Estimating the Change Point of Binary Profiles with a Linear Trend

advertisement

Estimating the Change Point of Binary Profiles

with a Linear Trend Disturbance

Alireza Sharafi

(corresponding author) M.S.C. Department of Industrial Engineering, Amirkabir University. a.sharafi@aut.ac.ir,

Majid Aminnayeri

Associate Prof. Department of Industrial Engineering, Amirkabir University. mjnayeri@aut.ac.ir,

Amirhossein Amiri

Assistant Professor. Department of Industrial Engineering, Faculty of Engineering, Shahed University. amiri@shahed.ac.ir,

Mohsen Rasouli

M.S. student. Department of Industrial Engineering, Isfahan University of Technology. mohsen.rasouli@in.aut.ac.ir,

sooner and corrective action can be implemented more

quickly. Identifying the real time of the process change

is known as change-point estimation problem.

Abstract

Identification of a real time of a change in a process,

when an out-of-control signal is present is significant.

This may reduce costs of defective products as well as

the time of exploring and fixing the cause of defects.

Another popular topic in the Statistical Process

Control (SPC) is profile monitoring, where knowing

the distribution of one or more quality characteristics

may not be appropriate for discussing the quality of

processes or products. One, rather, uses a relationship

between a response variable and one or more

explanatory variable for this purpose. In this paper, the

concept of Maximum Likelihood Estimator (MLE)

applied to estimate of the change point in binary

profiles, when the type of change is drift. Simulation

studies are provided to evaluate the effectiveness of

the change point estimator.

Change point problems are mainly classified according

to change types including step, drift and isotonic

shifts. To find the real time of a change, many authors

have suggested several methods such as Maximum

Likelihood Estimator (MLE), Cumulative Sum

(CUSUM), Exponentially Weighted Moving Average

(EWMA) and intelligent method, (artificial network,

clustering and decision tree). For example Pignatiello

and Samuel [1- 4] proposed a Maximum Likelihood

Estimator in different control charts to find the real

time of change point under a step shift. Perry and

Pignatiello [5, 6] used this method to estimate the

change point in the mean of normal and poisson

distribution with a linear trend disturbance,

respectively.

Keywords: binary profiles; change point; maximum

In the area of SPC, usually the quality of a process or a

product was represented by the distribution of one (or

more) quality characteristic and monitored by

univariate (or multivariate) control chart. However,

Kang and Albin [7] presented a popular topic with

widespread application in SPC namely, profiles

monitoring, in which a relationship between a

response variable and one or more independent

variables, known as profiles is monitored over time.

Scientists classify profiles based on the type of

relationships into the linear (simple, multiple and

polynomial), nonlinear and geometric profiles. Profiles

are studied in Phases I and II. In Phase I, Mestek et al.

likelihood estimator (MLE); statistical process control

(SPC), control chart

1- Introduction

Statistical Process Control (SPC) is used to monitor

and reduce the variation of a process. Control charts

are the most important tools in SPC which are used to

monitor quality characteristics. These charts can detect

any changes or shifts in a process; however, a shift

usually occurs much earlier before it is detected. When

a control chart signals a special cause, quality

engineers should identify and remove the cause(s) of

variation and return the process to in-control state.

However, knowing when a process has changed would

help quality engineers to limit the time window within

which they should search for assignable causes.

Consequently, the assignable causes can be identified

2

[8] used a T based control charts to monitor the

regression parameters of a simple linear profiles.

Mahmoud and Woodall [9] used a global F-test for

monitoring the regression coefficients in conjunction

with a univariate control chart to monitor the variance.

Mahmoud et al. [10] applied a likelihood ratio test to

monitor simple linear profiles. In Phase II, Kang and

1

Albin [7]

proposed

two

methods including a

2- Logistic Regression Model

2

multivariate T chart and a combination of EWMA-R

chart to monitor simple linear profiles. Kim et al. [11]

recommended three independent univariate EWMA

control charts to monitor shifts in parameters of a

simple linear profile.

Many categorical response variables have only two

categories: for example, whether you take public

transportation today (yes, no), or whether you have

had a physical exam in the past year (yes, no). Denote

a binary response variable by y and E ( y ) . The

value of can vary as the value of x changes, and

we replace by ( x ) . For n independent

observations, the number of successes has the

binomial distribution specified by the index n and

parameter . The relationships between ( x ) and

Identifying the change point in profiles has been

studied by some researchers. Mahmoud et al. [10] used

a likelihood ratio based method to identify the real

time of a step change in Phase I monitoring of a simple

linear profiles. Zou et al. [12] proposed a method

based on likelihood ratio statistics to find the change

point in parameters of a simple linear profile in Phase

II. Kazemzadeh et al. [13] used the same method to

estimate the change point in polynomial profiles under

a step shift in Phase I. Note that the change point

problem in profile data is under a different sampling

framework from that of the other models. In the profile

applications, multiple data sets are collected over time

in a functional data sampling framework and a

possible change point is take place after any data set.

x are usually nonlinear and the S -shaped curves are

often realistic shapes for this relationship which are

called the logistic regression models.

