Trent University Laboratory Biosafety Manual

advertisement

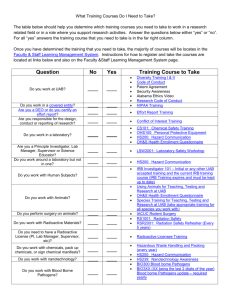

Introduction Despite a greater awareness of biosafety and biocontainment practices, infection of laboratory workers with the same agents used by them in the lab continues to result in sickness and mortality of these same workers. 1 Incidences of the transfer of biohazardous material into the general population may also be occurring. The SARS scare of 2002 in Toronto ON, coupled with the increased concern of bioterrorism and an increased awareness in the general public regarding acceptable levels of risk, have created a climate of concern with respect to the use, transportation, storage and disposal of potentially biohazardous substances. Laboratory Biosafety Guidelines have been published by both Health Canada (HC) and the Canadian Food Inspection Agency (CFIA) to address many of these concerns. The most recent editions of these guidelines (HC 3 rd edition 2, and CIA 2nd edition 3) are essentially mirror images with the requirements for Containment labs being the same. In Canada, work with Biohazardous materials which may infect humans is governed by Health Canada and would follow the guidelines and the requirements of the “Peach Book” which is the nickname given to HC Laboratory Biosafety Guidelines. Work with Biohazardous material which may affect wildlife or agriculture is governed by the CFIA guidelines and the requirements of the “Red Book” which is the nickname given to the CFIA Containment Standards for Veterinary Facilities which governs work in laboratories. The guidelines and requirements listed in this safety manual are the minimum expected to work with pathogens at Trent University. Researchers are expected to follow this manual as well as the appropriate governmental standards in all the work that they do. Working with pathogens at Trent University requires the submission of an application to work with pathogens to the Biosafety Committee. The application must be approved by this committee prior to work commencing. Any changes to the work procedures described in that application must have the approval of the Biosafety Committee or be as a result of increased safety and containment procedures. Certifications and inspections of labs are carried out by the Biosafety Officer on behalf of the committee (see pg. 25) What is a Biohazard? -Any organism or its toxin that is known or suspected to cause disease in animals or humans. -Biohazardous or infectious materials fall under class D, division 3 of WHMIS 1 Collins, C.H., and Kennedy, D.A. Laboratory-acquired infections. IN: Laboratory-acquired infections: history, incidence, causes and preventions. Oxford, UK: Butterworth-Heinemann, 1999; 1-37. 2 Laboratory biosafety guidelines 3rd edition. Ottawa: Health Canada: 2004. 3 Containment standards for veterinary facilities. Ottawa: Canadian Food Inspection Agency; 1996. 1 -Includes microorganisms such as viruses, bacteria, fungi and parasites and their toxins -Also includes blood and body fluids, as well as tissues from humans and animals -Transformed cell line and certain types of nucleic acids also are considered as biohazardous. What is Biological Safety? The combination of measures employed when handling biohazardous materials to avoid infecting oneself, others or the environment. This includes: -Engineering Controls (e.g., HVAC, BSC’s) -Administrative Controls (e.g., Biosafety Committee) - Practices and Procedures (e.g., Biosafety Manual, Laboratory Safety plan) -Personal Protective Equipment (e.g., Gloves, Lab coats, The primary operating theory behind Biosafety is that ultimately the safeguarding of a potentially hazardous infectious agent is based on a) the infectiousness and toxicity of the pathogen and b) the containment strategy use to control for unplanned exposures. Risk Groups The classification of organisms into risk groups reflects an attempt to categorize the relative hazards of infective organisms. The factors used to determine which risk group an organism falls into are: the pathogenecity, the infectious dose, the mode of transmission, host range, availability of preventative measures and the availability of effective treatment. The definitions below have been paraphrased for both human and animal/plant pathogens. See the appropriate guidelines for the specific definitions. Risk Group 1. (low individual and community risk) Any biological agent that is unlikely to cause disease in healthy workers or animals Risk Group 2. (moderate individual risk, low community risk) Any pathogen that can cause human or animal disease but under normal circumstances is unlikely to be a serious hazard to laboratory workers, the community, livestock or the environment. Laboratory exposures rarely cause infection leading to serious disease; effective treatment and preventative measures are available, and the risk of spread is limited 2 Risk Group 3. (high individual risk, low community risk) Any pathogen that usually causes serious human or animal disease or can result in serious economic consequences but does not ordinarily spread by casual contact from one individual to another, or that causes diseases treatable by antimicrobial or anti-parasitic agents Risk Group 4 (high individual risk, high community risk) Any pathogen that usually produces very serious human or animal/plant disease, often untreatable, and may be readily transmitted from one individual to another, or from animal to human or vice-versa, directly or indirectly, or by casual contact. A list of human pathogens categorized according to Risk group can be obtained by contacting the Office of Laboratory Security, Health Canada or by contacting the Canadian Food Inspection Agency. Unconventional Pathogens Some progressive neurological diseases (spongiform encephalopathies) are caused by agents referred to as unconventional agents, slow viruses or priors (proteinaceous infectious particles). Examples of such diseases are: Creutzfeldt-Jakob disease in humans, Mad Cow disease (BSE) in cattle and Scrapie in sheep and goats. These agents are resistant to destruction by chemical (10% formalin, gluteraldehyde, 70% ethanol, iodine) and physical (UV light, ionizing radiation, boiling) procedures that normally inactivate viruses. While there have been no documented cases of laboratory acquired infections, the following precautions should be observed when handling neurological tissue from infected or potentially infected humans or animals. -Handle tissue as Risk Group 2 or higher - Handle formalin-fixed tissues and paraffin-embedded blocks as if still infectious -Follow up-to-date disinfection protocols Tissue Culture All mammalian lines are to be considered infectious due to the possibility that they may contain or transmit infectious agents. Cells or primary cultures from animals and humans known or reasonably suspected to be infected should be in the risk group for the suspected agent. All primate cell lines, all cell lines exposed to or transformed by primate oncogenic virus and all mycoplasma containing cell lines should be handled at Level 2 containment. Any cell line containing mycoplasma should be likewise treated as Level 2 All other tissue culture work should be considered as Level 1. 3 All waste generated from tissue culture must be autoclaved or disinfected by other means prior to disposal. Animal Work By definition all work involving animals is considered biohazardous. Animals can harbour infectious organisms (naturally or through their use in research) which can be transmitted to humans The Trent University Animal Care Committee ensures that all work involving vertebrates and cephlapods meets all the standards and regulations of the Canadian Council on Animal Care and the Animals for Research Act. All work involving vertebrates and cephlapods use must receive prior approval from the Trent University Animal Care Committee (see www.trentu.ca/animalcare). Containment Levels The term containment levels (CL or AP) are selected to provide the end-user with a description of the minimum containment required for handling the organism safely in a laboratory setting. The characteristics of each containment level refer to the systems and operational procedures in place and may include, engineering controls, HVAC, work procedures etc… These levels are more fully defined in either the HC Laboratory Biosafety Guidelins (peach book), or the CFIA Containment Standards for Veterinary Facilities (red book). It is important to understand that the Risk Groups do not specify the containment level required to work with an organism. The containment level of the lab required for a specific pathogen is based on a Risk Assessment which is a critical step in the selection of the appropriate containment required. While the risk group can supply some of this information, the risk assessment may also include things like: potential for aerosol generation, quantity, concentration, stability in the environment, type of work (in vitro, in vivo, and in situ) as well as the use of recombinant organisms. Containment Level 1 (CL1) CL1 applies to the basic laboratory that handles agents requiring containment level 1. A CL1 lab has no special requirements beyond those suitable for a well designed and functional lab. Biological Safety Cabinets (BSC) are not required and work may be performed on the open bench. Containment Level 2 (CL2) CL2 applies to a laboratory in which agents requiring containment level 2 are handled. The primary exposure hazards associated with organisms requiring CL2 are through the ingestion, inoculation and mucous membrane route. Agents handled in a CL2 are generally not transmitted by airborne routes, but care must be taken to avoid the generation of aerosols which can become ingestion risks. Primary containment devices such as BSCs and centrifuges with 4 sealed rotors should