Optical Comms 2006 (supplemental)

advertisement

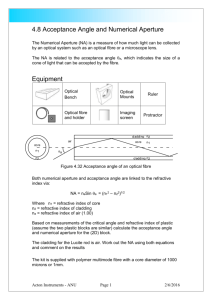

Q1 (i) Explain with the aid of a diagram what is meant by the terms acceptance angle and numerical aperture for an optical fibre. Hence derive an expression for the numerical aperture of a step index fibre with a core refractive index of n1 and a cladding refractive index of n2. [8 marks] (ii) Assuming an impulse-like input pulse to a step index fibre, derive from first principles an expression for the worst case pulse spreading caused by modal dispersion only, in terms of the numerical aperture, the fibre length and the fibre core refractive index. State all of your assumptions clearly. [12 marks] (iii) Hence, based on the results in part (a) and (b) discuss the trade-off between numerical aperture and fibre bandwidth and comment on the impact of this trade-off in an actual optical fibre system. [5 marks] Q2 (i) With the aid of suitable ray diagrams describe the two types of bending loss that can occur in a multimode fibre. Explain why is bending loss in a singlemode fibre is wavelength dependent. [8 marks] (ii) The theoretical strength of fibre is never achieved in real fibres. Explain briefly why this is so. Hence with the aid of an appropriate sketch explain how proof-testing is carried out after fibre manufacture and how it improves longterm fibre reliability. [6 marks] (iii) A fibre is proof tested for 1 second to a stress of 0.45 GPa. Show that with a maximum in-service stress of 0.14 GPa the predicted lifetime is in excess of 47.4 years, assuming the fatigue susceptibility parameter for the fibre is known to be 18.1. State any assumptions made clearly. [7 marks] (iv) Explain how contact with moisture and elevated temperatures reduce the lifetime of an optical fibre. [4 marks] Q1 (i) Cladding Fibre Axis Core If must be greater than c, the critical angle, for TIR and thus propagation to take place, then the maximum value of 1 under these circumstances is the fibre acceptance angle. Visualised in space the acceptance angle is defined is a conical half angle, for the fibre. The numerical aperture for a fibre is the sine of the acceptance angle. The analysis below applies only to rays entering along the axis, so called meridional rays. Assuming is equal to c, the critical angle, what is the value of But and by Snells Law so now 2 90 c n0 sin 1 n1 sin 2 1 sin 1(n1 sin(90 c )) 1 sin 1(n1 sin(90 c )) 1 sin 1 n 1 1 hence n0 is the refractive index of air =1 1 sin n 1 co s 2 c n 22 1 n 2 1 Simple trigonometry Simple trigonometry 1 sin 1 n 12 n 22 This last value is the maximum value that can take on if TIR is to take place, it is therefore called the fibre acceptance angle. Numerical aperture (NA) is defined as the sine of the acceptance angle for a fibre. From the analysis above the NA can be written as: NA (n12 - n22 ) (Assumes refractive index of air is approx 1.) [3 marks] (ii) In this simple analysis the difference in path length delay is analysed for two light rays, axial and extreme meridional. The resultant time delay difference effectively tells us the maximum possible pulse spread or “modal dispersion” A s s u m e : S t e p i n d e x f i b r e A n i m p u l s e l i k e f i b r e i n p u t p u l s e E n e r g y i s e q u a l l y d i s t r i b u t e d b e t w e e n r a y s w i t h p a t h s l y i n g b e t w e e n t h e a x i a l a n d t h e e x t r e m e m e r i d i o n a l W h a t i s t h e d i f f e r e n c e i n d e l a y f o r t h e t w o e x t r e m e s o v e r a l i n e a r p a t h l e n g t h L ? C l a d d i n g a 2 n c E x t r e m e m e r id io n a lr a y A x i a l r a y C o r e 1 n Transmission distance = L Tmax = Transmission time for extreme meridional ray Tmin = Transmission time for axial ray – Tmin. Now find Tmin and Tmax using the diagram below 2 n E x t r e m e m e r id io n a lr a y h a c a d F i b r e A x i s A x i a l r a y 1 n L D i s t a n c e 1 L n m i n T = = 1 ( c / n )= V e l o c i t y c m a x T o f i n d T r e a l i s e t h a t t h e r a y t r a v e l s a d i s t a n c e h b u t o n l y t r a v e l s a d i s t a n c e d t o w a r d t h e f i b r e e n d ( d < h ) . S o i f t h e f i b r e l e n g t h i s L t h e n t h e a c t u a l d i s t a n c e t r a v e l l e d i s : h . L d 1 L n U s i n g s i m p l e t r i g o n o m e t r y m a x T = c c o s 1 n U s i n g S n e l l ' s l a w : c o s c s i n == 2 n 2 1 L n m a x T = 2 c n 2 1 L L n 1 n = m a x m i n D e l a y d i f f e r e n c e t = T T c 2 c n Therefore the delay difference, which is effectively the maximum pulse spreading is given by: 2 2 1 1 2 L n n n 1 L n A s s u m e s < < 1 t = = 1 n 2 c n 2 c n Where is the relative refractive index difference. This can then be rewritten in terms of the numerical aperture and other parameters as: 2 L ( N A ) t = 2 c n 1 [10 marks] (iii) Based on results in part (a) and (b) we can state that 1. As the acceptance angle for a fibre increases the numerical aperture also increases. 