abstract The purpose of this investigation is to delve further into the

advertisement

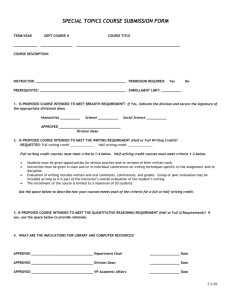

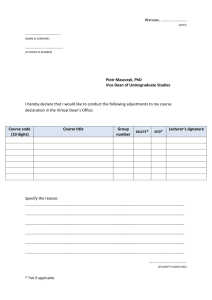

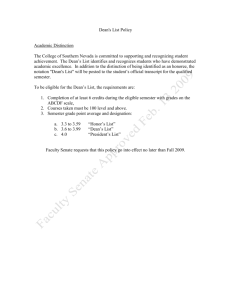

PRESSURE FLOW through a COILED TUBE UTKU ALHUN SALIM E. DARWICHE ANDREA S. LEVINE SURBHI PURI BE – 309 BIOENGINEERING LAB III FALL 2004 December 16, 2004 Department of Bioengineering School of Engineering & Applied Science UN IVERSITY of P ENNSY LVAN IA ABSTRACT The purpose of this investigation is to delve further into the pressure-flow experiments previously conducted. This experiment was geared towards investigating different factors on fluid flow and pressure. The variable factors considered were orientation of the coiled tubing, the radius of curvature of the coils, and change in viscosity of the fluid used (comparing water and 10% sucrose solution). Three hypotheses were tested. It was predicted that using the horizontal orientation of the coils would give experimental results relatively similar to the theoretical values. It was also hypothesized that the relationship between the experimental Dean’s number and the friction factor obtained would be dependent of any variation in the radius of coil curvature. The final hypothesis to be tested stated that the mathematically derived relationship of the Dean’s number and the friction factor would be maintained by fluids of varying viscosities. It was found that the horizontal orientation was, as per the hypothesis, is the preferred orientation in this experimental setup and this was mainly attributed to the effect of gravity on the fluid flow varying with different orientations (18.1% error). The second hypothesis was found to be true by the investigation. The results of the experiment showed that the relationship between the Dean’s Number and the Friction Factor is affected by the radius of coil curvature used. Finally the third hypothesis was supported by the data; the mathematical Dean’s number proof can be implemented to both, the water and the 10% sucrose solution. The sources of error (systemic and experimental) in this investigation give rise to the need for further research to be done on pressure flow in coiled tubing. Suggestions include isolating whether the coil number or the radius of coil curvature effect the relationship more and investigating the effect of viscosity on the theoretical relationship trends and more experimental trends between the Dean’s number and the friction factor, separately. HYPOTHESIS Due to the effect of gravity, both of the horizontal orientations (ascending and descending) would be more similar to the theoretical curve than the vertical orientations. In addition, the radius of curvature should affect the relationship between the Dean’s Number and the friction factor as it appears in the coefficient of the power function relating De and f. Finally, the relationship which Dean described mathematically should hold for fluids with different viscosities. Therefore, data from both the 10% sucrose solution and water can be fit on the same curve and the relationship between Dean’s Number and the friction factor will not be affected by the viscosity of the liquid. BACKGROUND Poiseuille’s law accurately describes the relationship between pressure-flow relationships in terms of radius of the tube and viscosity of the Newtonian fluids for laminar flow. However, Poiseuille’s law is not applicable to coiled tubes. This is due to the fact that the resistance to flow is greater in coiled tubes than that in straight tubes. The more rapidly flowing central parts of the flow are forced outwards by centrifugal action, while the slower parts along the walls are forced inwards, i.e. towards the center of curvature. With laminar flow, the effects even of a very slight curvature are dramatic when Reynolds’ number is not very small1. Since flow in curved tubes differs greatly from Poiseuille’s law, W. R. Dean developed a theory to describe it. The Reynolds’ number (Re), which is used to describe flow, is defined as: U d Re [1] where, U is the mean fluid velocity, d is inner diameter of the tube, and ν is the kinematic viscosity. The Dean’s number (De), a slight modification of the Reynolds’ number, is defined below for curved tubes: d U d d [2] De Re D D where, D is the diameter of curvature of the coil. This experiment investigates pressure-flow relationship in a coiled tube wrapped around cylinders of