be used as well as the appropriate Personal Protective Equipment (PPE). As well, environmental contamination must be minimized by the use of hand-washing and decontamination facilities such as autoclaves. Level 2 labs include clinical and diagnostic facilities, as well as research and teaching laboratories with level 2 agents. They require a class I or class II biological safety cabinet if any potential for aerosol or splash exists. An emergency plan must be developed for handling spills. All personnel who enter the facility must be informed of the hazards present. The biohazard sign with appropriate information must be posted. Containment Level 3 (CL3) CL3 applies to the laboratory that handles agents requiring containment level 3. These agents may be transmitted by the airborne route, often have a low infectious dose to produce effects and can cause serious or life-threatening disease. CL3 emphasizes additional primary and secondary barriers to minimize the release of infectious organisms into the immediate laboratory and the environment. Additional features to prevent transmission of Cl3 organisms are appropriate respiratory protection, HEPA filtration of exhausted laboratory air and strictly controlled laboratory access. Level 3 labs are specially designed and constructed and must undergo annual performance testing and verification. All work must be performed in type II or type III biosafety cabinets. All centrifugation must be performed in closed trunnion cup centrifuges. Staff must receive specific training for the agents employed, above the basic hazard information. PPE is very specific, including solid front clothing and dedicated footwear, for use only within the facility. Written protocols must be provided and posted. A medical surveillance program must be in effect. A reporting system for accidents must be in place. Containment Level 4 (CL4) CL4 labs have the maximum containment available and are suitable for facilities manipulating agents requiring containment level 4. These agents have the potential for aerosol transmission, often have a low infectious dose and produce very serious and often fatal disease; there is generally no treatment or vaccine available. The level of containment represents an isolated unit, functionally and, when necessary, structurally independent of other areas. CL4 emphasizes maximum containment of the infectious agent by complete sealing of the facility perimeter with confirmation by pressure decay testing; isolation of the researcher from the pathogen by his or her containment in a positive pressure suit or containment of the pathogen in a Class III BSC line; and decontamination of air and other effluents produced in the facility. There is only one CL4 lab in Canada in Winnipeg, Manitoba. 5 Risk Assessment Risk assessment is a critical step in the selection of the appropriate containment level for the microbiological work to be carried out. A detailed local risk assessment should be conducted to determine whether work requires containment level 1, 2, 3 or 4 facilities and operational practices. Individuals with varying expertise and responsibilities should be involved in the assessment and may include the facilities manager, the biosafety committee, a microbiologist, and the biosafety officer. Available information can be used as a starting point to assist in the identification of risk factors, including the recommended Risk Group of the organism. Additional information about specific organisms may also be obtained from the MSDS for the pathogen. A list of human pathogens can be obtained by calling the Office of Laboratory Security directly at (613) 957-1779 or by accessing their Web site at http://www.phac-aspc.gc.ca/ols-bsl/pathogen/organism_e.html. These MSDS‘s are produced by Health Canada and are written from the perspective of protecting human health only. Depending on the nature and purpose of the research, additional information and precautions may be necessary when working with animal and zoonotic pathogens. In addition to the Risk Group classifications, which are based on the risk factors inherent to the organism, the following factors associated with the laboratory operation should also be examined: - potential for aerosol generation -quantity -concentration -agent stability in the environment (inherent biological decay rate) -type of work proposed (e.g., in vitro, in vivo, aerosol challenge studies) -use of recombinant organisms (e.g., gene coding for virulence factors or toxins; host range alteration; oncogenicity; replication capacity; capability to revert to wild type) The containment level required for work with a particular agent is based on the manipulations generally associated with laboratory scale research and clinical procedures. If a particular procedure, such as preliminary identification, poses a lower hazard than manipulation of a live culture, then a lower containment level may be appropriate. On the other hand an increase in containment may be required if the local risk assessment indicates that the procedures pose a higher risk than routine laboratory scale and diagnostic manipulations. 6 Primary Containment Primary containment is the first line of defence against unplanned exposures. It usually involves a protective envelope that effectively encapsulates the infection agent or animal, or conversely the envelope may encapsulate the worker. The envelope ensures the protection of personnel and the immediate laboratory environment from exposure to the infectious agent. Primary containment is usually made up of biological safety cabinets, glove boxes and animal caging equipment. It also includes simple measures like stoppered bottles. Secondary Containment Secondary Containment protects the environment external to the laboratory from exposure and this includes the design of the facility and the operational practices of mechanical system and of the lab. Personal Protection The effective use of vaccines is often an overlooked form of protection against exposures. If vaccines exist for the pathogen being used, get immunized against it. Although the preferred method of protection is by reducing exposure at the source, to protect against the failure of the primary containment, PPE can become an important line of defense. In considering the use of PPE two criteria should be used: 1. degree of protection offered and 2. the ease of use. Once the PPE has been identified it is the responsibility of both the supervisor and the user to ensure that PPE is used and used properly. Each type of containment level (1, 2, 3, and 4) requires specific protective laboratory clothing. Personal Protective Equipment Laboratory Coats and Gowns The lab coat has two uses: to protect street clothing from biological or chemicals spills, and to offer some additional body protection Level 2 lab: lab coat, gown or smock or uniform. It is recommended that it be of 100% cotton due to flame retardancy and resistance to a number of chemicals. Level 3: solid front or wrap around gowns. Some institutions recommend a 2 piece scrub suit as mandatory under the solid front gown. 7 Head coverings Generally not required in most biological areas, unless a complete change of clothing is required for access, and where product protection is required. Shoes and shoe coverings Any area where there is a significant risk of dropping heavy objects should require the use of industrial safety shoes. For general biological use, comfortable shoes such as tennis shoes or nurses shoes are recommended. Sandals are not allowed in laboratories using biohazards due to the potential exposure to infectious agents. A change from street shoes is strongly recommended for those working in level 3 facilities and for those working with infected animals in animal rooms. Alternately, shoe coverings may be used in level 2 and level 3 labs when a complete change of shoes and a dedicated pair of shoes are not required. Gloves Gloves are the most widely used form of PPE. They are used for a wide variety of hazards including protection from heat, cold, solvents, caustics, toxins, infectious microorganisms, radioisotopes, cuts and animal bites and acids. Unfortunately, there is no ideal glove that will protect against all hazards. Gloves are made from a variety of materials including, rubber (latex), neoprene, neoprene-latex, nitrile, polyurethane, PVC etc... . Selection should depend on the hazard encountered. If biological work will include the use of chemical solvents such as toluene, benzene or carbon tetrachloride; rubber, neoprene, neoprene-latex, and PVC will be graded. Choose the glove appropriate to the task. If you are unsure, contact the vendor as to the correct choice of gloves for the application you intend. In microbiological labs, surgical gloves or latex, rubber or vinyl are generally the preferred choice. (Latex gloves are slowly being removed from service due to the increase in allergic responses to latex). They offer a high level of dexterity and a higher level of sensitivity; unfortunately they offer very little if any protection against needle sticks, sharps and animal bites. Remember that gloves are the weakest component of the PPE. Gloves should overwrap the cuff and lower sleeve of the laboratory clothing. When handling infected tissues during necropsies, often stainless steel mesh gloves are worn to protect against accidental cuts. Respiratory Protection Two types of respiratory protection exist. Those which supply clean air or those which remove the hazardous particulates. A respirator such as a full face or half face cartridge respirator, require quantitative fit testing according to OSHA 29 (of 8 the US). These type of respirators would be worn in atmospheres that pose and infectious or toxic hazard such as an animal room where infectious agents could be excreted in urine. Singe use paper dust masks are not classified