solution

advertisement

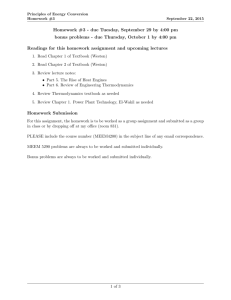

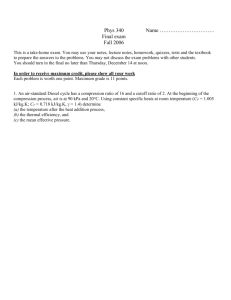

5-85 Ethylene glycol is cooled by water in a heat exchanger. The rate of heat transfer in the heat exchanger and the mass flow rate of water are to be determined. Assumptions 1 Steady operating conditions exist. 2 The heat exchanger is well-insulated so that heat loss to the surroundings is negligible and thus heat transfer from the hot fluid is equal to the heat transfer to the cold fluid. 3 Changes in the kinetic and potential energies of fluid streams are negligible. 4 Fluid properties are constant. Properties The specific heats of Cold water and ethylene glycol are Water given to be 4.18 and 2.56 20C kJ/kg.C, respectively. Hot Analysis (a) We take the ethylene glycol Glycol tubes as the system, which is a control volume. The energy balance for this 40C steady-flow system can be expressed in 80C the rate form as 2 kg/s E E out in Rate of net energy transfer by heat, work, and mass E system0 (steady) 0 Rate of change in internal,kinetic, potential,etc. energies E in E out m h1 Q out m h2 (since ke pe 0) Q out m c p (T1 T2 ) Then the rate of heat transfer becomes Q [m c p (Tin Tout )] glycol (2 kg/s)(2.56 kJ/kg. C)(80 C 40 C) = 204.8 kW (b) The rate of heat transfer from glycol must be equal to the rate of heat transfer to the water. Then, c p (Tout Tin )]water water Q [m m Q c p (Tout Tin ) 204 .8 kJ/s = 1.4 kg/s (4.18 kJ/kg. C)(55 C 20 C) 5-96 Two streams of water are mixed in an insulated chamber. The temperature of the exit stream is to be determined. Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential energy changes are negligible. 3 There are no work interactions. 4 The device is adiabatic and thus heat transfer is negligible. Properties From the steam tables (Table A-4), h1 hf @ 90C = 377.04 kJ/kg h2 hf @ 50C = 209.34 kJ/kg Analysis We take the mixing chamber as the system, which is a control volume since mass crosses the boundary. The mass and energy balances for this steady-flow system can be expressed in the rate form as m in m out m system0 (steady) 0 m in m out m1 m 2 m 3 Mass balance: Water 90C 30 kg/s Energy balance: E E inout E system0 (steady) Rate of net energy transfer by heat, work, and mass 3 0 Rate of change in internal,kinetic, potential,etc. energies E in E out m 1 h1 m 2 h2 m 3 h3 (since Q W ke pe 0) 1 Water 50C 200 kg/s 2 Solving for the exit enthalpy, h3 m 1 h1 m 2 h2 (30 )(377 .04 ) (200 )( 209 .34 ) 231 .21 kJ/kg m 1 m 2 30 200 The temperature corresponding to this enthalpy is T3 =55.2C (Table A-4) 5-124 A rigid tank initially contains air at atmospheric conditions. The tank is connected to a supply line, and air is allowed to enter the tank until mechanical equilibrium is established. The mass of air that entered and the amount of heat transfer are to be determined. Assumptions 1 This is an unsteady process since the conditions within the device are changing during the process, but it can be analyzed as a uniform-flow process since the state of fluid at the inlet remains constant. 2 Air is an ideal gas with variable specific heats. 3 Kinetic and potential energies are negligible. 4 There are no work interactions involved. 5 The direction of heat transfer is to the tank (will be verified). Properties The gas constant of air is 0.287 kPa.m3/kg.K (Table A-1). The properties of air are (Table A-17) Ti 295 K hi 295 .17 kJ/kg T1 295 K u1 210 .49 kJ/kg T2 350 K u 2 250 .02 kJ/kg Analysis (a) We take the tank as the system, which is a control volume since mass crosses the boundary. Noting that the microscopic energies of flowing and nonflowing fluids are represented by enthalpy h and internal energy u, respectively, the mass and energy balances for this uniform-flow system can be expressed as Mass balance: min mout msystem mi m2 m1 Energy balance: E Eout in Net energy transfer by heat, work, and mass Pi = 600 kPa Ti = 22C