different radii. Head Loss is defined as: 2 P L U HL 12 f [3] g D g where, f is the friction factor and is a function of the Dean’s number. In order to determine the experimental relationship between the friction factor and the Dean’s number, the equation is solved for f: P 2 D f [4] U 2 L Using Dean’s work, the theoretical relationship between the Dean’s Number and the friction factor is found to be: 64 d 0.36 0.64 f 0.37 De or using [2] f 23.68 De [5] Re D MATERIALS Stand Graduated Cylinder 4 Cylinders with different radii Tank with flow cutoff valve 1/8” ID tubing 46’ in length 10% Sucrose Solution Pressure Manometer Stopwatch Water METHODS The experimental set-up is illustrated in FIG 1, below. The water tank, supported on a stand, has a needle valve which enables control over the flow rate. The 1/8” ID tubing, connected to a manometer on the upstream, is coiled around a cylinder of known outer radius. The water is collected in a graduated cylinder and the flow rate is measured using a stopwatch to compute the volume of water flowing per unit time. Legend … Ma n o me te r … Wa te r Ta n k … Need le Va lv e Descending horizontal orientation of coiled tube … Ru l e r … S ta n d S to p wa tch Co i led Tu b e Di rec tio n o f flo w Mea su rin g cyl in d e r F IG 1. T HE E X P ER IM E N TA L S E T - U P . The first part of the experiment aimed to investigate the effects of different orientations of the coiled tubing. The four different types of orientations were horizontal (descending/ascending coils) and vertical (descending/ascending coils). The cylinder with an outer radius of 7.72 cm is used for all the different orientations; the number of coils was 26, and kept constant. The nomenclature used to define the orientation of coiling can be misleading; therefore, it is worthwhile to explain the rationale behind it. For the horizontal orientation, the tubes are actually coiled in a way that each individual coil is perpendicular to the plane of the table. On the other hand, for the vertical orientation, each individual coil is parallel to the plane of the table. Basically, horizontal and vertical are used to refer to the net direction of flow. A B C D 2. C O I L O R IE N TA TIO N S . A: Horizontal descending, B: Horizontal ascending, C: Vertical descending, D: Vertical ascending. F IG For each orientation, four different flows of water were measured, approximately at equal intervals of the height of water in the manometer. A maximum (approximately at 90 cm of water in the manometer), a minimum (~ 20 cm of H20) and two intermediate flows (~70 and 40 cm H20) were measured, three trials for each flow, for a total of 12 measurements. After determining which orientation to use throughout the second part of the experiment, the procedure was repeated using cylinders of different outer radii. Radius (cm) Number of coils Thin white tube 1.37 121 Graduated cylinder 3.36 65 Bottle 7.72 26 Bucket 12.50 17 Cylinder TAB LE 1. R AD I I NU MB ER O F C O ILS . OF C Y LIN D ER S A ND So as to investigate the effects of the radius of curvature on pressure-flow measurements, four different cylinders were used. The outer radii of the cylinders and the number of coils around each one are tabulated, on the right. The radius of curvature is calculated by adding the radii of the cylinder, and the tube wrapped around it. Once again, the pressure readings were taken from the manometer, and the volumetric flow rate was measured using a graduated cylinder and a stopwatch. The third and the final part of the project consisted of using a 10% sucrose solution, instead of water, to determine the possible effects of viscosity on fluid flow in a coiled tube. The procedure outlined for the first part of the experiment was repeated. R ES U LTS The first part of the experiment tested the first hypothesis; namely, whether orientation of coiling affects the relationship between Dean’s Number and the friction factor. Graph 1, below, shows the Different directions on same coil relationships for each orientation. 0.9 GR A P H Experimental and Theoretical f vs. De for Different Coil Orientations 0.8 0.7 Vertical orientation w/ coils t/b Color coding is given as follows Orientation w/ coils b/t andVertical is based on the nomenclature scheme introduced in the Horizontal Orientation with Methods coils b/t section. 