as true respirators. They do not offer adequate respiratory protection in infected animal rooms or other areas where infectious aerosols may be present, because one cannot be ensured of an adequate fit. They are acceptable for use during necropsies and other surgical procedures in order to maintain a sterile surgical field. The second type of respirator which supplies clean air includes hoods, helmets and full suits or self contained breathing apparatus. These are more bulky and ease of movement is often restricted. Eye or Face Protection Eye or facial protection is important because biological work may often use concentrated alkalis, and acids, concentrated disinfectants, including phenolics and quaternary ammonium compounds which can cause severe eye damage and blindness if splashed into the eye. Infection can also occur through the conjunctiva if certain pathogenic microorganisms are splattered into the eye. Full Face respirators or half face respirators plus splash goggles are often recommended when respirable aerosols or droplets may be produced. Safety glasses are intended to provide impact protections, but should not be used to protect against splashes. Fro these hazards, safety goggles or face shields should be used. Ordinary glasses offer better splash protection than nothing at all, however, they do not replace the need for approved safety eyewear. The use of Contact Lenses in laboratories is discouraged at Trent as in the event of an accident where the lens needs to be removed (for flushing) the time required the lens prior to flushing may result in additional injury. In addition some chemical vapours may be absorbed through the lens and trapped behind it. Biological Safety Cabinets Biological Safety Cabinets (BSCs) are the single most important safety device in the microbiology laboratory and second in overall importance only to safe work practices. There are three classes of BSCs. Class I cabinets have un-recirculated air flow away from the operator that is discharged through a HEPA filter. Class I cabinets provide good operator protections but do not protect the material within the cabinet (the product) from contamination. Class II cabinets have inward air flow for personnel protection, downward HEPA-filtered air for product protection and HEPA filtered exhaust air for environmental protection. They are divided into two types (A and B) based on construction, air flow velocities and patterns, and exhaust systems. Class III cabinets are totally enclosed and gas-tight with HEPA 9 filtered supply and exhaust air. Work is performed with attached long-sleeved gloves. Class III cabinets protect the worker and the product. NOTE: Horizontal Clean Benches which direct air towards the operator are not biological safety cabinets and must not be used for handling infectious, toxic or sensitizing agents. Laminar flow hoods are not such a cabinet, they protect a process not a person. All three classes of cabinets serve to minimize contact between the operator and the infectious agent by the use of directional airflows. All BSCs contain HEPA filters to ensure the exhaust from the cabinets is free of infectious material. BSCs should be located away from doors, drafts, convection currents, diffusers and high traffic areas. Selection of the proper class of BSC requires careful evaluation of the work involved. Class II (i.e., Type A and Type B) cabinets are designed for work involving microorganisms in CL 2, 3 and 4 facilities. Cabinet air from Type A cabinets may be recirculated back into the laboratory in level 2 and 3 facilities. Ducting a Type A cabinet out of the building is possible, providing the method of ducting uses “thimble” connections (i.e., small opening around the cabinet exhaust filter housing) and the balance of the cabinet exhaust system is not disturbed. The thimble must be removable or be designed to allow for proper certification of the cabinet (i.e., bubble tight damper to seal off the cabinet for decontamination, access port to allow scan testing of the HEPA filter). Class II, Type B cabinets can be used when manipulating small quantities of chemicals as an adjunct to work with microorganisms in CL2, 3 and 4 labs. Type B1 cabinets recirculate 30% of the air within the cabinet and are suitable for work with minute amounts of chemicals and radionuclide. These cabinets must be “hard ducted” (i.e., direct connection), preferably to their own dedicated exhaust system. The exhaust canopy must allow for proper BSC certification. Type B2 cabinets are total-exhaust cabinets with no air recirculation within them and are suitable for work with small amounts of volatile chemicals and radionuclides. These cabinets are also hard-ducted. Class III cabinets are designed for work with CL 4 level pathogens. Only cabinets which meet the National Sanitation Foundation (NSF) Standard No. 49 Class II Biohazard Cabinetry (1992) and bear an NSF 49 seal are to be purchased and installed in university labs. BSCs must be tested and verified before they are used upon installation and after repairs or relocation. Testing must be performed by qualified individuals and it is recommended that only NSF accredited field certifiers be used. 10 General Laboratory Biosafety Guidelines All Personnel must understand the hazards and be trained. A laboratory safety manual must be prepared. The laboratory must be kept neat, orderly and clean. Appropriate protective equipment must be worn. It must not be worn in non-laboratory areas. This includes gloves, which must be worn for all procedures involving direct skin contact; safety eyewear, which must be worn to protect against splashes; and lab clothing. Eating and drinking, inserting or removal of contact lenses, application of cosmetics are not permitted. Oral pipetting is strictly prohibited Long hair must be tied back. Hands must be washed after gloves are removed and before leaving the lab. Work surfaces must be cleaned and decontaminated daily Aerosol production is to be minimized All contaminated or infectious materials are to be decontaminated. Access to laboratories should be restricted. Hazard warning signs must be posted The use of needles, syringes and other sharp objects should be limited and disposed of into the appropriate “Sharps” Container and not into the regular garbage. Laboratory workers should be protected by immunization where appropriate A BSO and Biosafety Committee should be established. All work with Biohazardous agents must be approved by the Biosafety Committee All rooms designated as Containment labs will be done so by the Biosafety Committee OPERATIONAL PRACTICES GENERAL REQUIREMENTS The following general practices are required when working in any containment laboratory or animal facility: entry must be restricted to laboratory staff, animal handlers, maintenance staff and other persons on official business only persons meeting specific entry requirements (e.g. immunization, serum screening) may enter containment laboratories unless the facility 11 has been appropriately decontaminated a health and medical surveillance program must be provided as recommended by Health Canada personnel must receive training on the potential hazards associated with the work involved and the necessary precautions to prevent exposures to zoonotic agents and release of non-indigenous agents; personnel must show evidence that they understood the training provided; training must be documented and signed by both the employee and supervisor a documented procedural manual must be written and followed all persons (including visitors, maintenance staff, etc.) entering the containment area must be trained and know and follow the operational protocols for the project in process; trainees must be accompanied by a trained staff member persons entering a containment facility must be well prepared and bring all materials they will need with them; if something has been forgotten, traffic patterns must still be adhered to (i.e. do not go back to get it; either phone for someone to bring it or exit via proper protocols) employees working in the containment area must have general knowledge of the physical operation and design of the facility (e.g. air pressure gradients between zones, directional air flow patterns, alarm signals for air pressure failure, containment perimeter) traffic flow patterns from clean to dirty areas must be established and adhered to (i.e. move from least to most contaminated areas) smoke testing (i.e. with a smoke pencil) should be done periodically by lab staff to verify correct airflow entry/exit protocols for persons, animals, equipment, samples, waste, etc. must be written, posted and followed; general protocols must be supplemented with protocols specific for each project in progress emergency procedures for entry/exit, spill clean-up, air handling/biosafety cabinet failure, fire, animal escape and other emergencies must be written, posted and followed in the event of life-threatening emergencies, personal health and safety are a priority; exit protocols must be established whereby routine procedures are bypassed; a reporting area must be identified where further steps must be taken (e.g. disinfecting footwear, changing, showering) prior to leaving all spills, accidents, overt or potential exposures to infectious materials, and losses of containment (e.g. lab positive pressurization) must be reported immediately to the laboratory supervisor; written records of such incidents must be maintained an effective rodent and insect control program must be maintained 12 LABORATORIES The following describes the minimum operational practices required for containment level 2: laboratory personnel must be trained in and follow the safe use of laboratory equipment, biological safety cabinets, procedures to minimize the production of aerosols, decontamination and emergency response open