In a logistic regression model, there are n independent

experimental sets, with p predictor variables for each

set, which is shown by

xi ( xi1 , xi 2 ,, xip )T as well

as corresponding Bernoulli response variables namely

zi for i 1, 2,..., n . The probability of success in

Most researches in profile monitoring, assume the

response variable is continuous (usually Normal) and

characterize profiles with linear or nonlinear models.

However, in many industrial applications the response

variable is discrete such as binary (as in the case of a

product can be classified as defective or non defective)

or countable (as the number of defect products or

number of patients in a hospital). Yeh et al. [14]

studied binary profiles in Phase I. They proposed

each set is denoted by

i

and each

i

is a function of

xi . In the logistic regression model this function is

characterized by the link function g i , defined as

g i

2

different T control charts for monitoring logistic

regression profiles. Shang et al. [15] proposed a

control scheme based on EWMA-GLM to monitor the

relationship between the binary response and random

explanatory variables in Phase II. Their approach

assumes that explanatory variables are random

variable and takes different values in each profile

sample. To the best of our knowledge, Only Sharafi et

al. [16] suggested a method to identify the real time of

a step change in Phase II monitoring of binary profiles

and there is no more researches in this area. In this

paper we propose a Maximum Likelihood Estimator to

find the real time of a change in Phase II monitoring of

logistic regression profiles. Here, we assumed that the

type of the disturbance is drift. The rest of the paper is

organized as follows: Section 2 illustrates logistic

regression model and explains the steps of estimating

the model parameters. Section 3 presents the change

point model and assumptions of the problem. The

performance of the proposed model is investigated in

Section 4. Conclusions and some future researches are

provided in the final section.

log i

1 log i

1 xi1 2 xi 2 ... p xip

where 1 , 2 ,..., p

T

(1)

is the model parameters

vector. It is usual to set xi1 1 in order that 1 be the

intercept of the model. Equation (1) simplifies to

i

exp( xiT )

1 exp( x )

T

i

exp(i )

1 exp(i )

T

In this equation i xi

(2)

.

p

x

k ik

. We also assume

k 1

that data are grouped so that for the i th setting of the

predictor variables, there are

i 1,2,..., n .

mi observations,

n

M mi

is

total

number

of

i 1

mi

observations. The response variable is

yi zik ,

k 1

where

2

zik is the k th observation (0 or 1) in i th

yi follows a binomial

distribution with parameters mi , i . Albert and

predictor variable settings,

Initialize the estimate of ˆ (0) . Set i 0

Anderson [17] proposed MLE method to estimate the

model parameters for this purpose. They used the

following likelihood function:

m

y

m y

L (, y) i i i 1 i i i ,

i 1 y i

ˆ (i )

Calculate ˆ (i ) , ˆ (i ) , ˆ (i ) and W

(i )

ˆ (i )

ˆ (i ) W

qˆ

n

(3)

Where 1 , 2 ,..., n and y y1 , y2 ,..., yn

Taking the logarithm of the Equation (3) and using

i xiT

i

p

x

log

k ik

k 1

1 i

ˆ (i ) X

ˆ ( i 1) XT W

l (, y )

mi

n

( i 1)

ˆ

p

i

Yes

(4)

(i)

ˆ ˆ

Figure I. The procedure of estimation of logistic

regression parameters

Taking derivative of Equation (4) with respect to ,

and using iterative weighted least square estimation

method suggested by McCullagh and Nelder [18], the

logistic regression parameters can be estimated as

follows:

ˆ

XT WX

In

the

ˆ

XT Wq

Equation

3- MLE Change Point Estimator

Here, it is assumed that the underlying process initially

operates in a state of statistical control, with

observations coming from a poisson distribution with

the known parameters 0 ( is a p-dimensional

(5)

(5)

X x1 , x2 ,..., x n ,

T

ˆ diag m ˆ 1 ˆ , m ˆ 1 ˆ ,..., m ˆ 1 ˆ ,

W

1 1

1

2 2

2

n n

n

vector);

ˆ 1 y ˆ and ˆ m ˆ , m ˆ ,..., m ˆ .

qW

1 1

2 2

n n

f yij

T

The procedure iterations is described in the figure I.