0.6 Horizontal Orientation with coils t/b theoretical all Yellow: [C] Gold: [D] Power (Vertical orientation w/ coils t/b) Orange: [B] Power Red: [A] (theoretical all) f 0.5 f 1. f vs. De. 0.4 0.3 Power (Horizontal Orientation coilsblue b/t) line represents the Thewith navy Power (Horizontal Orientation expected theoretical curve. with coils t/b) 0.2 Power (Vertical Orientation w/ coils b/t) 0.1 0 0 20 40 60 80 100 The red [A] and orange [B] trends are the closest to the theoretical trend. De Both the experimental and the theoretical data were fit to power curves of the following form y=kx^n (Graph 1 in the Appendix). The Coefficients and R2 values are listed in the table below: Orientation K n R2 Vertical Descending 30.198 -1.1929 .987 Vertical Ascending 1.108 -.482 .864 Horizontal Descending 4.534 -.7881 .962 Horizontal Ascending 3.740 -.7491 .991 Theoretical 3.166 -.6251 .997 2 Table 2: Coefficients and R values of power curves fit to the orientation data. These coefficients fit the analysis above. Both A and B for horizontal orientations both are the closest numerically to their respective theoretical coefficients. The percent deviation from the theoretical for Horizontal Ascending is (k: 18.1% and n:19.8% ) and for Horizontal Descending is (k: 43.2% and n: 26.1% ) For Vertical Descending (VD) and Ascending (VA), these deviations are much higher (VD: k: 853% n: 90.8%, VA: k: 65.0%, n: 22.8% ) For the next part of the experiment, the relationship between the Dean’s Number and friction factor was plotted for different radii of curvature; only horizontal ascending loops were used. Both the experimental data and the theoretical data (friction factor calculated from Dean’s Numbers using the mathematical relationship) were plotted. Graph 2 combines the theoretical and experimental friction factor (f) data as it relates to De for all coil sizes and both 10% sucrose and water solutions. The theoretical data points were fit to a power function which differs with coil size; the lighter the blue color is, the larger the coil size. The power function curve flattens and shifts to the right as the coil decreases. The experimental data follows the same trend. Dashes mark theoretical data points while triangles mark experimental data points. No graphical distinction is made between water and sucrose data since the data distributions seem to overlap and follow the same trend (see appendix on data distribution). Experimental and Theoretical f vs. De f or dif f erent coil sizes 1.60E+00 f Experimental and Theoretical f vs. De for Different Radii of Curvature 1.40E+00 \\ 1.20E+00 f 1.00E+00 8.00E-01 6.00E-01 4.00E-01 2.00E-01 0.00E+00 0 20 40 60 80 100 120 140 D e De Small Medium Large X-Large Small exp Medium exp Large exp X-Large exp Pow er (Small) Pow er (Medium) Pow er (Large) Pow er (X-Large) GR A P H 2. f vs. De for different radii of curvature. The next part of the experiment of the experiment further explored the how well the experimental data matched the theoretical data for the relationship between Dean’s Number and friction factor for the different radii of curvature. It incorporates both sucrose and water data. 3b - Medium Theoretical & Exp f vs. De 3a - Small Theoretical & Exp f vs. De 1.4 1.2 1.2 1 1 0.8 f f 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0 0 0 50 De 100 0 150 De 100 150 3d - X- Large Theoretical & Exp f vs. De 3c - Large Theoretical & Exp f vs De f 50 1.6 1.6 1.4 1.4 1.2 1.2 1 0.8 0.8 f 1 0.6 0.6 0.4 0.4 0.2 0.2 0 0 0 0 20 40 De 60 80 20 40 60 80 De GRAPHS 3a, 3b, 3c and 3d show the theoretical and experimental f vs. De for small (a), medium (b), large (c) and x-large (d) coil sizes. The plots combine both sucrose and water data. Red points mark the experimental friction factor values (f) obtained for every De while navy points mark the theoretical values of f for the same De values. Table 3, below, shows the curve fits and exponential for both the theoretical and experimental y=kx^n curves for different radii: K n R2 Theoretical Experimental Theoretical Experimental Theoretical Experimental Small 6.79 1.87 -.612 -.373 .998 .601 Medium 5.70 4.59 -.670 -.721 .998 .974 Large 4.98 4.37 -.745 -.789 .981 .982 X-Large 4.33 3.42 -.774 -.777 .976 .985 TABLE 3: Coefficients of power fits of both the experimental and theoretical data for each different radius of curvature. Tube Note that if the data points encircled above in the small coil graph are taken out (they all refer to the measurement of the lowest flow in the small coils for sucrose which yielded a very unsteady pressure reading