wounds, cuts, scratches and grazes should be covered with waterproof dressings eating, chewing gum, drinking, smoking, storing food, and applying cosmetics are prohibited personal items such as purses and outdoor clothing should be kept separate from work areas the work area containing hazardous materials should be kept free from materials not pertinent to the work and that cannot be easily decontaminated (e.g. journals, books, correspondence); paperwork and report writing should be kept separate from such work areas laboratory reference material should be kept in the laboratory zone hands should be washed frequently (after handling infectious materials, after removing gloves, and before leaving the laboratory) open-toed and high-heeled shoes must not be worn in the laboratory long hair should be tied back so that it cannot come into contact with hands, specimens, containers, or equipment gloves (e.g. intact vinyl or latex) must be worn when handling infectious materials; metal mesh gloves can be worn underneath the latex or vinyl glove to provide protection from sharps and needles laboratory coats, gowns or coveralls must be worn when working in the laboratory; this clothing must not be worn in non-laboratory areas (e.g. offices, staff rooms, canteens, libraries) protective lab clothing should not be stored in the same locker as street clothing contaminated clothing must be decontaminated prior to laundering (unless laundering facilities are within the laboratory zone and have been proven to be effective in decontamination) eye and face protection must be worn when it is necessary to guard against splashing hazardous materials, flying particles, and harmful light or other rays laboratory doors must be kept closed as required by the facility design biological safety cabinets must be used for procedures with potential for producing infectious aerosols (e.g. with zoonotic agents) and with high concentrations or large volumes of zoonotic materials contaminated work surfaces must be decontaminated all contaminated materials must be decontaminated before disposal or cleaning for reuse 13 contaminated equipment leaving the laboratory for servicing or disposal must be appropriately decontaminated efficacy monitoring of autoclaves using biological indicators must be done at least weekly, depending on the frequency of use of the autoclave, and records of the results kept on file; cycle log records (i.e. time, temperature and pressure) must also be kept on file In addition to the general operational practices listed for level 2, the following describes the minimum operational practices required at containment level 3: a protocol specific to the operation of the lab must be developed and read by personnel; employees must certify in writing that they have understood the material in the protocol the laboratory zone must be kept locked infectious agents should be stored inside the laboratory zone; agents stored outside the zone must be kept locked, in leak proof containers personnel must have demonstrated proficiency in microbiological practices and techniques (e.g. experience in handling infectious organisms or cell cultures) personal items such as purses and outdoor clothing must not be brought into the laboratory zone a containment check must be performed prior to entering the laboratory zone (i.e. verify negative lab pressurization as designed) water seals must be maintained in drainage traps (i.e. through regular sink/shower usage and/or by filling traps in areas that are not being used) laboratory samples and supplies may be carried into the laboratory zone or passed through a ventilated pass-box; where the barrier autoclave is used to pass materials into the laboratory, the autoclave must have been cycled prior to opening the outer "clean side" door personnel entering the laboratory zone must remove street clothing and jewellery, and change into dedicated laboratory clothing and shoes where full body protective clothing is not worn a shower is required on exit from the laboratory; where a known or suspected aerosol exposure has occurred (e.g. dropping infectious materials) a shower is required on exit from the laboratory zone a shower (including washing hair, beards) is required on exit from a laboratory zone handling non-indigenous animal pathogens; eye glasses must be disinfected at the containment barrier a second layer of protective clothing (i.e. solid-front gowns with tight-fitting wrists, gloves) should be worn over laboratory clothing when directly handling infectious materials (e.g. dedicated for use at the biological safety cabinet) contaminated clothing must be decontaminated prior to laundering (unless laundering facilities are within the laboratory zone and have been proven to be effective in decontamination of the microorganisms likely to be encountered) 14 all activities with infectious materials are conducted in a biological safety cabinet; where this is not possible, other physical containment devices in combination with personal protective clothing and equipment must be used; no work with open vessels containing infectious materials is conducted on the open bench centrifugation of infectious materials must carried out in sealed safety cups or rotors that are loaded and unloaded in a biological safety cabinet all contaminated waste materials leaving the laboratory zone must be decontaminated through a double-door autoclave at the barrier before disposal; both doors of the autoclave must not be opened simultaneously heat sensitive materials that cannot be autoclaved out of the laboratory zone must be decontaminated at the containment barrier (e.g. fumigated with formaldehyde or vaporized hydrogen peroxide, disinfected using liquid chemicals, or other technology proven to be effective) ANIMAL FACILITIES Work with animals poses a variety of special hazards including exposure to zoometric agents (naturally occurring or experimentally infected), animal bites and scratches, kicks and crushing injuries, physical hazards (e.g. noise, temperature) and chemical hazards (e.g. cleaning agents, disinfectants). Allergic conditions can result from contact with animal fur or hair, bedding, and animal wastes. At least one-fifth of people who work with laboratory rodents, guinea pigs and rabbits develop allergies. Protection from allergens must be provided through engineering controls, ventilation, use of isolators and cages with filter tops and appropriate use of respiratory protection. Animal handlers must have knowledge of the species' general characteristics such as behaviour, instincts and physical attributes. Consideration should also be given to their natural ecto- and endoparasites and the zoonotic diseases to which they are susceptible including their route of excretion and dissemination. The following describes the minimum operational practices required in small animal facilities (SA facilities): coveralls and footwear must be worn when working in AP containment level 2 SA facilities personnel entering AP containment level 3 and 4 SA facilities must change into dedicated facility clothing and shoes gloves must be worn when handling infected animals hands must be washed after handling animals, after removing gloves and before leaving the facility HEPA-filtered respirators are required for handling animals in AP containment level 2 and 3 SA facilities where infectious aerosols of zoonotic agents may be generated and cannot be contained within a primary containment device 15 positive pressure ventilated suits are required for handling animals infected with HC containment level 4 zoonotic agents a shower (including washing hair, beards) is required on exit from AP containment level 3 SA facilities handling non-indigenous agents and when handling other agents where aerosols cannot be contained in primary containment devices; eye glasses must be disinfected at the containment barrier a shower is required on exit from AP containment level 4 SA facilities; a chemical shower is required when suits are worn where a clothing change is not performed on exit from each animal room, disinfectant footbaths are required (the disinfectant must be effective against the microorganisms of concern and changed regularly in accordance with the active life of the disinfectant) contaminated clothing must be decontaminated prior to laundering (unless laundering facilities are within the laboratory zone and have been proven to be effective against the microorganisms likely to be encountered) each animal room must be labeled with unique hazards and entry requirements (e.g. respiratory protection) animal room doors must be kept closed as required by facility design water seals must be maintained in drainage traps (i.e. through regular sink/shower/floor drain usage and/or by filling traps in areas that are not being used) cages housing infected animals must be appropriately labeled containment caging systems should be used in AP containment level 3 SA facilities to contain aerosols (e.g. laminar flow cabinets, solid wall and bottom cages covered with filter bonnets) containment caging systems must be used in AP containment level 4 SA facilities careful handling procedures must be employed so as to minimize the creation of aerosols and dissemination of dust from cages, refuse and animals proper methods of restraint must be used to minimize scratches, bites and accidental self-inoculations necropsy of small animals infected with a zoonotic agent and intranasal inoculation of animals in AP containment level 3 and 4 SA facilities should be conducted in a biological safety cabinet; animals must be securely transported to the biological safety cabinet supplies and materials are brought into the AP containment level 3 and 4 SA facilities by carrying them in or by way of a ventilated pass-through; barrier autoclaves, fumigation chambers or airlocks may also be used