2. pulse input also increases, in effect the modal dispersion increases. It is known that an increase in dispersion reduces the bandwidth of a fibre. Overall then it is apparent that there is significant trade-off between a high acceptance angle and a large fibre bandwidth. The impact of this trade-off in an actual optical fibre system is important, for good coupling efficiency for optical sources such as lasers or particularly LEDs a high fibre acceptance angle is very useful. But in effect this means that by selecting a fibre with a high NA value (eg. plastic optical fibre) and thus improving the coupling efficiency the result will be a reduction the fibre bandwidth. In simple terms the trade-off could be defined as one between transmitted (launched) power and bandwidth. As the transmitted power level influences the received power levels this means that in pure communications terms a difficult tradeoff between received power and transmission bandwidth can arise for system designers. [14 marks] Q2 (i) Macrobending: Bending loss caused by tight cable bends. At such a bend illustrated below the conditions for total internal reflection are not maintained for some rays. This occurs because for such rays have angles of incidence to the cladding less than the critical angle in the vicinity of the bend. Thus optical power is lost into the cladding. Microbending: Bending loss caused typically by microscopic deformations of the core cladding interface. At such a deformation illustrated below the conditions for total internal reflection are not maintained and some rays and thus optical power are lost into the cladding. It is considered to be more critical than macrobending since it is largely due to processing flaws rather than mishandling. The bending loss most often associated with poor cable installation is macrobending and with poor cable design the loss is most commonly microbending. Bending loss and wavelength in a singlemode fibre I n a s i n g l e m o d e f i b r e a s t h e s p o t s i z e o r m o d e f i e l d r a d i u s ( M F R ) i n c r e a s e s t h e l o s s a t a b e n d i n c r e a s e s , a s s h o w n i n t h e d i a g r a m b e l o w . Q u a l i t a t i v e l y t h i s i s b e c a u s e a g r e a t e r p r o p o r t i o n o f t h e m o d e f i e l d i s l o s t i f t h e M F R i s l a r g e L o w M F R = L o w e r L o s s C l a d d i n g C o r e M o d e f i e l d L a r g e r M F R = H i g h e r L o s s C l a d d i n g P o w e r l o s t v i a r a d i a t i o n f r o m c l a d d i n g C o r e M o r e p o w e r l o s t v i a r a d i a t i o n f r o m c l a d d i n g M o d e f i e l d The higher the operating wavelength above the cutoff wavelength the lower the fibre V-value But a lower V-value means a larger MFR, so for longer wavelengths the MFR and thus the loss increases. Thus for example the loss due to bending can be expected to increase at 1550 nm relative to 1330 nm [8 marks] (ii) Fibre is intrinsically very reliable in a benign environment with few documented failure mechanisms. Most failures are caused by poor cable choice, poor installation or accidental damage. The intrinsic tensile strength of fibre exceeds that of an equivalent steel wire so that the theoretical strength is 20 GPa (2,900,000 Psi). However due to surface defects such as cracks strength in practice is much lower, typically 5 GPa (725 kPsi). All produced fibres are proof tested after production using the apparatus sketched below. Between the constant speed motor and the constant torque motor the fibre is stressed to typically three times the normal service maximum. A weak fibre with large surface defects present after production will break under the applied stress and is not subsequently used within cables. A typical industry test involves a stress of 50 kPsi (350,000 kPa).This test guarantees a maximum surface defect size of 2.3 microns. The predicted lifetime at maximum service stress with such a defect size present is 30 years. Sketch of Proof Test Apparatus [6 marks] (iii) Solution: The time-to-failure tf in a fibre is normally assumed to be given by: n t = A s f where A is a constant and n is the so called fatigue susceptibility parameter. To estimate the lifetime at the maximum service stress of 0.1 GPa it is necessary find the constant A for the fibre. Given the proof test data and assuming that the proof test stress would have resulted in fibre failure just after 1 second then the time-to-failure can be set to 1 second. Thus rearranging the equation above in log form: log 1 = log A - n.log(0.45 GPa) Substituting for n=18.1 gives log A = 156.62 If the maximum stress is now assumed then the log of the time-to-failure is: log tf = 156.62- n.log(0.14 GPa) log tf = 156.62-147.44 = 9.17 The time-to-failure is 1.49 x 109 seconds or about 47.45 years. [7 marks] (iv) Effect of Moisture Moisture does not penetrate silica glass, so it does not affect propagation. But the presence of water as OH ions on the fibre surface accelerates crack growth. This process is called stress corrosion. Moisture protection is therefore of critical importance in fibre cables. Effect of Temperature At 90 degrees centigrade the fatigue susceptibility parameter is less than half that at 25 degrees, because higher temperatures increase the rate of the stress corrosion chemical reaction. The result is that fibre strength decreases by 25% at 90 degrees compared to 25 degrees. High tensile strength and zero moisture ingress cables are therefore essential at elevated temperatures [4 marks]