemble of both groups because the diameter of the pump laser is much larger than the distance between the ridges. The full width at half maximum of the spectrum is about 30 meV, indicating that the dots are of good optical properties and can be used for device applications. There are two peaks occurring at 1.31 m and 1.24 m, which correspond to the ground state and the first excited state transition, respectively. It is worth noting that such a long emission wavelength is unusual for InAs QDs in GaAs matrix grown by molecular beam epitaxy. Fig. 3 shows a row of QDs grown on the top of a ridge along [011] direction. It is found that the width of the top surface must be less than 100 nm in order to obtain a single row of QDs, while ridge width less than 50 nm, which is about the size of a QD, results in more uniform ones. The base size of the QDs is found to be comparable to the width of the ridge. Further deposition of InAs gives rise to higher QDs without significant change in lateral size. The line density of the QDs on the ridge is about 3.3x105 cm-1. The shape of the QDs on the ridge is asymmetric, i.e. triangular and lens 4 shape along [011] and [0-11] directions, respectively, as shown in fig. 3(a) and (b). This is attributed to the different surface energies of the (100) and (111)B facets, which were formed after the growth of buffer layer, for the nucleation of QD. This is consistent with the observation on growth rates of GaAs on various crystallographic planes14-15. As we increase the monolayer of InAs, the QDs evolve from triangular shape to arrow shape with a lateral size of about 50 nm as shown in fig. 3(c). Due to the preferential migration of indium adatoms from the (111)B facets up to the (100) top facet, the size of the QDs increases much faster in height than lateral size. The profile of the ridge after buffer layer growth changes as the direction of the ridge is changed from [011] to [0-11]. As shown in Fig. 4, both (311)A and (111)A facets develop during the growth of a GaAs buffer layer under the same process flow and growth conditions as Fig. 3. Due to the aforementioned growth mechanism, a single line of QDs can be selectively grown on the ridge with an asymmetric shape along [011] and [0-11] directions as well. The selective growth technique is expected to enable us to form single QD on the tip of a pillar as long as the top area is reduced to a size comparable to a QD. Shown in Fig.5 is an InAs QD formed on a pillar prepared by wet etching. Detailed optical properties of this single QD are under investigation. In summary, we have demonstrated the selective growth of InAs self-assembled 5 QDs on nano-scale patterns prepared by conventional photolithographic and wet chemical etching techniques. Due to the preferential migration of cation adatoms from (111) and (311) facets to (100) facet, a row of self-assembled InAs QDs with an asymmetric shape is formed on ridges along [011] and [0-11] directions, respectively. Defining the width of ridge and the thickness of InAs, respectively, can control the width and height of the InAs QDs thus formed. In addition, a single InAs QD has also been successfully grown on a nano-pillar prepared by the same technique. This work provides a viable way to novel QDs devices with a great flexibility and controllability. Acknowledgments The authors would like to acknowledge the support of Chunghwa Telecommunication Laboratories, Chunghwa Telecom Co. and the Optical Science Center, National Central University. This work was supported by the National Science Council of Republic of China under contract No. NSC 91-2120-E-008-001. 6 Reference 1. H. S. Park and V. G. Mokerov, Appl. Phys. Lett. 79, 418 (2001). 2. R. L. Sellin, I. Kaiander, D. Ouyang, T. Kettler, U. W. Pohl, D. Bimberg, N. D. Zakharov and P. Werner, Appl. Phys. Lett. 82, 841 (2003). 3. O. B. Shchekin and D. G. Deppe, Appl. Phys. Lett. 80, 3277 (2002). 4. Lin Jiang, Sheng S. Li, Nien-Tze Yeh, Jen-Inn Chyi, C. E. Ross, and K. S. Jones, Appl. Phys. Lett. 82, 1986 (2003). 5. E. Moreau, I. Robert, J. M. Gerard, I. Abram, L. Manin, and V. Thierry-Mieg, Appl. Phys. Lett. 79, 2865 (2001). 6. J. Sabarinathan, P. Bhattacharya, P. C. Yu, S. Krishna, J. Cheng, and D. G. Steel, Appl. Phys. Lett. 81, 3876 (2002). 7. R. Tsui, R. Zhang, K. Shiralagi, D. Convey, and H. Goronkin, Appl. Phys. Lett. 71, 3254 (1997). 8. R. Zhang, R. Tsui, K. Shiralagi, D. Convey, and H. Goronkin, Appl. Phys. Lett. 73, 505 (1998). 9. R. Zhang, R. Tsui, K. Shiralagi, and H. Goronkin, J. J. Appl. Phys. 38, 455 (1999). 10. J. Tatebayashi, M. Nishioka, T. Someya, and Y. Arakawa, Appl. Phys. Lett. 77, 3382 (2000). 7 11. C. K. Hahn, J. Motohisa, and T. Fukui, Appl. Phys. Lett. 76, 3947 (2000). 12. B. C. Lee, S. D. Lin, C. P. Lee, H. M. Lee, J. C. Wu, and K.W. Sun, Appl. Phys. Lett. 80, 326 (2002). 13. H. J. Kim, J. Motohisa, and T. Fukui, Appl. Phys. Lett. 81, 5147 (2003). 14. M. Lopez, T. Ishikawa, and Y. Nomura, Jpn. J. Appl. Phys. 32, 1051 (1993) 15. H. P. Meier, E. V. Gieson, W. Walter, C. Harder, M. Krahl and D. Bimberg, Appl. Phys. Lett. 54, 433 (1989) 8 Figure Captions Fig. 1. (a) Define the ridge pattern by standard lithography and wet etching process (b) Epitaxial growth method to form the trapezoid ridge Fig. 2. (a) Top-view SEM image of quantum dots formed on planar region (b) Photoluminescence spectrum of InAs quantum dots Fig. 3. Scanning electron microscope image of (a) InAs QDs linear array formed on the 40nm width ridge along [011] direction (b) The perpendicular direction view of QDs on the ridge pattern (c) The arrow shape of QDs are shown clearly Fig. 4. InAs QDs linear array formed on the 40 nm width ridge along [0-11] direction Fig. 5. Arrow shape single quantum dot formed on a nano-pillar 9 [011] PR Fig. 1(a) (100) facet [011] (111)B facet (111)B facet Fig. 1(b) 10 PL Intensity (a.u.) Fig. 2(b) Gaussian fitting FWHM = 30.5 meV 1000 1100 1200 1300 1400 1500 Wavelength (nm) Fig. 2(b) 11 Fig. 3(a) Fig. 3(b) [011] (111)B facet Buffer layer 55O Ridge pattern Fig. 3(c) 12 [0-11] Buffer layer (113)A facet (111)A facet 25O 55O Ridge pattern Fig. 4 13 Fig. 5 14