XRF: X-Ray Fluorescence Spectroscopy Analysis

advertisement

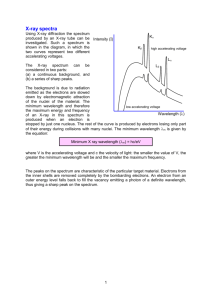

X-Ray Fluorescence (XRF) Becoming the most widely used method for elemental analysis of solids ADVANTAGES AND DISADVANTAGES Advantages of X-Ray Spectrometry * Simple spectra * Spectral positions are almost independent of the chemical state of the analyte * Minimal sample preparation * It is non-destructive * Applicable over a wide range of concentrations * Good precision and accuracy Disadvantages of X-Ray Spectrometry * X-ray penetration of the sample is limited to the top 0.01 - 0.1 mm layer * Light elements (below 22Ti) have very limited sensitivity although C is possible on new instruments * Inter element (MATRIX) effects may be substantial and require computer correction * Limits of detection are only modest * Instrumentation is fairly expensive NOMENCLATURE Simplified spectral lines observed in x-ray spectra (each energy shell actually comprises several energy levels, thus transitions are more numerous than shown). PRINCIPLES OF X-RAY FLUORESCENCE X-Ray Excitation Electron Excitation AUGER ELECTRON EMISSION (internal photoionisation) The Auger effect is more common in elements of low Z because their atomic electrons are more loosely bound and their characteristic Xrays more readily absorbed. X-RAY FLUORESCENCE YIELD The yield of X-ray photons is reduced by the Auger effect. The fluorescence yield ( ) is the ratio of X-ray photons emitted from a given shell to the number of vacancies created in that shell. Since production of Auger electrons is the only other competing reaction the ratio of Auger electrons to vacancies must be 1- . X-RAY ABSORPTION AND SCATTERING IN CONDENSED PHASES The probability of X-ray absorption as a function of path length through the sample is given by Beer's law for X-rays: I/I0 = exp(-µm d) where I/I0 is the fraction of X-rays transmitted through a thickness d of a material of density . The parameter µm is the mass absorption coefficient which is a function of the atomic number Z and the energy (wavelength) of the X-ray. The mass absorption coefficient for a complex sample is the weighted average of the coefficients for the constituent atoms. X-RAY MASS ABSORPTION COEFFICIENTS A plot of mass absorption coefficient vs energy of the X-ray photon for 82Pb. Abrupt changes are observed corresponding to absorption edges for K, L and M electrons. At the energy (wavelength) of the edge, the photons first become sufficiently energetic to eject K, L and M photoelectrons. X-RAY SOURCES The X-ray tube is energised by a high-voltage power supply with an output of 0.5 to 50 kV. The head of the vacuum tube consists of a target (anode), which is often made of tungsten and chromium. As accelerated electrons strike the target, X-rays are emitted. The tube also forms the X-rays into a beam through a Beryllium window. In the target the 74W is used to excite L and K lines of higher Z atoms and the 24Cr is used to excite atoms of 22Ti and below. Spectral Output X-ray spectrum produced by electron bombardment of a tungsten target: Continuum Spectrum: The continuum results from deceleration of electrons by the atoms in the target. The German term "bremsstrahlung" means "braking radiation." Characteristic Spectra: Electron bombardment also produces characteristic peaks K and K provided the accelerating potentials are sufficiently high. DETECTORS X-ray photons (as well as other energetic particles) can be measured using the following types of detectors: * gas-filled detectors register a current pulse from the collection of electron-ion pairs formed; * a semiconductor detector register a current pulse from the formation of electron-hole pairs; * a scintillation detector counts light pulses created when an X-rays passes through a phosphor; * a photographic plate. Gas-Proportional Counters A gas-proportional counter is filled with P90 gas (90% argon, 10% methane). X-rays ionise the gas, leaving electrons that migrate to the anode and positive ions that move to the case. Proportional counters use gas amplification: the detector voltage is raised to 500 to 700 V so that the primary electrons and ions, first formed, are accelerated to produce secondary electrons and ions when they collide with gas atoms. This yields a greatly increased signal which is, nevertheless, proportional to the energy of the original x-ray. Solid-State Detectors When an electron enters the crystal it ejects a high-energy photoelectron which ultimately dissipates its energy in multiple interactions which promote valence band electrons to the conduction band, leaving holes in the valence band. The electron-hole pairs are then collected by biasing the detector at -1000 V, giving rise to a current pulse for each x-ray entering the detector. Charge collection is much more efficient than in a gas. Lithium-Drifted Si(Li) Detectors A lithium-drifted Si(Li) detector is manufactured from high-purity p-type silica. However, p-type silica of sufficiently high purity is difficult to fabricate. Most Si crystals contain extrinsic holes, caused by impurities, which allow significant "leakage" of current at the required bias voltage. In order to compensate for these extrinsic holes, lithium, an n-type dopant, is diffused into the material at 350 - 450ºC under an electrical gradient. The lithium atoms compensate for the extrinsic charge-carriers in the p-type silicon and provide a wide "intrinsic" region of high resistance. Si(Li) detectors are operated at 77 K with a liquid N2 cryostat to