Chapter III

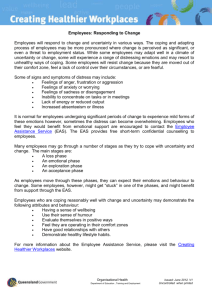

advertisement