Lab 1

advertisement

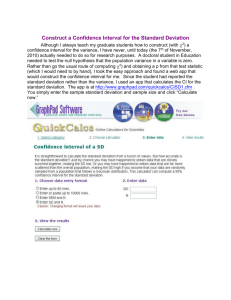

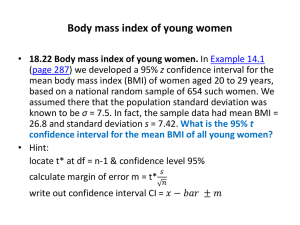

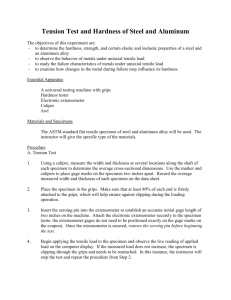

Uncertainties in Experimental Measurements In general, all experimental error derives from one of three sources: 1. Human error 2. Systematic error 3. Random error Experimental errors resulting from human factors are all too well-known to anyone who has spent much time in the laboratory. They may range from simple errors such as transposing two digits in writing down the reading of a gage or indicator, to more fundamental errors, such as misinterpreting the meaning of a set of experimental data. Human errors are, by-and-large, the most difficult type of error against which to guard. Repeated checking of results, along with a healthy degree of skepticism, is often required, especially when dealing with important results. Systematic errors are also frequently encountered. An example of systematic error is a voltmeter that consistently reads 2 mv below the correct value, or a thermocouple that gives a temperature reading 5° C too high. The cure for systematic error is calibration, that is, comparing the reading of a given instrument to a known standard, preferably a standard that is traceable to the National Institute of Standards and Technology (formerly the National Bureau of Standards). The use of uncalibrated, or out-of-calibration, instruments can be a recipe for disaster, especially if significant results are riding upon the reading of these instruments. Instruments whose accuracy is of importance must be recalibrated on a periodic schedule. The final source of error is random error. As its name implies, random errors are moreor-less distributed at random. If a sufficiently large number of measurements are made, the mean, or average, value of the measurements should approach the true value of the measured quantity, assuming the absence of any systematic error which would offset the measured values in one direction or the other. Often, random experimental errors, when f plotted as frequency of observation f vs. the measured value x, follow a bell-shaped distribution, mathematically known as a Gaussian or a normal distribution. An example is shown in the figure at right. Statistically, such distributions are completely characterized by their mean and standard deviation. Suppose that we have made n x x measurements of some quantity x, denoted by x1, i = 1, 2, ...., n. Then the mean value x is given by x 1 n xi n i 1 The standard deviation can be thought of as a measure of the amount by which individual measurements differ from the mean value. It is defined by n x x i 1 i x 2 n 1 More precisely, x defined in this fashion is known as the sample standard deviation. It is the quantity most often used in engineering practice. A variant, known as the population standard deviation, replaces the term n-1 by n in the denominator of the equation above. Most scientific calculators have routines that will calculate x and x rather easily. large small It turns out, that if the experimental values are in fact distributed according to a Gaussian or a normal distribution, then approximately 68% of the measured xi values will fall within the interval ( x x , x x ). Furthermore, it can be shown that 95% of the measured values will lie within the interval ( x 2 x , x 2 x ), and that 99% of the measured values in the interval ( x 3 x , x 3 x ). Hence, we can use the standard deviation to define confidence intervals, assigning a percentage confidence level to our answer to the question of whether of not a particular xi value will fall within a particular interval. The 95% confidence interval is widely used for engineering measurements. This is simply the interval ( x 2 x , x 2 x ). As an example, suppose that we obtain the following hand-timed values for the period of oscillation in seconds of a spring-mass system: 32.1 33.1 31.0 29.8 34.5 29.0 29.4 33.9 32.7 31.7 32.3 30.3 Entering these values into the equations previously given (or into a pocket scientific calculator), we obtain the following values: T 31.7 sec, T 1.8 sec . Hence we are 95% confident that the true value of the period T lies in the interval T 31.7 3.6 sec . Having dealt with the mean and the standard deviation, we now wish to deal with a more complicated matter, which is the propagation of experimental error. To put this into a concrete context, suppose that we wish to measure experimentally the volume V of a rectangular solid. The simplest way to do this is just measure the length of the three sides of the solid, call them a, b, and c, and to make use of the formula V abc . Suppose we make a sufficient number of measurements of a, b, and