prevent further diffusion and to reduce the level of random noise due to the thermal motion of charge carriers. WAVELENGTH DISPERSIVE XRF SPECTROSCOPY Instrumentation In wavelength dispersive spectrometers, the several x-ray lines emitted from the sample are dispersed spatially by crystal diffraction on the basis of wavelength. The detector then receives only one wavelength at a time. The crystal and detector are made to synchronously rotate through angles of θ and 2θ respectively. Bragg Diffraction Wavelength dispersive X-ray spectrometers function by separating the X-rays of interest using diffraction from a crystal. This follows from the Bragg equation: n = 2 d sin( ) where n is the diffraction order, d is the interplanar spacing of the atomic layer and the angle of incidence. Crystals Crystal Primary Range LiF 0.025 - 0.272 nm Si 0.055 - 0.598 nm pentaerythritol 0.076 - 0.834 nm CaSO4.2H2O 0.132 - 1.45 nm KAP* 0.232 - 2.54 nm lead stearates 6 - 15 nm is *Potassium hydrogen phthalate ENERGY DISPERSIVE XRF SPECTROSCOPY The primary X-ray beam excites several spectral lines from the sample. In energy dispersive XRF all wavelengths enter the detector at once. The detector registers an electric current having a height proportional to the photon energy. These pulses are then separated electronically, using a pulse analyser. WAVELENGTH AND ENERGY DISPERSION COMPARED Advantages of Energy Dispersion: * simplicity of instrumentation - no moving parts * simultaneous accumulation of the entire Xray spectrum * qualitative analysis can be performed in 30 s, or so * a range of alternative excitation sources can be used in place of high-power x-ray tubes with their large, heavy, expensive and powerconsuming supplies * alternative sources include, low power x-ray tubes, secondary monochromatic radiators, radioisotopes and ion beams. Advantages of Wavelength Dispersion: * resolution is better at wavelengths longer than 0.08 nm * higher individual intensities can be measured because only a small portion of the spectrum is admitted to the detector * with multichannel analysers sensitivity for weak lines in the presence of strong lines is limited because the strongest line determines the counting time * lower detection limits are possible SAMPLE PREPARATION Reproducible sample preparation methods are essential. Samples must be in a form that are similar to available standards in terms of matrix, density and particle size. * Solids, generally solids must be polished as surface roughness may give erratic results. * Powders and pellets, powdered samples are often pressed into pellets, suspensions may also be analysed * Fusions, with potassium pyrophosphate (K2P2O7) or a tetraborate (Na2B4O7 or Li2B4O7) present a homogenised sample which can often be analysed directly * Liquids and solutions, a x-ray transparent cover and sample cup must be provided to prevent volatility under vacuum conditions * support media, such as filter paper, millipore filters, ion-exchange membranes MATRIX EFFECTS Types of Matrix Effects In XRF absorption-enhancement effects arise from the following phenomena: 1. The matrix absorbs primary x-rays (primary-absorption effect); it may have a larger or smaller absorption coefficient than the analyte for primary source x-rays 2. The matrix absorbs the secondary analyte xrays (secondary-absorption effect); it may have a larger or smaller absorption coefficient for the analyte-line radiation 3. The matrix elements emit their own characteristic lines, which may lie on the short wavelength side of the analyte absorption edge, thereby exciting the analyte to emit additional radiation to that excited by the primary source of X-rays alone (enhancement) Absorption-Enhancement Effects Absorption-enhancement effects can be positive or negative on the basis of their effect upon analyte intensity. In the positive absorption effect, the matrix has a smaller absorption coefficient than the analyte for the primary and analyte-line radiation, and the analyte-line radiation is higher than would be predicted. In the negative absorption effect, the matrix has a larger absorption coefficient than the analyte, and the analyte-line intensity is lower than expected. In the enhancement effect, one or more spectral lines of the matrix elements excite analyte-line emission). This enhancement may take two forms: direct enhancement ( C both excite A) B and the third element and enhancement ( excites C excites B which in turn A). QUANTITATIVE ANALYSIS 1. Calibration-Standard Methods. The analyteline intensity from samples is compared with that from standards having the same form as the samples and, nearly as possible, the same matrix. 2. Internal Standardisation. The calibrationstandard method is improved by quantitative addition to all samples of an internal standard element having excitation, absorption and enhancement characteristics similar to those of the analyte in the particular matrix. The calibration function involves measuring the intensity ratio of the analyte and internal standard lines. 3. Matrix-Dilution Methods. The matrix of all samples is diluted to a composition such that the effect of the matrix is determined by the diluent rather than the matrix. 4. Thin-Film Methods. The samples are made so thin that absorption-enhancement effects substantially disappear. 