McCullagh and Nelder [18] proved that as

large

or

mi

is

constant,

is

1

so,

the

mass

probability

mi y

m y

i ij 1 i i ij where

y

ij

function

is

yij is the

value taken by the response variable for the i th value

of the predictor variable in the j th profile.

n becomes

distributed

The change type is also assumed to be drift or linear

trend change in the parameter i . Consider an in-

asymptotically as a p-dimensional normal distribution

N p , XT WX

No

1

ˆ ( i )q ( i )

XT W

k ik

p

mi log 1 exp k xik ,

i 1

k 1

1

i 1 k 1

i

n

(i )

( i 1)

ˆ ˆ

log y y x

i 1

(i )

, one can reexpress

the log-likelihood as

n

1

Update the estimation of

i i 1

T

T

y ˆ

. This procedure will be used in

control process with independent observations coming

from a binomial distribution with parameters mi and

MLE change point estimator described in Section 3.

i .

After elapsing an unknown amount of time, the

parameter i changes from its in control state of i 0

to an unknown out-of-control state of i1 , i1

i0 ,

and the function of i1 is given as

i1 i 0 b j

3

j 1, 2,..., T ,

(6)

where

Ln L ( , b y )

b is the slope (or magnitude) of the linear trend

i .

T

During the formulation of profiles j 1,2,..., the

process parameter

i

become larger with linear trend

some unknown value i1

T

b and equal to

i1 b j

1 b j

j 1 i 1

i1

yij

1 i1 b j

n

n

mi

(7)

n

j 1 i 1

T

i0

1 i 0

n

j 1 i 1

n

m Ln 1

i

j 1 i 1

i0

(10)

b j

yij Ln i1

j 1 i 1

1 i1 b j

T

n

T

b j

(8)

i1 b j

mi Ln 1 i 0 yij Ln 1 i1

j 1 i 1

b , and denote it as b̂ .

ˆ arg max { yij Ln

mi n

yij Ln i 0

1 i0

yij j 1 i 1

T

j

b

j

i1

Substituting b for b in Equation (8) and computing

Equation (8) over all possible change points in

search of the maximum log-likelihood function yields

Ln L( , b y ) Ln

j 1 i 1

i

MLE of the rate parameter,

The MLE of is the value of that maximizes the

likelihood function in Equation (7). Taking the

logarithm of Equation (7)

n

m 1

In Equation (9) there is no closed-form solution for b .

Perry and Pignatiello [6] proposed the Newton’s

method (also known as the Newton–Raphson method)

to find the MLE of the rate parameter, b . Newton’s

method is one of the Numerical analysis which is used

to find successively better approximations to the roots

of a function. We use Newton’s method to find the

n

n

yij

j 1 i 1

i 0 b j , where

mi n i 0

mi

L( , b y )

yij 1 1 i 0

j 1 i 1

i0

j 1 i 1

T

j

1 i1 b j i1 b j (9)

T is the last profile sampled in which the control chart

signaled an out-of-control state. Two unknown

parameters in model are and b , representing the

last profile taken from an in-control process and the

rate of the linear trend, respectively. To estimate these

unknown parameters, this paper used a MLE approach,

similar to Perry and Pignatiello [6]. We denote the

MLE estimator of the change point as ˆ . The

likelihood function is as follows:

n

j 1 i 1

is equal to its known in-control

value. For profiles j 1, 2,..., T the parameter

i

b

disturbance in

n

m Ln 1

j 1 i 1

i

i1

b j }

where ˆ is the MLE for the last profile taken from the

in-control process. Whenever this chart signals an outof-control state, the real time of a change can be

estimated via Equation (10).

n

mi Ln 1 i1 b j ,

j 1 i 1

To determine the unknown parameters in Equation (8),

( and b ), an expression is required for b in terms of

which maximize the log-likelihood function in

Yeh et al. [14] introducted five Hotelling T control

charts to monitor binary profiles in Phase I. The

plotting statistic for profile j is defined as

Equation (8), defined as b . Obtaining this expression

is not a trivial task. The partial derivative of Equation

(8) with respect to b is given by

T j2 j

2

T

S 1 j ,

(11)

where ˆ j is estimator of the logistic regression

parameters in

j th profile and S is the variance

covariance matrix of ˆ j . Any of these

T 2 charts uses

a different method to estimate the mean vector and

4

Now, suppose an out-of-control process whose

parameter vector i

shifts from i 0

to

2

covariance matrix. They showed TI control chart

which estimate the covariance matrix by averaging the

covariance estimates of each given sample, provides

more effective way to detect step shifts and drift.

