ERT 245 LAB 2 LINEAR N RADIAL HEAT

advertisement

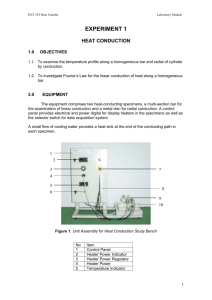

LAB 2 LINEAR AND RADIAL HEAT CONDUCTION APPARATUS 1.0 OBJECTIVES 1.1 To investigate the thermal conductivity and thermal contact resistance of brass in linear direction. 1.2 To investigate the thermal conductivity of brass in radial direction. 2.0 INTRODUCTION The Linear and Radial Heat Conduction Apparatus is designed for students to study the principles of conduction heat transfer. The student is able to determine the relationship between the rate of heat transfer and temperature gradient, the crosssectional area and length of the conducting path and thermal conductivity of the material. 2.1 Unit Assembly The equipment comprises two heat-conducting specimens, a multi-section bar for the examination of linear conduction and a metal disc for radial conduction. A control panel supplies electrical power to the heaters and shows readings for all relevant measurements. A small flow of cooling water provides a heat sink at the end of the conducting path in each specimen. -1- 1 7 2 3 8 4 9 5 6 Figure 1: Unit Assembly for Heat Conduction Study Bench (Model: HE 105) 1. 2. 3. 4. Control Panel Heater Power Indicator Heater Power Regulator Temperature Indicator 6. 7. 8. 9. Thermocouple Connectors Thermocouples Radial Module Linear Module 5. Temperature Selector -2- 2.2 Specifications a) Linear Module Consists of the following sections: i) Heater Section Material : Brass Diameter : 25 mm ii) Cooler Section Material : Brass Diameter : 25 mm iii) Interchangeable Test Section - Insulated Brass Test Section with Temperature Sensors Array (Diameter = 25mm, Length = 30 mm) - Insulated Brass Test Section (Diameter = 13mm, Length = 30 mm) - Insulated Stainless Steel Test Section (Diameter = 25mm, Length = 30 mm) b) Radial Module Material : Brass Diameter : 110 mm Thickness : 3 mm c) Instrumentations Linear module consists of a maximum of 9 type K thermocouple temperature sensors at 10 mm interval. For radial module, 6 type K thermocouple temperature sensors at 10 mm interval along the radius are installed. Each test modules are installed with a 100 Watt heater. 2.3 Overall Dimensions Test Modules Assembly Height : 0.20 m Width : 0.34 m Depth : 0.30 m Panel Height : 0.20 m Width : 0.30 m Depth : 0.55 m 2.4 General Requirements Electrical Water : : 240 VAC, 1-phase, 50Hz Laboratory tap water, 20 LPM @ 20 m head Drainage point -3- 2.5 Linear Module Fourier's Law of Heat Conduction is most simply demonstrated with the linear conduction module. This comprises a heat input section fabricated from brass fitted with an electrical heater. Three temperature sensors are installed at 10mm intervals along the working section, which has a diameter of 25mm. A separate heat sink section also of brass is cooled at one end by running water while its working section is also fitted with thermistor temperature sensors at 10mm intervals. The heat input section and the heat sink section may be clamped directly together to form a continuous brass bar with temperature sensor at 10mm intervals, alternatively any one of three intermediate sections can be fitted between these two. The first of these is a 30mm length of the same material (brass) and is the same diameter as the heat input and heat sink sections and is again fitted with temperature sensors at 10mm intervals. This section is clamped between the two basic sections forms a relatively long uniform bar with nine regularly spaced temperature sensors. The second center section, which may be fitted, is again brass and 30mm long but has a diameter of 13mm and is not fitted with temperature sensors. This section allows a study of the effect of a reduction in the cross-section of the heatconducting path. The third center section, which may be fitted, is of stainless steel and has the same dimensions as the first brass section. No temperature sensors are fitted. This section allows the study of the effect of a change in the material while maintaining a constant cross-section. The mating ends of the sections are finely finished to promote good thermal contact although heat- conducting compound may be smeared over the surfaces to reduce thermal resistance. The heat-conducting properties of insulators may be found by simply inserting a thin specimen between the heated and cooled metal sections. An example of such an insulator is a piece of paper. Heat losses from the linear module are reduced to a minimum by a heat-resistant casing enclosing an air space around the module. The interchangeable center sections have their own attached casing pieces, which fit with those of the heat input and heat sink sections. The temperature sensors come with miniature thermocouple plugs. There are to be connected to the panel for temperature measurement readings. Therefore temperature gradients can be readily plotted from rapidly acquired data on the computer. -4- 2.6 Radial Module The radial conduction module comprises a brass disc 110mm diameter and 3mm thick heated in the center by an electrical heater and cooled by cold water in a circumferential copper tube. Temperature sensors are fitted to the center of the disc and at 10mm intervals along a radius there being six in all. Again heat losses are minimized by preserving an air gap around the disc with a heat-resistant casing. As in the linear module, the temperature sensors are to be connected to the panel for temperature displays. 