Experiment: Fourie`s Law study for linear

advertisement

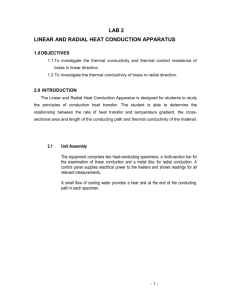

Heat Transfer Lab Conduction Heat Transfer Unit LAB 1 HEAT CONDUCTION 1.0 OBJECTIVES A) To investigate Fourier’s Law for the linear conduction of heat along a homogeneous bar B) To examine the temperature profile and determine the rate of heat transfer resulting from radial conduction through the wall of a cylinder 2.0 INTRODUCTION Thermal conduction is the mode of heat transfer, which occurs in a material by virtue of a temperature gradient. A solid is chosen for the demonstration of pure conduction since both liquids and gases exhibit excessive convective heat transfer. In a practical situation, heat conduction occurs in three dimensions, a complexity which often requires extensive computation to analyze. In the laboratory, a single dimensional approach is required to demonstrate the basic law that relates rate of heat flow to temperature gradient and area. The Heat Conduction Study Bench consists of two electrically heated modules mounted on a bench support frame. One module contains a cylindrical metal bar arrangement for a variety of linear conduction experiments while the other consists of a disc for radial conduction experiment. Both test modules are equipped with an array of temperature sensors. Cooling water, to be supplied from a standard laboratory tap is fed to one side of the test pieces in order to maintain a steady temperature gradient. The instrumentation provided permits accurate measurement of temperature and power supply. Fast response temperature probes with a resolution of 0.1°C are used. The power control circuit provides a continuously variable electrical output of 0-100 Watts. The test modules are designed to minimize errors due to true three-dimensional heat transfer. The basic principles of conduction can be taught without knowledge of radiation or convective heat transfer. The linear test piece is supplied with interchangeable samples of conductors and insulators to demonstrate the effects of area, conductivity and series combinations. Contact resistance may also be investigated, and the important features of unsteady state conditions may be demonstrated. 1 Heat Transfer Lab 3.0 Conduction Heat Transfer Unit EQUIPMENTS/UNIT ASSEMBLY The equipment comprises two heat-conducting specimens, a multi-section bar for the examination of linear conduction and a metal disc for radial conduction. A control panel provides electrical and power digital for display heaters in the specimens as well as the selector switch for data acquisition system A small flow of cooling water provides a heat sink at the end of the conducting path in each specimen. 1 2 3 4 7 5 6 8 9 10 Figure 1: Unit Assembly for Heat Conduction Study Bench 1. Control Panel 2. Heater Power Indicator 3. Heater Power Regulator 4. Heater Power 5. Temperature Indicator 6. Temperature Selector 7. Main Power Switch 8. Temperature Sensors 9. Radial Module 10. Linear Module 2 Heat Transfer Lab Conduction Heat Transfer Unit 2.1 Specifications a) Linear Module Consists of the following sections: i) Heater Section Material : Brass Diameter : 25 mm ii) Cooler Section Material : Brass Diameter : 25 mm iii) Interchangeable Test Section - Insulated Test Section with Temperature Sensors Array (Brass) (Diameter = 25mm, Length = 30 mm) - Insulated Test Section (Brass) (Diameter = 13mm, Length = 30 mm) - Insulated Test Section (Stainless Steel) (Diameter = 25mm, Length = 30 mm) b) Radial Module Material : Brass Diameter : 110 mm Thickness : 3 mm c) Instrumentations Linear module consists of a maximum of 9 temperature sensors at 10 mm interval. For radial module, 6 temperature sensors at 10 mm interval along the radius are installed. Each test modules are installed with 100 Watt heater. 2.2 Overall Dimensions Height : 0.80 m Width : 0.80 m Depth : 0.35 m 2.3 General Requirements Electrical : 240 VAC, 1-phase, 50Hz Water : Laboratory tap water, 20 LPM @ 20 m head Drainage point 3 Heat Transfer Lab Conduction Heat Transfer Unit 2.4 Linear Module Fourier's Law of Heat Conduction is most simply demonstrated with the linear conduction module. This comprises a heat input section fabricated from brass fitted with an electrical heater. Three thermistor temperature sensors are installed at 10mm intervals along the working section, which has a diameter of 25mm. A separate heat sink section also of brass is cooled at one end by running water while its working section is also fitted with thermistor temperature sensors at 10mm intervals. The heat input section and the heat sink section may be clamped directly together to form a continuous brass bar with temperature sensor at 10mm intervals, alternatively any one of three intermediate sections can be fitted