5. Standard Addition and Dilution Methods. The analyte concentration is altered quantitatively in the sample itself. The sample is subjected to one or more quantitative incremental concentrations or dilutions of the analyte. The intensity of the analyte lines is measured for effectively the same matrix in each case. 6. Mathematical Corrections. Absorptionenhancement effects are corrected mathematically by the use of influence coefficients for each element present (these are derived experimentally from reference samples). The basic approach is that the XRF intensity at a particular wavelength will in some way be affected by each element in the sample. Calibration Quantitative XRF analyses require calibration of the measuring arrangement, which may be performed by two major approaches: empirical calibration fundamental parameters (FP) calibration. The empirical calibration is based on the analysis of standards with known elemental compositions. To produce a reliable calibration model, the standards must be representative of the matrix and target element concentration ranges of the sample to be analyzed. Maintaining the same sample morphology (particle size distribution, heterogeneity and surface condition) and source/sample geometry for both standard and sample measurements is essential in empirical calibrations. Alternatively, “standardless” FP techniques may be used, which rely on built-in mathematical algorithms that describe the physics of the detector’s response to pure elements. In this case, the typical composition of the sample must be known, while the calibration model may be verified optimized by one single standard sample. and Detection limits Two types of detection limits considered in XRF analysis: should be a) instrument detection limits, which represent the threshold concentration of a given element that a particular instrument can resolve and b) method detection limits, related to sample preparation and analysis time. Depending on the element to be analyzed and the sample matrix, typically achieved detection limits vary between 10 and 100 ppm. XRF applications During the last two decades, the development in X-ray detectors has established the XRF method as a powerful technique in a number application fields, including: Ecology and environmental management: measurement of heavy metals in soils, sediments, water and aerosols Geology and mineralogy: qualitative and quantitative analysis of soils, minerals, rocks etc. Metallurgy and chemical industry: quality control of raw materials, production processes and final products Paint industry: analysis of lead-based paints Jewelry: measurement of precious metals concentrations Fuel industry: monitoring the amount of contaminants in fuels Food chemistry: determination of toxic metals in foodstuffs Agriculture: trace metals analysis in soils and agricultural products Art Sciences: study of paintings, sculptures etc. in order to make an expertise EDX Microanalysis As the name suggests, this refers to the analysis of a sample on a microscopic scale, resulting in structural, compositional and chemical information about the sample. There exists a whole host of analytical techniques that exploit the many signals which may be generated within the sample. X-ray microanalysis specifically gives information about the elemental composition of the specimen, in terms of both quantity and distribution. K X-rays L X-rays On entering a sample, the energetic incident electrons undergo a number inelastic and elastic scattering events resulting in a zig-zag path into the sample until they either come to rest or are backscattered out of the surface. The distribution of trajectories is contained within the so called ‘interaction volume’, the shape and dimensions of which are strongly affected by both: - the atomic number and the incident energy of the electrons. At any point along a given trajectory, characteristic X-rays can be produced provided that the energy of the electron or indeed X-ray is greater than the absorption edge associated with that characteristic emission line. The volume of the sample from which X-rays are produced is known as the X-ray production volume or X-ray generation volume, the size and dimensions of which depends on the X-ray line being excited and the density of the material. For example, in the case of lead, the sample volume producing the higher energy L series X-rays will be smaller and nearer to the surface than the volume from which M series X-ray lines are generated. J(rz) Depth (microns) 0 The typical features of the j(rz) curve are shown in the adjacent figure. Near the surface, X-ray production is greater than for a thin unsupported film because of scattered electrons travelling up from below being able to generate X-rays and therefore resulting in the value of j(rz) being greater than one. After initially rising to a maximum, the curve decreases due to scattering and deceleration of the electrons, eventually falling to zero. Geometry The position of the front end of the detector in relation to the surface of the sample is important in order to optimise the collection of X-rays. Detector Working distance Entrance angle Sample at ideal working distance for X-ray microanalysis Sample at incorrect working distance for X-ray microanalysis EDX-Mapping The X-ray spectrum detected by EDX can be used to construct a true color response that would be obtained if the human visual sensitivity to the electromagnetic spectrum could be offset to the X-ray wavelength region. This color input is then used to augment a conventional electron image. In this way the detail of the original electron image is retained whilst portraying the underlying elemental composition because the spectrum from each compound gives it a characteristic color. Thus topographic and compositional information from all elements is compressed into a single view giving the analyst a useful 'first look' to guide further microanalysis. Quantitative microanalysis Quantitative analysis of elements in any sample, requires an accurate measure of the intensity of peaks, before the concentration of elements in a sample can be calculated. In determining peak areas in spectra, two problems arise, 1) a typical spectrum contains characteristic peaks, which are superimposed on a slowly varying background, which is 'noisy' because of statistical variations. This background contribution needs to be carefully subtracted from the spectrum. 