providing that they have been decontaminated before opening the outer "clean side" door animal bedding must be removed in a manner that minimizes the generation of aerosols and dust; for AP containment level 3 and 4 SA facilities handling zoonotic agents, cages must be decontaminated prior to removing bedding 16 all contaminated materials must be decontaminated before disposal or cleaning for reuse autoclaving is the preferred method of decontaminating cages prior to washing; temperature of the final rinse water in mechanical cage washers should be at least 82oC animal carcasses and tissues must be incinerated or processed through new technology proven to be effective (e.g. tissue autoclave); carcasses must be transported from the animal room for disposal in leak proof containers that are appropriately labeled. POST-MORTEM ROOMS Hazards in the post-mortem (PM) room are not limited to splashes and aerosols of infectious materials. Accidents can be caused by cutting instruments, sharp ends of cracked bones, slippery floors, electrical equipment, chemical fixatives and disinfectants. General precautions: only authorized staff are allowed to use the necropsy facilities staff must be trained in the use of all equipment and tools (e.g. electric hoist/monorail, tools, PM table, incinerator) staff must be trained in proper disinfection and cleaning procedures the area must be kept neat and tidy; equipment, paper, reports, etc. should be stored securely and not be accumulated in the PM room to facilitate cleaning and decontamination; floors should be clear of obstructions specific protocols for each project must be developed and followed; these include entry/exit protocols (for people, animals, equipment and samples), protective clothing and equipment, disinfection and cleaning protocols, use of the incinerator and autoclaves, and emergency procedures Preparation for necropsy: protective clothing appropriate to the AP containment level and potential hazards must be worn in the PM room; this should include the removal of street clothing and donning of protective clothing and footwear; HEPAfiltered respirators are required when the potential for infectious aerosols exist; waterproof aprons, gloves and eye/face protection (face shield, goggles) should also be worn; a safety helmet is required when operating an electrical hoist/monorail 17 specific protocols must be developed for the movement of animals and carcasses into the PM room (e.g. hoist for large animals, cart for small livestock, secure containers for poultry and laboratory animals) Necropsy Procedures: necropsy safety procedures specific to the species involved must be followed (i.e. use of cutting instruments to avoid injury) the animals (especially birds and small lab animals) should be wetted with water and/or disinfectant prior to necropsy skilful technique is required to prevent excessive spread of contamination and the formation of aerosols originating from fluids and tissues (this is particularly important for work with zoonotic agents); every effort should be made to confine the spread of contamination; this is especially true when there is a likelihood of material being dropped from an elevated position Cleaning and disposal procedures: upon completion of the post mortem, all necropsy tools and instruments must be decontaminated by autoclaving or disinfection (the disinfectant must be effective against the microorganisms of concern); as some disinfectants are inactivated in the presence of organic materials, gross contamination should be removed prior to disinfection disposable sharps, needles, blades, glass slides, etc. must be discarded into an appropriate sharps container for decontamination the necropsy table, floor and other contaminated work areas must be cleaned and disinfected at the end of an experiment using an appropriate procedure; preliminary washing using a general purpose disinfectant/detergent should be done; special care must be exercised when using a hose to wash the area (i.e. prevent the spread of contamination and formation of aerosols); decontamination of the PM room can then be achieved by spraying or fumigating with a disinfectant effective against the microorganisms of concern specimens (fresh, frozen or fixed) for further study should be placed in leak proof containers, appropriately labeled; the outside of the container must be cleaned and disinfected at end of necropsy or upon exit from the PM room; samples may only be opened in a laboratory zone of the same AP containment level all animal waste must be incinerated or processed through new technology proven to be effective (e.g. tissue autoclave); the incinerator or tissue autoclave should be located adjacent to the PM room where large specimens must be divided into smaller pieces and transported to the incinerator, pieces should be placed carefully into leak proof containers to avoid splashes and aerosols; the outsides of containers must be cleaned down and disinfected prior to transport 18 out of the PM room; the containers must be labeled with the contents and the name and phone number of a contact person Exit procedures: the requirement for showering out of the PM room is dependent on the microorganism of concern; a full shower out of the facility (including washing hair, beards and glasses) is mandatory when working with zoonotic level 3 and 4 agents, and non-indigenous agents contaminated protective clothing must be decontaminated prior to disposal or re-use; contaminated laundry is autoclaved prior to processing (unless using a pass-through laundry machines proven to be effective against the microorganism of concern) Specific Techniques Good Microbiological Technique (GMT) Just like Chemists have Good Laboratory Practices, (GLP). Professionals who work with microorganisms have Good Microbiological Techniques (GMT). These are standard operating procedures developed from years of experience which usually not only provide the best and most consistent results but also typically meet the highest health and safety standard as well. The following page will cover some of the most frequently used manipulations and procedures used in a microbiology lab. As with all things planning your sequence of events is perhaps the most important step one can make. 1. Working in BSCs Before using the cabinet 1. Turn off the UV lamp; turn on the fluorescent lamp 2. Disinfect work surfaces with appropriate disinfectant (see chapter on disinfection) 3. Place essential items inside cabinet 4. Allow the blower to run for 5 – 10 minutes before work. After Completion of work 1. Leave blower on at least 5 minutes to purge cabinet 2. Remove and decontaminate equipment and materials with the appropriate disinfectant 3. Disinfect the cabinet surfaces 4. Turn off blower and fluorescent lamp, turn on UV lamp. 19 Maintenance Twice daily: Work surfaces wiped down Weekly: UV lamp should be wiped clean (dust decrease the intensity of the lamp) Monthly: All vertical surfaces wiped down Annually: UV lamp intensity verified (intensity decrease with time) Annually: Decontamination with formaldehyde gas and certification 2. Safe Use of Centrifuges Check centrifuge tubes for stress lines prior to use Avoid overfilling Ensure Caps or stoppers are properly in place Use sealed buckets or rotors which can be loaded and unloaded in BSCs. Ensure all buckets are properly balanced Ensure centrifuge achieves run conditions before leaving Ensure centrifuge completely stopped before opening lid Ensure equipment interlocks working properly Check immediately for spills or leaks prior to removing samples Clean all spills promptly and completely 3. Needles and Syringes Avoid the use of needles and syringes whenever possible Perform all operations within a BSC Fill syringes carefully, avoid frothing or introduction of bubbles Shield needles with disinfectant soaked cotton when withdrawing from stoppers Do not bench Shear or recap needles. Dispose of in Biohazard Sharps Containers (Yellow labeled containers which may or may not contain disinfectant) If needles must be recapped, use one handed scoop method or holder 4. Hand washing One of the best defenses to prevent exposure In CL 1 lab, a non antiseptic soap can be used In CL 2 and 3 labs, antiseptic hand washing solutions are required. Most of the common antiseptic solutions contain chlorhexine gluconate or trichlosan. An alternative is to use alcoholic hand rubs. They contain an emollient to counteract the drying action of alcohol. Liquid dispensers should be used rather than bars. When to wash? Before starting any manipulations Before leaving the lab When hands are obviously soiled 20 Before and after completing any task in a BSC Every time gloves are removed. Before contact with one’s face and hands At the end of the day How to Hand wash Properly 1. 2. 3. 4. Turn on faucets and wet hands with tepid water Dispense soap into a cupped hand Spread soap or compound around both hands and between fingers. Wash (lather hands for at least 10 sec. Vigorously rub both sided of hands starting a few inches above the wrist, extending downwards between the fingers and around and under the fingernails. Beware of the creases in your hands 5. Rinse thoroughly under the tepid running water, Rinsing should start above the wrist area and proceed to the tips of the fingers. Note if faucets are not knee or foot-operated do not turn of water yet. 6. Dry hands thorough with paper towels. If hand operated, turn faucets off once hands dry, using the paper towel to protect hands. Decontamination, Disinfection and Sterilization Definitions Decontamination: Destruction or removal of microorganisms to a lower level, such that there is no danger of infection to unprotected individuals. Sterilization: Use of physical or chemical means to bring about the total destruction of al viable microorganisms. Disinfection: Use of physical or chemical agents to destroy pathogens and potential pathogens on inanimate objects. It is a basic biosafety principle that all contaminated materials be decontaminated prior to disposal. Decontamination includes both sterilization (the complete destruction of all microorganisms, including bacterial spores) and disinfection (the destruction and removal of specific types of microorganisms). It is the responsibility of all laboratory workers to ensure the effective use of products for decontamination of materials, equipment and samples from containment zones; of surfaces and rooms; and of spills of infectious materials. There are basically two methods for accomplishing decontamination, sterilization and disinfection; Physical methods and Chemical methods. 