between these two. The first of these is a 30mm length of the same material (brass) and is the same diameter as the heat input and heat sink sections and is again fitted with thermistor sensors at 10mm intervals. This section is clamped between the two basic sections forms a relatively long uniform bar with nine regularly spaced temperature sensors. The second center section, which may be fitted, is again brass and 30-mm long but has a diameter of 13mm and is not fitted with temperature sensors. This section allows a study of the effect of a reduction in the cross-section of the heat-conducting path. The third center section, which may be fitted, is of stainless steel and has the same dimensions as the first brass section. No temperature sensors are fitted. This section allows the study of the effect of a change in the material while maintaining a constant cross-section. The mating ends of the five sections are finely finished to promote good thermal contact although heat- conducting compound may be smeared over the surfaces to reduce thermal resistance. The heat-conducting properties of insulators may be found by simply inserting a thin specimen between the heated and cooled metal sections. An example of such an insulator is a piece of paper. Heat losses from the linear module are reduced to a minimum by a heat-resistant casing enclosing an air space around the module. The interchangeable center sections have their own attached casing pieces, which fit with those of the heat input and heat sink sections. The thermistor temperature sensors are connected to miniature plugs fitted to the casing and connections from the sensors to the temperature input module are made via nine sensor leads fitted with appropriate sockets. Therefore temperature gradients can be plotted. 2.5 Radial Module The radial conduction module comprises a brass disc 110mm diameter and 3mm thick heated in the center by an electrical heater and cooled by cold water in a circumferential copper tube. Thermistor temperature sensors are fitted to the center of the disc and at 10mm intervals along a radius there being six in all. Again heat losses are minimised by preserving an air gap around the disc with a heat-resistant casing. 4 Heat Transfer Lab Conduction Heat Transfer Unit As in the linear module, the thermistor connections are brought out to plugs in the casing to which six sensor leads fitted with appropriate sockets may be connected to obtain the temperature. 2.6 Control Panel Either of the heat-conduction modules may be connected to a control panel which allows the heater input power to be set and the temperature at any of the sensors to be shown in °C. Heater power is controlled by a variable autotransformer and displayed on a digital indicator. Power outputs from 0 to 100 watts may be obtained. 5 Heat Transfer Lab 3.0 Conduction Heat Transfer Unit SUMMARY OF THEORY 3.1 Linear Conduction Heat Transfer dx Q dT Figure 2: Linear temperature distribution It is often necessary to evaluate the heat flow through a solid when the flow is not steady e.g. through the wall of a furnace that is being heated or cooled. To calculate the heat flow under these conditions it is necessary to find the temperature distribution through the solid and how the distribution varies with. Using the equipment set-up already described, it is a simple matter to monitor the temperature profile variation during either a heating or cooling cycle thus facilitating the study of unsteady state conduction. THS kH kS kC THI TCI XH XS XC TCS Figure 3: Linear temperature distribution of different materials 6 Heat Transfer Lab Conduction Heat Transfer Unit Fourier’s Law states that: Q kA dT dx (1) where, Q = heat flow rate, [W] W k = thermal conductivity of the material, Km A = cross-sectional area of the conduction, [m2] dT = changes of temperature between 2 points, [K] dx = changes of displacement between 2 points, [m] From continuity the heat flow rate (Q) is the same for each section of the conductor. Also the thermal conductivity (k) is constant (assuming no change with average temperature of the material). Hence, AH (dT ) AS (dT ) AC (dT ) (2) (dx H ) (dx S ) (dx C ) i.e. the temperature gradient is inversely proportional to the cross-sectional area. AC AH AC XH XS Q AC XC Figure 4: Temperature distribution with various cross-sectional areas 7 Heat Transfer Lab 3.2 Conduction Heat Transfer Unit Radial Conduction Heat Transfer (Cylindrical) Temperature Distribution Ti To Ri Ro Ri Ro Figure 5: Radial temperature distribution When the inner and outer surfaces of a thick walled cylinder are each at a uniform temperature, heat rows radially through the cylinder wall. From continuity considerations the radial heat flow through successive layers in the wall must be constant if the flow is steady but since the area of successive layers increases with radius, the temperature gradient must decrease with radius. The amount of heat (Q), which is conducted across the cylinder wall per unit time, is: 2Lk (Ti To ) R ln o Ri where, Q (3) Q = heat flow rate, [W] L = thickness of the material, [m] W k = thermal conductivity of the material, Km Ti = inner section temperature, [K] To = outer section temperature, [K] 8 Ro = outer radius, [m] Ri = inner radius, [m] Heat Transfer Lab 4.0 Conduction Heat Transfer Unit EXPERIMENTAL PROCEDURES 4.1 General Start-up Procedures 1. Make sure that the main switch is off. Insert an intermediate section into the linear module and clamp together. 