Laboratory Biosafety Manual - OSEH

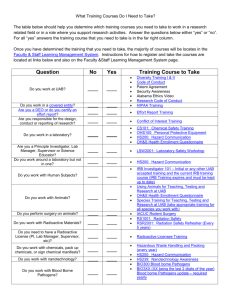

advertisement