These control charts also can be used in Phase II. So

i1 i 0 b j . A Monte Carlo simulation

study is accomplished to examine the performance of

the estimator. The change point is simulated at profile

50 ( 50 ). For profiles j 1, 2,...,50 the

independent observations is produced by binomial

distribution with parameters 50 and i 0 . Starting at

2

we used TI control chart to detect the out-of-control

state in Phase II. Covariance matrix in Phase II is

computed using the following equation:

( XT WX ) 1 ,

where

profile 51, observations are simulated from the out-of-

(12)

W

is

equal

control process with i1

to

i 0 b j 50 until the

diag{m 1 (1 1 ), m 2 (1 2 ),, m n (1 n )}

TI2 chart signals an out-of-control. At this time, the

. The upper control limit for the proposed control chart

change point estimator is used and the real time of the

process change is determined. This procedure is

repeated 10,000 times for each magnitude of the

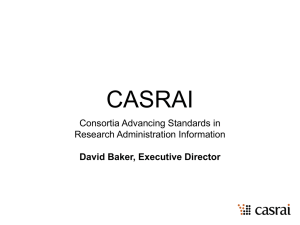

change under study, which is described in the figure II.

is also equal to 2, ,the percentile points on the

2

chi-square distribution with 2 degrees of freedom.

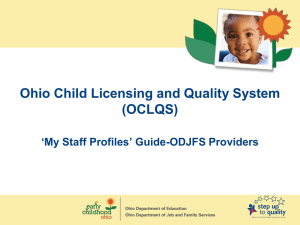

The results are summarized in Tables I and II and

Figure III. Table I shows the expected length of each

simulation run E T which is the expected value of

4- Performance of the MLE Estimator

To estimate the performance of the MLE estimator, an

example is given. In this example, number of

explanatory variables is equal to 2, (p=2). Thus the

link function is simplified as g i 1 2 xi ,

the number of samples taken until the first alarm is

given by the control chart, i.e. E T ARL 50 .

Table I also shows the average change point estimate

and the standard deviation of the change point

estimator under different magnitude of the shifts

considered. Because the actual change is at time 50,

the average change point estimate, , should be close

to 50.

where 1 and 2 are the intercept and the slope of the

regression function respectively and is shown by the

vector 1 , 2

T

We set the matrix X as:

T

1

...

1

1

X =

,

log 0.1 log 0.2 ... log 0.9

It is assumed that the number of experiments in each

predictor variable is constant and equal to 50 ,

Produce 50 independent incontrol profiles with the

vector of i 0

( mi 50 for i 1,2,...,9 ) and the in-control i 0 is

0.04,0.06,0.13,0.27,0.48,0.68,0.82,0.89, 0.91T .

initial is estimated as 2.5, 3.46

T

from historical

2

2,0.005

10.59 .

i

The

dataset in Phase I. The upper control limit for the TI

control chart is equal to

Make a change in the vector of

10,000

times

repeat

2

The

covariance matrix of the logistic regression parameters

( ) in Phase II is computed by Equation (12) as

follows:

Estimate the logistic parameters and

depict control chart until issuing an outof control signal

Calculate for all profiles

Determine the largest as the

change point

Figure II. The flowchart of the simulation procedure

(X T WX) 1

0.06627

0.07693

0.07693

0.1179

5

Table I. Expected number of samples until the signal and

standard deviations of the change point estimators

with 10,000 simulations runs when 50

b

E T

se(ˆ)

0.003

56.13

51.82

2.39

0.005

55.01

51.21

1.73

0.007

53.86

50.86

1.32

0.01

53.02

50.58

1.01

0.015

52.43

50.44

0.74

0.02

52.04

50.29

0.51

0.025

51.72

50.21

0.41

Figure III. The performance of the MLE estimator

Table II shows the results of proportion of 10,000

simulation runs that the estimator lies within a

specified tolerance of the real change point value. For

example if b 0.01, the estimated probability that ˆ

lies within 1 or less from the real change point is 0.81.

Also in this case, in 46% of the simulation runs the

estimator correctly identifies the real time of the

change.

As shown in Table I, for drift rate parameter equal to

0.003 the expected number of samples taken until the

signal is 56.13, the average change point estimate is

51.82 and the standard deviation of the change point

estimator is 2.39. Moreover, the performance of the

estimator improves significantly with increases in

magnitude of the drift rate parameter b . Figure III

also indicates this issue. As perceived from this figure,

with increasing b , the expected number of samples

taken until the signal and average change point

estimator are becoming near to 51 and 50,

respectively. Furthermore, the standard deviation of

the change point estimator, that is shown shady, is

becoming smaller.