2. Connect one of the cooling water tubes to the water supply and the other to the drain. 3. Connect the heater supply lead for the linear conduction module into the power supply socket on the control panel. 4. Connect the nine sensor leads to the nine plugs on top of the linear conduction module. Connect the left-hand sensor lead from the module to the place marked TT1 on the control panel. Repeat this procedure for the remaining eight sensor leads, connecting them from left to right on the module and in numerical order on the control panel. 5. Turn on the water supply and ensure that water is flowing from the free end of the water pipe to drain. This should be checked at intervals. 6. Turn the heater power control knob on the control panel to 0 Watt position by turning the knob fully anti clockwise. 7. Switch on the main switch and the digital readouts will be illuminated. 8. Set the heater power control to give a reading of 20 watts on the digital indicator. 9. Make sure that the temperature reading decreases towards the water-cooled end for the entire temperature sensor. 10. Turn off the heater power control and switch off the main switch. 11. Exchange the two-heater supply leads at the control panel. 12. Remove the central specimen from the linear module, leaving the three sensor leads still connected to the specimen. 13. Connect the remaining six sensor leads to the radial module, with the TT1 connected to the innermost plug on the radial. Connect the remaining five sensor leads to the radial module correspondingly, ending with TT 9 sensor lead at the edge of the radial module. 14. Set the heater power control to give a reading of 20 watts on the digital indicator. 9 Heat Transfer Lab Conduction Heat Transfer Unit 15. Make sure that the temperature reading decreases towards the edge of the disc. 16. The equipment is now pre-checked for experiment. Note: i. Care should be exercised to avoid overheating the linear conduction module especially when poor heat conductors are used as the intermediate section. The temperature at the hot end of the module should be checked at regular intervals to ensure that it does not rise above 100 °C. ii) Always switch off the main switch before connecting the power and sensor leads. 4.2 Experiment Procedures Experiment A: To investigate Fourier’s Law for the linear conduction of heat along a homogeneous bar 1. Make sure that the main switch is initially off. Then Insert a brass conductor (25mm diameter) section intermediate section into the linear module and clamp together. 2. Turn on the water supply and ensure that water is flowing from the free end of the water pipe to drain. This should be checked at intervals. 3. Turn the heater power control knob control panel to the fully anticlockwise position and connect the sensors leads. 4. Switch on the power supply and main switch, the digital readouts will be illuminated. 5. Turn the heater power control to 40 Watts and allow sufficient time for a steady state condition to be achieved before recording the temperature at all nine sensor points and the input power reading on the wattmeter (Q). This procedure can be repeated for other input power between 0 to 40 watts. After each change, sufficient time must be allowed to achieve steady state conditions. Record all your data in Table 1. 6. End of experiment 7. Plot the temperature, T versus distance, x. Calculate the thermal conductivity at heater power is 5 watts. 10 Heat Transfer Lab Conduction Heat Transfer Unit Note: i) When assembling the sample between the heater and the cooler take care to match the shallow shoulders in the housings. ii) Ensure that the temperature measurement points are aligned along the longitudinal axis of the unit. Experiment B: To examine the temperature profile and determine the rate of heat transfer resulting from radial conduction through the wall of a cylinder 1. Make sure that the main switch is initially off. 2. Connect one of the water tubes to the water supply and the other to drain. 