c so that we can calculate means and standard deviations, and hence confidence intervals, for each of these quantities. The question then arises: how confident are we of the resulting value of the volume? To pose this question more precisely, what are the confidence limits for the calculated volume? Before attempting to give an answer to this question, let us pose it in a more general form. Suppose we have a quantity Q which depends upon a number of experimentally-measured quantities x1, x2, x3, ..... according to Q f x1 , x2 , x3 , . Here f is some known function. Suppose also that we know the statistical parameters of each of the xi, i.e., xi and xi What are the corresponding values of the mean and the standard deviation for Q? In general, this is not an easy question to answer. However a simple answer does exist in the case for which the quantities xi are Gaussian (normally) distributed and are independent of each other. In this case, the mean value of Q is given simply by Q f x1 , x 2 , x 3 , and the standard deviation by f Q x1 2 f x1 x 2 x1 x1 , x2 x2 , 2 f x2 x 3 x1 x1 , x2 x2 , 2 x3 x1 x1 , x2 x2 , This last formula can also be written in terms of the uncertainties x1 , x2 , x3 , x1 2 x1 , etc., so that f Q x1 2 f x1 x 2 x1 x1 , x2 x2 , 2 f x 2 x 3 x1 x1 , x2 x2 , , where 2 x3 x1 x1 , x2 x2 , As an example, suppose that we want to calculate the uncertainty in the volume of a right circular cylinder V resulting from uncertainties in measurements in the cylinder radius and the cylinder height. We have that V r 2 h. Further suppose that, as a result of experimental measurements, we establish that r = 25 0.5 mm and h = 200 1 mm, where the quantities after the sign indicate the uncertainties at the 95% confidence level. Then V r 2 h (25)2 (200) 3.93x10 5 cm 3 and V r 2rh r 25, h 200 314 . x10 4 mm 2 r ,h V r 2 r 25, h 200 1.96 x10 3 mm 2 h r ,h Hence V V V r h r h 2 2 . x10 0.5 196 . x10 1 314 4 2 3 2 158 . x10 4 cm 3 The fractional uncertainty in the volume is then V V 1.58 x10 4 0.0403 3.93x10 5 or about 4%. The Experiment We will be doing two simple measurements and quantifying the error in each. The first involves an examination of the scatter in hardness measurements, the second the error propagation in a volume measurement. 1. Our first experiment makes use of a device that makes hardness measurements on metals. As it is commonly defined, hardness means the resistance to penetration of an indenter under a prescribed load. We will be carrying out a series of so-called Rockwell hardness tests, which simply refers to a prescribed combination of load and indenter. Before making any measurements, check the machine weights located at the back of the Rockwell hardness tester. They should total 100 kg. Then check the lever located at the right-hand side of the machine. It should be in the forward position. Now place the specimen provided by the instructor on the anvil. Turn the three-armed handle clockwise to raise the anvil and move the specimen against the indenter. After the indenter contacts the specimen, continue to raise the anvil until the small dial hand points to the black dot on the dial face. At this point, a preload of 10 kg has been applied to the specimen. Use the knurled ring at the base of the anvil to position the large hand at the Set position on the dial. Now apply the load of 100 kg by pressing the semicircular lever below the three-armed handle. You will note that the right-side lever will rotate slowly towards the rear as the load is applied. After the large hand on the dial stops moving (this may take approximately 20 seconds or so), pull the right-side lever to the forward position once again and record the reading on the C scale. Repeat this procedure at different points on the specimen for a total of 10 trials. Then calculate and record on the lab sheet the mean, the standard deviation, and the 95% confidence level for the hardness data. 2. The instructor will provide you with a rectangular block containing a circular cylindrical hole. Using the calipers provided, take five measurements of each of the three dimensions of the rectangular block, plus five measurements of the hole radius. Record these on the data sheet, along with the mean value, the standard deviation, and the 95% confidence level. In terms of these quantities, write down an equation for the volume of the block. Calculate the volume of the block using the mean dimensions. Then derive an equation for the uncertainty in the volume V in terms of the uncertainties in the dimensions. Use the calculated values to obtain the uncertainty in the calculated volume. Finally, divide by the mean volume to obtain the percentage uncertainty in the volume.