21 Physical Methods Heat: Autoclaves: most practical and recommended Incineration: for disposal of sharps and tissues Irradiation: U.V. light: wavelength of 253 nm is germicidal Gamma: disrupts DNA and RNA Filtration: HEPA: Biological safety cabinets, ventilation 0.2 micron physically removes particulates Chemical Methods Generally used for disinfection rather than sterilization Choice depends on many factors (number and nature of organism, type of item to be disinfected, purpose of treatment, other chemicals, contact time required for disinfection, toxicity, cost) Most common are chlorine compounds and alcohols Disinfection: What to use for my organism? Vegetative bacteria (Ecoli, ect.) 1% domestic bleach 75% Ethanol Quaternary ammonia 6% formulated Hydrogen peroxide Mycobacteria and fungi 1 % domestic bleach Phenolic compounds 75% Ethanol 6% formulated Hydrogen peroxide Spore forming bacteria (Bacillus) (Time extended for several hours to ensure sporicidal) 10% domestic bleach Gluteraldehyde Formaldehyde 6% formulated Hydrogen peroxide Enveloped viruses (HIV, Herpes) 1 % domestic bleach 75% Ethanol 22 Quatenary ammonia 6% formulated Hydrogen peroxide Non enveloped viruses (Hepatitis, Adenovirus) 10% domestic bleach 6% formulated Hydrogen peroxide Gluteraldehyde Formaldehyde Disinfection for Prions Autoclave at 132-136 oC for 60 minutes, or Autoclave at 121 o C for 4.5 hours, or; Soak in 1N sodium hydroxide for 1 hour, then autoclave at 121 o C for 1.5 hours, or Soak in 3% SDS for 1 hour, then autoclave at 121 o C for 1 hour Treat work surfaces with 10 % sodium hypochlorite (industrial strength bleach) for at least 30 minutes. 2N sodium hydroxide may also be used to treat surfaces. If skin becomes contaminated, treat for 5-10 minutes with 1N sodium hydroxide followed by extensive washing with water. 23 Chemical Decontamination Methods Halogen Releasing Chemical Germicides Chemical Type Compound Chlorine Compounds Effective Advantages Concentratio n; Contact Times Disadvantages Examples of Uses Toxic, corrosive to skin and metals Unstable at optimum pH of 6 Inactivated by organic matter General disinfectant Emergency spill clean up temperatures As for liquid bleach but more stable Deteriorates under light and heat; shelf life of dilutions: I week As for liquid bleach, but shelf life is longer As for liquid bleach Stable at pH 6. More stable than hypochlorites. No strong smell. Toxic, corrosive inactivated by organic matter As for liquid bleach As for liquid bleach More stable, less affected Deteriorates under As for liquid bleach by organic matter than humidity, light and heat. hypochlorites Leaves powdery Longer activity than residue. hypochlorites Demand release of chlorine in situ Longer activity than Aqueous solutions chlorine compounds. decompose under light Less corrosive, toxic than other chlorine compounds Effective at pH 6-10 Broad spectrum Not consistently Instrument disinfection. Gas sterilization of germfree animal chambers Germicidal over a wide pH range Less toxic and less irritating than aqueous or alcoholic iodine solutions sporocidal antiseptics Readily neutralized by organic matter May allow growth of Pseudomonas species and other bacteria Surface decontamination of skin prior to procedures Sodium Hypochlorite 0.1-1% free solution (domestic chlorine bleach) 10-60 minutes Broad spectrum Inexpensive Widely available Bactericidal at low Calcium hypochlorite As for liquid (granules, powder, bleach tablets) Sodium Dichloisocyanu-rate Waste liquids Surface decontamination Instrument disinfection As for liquid bleach (NaDCC) (tablets, powder) Chloramine~T (Sodium tosylchloramide) (powder) — Chlorine Dioxide Iodine Preparations Iodophors 0.003-1% free iodine 10-30 minutes Germicidal soap and Household sodium hypochlorite (Javex) is recommended for most applications. A 10% dilution for most disinfection purposes, with full strength used for spills. 24 Heat Decontamination Methods Type Principle/Conditions Advantages Dry Heat Thermal inactivation: destroys by oxidation Non-corrosive Simple design and principle Hot Air Oven 160-180°C for 2-4 hours Red-heat Flame Oxidation to ashes (fuming) Penetrates water-insoluble materials (e.g.,grease and oil) Less corrosive to metals and sharp instruments than steam ~ Rapid Incineration Oxidation to ashes Reduces volume of waste (burning) by up to 95% 1 -60 minutes: temperatures may exceed 1000°C Moist Heat Irreversible coagulation of microbial proteins Pasteurization Heating to below boiling point (normally 60-709C) for up to 30 minutes Tyndallization Heating to 80-i009C for 30 mm on 3 consecutive days with incubation periods in between Boiling Autoclaving Uses Materials that are damaged by, or are impenetrable to, moist heat Slow diffusion, penetration. Anhydrous materials, Loading, packing critical to such as oils, greases and performance. powders Not suitable for reusable plastics Laboratory glassware,instruments ~ Initial contact with flame can Inoculating loops, needles produce a viable aerosol Possibility of accidental fire Improper use may lead to For decontamination of emission of pathogens in smoke Requires transport of infectious waste. Excess plastic (>20%) content reduces combustibility More rapid and more effective than dry heat Can be used on heat Not reliably sporicidal sensitive liquids and medical devices Low cost Resistant spores germinate Time consuming Not reliably and are killed on the second sporicidal and third day Maximum temperature Minimal equipment required obtainable is I OOLIC at sea level. Minimum 10 minutes Steam under pressure 121 Minimal time required o C at 15 psi for 15-90 Most dependable sterilant for lab use mins. Disadvantages Less effective than moist heat; requires longer times and/or higher temperatures Cumbersome: not practical for everyday use Not reliably sporicidal Loading and packing critical to performance Shielding dirt must first be removed Maintenance and quality control essential Damages heat sensitive items waste items prior to disposal in landfill Milk and dairy products Some heat-sensitive medical equipment Heat sensitive materials such as bacteriological media, solutions of chemicals, biological materials Small instruments and equipment Preparation of sterile glassware, media and instruments. Decontamination of reusable material Decontamination of infectious waste 25 Chemical Decontamination Methods Non Halogen Chemical Germicides Type Effective concentration; contact times Advantages Disadvantages Alcohols 70-85% ethanol 60-95% isopropanol 3-30 minutes Low toxicity Low residue Non corrosive Rapid evaporation, reduces Skin disinfectant contact time Flammable, Surface decontamination skin desiccant Non Bench top, cabinet wipe down sporicidal, ineffective with unconventional agents 0.04-5% 1 0-30 minutes Leaves an active residue Biodegradable 0.05 -1.5% 10-30 minutes Has combined detergent and germicidal activity Stable Working dilutions have low toxicity Rapid action no residue Low toxicity Environmentally safe 30% is sporicidal Broad spectrum sporicidal at low temperatures Can tolerate organic load Rapid action Broad spectrum Does not corrode metal Can tolerate organic load - Phenolic compounds - Quaternary Ammonium compounds ---- Hydrogen peroxide 3-30% 1 -60 minutes New “formulated” 6% has additives Peracetic acid 0.001-0.3% 10-60 minutes gas phase 2-4% 5-120 minutes 0.5-2.5% aqueous 2-30 minutes (up to 12 hours to kill all spores) Aldehydes Gluteraldehyde Aldehydes Formalin (37% formaldehyde) 3-27% formalin in 70-90% water 10-30 minutes Broad spectrum Inexpensive Does not corrode metal Can tolerate organic load Aldehydes Formaldehyde 1-3 hours As for formalin Effective penetration gas (paraformaldehy de) Ethylene Oxide 50-200 mg/L Gas 1-12 hours Broad spectrum No heat or moisture Released Penetrates packaging materials Examples of uses - ~ Pungent odour, corrosive , toxic Non sporicidal, limited activity against viruses Not sporicidal, limited against viruses, myeobaeteria Not readily biodegradable Disinfection of floors and other surfaces Antiseptic soaps ~ Surface decontamination Equipment wipe down antiseptic Limited sporicidal activity Corrosive to some metals, irritant Concentration dependant Surface decontamination Instruments and equipment Pungent odour Corrosive to some metals Shelf life of dilution is less than 1 week irritant to skin and eyes Expensive Requires good ventilation pH, temperature dependant Pungent odour Toxic Less than 2 week shelf life Pungent odour Irritant Potential carcinogen May require 24 hours to kill spores As for formalin Toxic Flammable Poor penetration of covered surfaces Flammable, reactive Toxic; potential carcinogen and mutagen. Some sterilized items may require 24 hours for out gassing Instruments and equipment Gas phase sterilization of chambers for germ free animals Cold sterilant and fixative Surface decontamination Instruments, equipment, glassware Cold sterilant and fixative Surface decontamination Instruments and equipment ~ On site decontamination of biological safety cabinets, HEPA filters Enclosed area Heat or moisture