3. Connect the heater supply lead for the radial conduction module into the power supply socket on the control panel. 4. Connect the six sensor (TT1, 2, 3 & 7, 8, 9) leads to the radial module, with the TT1 connected to the innermost plug on the radial. Connect the remaining five sensor leads to the radial module correspondingly, ending with TT 9 sensor lead at the edge of the radial module. 5. Turn on the water supply and ensure that water is flowing from the free end of the water pipe to drain. This should be checked at intervals. 6. Turn the heater power control knob control panel to the fully anticlockwise position. 7. Switch on the power supply and main switch, the digital readouts will be illuminated. 8. Turn the heater power control to 40 Watts and allow sufficient time for a steady state condition to be achieved before recording the temperature at all six sensor points and the input power reading on the wattmeter (Q). This procedure can be repeated for other input power between 0 to 40 watts. After each change, sufficient time must be allowed to achieve steady state conditions. Record all your data in Table 2. 9. End experiment 10. Plot of the temperature, T(°C) versus distance, r 11 Heat Transfer Lab Conduction Heat Transfer Unit 11. Plot the temperature T(K) versus ln(r) Calculate the amount of heat transferred at heater power of 5 watts. 4.3 General Shut-down Procedures 1. Turn the heater power control knob on the control panel to 0 Watt position by turning the knob fully anti clockwise. Keep the cooling water flowing for at least 5 minutes through the module to cool down the test metal. 2. Switch off the main switch and power supply. Then, unplug the power supply cable. 3. Close the water supply and disconnect the cooling water connection tubes if necessary. Otherwise, leave the connection tubes for next experiment. 4. Disconnect the heater supply lead for the linear conduction module into the power supply socket on the control panel. Disconnect the sensor leads if necessary 12 Heat Transfer Lab Conduction Heat Transfer Unit KOLEJ KEJURUTERAAN UTARA MALAYSIA LAB 1 CONDUCTION HEAT TRANSFER Result Lab Sheet GROUP NUMBER :___________________________ STUDENT NAME : DATE OF EXPERIMENT :___________________________ GROUP MEMBERS NAME: 1)_______________________________signature:__________ 2)_______________________________signature:___________ 3)_______________________________signature:__________ 4)_______________________________signature:___________ 5)_______________________________signature:___________ Mark : 13 Heat Transfer Lab 5.0 Conduction Heat Transfer Unit DATA & RESULTS Experiment A Table 1 Heater TT1 Power, Q (°C) (Watts) 5 TT2 (°C) TT3 (°C) TT4 (°C) 10 15 20 14 TT5 (°C) TT6 (°C) TT7 (°C) TT8 (°C) TT9 (°C) Heat Transfer Lab Conduction Heat Transfer Unit Experiment B Table 2 Test A Node Radius Heater TT1 Power, Q (°C) (Watts) 5 B 10 C 15 D 20 TT1 TT2 TT2 (°C) Table 3 TT3 ln r Temperature (°C) Temperature (K) 15 TT3 (°C) TT7 (°C) TT7 TT8 (°C) TT8 TT9 (°C) TT9 Heat Transfer Lab Conduction Heat Transfer Unit Graph Experiment A 16 Heat Transfer Lab Conduction Heat Transfer Unit Graph Experiment B 17 Heat Transfer Lab 6.0 Conduction Heat Transfer Unit QUESTIONS Answer all questions below: 6.1 Give 3 sources of error in the experiment? 6.2 What is the physical mechanism of heat conduction in a solid, a liquid, and a gas? 6.3 What is meant by thermal resistance? 6.4 Define thermal conductivity and explain its significance in heat transfer? 18 Heat Transfer Lab 6.4 Conduction Heat Transfer Unit Consider a 3-m-high, 5-m-wide, and 0.3-m-thick wall whose thermal conductivity k=0.9 W/m.°C(Fig.1). On a certain day, the temperatures of the inner and the outer surface of the wall are measured to be 32°C and 27°C, respectively. Determine the rate of heat loss through the wall on that day? Wall H=3m W=5m L=0.3m Figure 1 19 Heat Transfer Lab 6.4 Conduction Heat Transfer Unit A thick-walled tube of stainless steel [18%Cr, 8%Ni, k=19W/m.°C] with 2-cm inner diameter (ID) and 4-cm outer diameter (OD) is covered with a 3-cm layer of asbestos insulation [k=0.2W/m.°C] (Fig.2). If the inside wall temperature of the pipe is maintained at 600°C, calculate the heat loss per meter of length. Stainless steel T1= 600°C r1 r2 r3 Asbestos T2 = 100°C Figure 2 20 Heat Transfer Lab 7.0 Conduction Heat Transfer Unit DISCUSSION Include a discussion on the result noting trends in measured data, and comparing measurements with theoretical predictions when possible. Include the physical interpretation of the result, the reasons on deviations of your findings from expected results, your recommendations on further experimentation for verifying your results and your findings. 8.0 CONCLUSION Based on data and discussion, make your overall conclusion by referring to experiment objective 21