in the monometer) the correlation factor (R2) becomes 0.987. D IS C U S S IO N 1 summarizes the first part of the experiment, where the orientation of the coiled tubing was varied to determine the optimum direction of flow. The orientation was shown to affect the relationship between the friction factor and Dean’s Number as predicted by our hypothesis. The main difference between the orientations of the coiled tubing is the effect of gravity on the direction of fluid flow. For the horizontal ascending and descending orientations, the fluid flows in a perpendicular fashion through each individual coil. Therefore, to a good approximation, the number of ascending coils and the number of descending coils are equal to cancel out the effect of gravity. However, for the vertical ascending and descending orientations, this is not the case. For the ascending one, the fluid moves against the force of gravity; this greatly hinders the flow. For the descending one, the fluid moves along the force of gravity; this enhances the flow. Therefore we chose to use the horizontal ascending position as it yielded the least % error from the theoretical curve (k: 18.1% and n: 19.8%). G R A P H S 3 a, b, c, d show the distribution of water and glucose data superimposed on one graph for each radius of curvature, separately. As shown by the graphs, the relationship between f and the Dean’s Number was not affected by the viscosity. Referring to Equations [1] and [2], it can be seen that Reynolds number is a function of viscosity, and Dean’s number is a function of the Reynolds’ number, therefore Dean’s number is a function of the viscosity of the fluid. However, the number of fluids with different viscosities tested should be increased to determine whether this observation will hold true. The values for the Dean’s number are also found to be lower for the more viscous 10% sucrose solution, occupying a broader range. According to the theoretical and experimental data, there is a distinct relationship between the Dean’s Number and the friction factor for each cylinder. Theoretically, this is expected as from equation [5] the coefficient multiplying De contains the coil diameter. Indeed, it was found, by plotting both experimental and theoretical curves, that as the radius of curvature increased, the data was shifted down to the left and the largest cylinders yielded more precise data points. However, note that as coil size increased, coil number increased as well. While coil number is not accounted for in the theoretical equation and therefore should not matter, the fact that it was not maintained constant might suggest that increased coil number also has an effect on the friction factor values. Unfortunately, since both parameters varied together we cannot conclusively say that coil number does not affect the friction factor. In addition, since f proportional to De0.36 (according to Equation [5]), then an increase in the radius of curvature will increase the diameter of curvature and will therefore decrease the Dean’s Number. The decrease in Dean’s Number will lead to a lower theoretical f, causing a lower friction factor which explains the curves’ shift downwards and to the left for increasing radii. While it would make sense that radius of curvature would influence the Dean’s Number, as it is accounted for in the equation, further work should be done to explore this relationship and the relationship between coil number, Dean’s Number, and friction factor. Sucrose and water data are shown to lie on the same curve (for each cylinder separately). This demonstrates our hypothesis that the relationship between Dean’s Number and friction factor do not vary based on viscosity. As can been seen in Graph 4, more sucrose values could be obtained for a lower Dean’s number for both theoretical and experimental cases. Indeed, the higher viscosity for approximately the same flow rates would decrease the Dean’s Number. Graph 3 suggests that at lower f values (as well as higher Dean’s values), the theoretical and experimental Dean values do not differentiate drastically. Indeed, flow being higher in these cases, generally the volume and time measurements are more accurate. Additionally, it seems that with increasing coil size the GRAPH repeatability and accuracy of the readings increase. With smaller coil sizes, it is harder to simulate an efficient flow system; hence, some aberrant data with decreasing coil size and