sensitive supplies, equipment and instruments Requires specialized equipment and training 26 Autoclaves Infectious laboratory wastes (Petri dishes, pipettes, culture tubes, glassware etc...) can be effectively decontaminated in either a gravity displacement or prevacuum autoclave. The effectiveness of decontamination by steam autoclaving depends upon various loading factors that influence the temperature to which the material is subjected and the contact time. Particular attention must be given to packaging, including the size of containers and their distribution in the autoclave. Containers of waste must allow steam penetration and must be arranged in the autoclave in a manner that permits free circulation of steam. Tight-fitting containers do not permit steam penetration. Piling containers above one another and overloading can result in decontamination failure. Effective operating parameters for autoclaves should be established by developing standard loads and their processing times through the use of thermocouples and biological indicators placed at the centre of the load (i.e., the most difficult areas of the load to decontaminate). Biological indicators are also used for routine monitoring (e.g., weekly based on the frequency of use) of the sterilization process. A biological indicator is a standardized population of bacterial spores intended to demonstrate favourable sterilization conditions in the load. Attention must be paid to appropriate selection of the indicator, as the design and construction vary depending on its intended use (i.e., liquid versus dry load, self-contained system, enzyme-based rapid method). Chemical indicators are meant to be used in conjunction with biological indicators and physical monitors (i.e., pressure and temperature readings). They provide instant results for dayto-day monitoring that the load has been processed; however, they must not be used as the sole indicator of sterility. Spill Response Spill response will vary depending on the nature of the spill, the size, the location and the material. Spills should be cleaned up immediately to ensure proper decontamination. If you must leave the scene, the door must be posted informing other of the spill and the hazards. All spills must be reported to Security and the BSO. Spills within Biological Safety Cabinets Leave the ventilation on Flood the spill with 10 % bleach and cover with absorbent Leave for 20 minutes Pick up absorbent material All items within the cabinet should also be disinfected (wiped down or autoclaved) All waste should be autoclaved Ventilation should run 10-15 mins Spill outside of BSCs, in a lab (large spills) 27 Evacuate the area for 30 minus to allow aerosols to settle Assemble cleaning supplies and PPE Using Concentrated disinfectant such as 5% hypochlorite (undiluted bleach) pour disinfectant from outside, towards inside. Cover with absorbent and allow disinfectant to act for 20 min. If spill is of blood or other heavy organic material, wipe up most of the material, then allow disinfectant to act for 20 min) All adjacent areas should also be disinfected or wiped down All waste should be autoclaved Spills occurring in Centrifuges Leave lid closed and allow aerosols to settle for at least one (1) hour Thoroughly wipe down inside of centrifuge, including the lid with paper towels soaked in disinfectant Disinfect the entire rotor, especially the bucket where spill occurred within the centrifuge Remove rotor from centrifuge and repeat disinfection. Rinse both rotor and inside of centrifuge with water if bleach was used All waste should be autoclaved. Spills occurring during transport Clean-up must be initiated immediately (as hallways are not negatively pressured) Follow directives for spills outside of biological safety cabinet. Biological Waste Biological Waste includes the following Sharps and biomedical waste Tissue Culture Waste Microbiological waste, including media Sharps should be disposed of in the proper containers and once full, will be picked up for disposal. Tissue culture and microbiological waste is decontaminated prior to disposal. Material can be either autoclaved or chemically decontaminated All biological waste is to be decontaminated. 28 Procedures for Working with Biohazardous Material at Trent The tricouncil granting agencies require that Biosafety Guidelines (Health Canada and the Canadian Food Inspection Agency) for work with biohazardous material are met. To accomplish this, the University has set up a Biosafety Committee to oversee the Biosafety Program at the University. The terms of reference are attached (Appendix 1.) and membership is made up of a broad range of stakeholders including qualified faculty, staff, physical resources and members of the Office of Research and Graduate Studies. The Biosafety committee is responsible for ensuring that all work with biohazardous materials meets or exceeds the guidelines set out by Health Canada or the Canadian Food Inspection Agency. Personnel proposing work with biohazardous substances are required to get approval from the Biosafety Committee. The Biosafety committee will ensure that: rooms for proposed work meet the appropriate containment standards, that the work procedures for the specific pathogen are appropriate and meet the guidelines, and that a training program for working with Biohazardous organisms is available. How Do I Get Approval to Work with Biohazardous Substances? Primary investigators are responsible for completing the Biosafety Protocol application attached (Appendix 2). Much of the information requested will require the applicant to read the relevant sections of either the Red or Peach Book. Applicants are encouraged to submit this protocol to the committee with as much lead time as possible as certification of rooms, import permits etc… require considerable time to prepare. The Biosafety committee will review all applications for work with biohazards in as timely fashion as possible. The Biosafety committee may request changes, and alterations to work procedures if it determines they are necessary to meet the guidelines. Research applications which require Biosafety Committee approval prior to submission should ensure that there is appropriate time available to the committee to do its work. Laboratory Biosafety Program Each lab involved in work with biohazardous substances must have a documented Biosafety program in place. For assistance with this contact the BSO and read the “Peach Book” or “Red Book”. Typically Biosafety programs address cradle to grave issues of working with the pathogen and specific safety requirements beyond the scope of this document. 29 Biosafety officer Currently the role of Biosafety Officer is being fulfilled by the Science Facilities Manager. The BSO is responsible to ensure that the guideline and regulations involving working with biohazardous substances are being met and that safe work conditions and practices are being adhered to. The BSO has the authority to temporarily suspend work, if it is deemed unsafe. This suspension, upon review by the Biosafety committee may be revoked or permanently installed if necessary without prejudice. Procedure for the importation of pathogens from outside of Canada. The importation of pathogens to Canada has become considerably more complicated over the last couple of years. The increase in border security (on both sides of the border) as well as the new terrorism legislation in the U.S. has resulted in a situation where considerable lead time is required for the application and approval process. In addition, it has become apparent, that even when Canadian approval is granted, the U.S. export laws have made the process additionally complicated. Contact the BSO well in advance (as much as two to three months) for assistance with this. The university will not authorize the importation of a pathogen, however without a Project Approval in advance. 30 Appendix 1. Biosafety Committee Terms of Reference Membership A.V.P. Research *Chair* Research Officer H and S officer 1 other faculty science Director Physical Resources Assoc. Dean of Science Faculty with microbiology or cell biology background 1 rep MNR who has responsibility for Biosafety within MNR operations at Trent. Biosafety officer (BSO) Director Health Services (Faculty shall be appointed by the V.P. academic for 2 year terms and should have a thorough background in microbiology or cell biology. If possible, faculty appointments should be staggered so that a measure of stability is achieved) Mandate 1. To set policy for the University on actions or policies related to Biosafety 2. Oversee the university’s biosafety program( the acquisition, use, storage, transfer and disposal of biohazardous or potentially biohazardous material), recommend changes and provide direction as required. 3. To review, assess and approve all work at the university which may represent a Biosafety hazard for personnel or animals in and around the university. Certification of such research programs will follow policies as laid out by the Tri-Council funding organizations. 4. The committee will approve applications for research involving the use of genetically modified organisms. 5. To develop and recommend policies and procedures to meet or exceed the requirements for each containment level as stated in the most current version of the HC Laboratory Biosafety Guidelines or the most current version of the CFIA Containment standards or veterinary facilities. 6. In collaboration with the Biosafety officer, conduct inspections of CLII and above labs annually with a written report including deficiencies and recommendations with respect to the operation of the labs. 7. To recommend to the university the appropriate changes as required to the Occupational Health and Safety Program of the university. 