2.7 Control Panel Either of the heat-conduction modules may be connected to a control panel which allows the heater input power to be set and the temperature at any of the sensors to be shown in °C on the computer. Heater power is controlled by a variable autotransformer and displayed on a digital indicator. Power outputs from 0 to 100 watts may be obtained. Note: The insulation material of the test modules can withstand up to 100 °C only. Reduce the heater power immediately if the temperature nearest to the heater is too high. -5- 3.0 SUMMARY OF THEORY 3.1 Linear Conduction Heat Transfer dx Q dT Figure 2: Linear temperature distribution It is often necessary to evaluate the heat flow through a solid when the flow is not steady e.g. through the wall of a furnace that is being heated or cooled. To calculate the heat flow under these conditions it is necessary to find the temperature distribution through the solid and how the distribution varies with. Using the equipment set-up already described, it is a simple matter to monitor the temperature profile variation during either a heating or cooling cycle thus facilitating the study of unsteady state conduction. THS kH kS kC THI TCI XH XS XC Figure 3: Linear temperature distribution of different materials -6- TCS Fourier’s Law states that: Q kA dT dx (1) where, Q = heat flow rate, [W] W k = thermal conductivity of the material, Km A = cross-sectional area of the conduction, [m2] dT = changes of temperature between 2 points, [K] dx = changes of displacement between 2 points, [m] From continuity the heat flow rate (Q) is the same for each section of the conductor. Also the thermal conductivity (k) is constant (assuming no change with average temperature of the material). Hence, AH (dT ) AS (dT ) AC (dT ) (2) (dx H ) (dx S ) (dx C ) i.e. the temperature gradient is inversely proportional to the cross-sectional area. AC AH AC XH XS Q AC XC Figure 4: Temperature distribution with various cross-sectional areas -7- 3.2 Radial Conduction Heat Transfer (Cylindrical) Ti To Ri Temperature Distribution Ro Ri Ro Figure 5: Radial temperature distribution When the inner and outer surfaces of a thick walled cylinder are each at a uniform temperature, heat rows radially through the cylinder wall. From continuity considerations the radial heat flow through successive layers in the wall must be constant if the flow is steady but since the area of successive layers increases with radius, the temperature gradient must decrease with radius. The amount of heat (Q), which is conducted across the cylinder wall per unit time, is: Q 2Lk (Ti To ) R ln o Ri (3) where, Q = heat flow rate, [W] L = thickness of the material, [m] W k = thermal conductivity of the material, Km Ti = inner section temperature, [K] To = outer section temperature, [K] Ro = outer radius, [m] Ri = inner radius, [m] -8- Linear Heat Conduction A = πD2/4, D = 0.025 m Measuring Point Distance from Heater (mm) 1 10 2 20 3 30 4 40 5 50 6 60 7 70 8 80 9 90 Radial Heat Conduction L = 0.003 m Measuring Point Radius, (mm) 1 0 2 10 3 20 4 30 5 40 6 50 -9- 4.0 EXPERIMENTAL PROCEDURES 4.1 Experiment 1: To investigate the thermal conductivity and thermal contact resistance of brass in linear direction. i. Set the power of the heater. ii. Wait for 25 to 30 minutes until the temperature achieved at every measuring point is stable. iii. Record the respective final temperature values at every point. iv. Record temperatures for power input from 0 to 20 watts 4.2 Experiment 2: To investigate the thermal conductivity of brass in radial direction. i. Set the power of the heater. ii. Wait for 25 to 30 minutes until the temperature achieved at every measuring point is stable. iii. Record the respective final temperature values at every point. iv. Record temperatures for power input from 0 to 20 watts 6.0 RESULTS AND CALCULATIONS 6.1 Data table for experiment 1 Power, Q (W) 5.0 10.0 15.0 20.0 Distance from heater end, x (m) TT1 (°C) TT2 (°C) TT3 (°C) TT4 (°C) TT5 (°C) TT6 (°C) TT7 (°C) 0.010 0.020 0.030 0.040 0.050 0.060 0.070 0.080 0.090 - 10 - TT8 (°C) TT9 (°C) 6.2 Data table for experiment 2 Heater Power, Q (Watts) 5 10 15 20 Distance from heater end, x (m) TT1 TT2 TT3 TT4 TT5 TT6 (°C) (°C) (°C) (°C) (°C) (°C) 0.010 0.020 0.030 0.035 0.065 0.070 6.3 Determine the thermal conductivity of both experiments. 6.4 Determine the thermal contact resistance for experiment 1. 6.5 Show the temperature profile (graph) of both experiments. 7.0 CONCLUSIONS 7.1 Discuss /compare the thermal conductivity values obtained for linear and radial heat conduction. - 11 -