Table II shows that the performance of the MLE

estimator improves significantly with increases in

magnitude of the shift in the slope, b .

Table II. Estimated precision performances over a range of

i with 10,000 simulations runs when 50

b

0.003

0.005

0.007

0.01

0.015

0.02

0.025

p̂ ˆ 0

0.21

0.30

0.36

0.46

0.57

0.72

0.83

p̂ ˆ 1

0.47

0.59

0.70

0.81

0.85

0.97

0.99

p̂ ˆ 2

0.64

0.81

0.89

0.94

0.99

1.00

1.00

p̂ ˆ 3

0.79

0.92

0.98

1.00

1.00

p̂ ˆ 4

0.90

0.98

1.00

p̂ ˆ 5

0.97

1.00

p̂ ˆ 6

1.00

6

[10] Mahmoud, M. A., Parker, P. A., Woodall, W. H.,

Hawkins, D. M. (2007) A change point method for linear

profile data. Quality and Reliability Engineering

International, 23(2), 247-268.

5- Conclusions

In this paper, we provided the MLE method to estimate

the change point in phase II monitoring of logistic

regression profiles, when the type of change is drift. The

results of this study showed that the performance of the

proposed estimator is fine to identify the real time of

change point under different magnitude of drift rate.

[11] Kim, K., Mahmoud, M. A., Woodall, W. H. (2003). On

the monitoring of linear profiles. Journal of Quality

Technology, 35(3), 317-328.

Developing this method to the other distributions of the

exponential family such as Poisson and Gama would be

future researches in this area. Furthermore the other types

of the change, including step changes and isotonic

changes could be investigated by researchers.

[12] Zou C, Zhang Y, Wang Z. Control chart based on

change point model for monitoring linear profiles. IIE

Transactions 2006; 38(12), 1093-1103.

References

[14] Yeh, B., Huwang, L., Li, Y. M. (2009). Profile

monitoring for a binary response. IIE Transaction, 41(11),

931-941.

[13] Kazemzadeh, R. B., Noorossana, R., Amiri, A. (2008).

Phase I monitoring of polynomial profiles. Communications

in Statistics - Theory and Methods, 37(10), 1671-1686.

[1] Pignatiello, J. J., Samuel, T. R. (1998a). Identifying the

time of a step change with X control charts. Journal of

Quality Engineering, 10(3), 521-527.

[15] Shang, Y., Tsung, F. and Zou, C. (2011). Phase II

profile monitoring with binary data and random predictors.

Journal of Quality Technology, 43(3), 196-208.

[2] Pignatiello, J. J., Samuel, T. R. (1998b). Identifying the

time of a step change in a normal process variance. Journal

of Quality Engineering, 10(3), 529-538.

[16] Sharafi, A., Aminnayeri, M. and Amiri, A. (2012).

Identifying the time of step change in binary profiles. To

appear in the International Journal of Advanced

Manufacturing Technology, DOI: 10.1007/s00170-0123899-4.

[3] Pignatiello, J. J., Samuel, T. R. (1998c). Identifying the

time of a step change in a poisson rate parameter. Journal

of Quality Engineering, 10(3), 673-681.

[4] Pignatiello, J. J., Samuel, T. R. (2001). Estimation of the

change point of a normal process mean in SPC

applications. Journal of Quality Technology, 33(1), 82-95.

[17] Albert, A., Anderson, J. A. (1984). On the existence of

maximum likelihood estimates in logistic regression models.

Biometrika, 71(1), 1-10.

[5] Perry, M. B., Pignatiello, J. J. (2005). Estimation of the

change point of a poisson rate parameter with a linear

trend disturbance. Quality and Reliability Engineering

International, 22(4), 371-384.

[18] McCullagh, P., Nelder, J. A. (1989). Generalized

linear models, 1nd ed. London, UK: Chapman & Hall.

[6] Perry, M. B., Pignatiello, J. J. (2006). Estimation of the

change point of a normal process mean with a linear trend

disturbance. Quality Technology and Quantitative

Management, 3(3), 101-115.

[7] Kang, L., Albin, S. L. (2000). Online monitoring when

the process yields a linear profile. Journal of Quality

Technology, 32(4), 418-426.

[8] Mestek, O., Pavlik, J., Suchnek, M. (1994). Multivariate

control charts: Control charts for calibration curves.

Freseniusí Journal of Analytical Chemistry, 350, 344-351.

[9] Mahmoud, M. A., Woodall, W. H. (2004). Phase I

analysis of linear profiles with calibration applications.

Technometrics, 46(4), 380-391.

7