2) The energy resolution of the detector imposes a limit on the separation of peaks. Identification of peaks is generally not a problem, but overlapping peaks require deconvolution, before being able to extract the true peak intensities relevant to the elements present in the sample. Once these intensities have been determined, a comparison is then made with standards of known composition, followed by application of matrix corrections, before the concentration of each element can be determined. Background subtraction The simple method of linear interpolation of the background beneath a peak is not appropriate, since the background is non linear, both locally in the vicinity of peaks, and over the entire energy range. There are various schools of thought as how to best remove this background and to separate peaks from each other: 1) One such method relies on the fitting of a theoretical background to the spectrum background, and then using a least squares fitting technique to obtain peak intensities. However, construction of a model to fit the background requires an accurate knowledge of a number of physical parameters, which are often difficult to determine precisely. 2) A second method suppresses the background, using a filtering method which avoids any specific shape calculation. The peak intensities are then obtained by using a least squares fit of standard peaks, in which the background has also been suppressed. Peak deconvolution The energy resolution of an EDS imposes a limit on the separation of peaks. There are several examples of peak overlap which commonly occur: the Ka peaks for Be, B, C, O, N and F, are sufficiently close for the tails of one peak to overlap into the neighbouring peak. Overlaps between the Kb line of one element and the Ka line of another, often overlap. Examples include the V Kb and Cr Ka (15eV apart) and overlaps between lines from different shells e.g. between Mo La and S Ka, can often occur. When peaks overlap, it is possible to extract individual peak areas, provided that the corresponding peak shapes are accurately known. These peak shapes or profiles are fitted to the spectrum using the method of least squares. Clearly the accuracy of the fitting depends on the similarity of the peaks in the unknown spectrum, to those of the profiles, and this is reflected in the accuracy of the peak intensities. This is particularly important when small peaks and larger peaks overlap. The fitting of profiles to the unknown spectrum requires that the gain and the system resolution should be matched between the two. Optimization of spectra, in terms of gain and resolution, can be taken into account by using an optimization standard which produces suitable known peaks. Matrix corrections Atomic number The atomic number of the material and the incident beam energy have a profound effect on both the number of electrons backscattered out of the material and the rate at which the electrons lose their energy within the sample. Both of these factors will have an affect on the number of X-rays produced at a given depth in the interaction volume and hence the shape and area of the j(rz) curve which corresponds to the total number of X-ray generated. The atomic number correction is largest when considering light elements within a heavy sample matrix. Fluorescence correction Fluorescence arises as a result of the ionization of atom shells by X-rays rather than electrons. The result is the emission of characteristic Xrays. This contribution to the spectrum will be in addition to those X-rays which have been produced directly by electrons. Fluorescence can only occur if the energy of the incident Xray is greater than the critical excitation energy. There will be a fluorescence contribution from both the continuum and characteristic X-rays but the contribution from characteristic X-rays is the most dominant. Electron Beam FeK CrK Resolution and count rate Energy resolution is the primary test of detector performance, and the main specification for an EDX detector is the resolution at Mn. The benefits of improved resolution, are improved detection limits, because a narrower peak is higher above the background. Well defined peak shapes make peak ID faster and more reliable, and in addition, overlapped peaks are better resolved, leading to significantly improved detection limits, and accuracy of routines used in quantitative analysis. The acquisition rate into the spectrum is important and this is related to the input count rate, via the deadtime and the selected processing time. Input rate: This shows the approximate rate of photons striking the detector. Acquisition rate: This shows how fast the system is accumulating spectrum counts. Deadtime (%): is the percentage time for which the pulse processor is unavailable for further counting. (see acquisition rate).