Esystem Change in internal,kinetic, potential,etc. energies Qin mi hi m2u2 m1u1 (since W ke pe 0) The initial and the final masses in the tank are V1 = 2 m P1 = 100 kPa T1 = 22C 3 · Q m1 P1V (100 kPa )( 2 m3 ) 2.362 kg RT1 (0.287 kPa m3/kg K )( 295 K ) m2 P2V (600 kPa )( 2 m3 ) 11.946 kg RT2 (0.287 kPa m3/kg K )(350 K ) Then from the mass balance, mi m2 m1 11.946 2.362 9.584 kg (b) The heat transfer during this process is determined from Qin mi hi m2u2 m1u1 9.584 kg 295.17 kJ/kg 11.946 kg 250.02 kJ/kg 2.362 kg 210.49 kJ/kg 339 kJ Qout 339 kJ Discussion The negative sign for heat transfer indicates that the assumed direction is wrong. Therefore, we reversed the direction. 6-19E The work output and heat rejection of a heat engine that propels a ship are given. The thermal efficiency of the engine is to be determined. Assumptions 1 The plant operates steadily. 2 Heat losses from the working fluid at the pipes and Furnac other components are negligible. qeH Analysis Applying the first law to the heat engine gives HE q H wnet q L 500 Btu/lbm 300 Btu/lbm 800 Btu/lbm wnet qL Substituting this result into the definition of the thermal efficiency, sink th wnet 500 Btu/lbm 0.625 qH 800 Btu/lbm 6-40 The COP and the refrigeration rate of a refrigerator are given. The power consumption and the rate of heat rejection are to be determined. Assumptions The refrigerator operates steadily. Analysis (a) Using the definition of the coefficient of performance, the power input to the refrigerator is Kitchen air determined to be COP=1.2 Q L 60 kJ/min Wnet,in 50 kJ/min 0.83 kW R COP 1.2 R (b) The heat transfer rate to the kitchen air is determined from the energy balance, Q L cool space Q H Q L Wnet,in 60 50 110 kJ/min 6-50 A house is heated by resistance heaters, and the amount of electricity consumed during a winter month is given. The amount of money that would be saved if this house were heated by a heat pump with a known COP is to be determined. Assumptions The heat pump operates steadily. Analysis The amount of heat the resistance heaters supply to the house is equal to he amount of electricity they consume. Therefore, to achieve the same heating effect, the house must be supplied with 1200 kWh of energy. A heat pump that supplied this much heat will consume electrical power in the amount of Wnet,in Q H 1200 kWh 500 kWh COP HP 2.4 which represent a savings of 1200 – 500 = 700 kWh. Thus the homeowner would have saved (700 kWh)(0.085 $/kWh) = $59.50 6-54 The rate of heat loss, the rate of internal heat gain, and the COP of a heat pump are given. The power input to the heat pump is to be determined. Assumptions The heat pump operates steadily. Analysis The heating load of this heat pump system is the 60,00 difference between the heat lost to the outdoors and the 0 kJ/h House heat generated in the house from the people, lights, and Q H appliances, HP Q H 60,000 4,000 56,000 kJ / h COP = Using the definition of COP, the power input to the heat pump is determined to be Outside2.5 Wnet,in Q H 56,000 kJ/h 1 kW 6.22 kW COP HP 2.5 3600 kJ/h 6-58 A commercial refrigerator with R-134a as the working fluid is considered. The evaporator inlet and exit states are specified. The mass flow rate of the refrigerant and the rate of heat rejected are to be determined. QH Assumptions 1 The refrigerator operates steadily. 2 The kinetic and potential energy Condenser changes are zero. Properties The properties of R-134a at the Expansion evaporator inlet and exit states are (Tables Win valve A-11 through A-13) Compressor P1 120 kPa h1 65 .38 kJ/kg x1 0.2 P2 120 kPa h2 238 .84 kJ/kg T2 20C Evaporator 120 kPa x=0.2 Analysis (a) The refrigeration load is Q L (COP)W in (1.2)(0.45 kW) 0.54 kW The mass flow rate of the refrigerant is determined from QL 120 kPa -20C m R Q L 0.54 kW 0.0031 kg/s h2 h1 (238 .84 65 .38) kJ/kg (b) The rate of heat rejected from the refrigerator is Q H Q L W in 0.54 0.45 0.99 kW