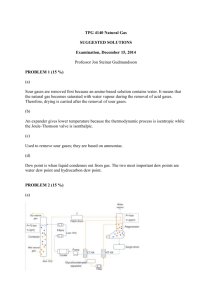

CALCULATIONS IN NATURAL GAS COURSE

advertisement

TPG 4140 CALCULATIONS IN NATURAL GAS COURSE Prof. J.S. Gudmundsson September 2012 Molecular Weight M can be found from the gas composition, using an Excel sheet. An example is shown below (gas composition from GPA 1998). Components Molecular weight Mole fraction g/mole yi Methan, CH4 16,042 0,8319 Ethan, C2H6 30,07 0,0848 Propan, C3H8 44,10 0,0437 i-Butane, C4H10 58,12 0,0076 n-Butane, C4H10 58,12 0,0168 i-Pentane C5H12 72,15 0,0057 n-Pentane C5H12 72,15 0,0032 Hexane C6H14 86,18 0,0063 Heptane C7H16 100,21 0 Hydogen, H2 2,02 0 Nitrogen, N2 28,01 0 Oxygen, O2 32,00 0 Carbon dioxid, CO2 44,01 0 Hydrogensulfid, H2S 34,08 0 Dihydrogenoksid, H2O 18,02 0 Σ Mole fraction 1,0000 Total molecular weight gas 20,43 g/mole M = 20.43 g/mol = 20.43 kg/kmol Specific Gravity Definition of specific gravity, ratio of the molecular weight of natural gas to that of common air (without water vapour). M taken from above. M gas gas air s.c. M air Mgas = 28.97 [kg/kmol] The subscript gas is not necessarily used. The specific gravity was also calculated in the Excel sheet, rounded up to γ = 0.71 Reduced Pressure and Temperature Reduced pressure and temperature are also called pseudocritical pressure and temperature, expressed as pr p pr Tr Tpr p pc T Tc where the subscript c stands for critical. Key’s Rule is used to obtain the critical pressure and temperature for natural gas mixtures pc pci yi i Tc Tci yi i The critical pressure and temperature for individual natural gas components are available in handbooks and tables. The symbol yi stands for mole fraction. For the natural gas composition taken from GPA (1998) critical pressure and temperature were estimated to be 4.57 MPa and 218 K. Based on the Excel sheet, the corresponding numbers are 4.6 MPa and 218 K. Critical pressure and temperature can also be obtained from semi-empirical equations based on specific gravity, for example from Rojey & Jaffret (1997) p pc 4.892 0.405 [MPa] Tpc 94.72 170.75 [K] Such equations tend to be based on natural gas found in certain oil and gas provinces. There is an error in the critical temperature equation in Rojey & Jaffret (1997). There should be a plus in the equation, as shown above. Using a specific gravity of 0.705 the critical pressure and temperature are estimated 4.606 MPa and 215 K. These are reasonably close to the above values. Compressibility Factor Assuming a pressure of 80 bara and temperature of 30 C the z-factor can be estimated from the figure below (commonly called the Standing-Katz diagram) The reduced pressure is 80 105 1.75 4.57 106 pr and the reduced temperature Tr 30 273.15 1.39 218 Read from diagram z = 0.79 The reduced pressure and temperature from the Excel sheet are 1.75 and 1.39. That is, exactly the same. The Hall-Yarborough method in the Excel spreadsheet is considered one of the more accurate semi-empirical equations for z-factor. Read from spreadsheet z = 0.7831 Gas Density Need molecular weight, z-factor and the local temperature and pressure. pM zRT Using the values obtained above, the density of the gas at 80 bara and 30 C can be calculated as 80 105 20.43 82.8 kg/m3 0.7831 8314 (30 273.15) The same result is obtained from the Excel spreadsheet, which also gives the viscosity as 0.0139 mPa.s Friction Factor and Reynolds Number The friction factor in commercial pipes can be calculated from the Haaland equation 6.9 n k 1.11n 1 1.8 log n f Re 3.75d where n = 3 for natural gas pipelines ( n = 1 for liquid flow). The Reynolds number is give by Re ud and the relative roughness by k/d. Pressure Drop Horizontal Pipeline In general, equations for pressure drop in pipelines can be used to calculate the pressure drop, the diameter and the flow capacity, depending of which of the variables are given and what result is required. Approximate calculations can be carried out for gas pipelines using the Darcy-Weisbach equation p f f L 2 u 2 d where average gas properties are used. For illustration purposes, assume 7 MSm3/d flowrate (10 % of Ormen Lange). Assume inlet pressure 200 bara and outlet pressure 100 bara. Assume 500 km distance. Therefore, pressure gradient (200-100)/500 km = 20 bar/100 km. Assume constant temperature of 10 C. The simplest way to find the z-factor is to use the available Excel spreadsheet. At 200 bara and 10 C the z-factor is 0,6806. At 100 bara and 10 C the z-factor is 0.6638. The average z-factor is therefore 0.6722. From spreadsheet, average density 194 kg/m3 and average viscosity 0.0218 mPa.s. The velocity depends on the pipeline diameter and mass flowrate. To know the mass flowrate we need the density of the gas at standard conditions, use Excel spreadsheet and assume z = 1. We note that 1 atm = 1.01325 bara. Density at s.c. 0.864 kg/m3. Therefore the mass flowrate is m 7 106 0.864 70 kg/s 24 3600 Average velocity is given by u such that m A d5 8 fLm2 2 p Assuming an average friction factor of 0.015 the diameter can be estimated d5 8 0.015 500000 70 0.219 10 3 2 5 3.1416 194 100 10 giving a diameter of 0.19 m and an average flow velocity of 2.4 m/s (from spreadsheet). The corresponding Reynolds number is about 40 million and a friction factor of 0.0544. Calculating again d5 8 0.0544 500000 70 0.794 10 3 2 5 3.1416 194 100 10 gives a diameter of 0.24 m and an average flow velocity of 1.9 m/s. The Reynolds number is about 40 million so the friction factor will be the same. Therefore, a couple of iterations give a pipeline diameter of about 240 mm (about 91/2 inch). A similar iteration procedure can be followed using the pressure drop in gas pipelines equation, but it is more involved and will not be illustrated her. d A2 M d p 22 2 2 p 2 p1 ln 2 L 0 f p1 f m 2 z RT