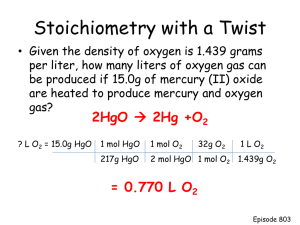

Problem 1: Let K denote K2CrO4 and W denote water

advertisement

CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ Open Book and Open Notes Exam Score Problem 1 ______/20 Problem 2 ______/30 Problem 3 ______/50 Total ______________/100 1 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ Problem 1: (20 points) Calculate the specific volume of propane at a pressure of 6000 kPa and a temperature of 230ºC. 2 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ Problem 2: (30 points) A mixture of 50 mole % benzene and 50 mole % toluene is contained in a cylinder at 39.36 in Hg absolute pressure. Calculate the temperature range in which a two phase system can exist. 3 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ Problem 3: (50 points) A pelletized mixture of Fe2O3 (hematite) and carbon at 298ºK is reacted with oxygen at 298ºK to produce CO2(g) and Fe(l) by the following reaction sequence: 1) C(s) + ½ O2(g) CO 2) ½ Fe2O3 (s) + 3/2 CO Fe(s) + 3/2 CO2 Oxygen is fed to the reactor with 0% excess. You are to answer A and B assuming that the reactor is adiabatic. A) Determine the amount of carbon required for this process per mole of Fe(l) produced, if all the Fe2O3 is reacted and the products leave the separator at 1900ºK. Note, that excess carbon may be reacted in reaction 1 to provide any needed heat. B) Determine the heat, Q, required for the separator per mole of Fe(l) produced, if all the Fe2O3 is reacted and the products leave the separator at 1900ºK. O2(g) C(s) Fe2O3(s) 298ºK Reactor Separator CO(g) CO2(g) 1900ºK Fe(l) 1900ºK Data for Problem: Heat of Formation Hf º (kJ/mole) O2(g) 0 N2(g) 0 CO(g) -110.599 CO2(g) -393.798 Fe2O3(s) -824.8 Fe(l) Fe(s) 0 C(s) 0 Heat Capacity (J/(mole ºK)) 34.8 32.8 34.0 55.3 42.5 40.2 24.5 8.5 4 Melting Point Heat of Fusion (ºK) (kJ/gmole) 1838ºK 83.3 kJ/gmole 1809ºK >2300ºK 18.8 kJ/gmole - CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ 5 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ 6 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ Solution 1) Basis 1 kg propane Tc=370K, Pc=4255kPa, Mw= 44.09 kg/kmol, R=8.314(kPa m3/kmol K) Tr=(230+273.15)/370=1.36 Pr=6000/4255=1.408 From General compressibility chart z ~ 0.8 V^/Mw=zRT/(PMw) V^/Mw= 0.8*8.314(kPa m3/kmol K)*(503K)/(6000*kPa*44.09 kg/kmole)=0.0127 m3/kg 2) 7 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:_______Solution ________________________ 3) Solution Basis: 1 mole Fe(l) Product at 1900K set T.ref = 298K therefore ΔHrxn must be supplied by extra C in reaction 1 1) 3/2C(s) + 3/4 O2(g) 3/2 CO 2) ½ Fe2O3 (s) + 3/2 CO Fe(s) + 3/2 CO2 ΔHºrxn = 3/2*(-110.51 kJ/gmole) ΔHºrxn = -12.87 kJ/gmole 3) Fe(s) Fe(l) 3/2C(s) + 3/4 O2(g) +½ Fe2O3 (s) Fe(l) + 3/2 CO 2 3 C p_rxn Cp_Fe_liq H0 rxn 2 Cp_CO2 3 2 Cp_C 3 4 Cp_O2 ΔHºrxn = + 18.8 kJ/gmole overall reaction is exothermic 1 2 Cp_Fe2O3 63.35 1 mol K J 1 kJ Hf_CO2 Hf_Fe2O3 178.297 2 mole 2 3 H rxn ( T) H0 rxn T C p_rxn d t H f_Fe 298 K H rxn( 1900 K) 58.01 kJ mole At 1900K the overall reaction is exothermics, so no extra C is required. Actually cooling is required either in the reactor or at the separator. Ans A: 3/2 moles C required! Ans B: must cool Q = 58.01 kJ. 8