number is shown to exist; also, pressure seems to fluctuate more at low flows for small coil sizes. In general, all comparisons of sucrose and water data to the calculated theoretical values, showed good correlations between the data sets. The results of this investigation support the hypothesis that Dean’s mathematical proof will apply for varying viscosities. Graph 4 shows both sucrose and water data (with all other factors kept constant), confirms that the data of the two solutions of different viscosities can be integrated on a curve and the trends between Dean’s Number and the friction factor will remain unaffected. Although care was taken to minimize experimental error (including having the same people perform the same jobs in order to minimize errors due to inaccuracies in measuring equipment), there are sources of error. Inherent in this experiment is error due to timing and measuring volumes and pressures. In addition, a negative systematic error was found. This could be due to slowly fluctuating pressures, which may have been read before they rose to the final constant pressure. This could be confounded in slow flows, as the pressure rise was gradual; resulting in thinking the pressure was constant before it actually was. Finally, the sucrose solution may not have been fully mixed or dissolved, which would introduce error into the viscosity used. Flow in curved pipes has not been studied extensively as implied by the lack of the Dean’s number in scientific literature. However, “Flow in Curved Pipes” by S. A. Berger, Talbot, and L. S. Yao [Annual Reviews of Fluid Mechanics, 1983, 15:461-512] is an extensive study in this particular area of fluid dynamics. The study introduces the use of the toroidal coordinate system and a series of complex differential equations in investigating about the subject. In short, the Dean’s number is defined as a function of the inertia, and centrifugal and viscous forces. Together with another parameter dependent upon the geometry of the tube, the Dean’s number is found to characterize the flow in curved pipes. The review stressed on finding the velocities of the fluid at different points in the cross section and discussed the diverse definitions of Dean’s number and their boundary limits. However, it did not stress or elaborate on the pressure-flow relationship as it relates to Dean’s number, rather it focused on other consequences of the secondary flow due to centrifugal forces. It was also mentioned that critical Re numbers for curved pipes were 3 to 5 folds higher than that for straight tubes which basically says that the onset of turbulence occurs at higher flow rates in coiled tubes. CONCLUSION Future projects should focus on determining both how the number of coils and the radii of curvature in isolation affect the Dean’s Number-friction factor relationship. This will allow us to determine which factor contributes more to the variation in the relationship. Also, a greater number of fluids with a broad range of viscosities should be used to further determine whether the relationship between Dean’s Number and friction holds for fluids with different viscosities. Two fluids are not enough to fully determine whether viscosity affects this relationship; however, it does indicate that this relationship does not vary with viscosity. Furthermore, non-Newtonian fluids can be used to investigate further into the subject. APPENDIX: Different directions on same coil 0.9 Vertical Descending 0.8 Vertical Ascending -1.1929 y = 30.198x R2 = 0.9865 0.7 0.6 y = 3.1663x-0.6251 0.5 R = 0.9971 Horizontal Descending 2 f Horizontal Ascending -0.7881 0.4y = 4.5337x 2 R = 0.9618 0.3 y = 3.7395x-0.7491 0.2 2 R = 0.9909 theo all Power (Vertical Descending) Power (theo all) -0.482 0.1 y = 1.1075x R2 = 0.8643 0 Power (Horizontal 0 20 40 60 80 100 Descending) De Power The above graph shows the equations for the trend lines to which the data (Horizontal points were fit. This Ascending) relates to the data taken for water at different orientation of coiling. The below Powergraph shows the (Vertical experimental data distribution as it varies from water to sucrose. Ascending) Sucrose and Water De and experimental f distribution 1.4 1.2 1 0.8 f Water Sucrose 0.6 0.4 0.2 0 0 50 100 De 150 REFERENCES: 1 W. H. Dean and C. M. White “Flow in Curved Pipes” by S. A. Berger, Talbot, and L. S. Yao [Annual Reviews of Fluid Mechanics, 1983, 15:461-512] 3 Project report spring 2004 2