8. The committee will review its Terms of reference annually and make changes as necessary. Meetings The biosafety committee should meet a minimum of 4 times a year. Quorum A quorum shall consist of the majority plus one but must include the biosafety officer. 31 Appendix 2 Office of the Associate Dean Science Office of the Associate Vice President of Research Biosafety Project Approval and Materials Registration This protocol must be completed by each Principal Investigator holding a grant administered by Trent University or supervising a research project where the use of biohazardous infectious materials are described and used. This form must also be completed if animal work is proposed involving the use of biohazardous agents or animals carrying zoonotic agents infectious to humans or wildlife. Completed forms are to be sent to the Office of Research for distribution to the Biosafety Committee. For questions regarding the completion of this form please contact the Biosafety Officer at ext 7061. Any changes to this form or to the projects described within must be completed and forwarded on to the Biosafety Committee for reassessment. Information on Biosafety at Trent can be accessed on the Web at www.trentu.ca/sciencedean or www.trentu.ca/research Please attach MSDS from Public Health Agency Canada (if available) or any other information regarding the pathogenecity of the organism. Other sources of information on Pathogens include U.S. CDC, UN Biosafety Program Project # (for internal use only) _______________ Principal Investigator: Department: Office Number: Phone Number: Email Address: Project(s) Title(s): protocol. Give all the Project(s) title(s) which will be covered by the 32 Lay Summary(s): Give a separate lay summary for each project included in this Protocol. List each pathogen in each project. Location where experimental work to be carried out: Building Room(s) **For work being performed at affiliated institutions or away from Symons Campus please indicate full address. If the affiliated institution has a safety officer, their signature of approval will be required prior to review by the Biosafety Committee review** Funding Agency/Agencies: Names of all personnel working under the Principal Investigator in the location listed above. 1. 3. 5. 2. 4. 6. Note: All personnel (students and staff) who will be working with Biohazardous material rated as risk group 2 or above are required to take the Biosafety course. Contact the Biosafety Officer or Science Facilities Manager (ext. 7061) for course information. 33 Methods: (Describe in detail the methods you will be using in the proposed project. Attach additional pages if necessary). 1.0 Microorganisms Does your work involve the use of microorganisms? If not proceed to 2. Yes No Is this for active work; Yes No Or is this for a storage permit Yes No (Note: All substances considered as biohazardous risk group 2 or greater must be permitted and an inventory maintained, even if no experimental work is on-going). 34 Please complete the table below: Name of Is the Microorganism microorganism (Family/genus/sp. known to be a e.g., Pox human viridae/Vaccinia) pathogen? Yes/No (if yes give name of disease) Is the microrganism known to be an animal pathogen? Is the microorganism known to be a zoonotic agent? Yes/No (if yes give name of disease) Yes/No (if yes explain the risk) Risk Group (1,2,or 3) Maximum quantity to be cultured or in possession at any one time? Yes/No For each substance listed above what is the source of the microorganism? 1 2 3 4 5 6 2.0 Cell Culture Does your work involve the use of cell cultures? If no proceed to 3. Please complete the table below: Cell Type Name of Cell Line Yes Is this cell type used in work? Yes/No No Established or Primary* (print one) Human Rodent Other * derived from fresh tissue For each cell line list the supplier of primary cell culture tissue? 35 For each cell types give the HC or CFIA risk group (1 2 3). 3.0 Use of Human Source Materials Does your work involve the use of human source materials? If no proceed to 4.0 Indicate if the following will be used in the lab. Human blood (whole) or other bodily fluids? If Yes please Specify: Yes No Yes No Human blood (fraction) or other bodily fluids? If Yes please specify: Yes No Human Organs (unpreserved) ? If Yes please specify: Yes No Human tissues (unpreserved) ? If yes please specify: Yes No Yes No Yes No Yes No Yes No Yes No Yes No 4.0 Genetically Modified Organisms and Cell lines Will genetic modifications be made to the organism or cell line? If no please proceed to 5.0 Will genetic sequences from the following be involved? Genes from any CDC class 1 pathogens If yes pleas specify: Other human or animal pathogen and/or their toxins If yes please specify: Will intact genetic sequences be used from: SV 40 Large T antigen If Yes please specify: Known oncogenes If Yes please specify: Will a live vector(s) (viral or bacterial) be used for gene transduction 36 If Yes name vector: Will virus be replication defective Will virus be infectious to humans or animals Will this be expected to increase the Containment level required Yes Yes Yes No No No 5.0 Animal Experiments Will any of the agents listed be used in live animals Yes No Name of animal species to be used ACC protocol number (All experiments with vertebrate animals requires approval f the Animal Care Committee). If using murine cell lines, was the cell line tested for murine or mammalian pathogens. Yes No Yes No Yes No Yes No Yes No 6.0 Biological Toxins Will toxins of biological origin be used If no please proceed to 7.0 If yes, please name the toxin: What is the LD 50 of the toxin: 7.0 Import Requirements Will the agent(s) be imported (or were they imported originally prior to your acquisition)? If no proceed to 8.0 Has an Import permit been obtained from HC for human pathogens? Has an Import permit been obtained from CFIA and has a letter from HC indicating that an HC permit is not required, been obtained Has a copy of the permit been sent to the BSO Yes No Note: Importation requirements for human, animal and plant pathogens vary considerably contact the BSO for assistance in obtaining these permits. Persons receiving hazardous substances will require Transport Dangerous Goods training. Contact the Science Facilities Manager for details. All imports require the approval and signature of the BSO prior to acquisition. 37 8.0 Radioactive Material. Will Radioactive material be used. If yes please give the Radiation Permit #. If no proceed to 9.0. Yes No Note: Work with Radioactive substances at Trent University requires a Radiation Work Permit and that all personnel handling Radioactive Material have taken the Radiation Safety Course. Contact the RSO or the Science Facilities Manager at ext. 7061. 9.0 Training Requirements for Personnel named on Form All personnel named on the above form who will be using any of the above named agents are required to attend the following training course given by the Health and Safety cocoordinator and the BSO as a minimum. The use of animals or radioactive substances will require additional training. Contact the Environmental Health and Safety Officer or the Science Facilities Manager for additional information. Biosafety WHMIS As the principal investigator, I have ensured that all of the personnel named on the form who will be using any of the biohazardous agents in Sections 1-8 have been trained. Signature: Date: 9. Containment levels For the work described above please and based on your Hazard Risk Assesment circle the highest containment level required 1 2 3 Has the facility (Building and room number) been certified by the Biosafety Committee for this level of containment? Yes No 38 10. Methodology Attach the specific methodology you will use for your work. Include descriptions of techniques such as any method which may produce aerosols (i.e., vortexing, centrifuging, mixing of solutions). Include the specifics of your decontamination of instruments, equipment, waste products and sample destruction. 11. Principal Investigator Commitment I agree to conduct my research in accordance with all of the regulations and guidelines (Federal, Provincial and Institutional) which this project may fall under. I agree that all of the information above is accurate to the best of my knowledge and I agree not to change the project, with the exception of improving safety, without notifying and getting the approval of the Biosafety Committee first. Signature of Principal Researcher: Approvals Date: Trent Bio-safety Committee Chair, Bio-Safety Committee Signature:____________________________ Date:________________ Dr. James Parker, AVP Research Bio-Safety Officer Signature:_____________________________ Date:________________ Chris Williams Health & Safety Officer Signature:_____________________________ Date:________________ Bill Gibson External Safety Officer Signature: Date:________________ 39 12. Suggested Readings 1. The Laboratory Biosafety Guidelines, 3rd ed. Health Canada, Minister of Public Works and Government Services, Ottawa, Ontario, Canada, 2004. 2. Containment Standards of Veterinary Facilities, 2nd ed. Ottawa: Agriculture and Agri-Food Canada, Minister of Supply and Services Canada, No. 1921/E, 1996. Canada. 3. Laboratory Biosafety Manual. Geneva: World Health Organization, 1993. 4. Richmond, J.Y. and McKinnery, R.W. Biosafety in microbiological and biomedical laboratories. Washington, DC: U.S. Government Printing Office 1999. 5. Biosafety, University of Ottawa. Environmental and Health Services. 2003 Web sites of interest. Office of Laboratory Security www.phac-aspc.gc.ca/ols-bsl/ Canadian Food Inspection Agency www.inspection.gc.ca/english/toce.shtml Health Canada Biohazard MSDS www.phac-aspc.gc.ca/msds-ftss/index.html National Center Disease Control www.cdc.gov/ncidod World Health Organization www.who.int/csr/labepidemiology/projects/biosafetymain/en/ 40